THERMAL & STRUCTURAL ANALYSIS ON DISC BRAKE ROTOR WITH DRAFTING USING CATIA - VBA

- 1. A PROJECT ON THERMAL & STRUCTURAL ANALYSIS ON DISC BRAKE ROTOR WITH DRAFTING USING CATIA - VBA Under the guidance of Asst.Prof. Dhole P.V. Presented by Bachchewar Rohit Gadkari Ambika Suryawanshi Nitin 1

- 2. Contents INTRODUCTION LITERATURE REVIEW ABSTRACT Problem Statement Overview of disc brake CAD Designs Thermal Analysis Structural Analysis VBA Programming Conclusion Future Scope References 2

- 3. INTRODUCTION In today’s growing automotive market the competition for better performance vehicle is growing enormously. The disc brake is a device for slowing or stopping the rotation of a wheel. Brake convert K.E. to Mechanical energy(Heat). Project consist of two types of analysis thermal , structural & VBA Programming. Thermal analysis is done to check the thermal resistance of model Honda Unicorn 160. Structural analysis is done to find the strength of the model. VBA programming is used to automate drafting task. 3

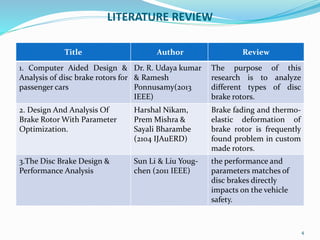

- 4. LITERATURE REVIEW Title Author Review 1. Computer Aided Design & Analysis of disc brake rotors for passenger cars Dr. R. Udaya kumar & Ramesh Ponnusamy(2013 IEEE) The purpose of this research is to analyze different types of disc brake rotors. 2. Design And Analysis Of Brake Rotor With Parameter Optimization. Harshal Nikam, Prem Mishra & Sayali Bharambe (2104 IJAuERD) Brake fading and thermo- elastic deformation of brake rotor is frequently found problem in custom made rotors. 3.The Disc Brake Design & Performance Analysis Sun Li & Liu Youg- chen (2011 IEEE) the performance and parameters matches of disc brakes directly impacts on the vehicle safety. 4

- 5. ABSTRACT The disc brake is a device used for slowing or stopping the rotation of the vehicle. Number of times using the brake for vehicle leads to heat generation during braking event, such that disc brake undergoes breakage due to high Temperature. Disc brake model is done by CATIA/CREO and analysis is done by using ANSYS workbench. The main purpose of this project is to study the Thermal analysis of the Materials for the GRAY CAST IRON. A comparison between the four models for the Thermal values and material properties obtained from the Thermal analysis low thermal gradient model is preferred. Also in this project we added a VBA Programming for Disc Modeling. 5

- 6. Problem Statement A problem in disc brake occurs because of uneven stress & heat dissipation during braking of two wheeler as follows- Cracking , rusting, poor stopping ,noise, vibration , pulling, dragging, pulsation etc. The material of brake is subjected to high compressive stresses hence it affect the overall area of disc rotor. 6

- 7. Overview of disc brake A brake is a device through which frictional resistance is applied to moving machine member, to stop the motion of machine. The energy absorbed by brake is dissipated in the form of heat. 7

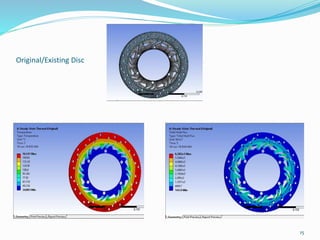

- 8. Original Design of Unicorn 160 8

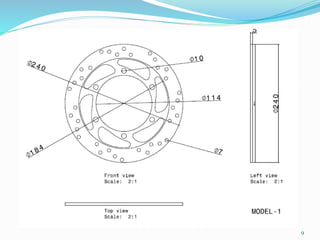

- 9. 9

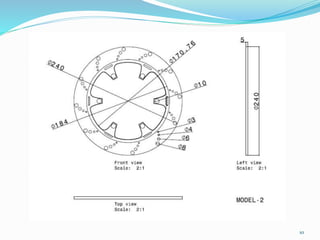

- 10. 10

- 11. 11

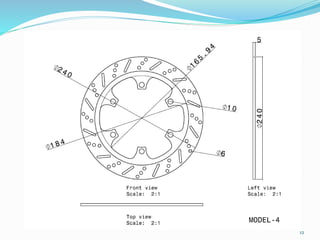

- 12. 12

- 13. Thermal Analysis Objective :- Evaluating the performance of disc brake of bike under various braking condition. To study the heat & temp distribution and results are compared for better performance. To find out total heat flux capacity among the 4 CAD models. 13

