Unconventional machining process

- 2. INTRODUCTION We all know that the term machinability refers to the case with which a metal can be machined to an acceptable surface finish. Nontraditional machining processes are widely used to manufacture geometrically complex and precision parts for aerospace, electronics and automotive industries.

- 3. In ordinary machining we use harder tool to work on work piece, this limitations is overcome by unconventional machining, unconventional machining is directly using some sort of indirect energy For machining. Ex: sparks , laser, heat, chemical etc. applied in EDM , laser cutting machines etc. Non conventional Machining is a recent development in machining techniques.

- 4. The requirements that lead to the development of nontraditional machining. Very high hardness and strength of the material. The work piece: too flexible or slender to support the cutting or grinding forces. The shape of the part is complex, such as internal and external profiles, or small diameter holes. Surface finish or tolerance better than those obtainable conventional process. Temperature rise or residual stress in the work piece are undesirable.

- 5. Conventional machining involves the direct contact of tool and work -piece, whereas unconventional machining does not require the direct contact of tool and work piece. Conventional machining has many disadvantages like tool wear which are not present in Non-conventional machining.

- 6. Advantages of Non-conventional machining: 1) High accuracy and surface finish 2) Less/no wear 3) Tool life is more 4 ) Quieter operation

- 7. Disadvantages of non-conventional machining: 1) High cost 2) Complex set-up 3) Skilled operator required

- 8. MACHINING CHARACTERISTICS The machining characteristics of different non- conventional processes can be analysed withrespect to : Metal removal rate Tolerance maintained Surface finish obtained Depth of surface damage Power required for machining

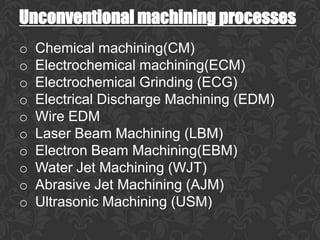

- 9. Unconventional machining processes o Chemical machining(CM) o Electrochemical machining(ECM) o Electrochemical Grinding (ECG) o Electrical Discharge Machining (EDM) o Wire EDM o Laser Beam Machining (LBM) o Electron Beam Machining(EBM) o Water Jet Machining (WJT) o Abrasive Jet Machining (AJM) o Ultrasonic Machining (USM)

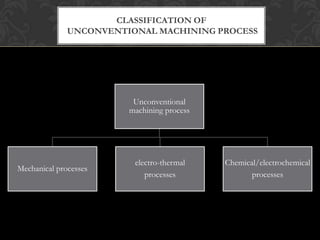

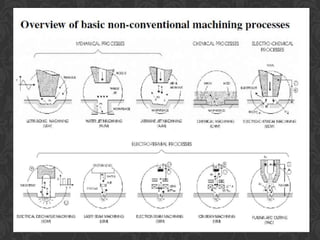

- 10. CLASSIFICATION OF UNCONVENTIONAL MACHINING PROCESS Mechanical processes electro-thermal processes Chemical/electrochemical processes Unconventional machining process

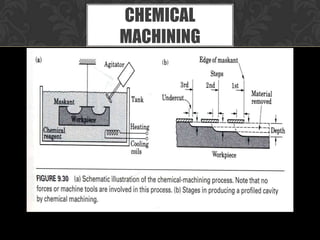

- 12. Oldest nontraditional machining process. Material is removed from a surface by chemical dissolution using chemical reagents or etchants like acids and alkaline solutions. CHEMICAL MACHINING (CM)

- 13. Types of chemical machining 1. Chemical Milling By selectively attacking different areas of work piece with chemical reagents shallow cavities can be produced on plates, sheets, forging and extrusion. 2. Chemical blanking It is similar to blanking in sheet metals except material is removed by chemical dissolution rather than by shearing. Used in bur free etching of printed circuit boards, decorative panels etc. 3. Photochemical blanking This process is effective in blanking fragile work pieces and materials. Material is removed using photographic techniques. Applications are electric motor lamination, flat springs, masks for color television, printed circuit cards etc.

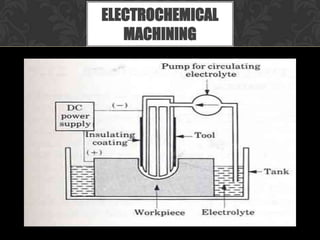

- 15. Reverse of electroplating An electrolyte acts as a current carrier and high electrolyte movement in the tool-work-piece gap washes metal ions away from the work piece (anode) before they have a chance to plate on to the tool (cathode). Tool – generally made of bronze, copper, brass or stainless steel. Electrolyte – salt solutions like sodium chloride or sodium nitrate mixed in water. Power – DC supply of 5-25 V. ELECTROCHEMICAL MACHINING

- 16. Process leaves a burr free surface. Does not cause any thermal damage to the parts. Lack of tool force prevents distortion of parts. Capable of machining complex parts and hard materials ECM systems are now available as Numerically Controlled machining centers with capability for high production, high flexibility and high tolerances. ADVANTAGES OF ECM

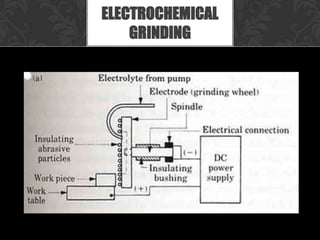

- 18. Combines electrochemical machining with conventional grinding. The equipment used is similar to conventional grinder except that the wheel (bonded with diamond or Al oxide abrasives) is a rotating cathode with abrasive particles where abrasives serve as insulator between wheel and work piecee. A flow of electrolyte (sodium nitrate) is provided for electrochemical machining. ELECTROCHEMICAL GRINDING (ECG)

- 19. Suitable for grinding very hard materials where wheel wear is very high in traditional grinding process .

