Oil Characteristics, Oil Heat Calculations presentation.ppt

- 1. 1 HVAC222 - Oil Oil Characteristics Oil Heat Calculations

- 2. 2 Fuel Oil Weight • Measured in API Gravity – API = American Petroleum Institute – Ranges from 0 to 99 degrees • The lighter the oil, the higher the rating. – 20 degrees = 7.77 pounds – 40 degrees = 6.87 pounds • These are measured with a hydrometer

- 3. 3 Viscosity • The resistance to flow (thickness of oil) • Time required for an oil sample at a given temperature to flow through a fixed restriction. • Heavier oils have a higher restriction. • As the temperature rises; viscosity goes down.

- 4. 4 Viscosity • As the temperature drops, viscosity goes up. – An outdoor oil tank needs to be protected from cold as the viscosity can go so far up the oil will not flow through the filter properly.

- 5. 5 Flash Point • The temperature at which the oil will give off sufficient vapor to support a flash fire (momentary, not combustion). • The lowest temperature vapors will ignite in the air when exposed to flame. • The maximum safe storage and handling temperature.

- 6. 6 Distillation Range • Used as a measurement for lighter oils. • It is the temperature at which oil will boil.

- 7. 7 Water and Sediment content • Percentage of water and impurities in the oil. • Heavier oils have more water and sediment. • Water and sediment can cause: – Interrupted flame – Clogged burners

- 8. 8 Pour Point • The lowest temperature at which oil can be poured.

- 9. 9 Types of oil • #1 - Kerosene • #2 - Home Heating Oil • #4 - Industrial • #6 - Bunker Oil

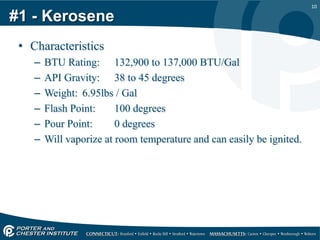

- 10. 10 #1 - Kerosene • Characteristics – BTU Rating: 132,900 to 137,000 BTU/Gal – API Gravity: 38 to 45 degrees – Weight: 6.95lbs / Gal – Flash Point: 100 degrees – Pour Point: 0 degrees – Will vaporize at room temperature and can easily be ignited.

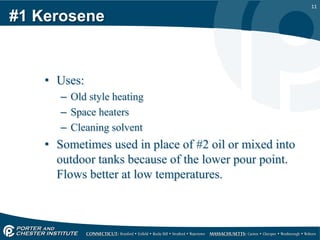

- 11. 11 #1 Kerosene • Uses: – Old style heating – Space heaters – Cleaning solvent • Sometimes used in place of #2 oil or mixed into outdoor tanks because of the lower pour point. Flows better at low temperatures.

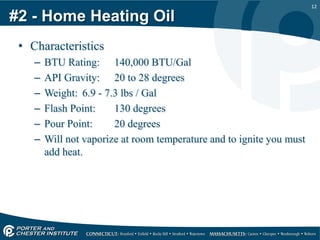

- 12. 12 #2 - Home Heating Oil • Characteristics – BTU Rating: 140,000 BTU/Gal – API Gravity: 20 to 28 degrees – Weight: 6.9 - 7.3 lbs / Gal – Flash Point: 130 degrees – Pour Point: 20 degrees – Will not vaporize at room temperature and to ignite you must add heat.

- 13. 13 #2 - Home Heating Oil • Uses: – Residential Home Heating – Residential Hot Water – Light Commercial Applications

- 14. 14 #4 - Industrial Oil • Characteristics – BTU Rating: 145,000 BTU/Gal – API Gravity: 20 to 28 degrees – Weight: 7.78 lbs / Gal – Flash Point: 130 degrees – Pour Point: 20 degrees – Does not require pre-heating – Industrial heat and power.

