Sol gel coating

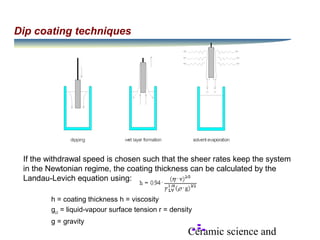

- 1. Ceramic science and Dip coating techniques If the withdrawal speed is chosen such that the sheer rates keep the system in the Newtonian regime, the coating thickness can be calculated by the Landau-Levich equation using: h = coating thickness h = viscosity gLV = liquid-vapour surface tension r = density g = gravity

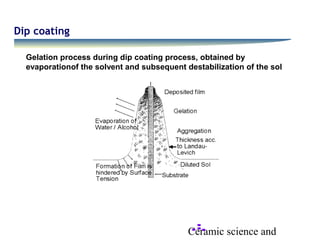

- 2. Ceramic science and Dip coating Gelation process during dip coating process, obtained by evaporationof the solvent and subsequent destabilization of the sol

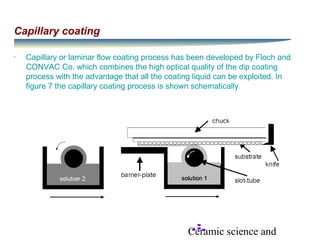

- 3. Ceramic science and Capillary coating • Capillary or laminar flow coating process has been developed by Floch and CONVAC Co. which combines the high optical quality of the dip coating process with the advantage that all the coating liquid can be exploited. In figure 7 the capillary coating process is shown schematically.

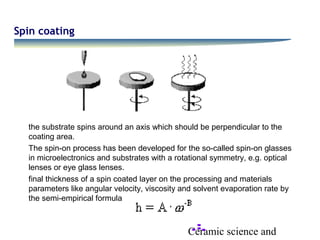

- 4. Ceramic science and Spin coating the substrate spins around an axis which should be perpendicular to the coating area. The spin-on process has been developed for the so-called spin-on glasses in microelectronics and substrates with a rotational symmetry, e.g. optical lenses or eye glass lenses. final thickness of a spin coated layer on the processing and materials parameters like angular velocity, viscosity and solvent evaporation rate by the semi-empirical formula

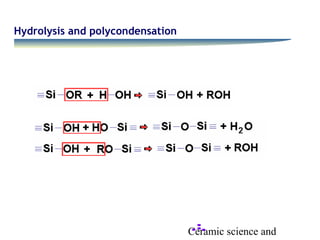

- 6. Ceramic science and Hydrolysis and polycondensation

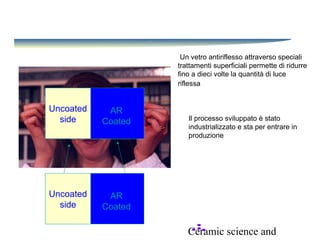

- 7. Ceramic science and Un vetro antiriflesso attraverso speciali trattamenti superficiali permette di ridurre fino a dieci volte la quantità di luce riflessa Uncoated side AR Coated Il processo sviluppato è stato industrializzato e sta per entrare in produzione Uncoated side AR Coated

- 8. Ceramic science and Glass Strength improvement Compressive stress coatings can be obtained by densifying ceramic or glass coating systems, having a lower thermal coefficient of expansion than the substrate glass and at the same time can be densified below the Tg of glass. So it has been shown that borosillicate sol-gel coatings after densification can improve the bending strength of float glass by the factor of 4. Inorganic-organic composite coatings also show that the strength of glass bottles can be improved substantially.