Lubricant properties

- 1. Lubricant Properties Engr. Tarique Ahmed Memon Lecturer @ Department of Mechanical Engineering Quaid-e-Awam University of Engineering, Science & Technology (QUEST) Campus Larkano, Sindh, Pakistan.

- 2. CHARACTERISTICS OF GOOD LUBRICANT:- 1. LOW VAPOUR PRESSURE. 2. HIGH BOILING POINT. 3. NON CORROSIVE NATURE. 4. GOOD THERMAL CONDUCTIVITY. 5. ADEQUATE VISCOSITY. 6. HIGH FLASH & FIRE POINT. 7. HIGH OILINESS. 8. LOW VOLATILITY. 9. LOW FREEZING POINT. 10. DOES NOT FORM EMULSION.

- 3. Properties of Lubricants • 1. Viscosity • Viscosity Index • 2. Flash point 3. Fire point • 4. Cloud point 5. Pour point • 6. Oiliness 7. Corrosion • 8. Emulsification 9. Physical stability • 10. Chemical stability 11. Neutralization number • 12. Adhesiveness 13. Film strength 14. Specific gravity • 15. Volatility

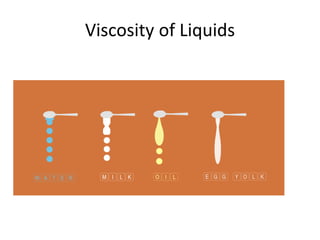

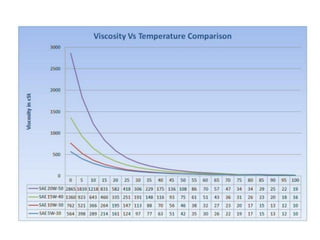

- 4. Viscosity • Viscosity is the most important characteristic of lubricating oil. • Viscosity refers to the tendency of oil to resist flowing. • Viscosity changes with temperature, since increasing temperature causes oil to thin and have a lower viscosity, while decreasing temperature causes oil to thicken and have a higher viscosity.

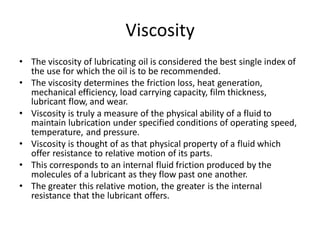

- 5. Viscosity • The viscosity of lubricating oil is considered the best single index of the use for which the oil is to be recommended. • The viscosity determines the friction loss, heat generation, mechanical efficiency, load carrying capacity, film thickness, lubricant flow, and wear. • Viscosity is truly a measure of the physical ability of a fluid to maintain lubrication under specified conditions of operating speed, temperature, and pressure. • Viscosity is thought of as that physical property of a fluid which offer resistance to relative motion of its parts. • This corresponds to an internal fluid friction produced by the molecules of a lubricant as they flow past one another. • The greater this relative motion, the greater is the internal resistance that the lubricant offers.

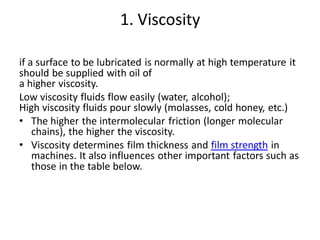

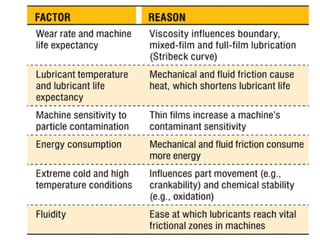

- 8. 1. Viscosity if a surface to be lubricated is normally at high temperature it should be supplied with oil of a higher viscosity. Low viscosity fluids flow easily (water, alcohol); High viscosity fluids pour slowly (molasses, cold honey, etc.) • The higher the intermolecular friction (longer molecular chains), the higher the viscosity. • Viscosity determines film thickness and film strength in machines. It also influences other important factors such as those in the table below.

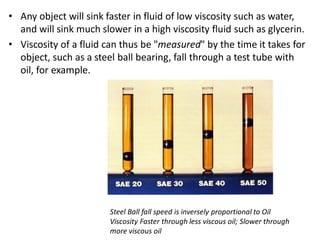

- 10. • Any object will sink faster in fluid of low viscosity such as water, and will sink much slower in a high viscosity fluid such as glycerin. • Viscosity of a fluid can thus be "measured" by the time it takes for object, such as a steel ball bearing, fall through a test tube with oil, for example. Steel Ball fall speed is inversely proportional to Oil Viscosity Faster through less viscous oil; Slower through more viscous oil

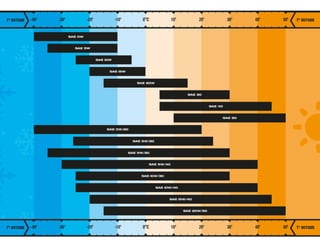

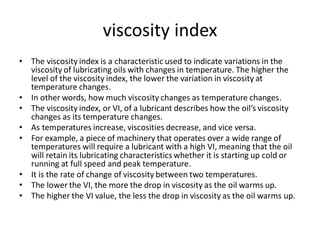

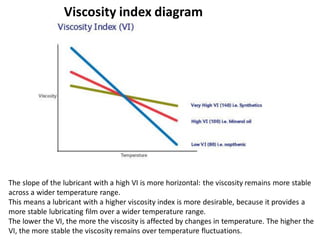

- 13. viscosity index • The viscosity index is a characteristic used to indicate variations in the viscosity of lubricating oils with changes in temperature. The higher the level of the viscosity index, the lower the variation in viscosity at temperature changes. • In other words, how much viscosity changes as temperature changes. • The viscosity index, or VI, of a lubricant describes how the oil’s viscosity changes as its temperature changes. • As temperatures increase, viscosities decrease, and vice versa. • For example, a piece of machinery that operates over a wide range of temperatures will require a lubricant with a high VI, meaning that the oil will retain its lubricating characteristics whether it is starting up cold or running at full speed and peak temperature. • It is the rate of change of viscosity between two temperatures. • The lower the VI, the more the drop in viscosity as the oil warms up. • The higher the VI value, the less the drop in viscosity as the oil warms up.