- 15. 15 #6 - Bunker Oil • Characteristics – BTU Rating: 153,000 BTU/Gal – API Gravity: 8 to 15 degrees – Weight: 8.44 lbs / Gal – Flash Point: 50 degrees – Pour Point: Can not pour

- 16. 16 Oil Heat Calculations • BTU Output: – The amount of heat being used to heat the space. – Heating oil has a BTU content of 140,000 BTU’s per gallon.

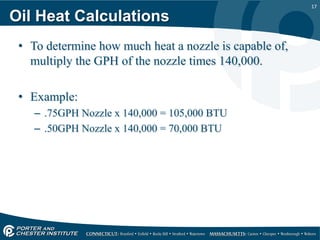

- 17. 17 Oil Heat Calculations • To determine how much heat a nozzle is capable of, multiply the GPH of the nozzle times 140,000. • Example: – .75GPH Nozzle x 140,000 = 105,000 BTU – .50GPH Nozzle x 140,000 = 70,000 BTU

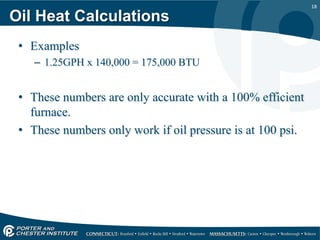

- 18. 18 Oil Heat Calculations • Examples – 1.25GPH x 140,000 = 175,000 BTU • These numbers are only accurate with a 100% efficient furnace. • These numbers only work if oil pressure is at 100 psi.

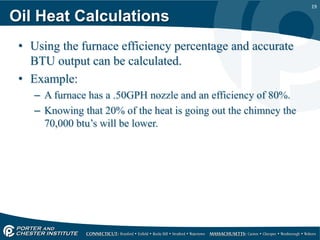

- 19. 19 Oil Heat Calculations • Using the furnace efficiency percentage and accurate BTU output can be calculated. • Example: – A furnace has a .50GPH nozzle and an efficiency of 80%. – Knowing that 20% of the heat is going out the chimney the 70,000 btu’s will be lower.

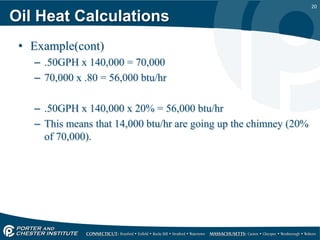

- 20. 20 Oil Heat Calculations • Example(cont) – .50GPH x 140,000 = 70,000 – 70,000 x .80 = 56,000 btu/hr – .50GPH x 140,000 x 20% = 56,000 btu/hr – This means that 14,000 btu/hr are going up the chimney (20% of 70,000).

- 21. 21 Calculating Air Flow • The volume of air is defined as Cubic Feet Per Minute (CFM) • To calculate the CFM of a furnace the BTU’s must be known. • Q = The quantity of useable BTUS of a system.

- 22. 22 Calculating Air Flow • Example: A furnace has a .50GPH nozzle and is 90% efficient. • Q = 140,000 x .50 x .90 • Q = 63,000 • Now take a supply duct temperature reading with the burner and fan on.

- 23. 23 Calculating Air Flow • Next take a return air temperature reading with the burner and fan on. • Subtract the return from the supply to get your Delta-T (Temperature difference). • Multiply this number by 1.08 (this is a constant).

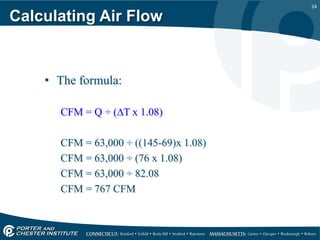

- 24. 24 Calculating Air Flow • The formula: CFM = Q ÷ (∆T x 1.08) CFM = 63,000 ÷ ((145-69)x 1.08) CFM = 63,000 ÷ (76 x 1.08) CFM = 63,000 ÷ 82.08 CFM = 767 CFM

- 25. 25 Calculating Air Flow • This calculation can help the duct designer or technician decide if the ductwork is undersized and can also help determine if air conditioning can be added to the ductwork. • Air Conditioning requires 400CFM per Ton (12,000 BTU’s)