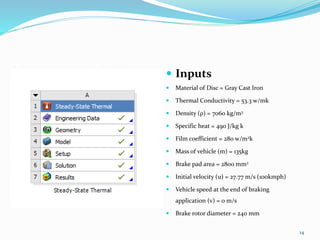

- 14. Inputs Material of Disc = Gray Cast Iron Thermal Conductivity = 53.3 w/mk Density (ρ) = 7060 kg/m3 Specific heat = 490 J/kg k Film coefficient = 280 w/m2k Mass of vehicle (m) = 135kg Brake pad area = 2800 mm2 Initial velocity (u) = 27.77 m/s (100kmph) Vehicle speed at the end of braking application (v) = 0 m/s Brake rotor diameter = 240 mm 14

- 16. 16

- 17. Structural Analysis It is the determination of effects of lodes on physical structure & their components. Problem of analysis of structural that it subjected to dynamic loads are considered in dynamics of structure Objective :- To ensure the reliability & durability of structures, given an economically sound expenditure of materials. 17

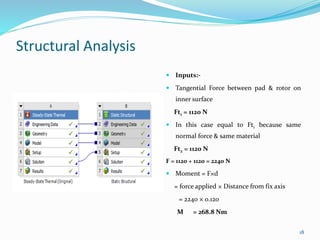

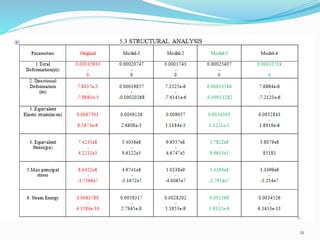

- 18. Structural Analysis Inputs:- Tangential Force between pad & rotor on inner surface Ft1 = 1120 N In this case equal to Ft1 because same normal force & same material Ft2 = 1120 N F = 1120 + 1120 = 2240 N Moment = F×d = force applied × Distance from fix axis = 2240 × 0.120 M = 268.8 Nm 18

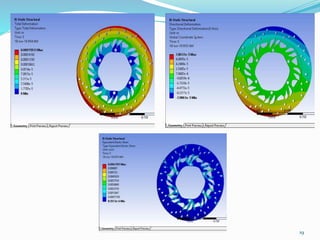

- 19. 19

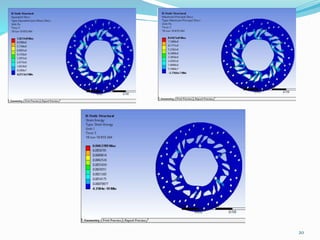

- 20. 20

- 21. 21

- 22. VBA Programming Visual Basic Programming Language (VBA) To reduce time span of design modeling. To understand VBA firstly we know the what is mean by macro & VB script…? A macros is a series of functions , written in a scripting language , that you group in a single command to perform the requested task automatically. VB script is a subset of the visual basic Programming Language . 22

- 23. Flow Chart for manual modeling 23

- 24. 24

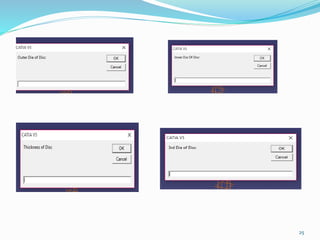

- 25. 25

- 26. 26

- 27. Conclusion From the study of various designs patterns for gray cast iron material it is observed that the disc having max surface area will dissipate more heat & final temp after braking. It improves overall brake performance of disc brake. Initial designs are compared & analyzed using simplified models from which best solution is chosen. Decreasing amount of physical testing for new design. The temp distribution throughout the disc rotor is uniform Due to VBA time for modeling of disc is reduced. 27

- 28. Future Scope Thermal analysis of the disc brake with different materials. Structural analysis of disc brake with different materials. Automate the design procedure & reduce time of modeling. 28

- 29. References Dr. R. Udaya kumar 2013 IEEE paper on Computer Aided Design & Analysis of disc brake rotors for passenger cars. 2. Harshal Nikam, Prem Mishra & Sayali Bharambe International Journal of Automobile Engineering Research & Development (IJAuERD) ISSN(9):2277- 4785;ISSN(E);2278-9413 Vol-4,Issue 4,Aug 2014,21-30 paper on Design And Analysis Of Brake Rotor With Parameter Optimization. 3. Sun Li & Liu Youg-chen from chian, 2011 IEEE the performance and parameters matches of disc brakes directly impacts on the vehicle safety. 4. Brakes and Dynamometer”-Theory of Machine by R.S. Khurmi & J.K. Gupta-732 5. Heat Transfer- by Rajput 6. Disc Brake” - http://en.wikipedia.org/wiki/Disc_brake 29