- 14. Viscosity index diagram The slope of the lubricant with a high VI is more horizontal: the viscosity remains more stable across a wider temperature range. This means a lubricant with a higher viscosity index is more desirable, because it provides a more stable lubricating film over a wider temperature range. The lower the VI, the more the viscosity is affected by changes in temperature. The higher the VI, the more stable the viscosity remains over temperature fluctuations.

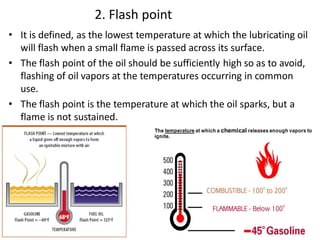

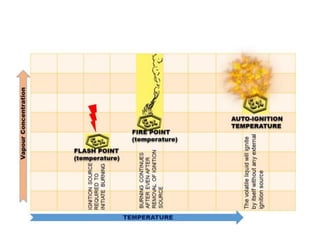

- 15. 2. Flash point • It is defined, as the lowest temperature at which the lubricating oil will flash when a small flame is passed across its surface. • The flash point of the oil should be sufficiently high so as to avoid, flashing of oil vapors at the temperatures occurring in common use. • The flash point is the temperature at which the oil sparks, but a flame is not sustained.

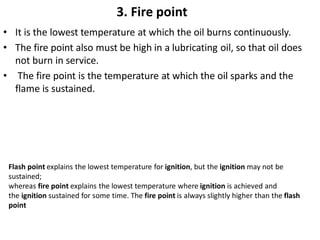

- 16. 3. Fire point • It is the lowest temperature at which the oil burns continuously. • The fire point also must be high in a lubricating oil, so that oil does not burn in service. • The fire point is the temperature at which the oil sparks and the flame is sustained. Flash point explains the lowest temperature for ignition, but the ignition may not be sustained; whereas fire point explains the lowest temperature where ignition is achieved and the ignition sustained for some time. The fire point is always slightly higher than the flash point

- 18. 4. Cloud point • When subject to low temperatures the oil changes from liquid state to a plastic or solid state. • In some cases the oil starts solidifying which makes it to appear cloudy. • The temperature at which this takes place is called the cloud point. • Petroleum-based lube oils contain dissolved wax. • At a low enough temperature, referred to as the cloud point, this wax will separate from the oil and form wax crystals. • These crystals can clog filters and small openings, deposit on surfaces such as heat exchangers, and increase the viscosity of the oil.

- 19. 5. Pour point • The lowest temperature at which a lubricant will flow or pour like a liquid. • It is an indication of its ability to move at low temperatures. • This property must be considered because of its effect on starting an engine in cold weather and on free circulation of oil through exterior feed pipes when pressure is not applied. • The pour point refers to the minimum temperature at which a lubricant continues to flow. • Below the pour point, the oil tends to thicken and to cease to flow freely. • Pour Point is therefore measured typically with lubricants, wherein Pour Point is the lowest (coldest) temperature that a fluid will still flow, though at a low flowability rate.

- 20. 6. Oiliness • This is the property which enables oil to spread over and adhere to the surface of the bearing. It is most important in boundary lubrication. • It is an important properties of a lubricant, it shows the capacity of a lubricants to stick on the surface of machine parts under high pressure and load

- 21. 7. Corrosion Stability • It is properties of lubricant which represents its resistance toward the metals. • A lubricant should not corrode the working parts and it must retain its properties even in the presence of foreign matter and additives.

- 22. 8. Emulsification • A lubricating oil, when mixed with water is emulsified and loses its lubricating property . • The emulsification number is on index of the tendency of on oil to emulsify with water. • It is the property of a lubricant due to which the lubricating oil mixed with water to form an emulsion. • A good lubricant should have low emulsion number.

- 23. 9. Physical Stability • A lubricating oil must be stable physically at the lowest and highest temperatures between which the oil is to be used. • At the lowest temperature there should not be any separation of solids, and at the highest temperature it should not vaporize beyond a certain limit.

- 24. 10. Chemical Stability • A lubricating oil should also be stable chemically. • There should not be any tendency for oxide formation.

- 25. 11. Neutralization Number • An indication of the acidity or basicity (alkalinity) of an oil. • The neutralization number is expressed in milligrams of potassium hydroxide or hydrochloric acid needed to neutralize any acid or base in one gram of oil. • The Acid Number (AN) test uses potassium hydroxide as the neutralizing agent, and the Base Number (BN) test uses hydrochloric acid as the neutralizing agent.

- 26. 12. Adhesiveness • It is the property of lubricating oil due to which the oil particles stick with the metal surfaces.

- 27. 13. Film strength • It is the property of a lubricating oil due to which the oil retains a thin film between the two surfaces even at high speed and load. • The film does not break and the two surfaces do not come in direct contact. • Adhesiveness and film strength cause the lubricant to enter the metal pores and cling to the surfaces of the bearings and journals keeping them wet when the journals are at rest and presenting metal to metal contact until the film of lubricant is built up.

- 28. 14. Specific Gravity • It is a measure of density of an oil. • It is an indication regarding the grade of lubricant by comparing one lubricant with other. • It is determined by a hydrometer which floats in the oil, and the gravity is read on the scale of the hydrometer at the surface of the oil.

- 29. 15. Volatility • It shows the evaporation behavior of lubricant at high temperature. • A good lubricant should have low volatility

- 30. THE END