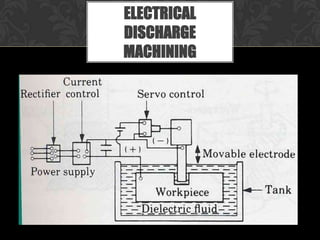

- 21. Based on erosion of metals by spark discharges. EDM system consist of a tool (electrode) and work piece, connected to a dc power supply and placed in a dielectric fluid. When potential difference between tool and work piece is high, a transient spark discharges through the fluid, removing a small amount of metal from the work piece surface. This process is repeated with capacitor discharge rates of 50-500 kHz. ELECTRICAL DISCHARGE MACHINING

- 22. dielectric fluid – mineral oils, kerosene, distilled and deionized water etc. role of the dielectric fluid 1. acts as a insulator until the potential is sufficiently high. 2. acts as a flushing medium and carries away the debris. 3. also acts as a cooling medium. Electrodes – usually made of graphite. EDM can be used for die cavities, small diameter deep holes,turbine blades and various intricate shapes.

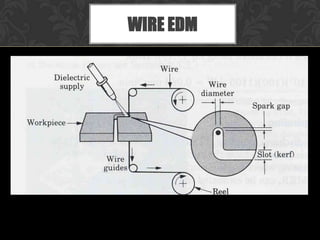

- 24. This process is similar to contour cutting with a band saw. a slow moving wire travels along a prescribed path, cutting the work piece with discharge sparks. wire should have sufficient tensile strength and fracture toughness. wire is made of brass, copper or tungsten. (about 0.25mm in diameter). Wire EDM

- 25. WIRE EDM

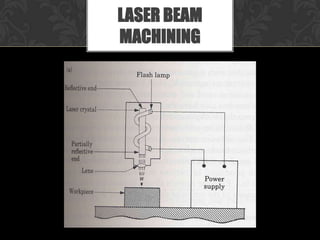

- 26. In LBM laser is focused and the work piece which melts and evaporates portions of the work piece. Low reflectivity and thermal conductivity of the work piece surface, and low specific heat and latent heat of melting and evaporation – increases process efficiency. Application - holes with depth-to-diameter ratios of 50 to 1 can be drilled. e.g. bleeder holes for fuel-pump covers, lubrication holes in transmission hubs. Laser beam machining (LBM)

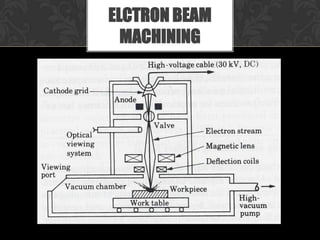

- 28. Similar to LBM except laser beam is replaced by high velocity electrons. When electron beam strikes the work piece surface, heat is produced and metal is vaporized. Surface finish achieved is better than LBM. Used for very accurate cutting of a wide variety of metals. Electron beam machining (EBM)

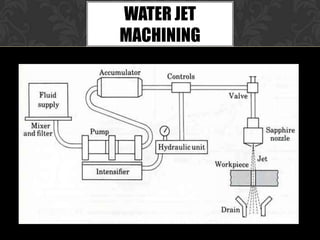

- 30. Water jet acts like a saw and cuts a narrow groove in the material. Pressure level of the jet is about 400MPa. Advantages - no heat produced - cut can be started anywhere without the need for predrilled holes - burr produced is minimum - environmentally safe and friendly manufacturing Application – used for cutting composites, plastics, fabrics, rubber, wood products etc. Also used in food processing industry. WATER JET MACHINING (WJT)

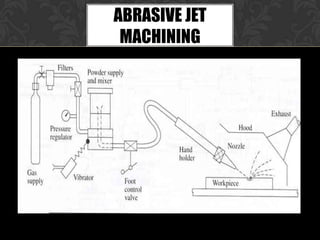

- 32. In AJM a high velocity jet of dry air, nitrogen or CO2 containing abrasive particles is aimed at the work piece. The impact of the particles produce sufficient force to cut small hole or slots, deburring, trimming and removing oxides and other surface films. Abrasive Jet Machining (AJM)

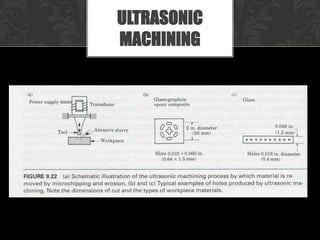

- 34. In UM the tip of the tool vibrates at low amplitude and at high frequency. This vibration transmits a high velocity to fine abrasive grains between tool and the surface of the work piece. Material removed by erosion with abrasive particles. The abrasive grains are usually boron carbides. This technique is used to cut hard and brittle materials like ceramics, carbides, glass, precious stones and hardened steel. ULTRASONIC MACHINING (UM)

- 36. Made by: Vatsal Vaghela (111) THANK YOU