Open Access

Open Access

ARTICLE

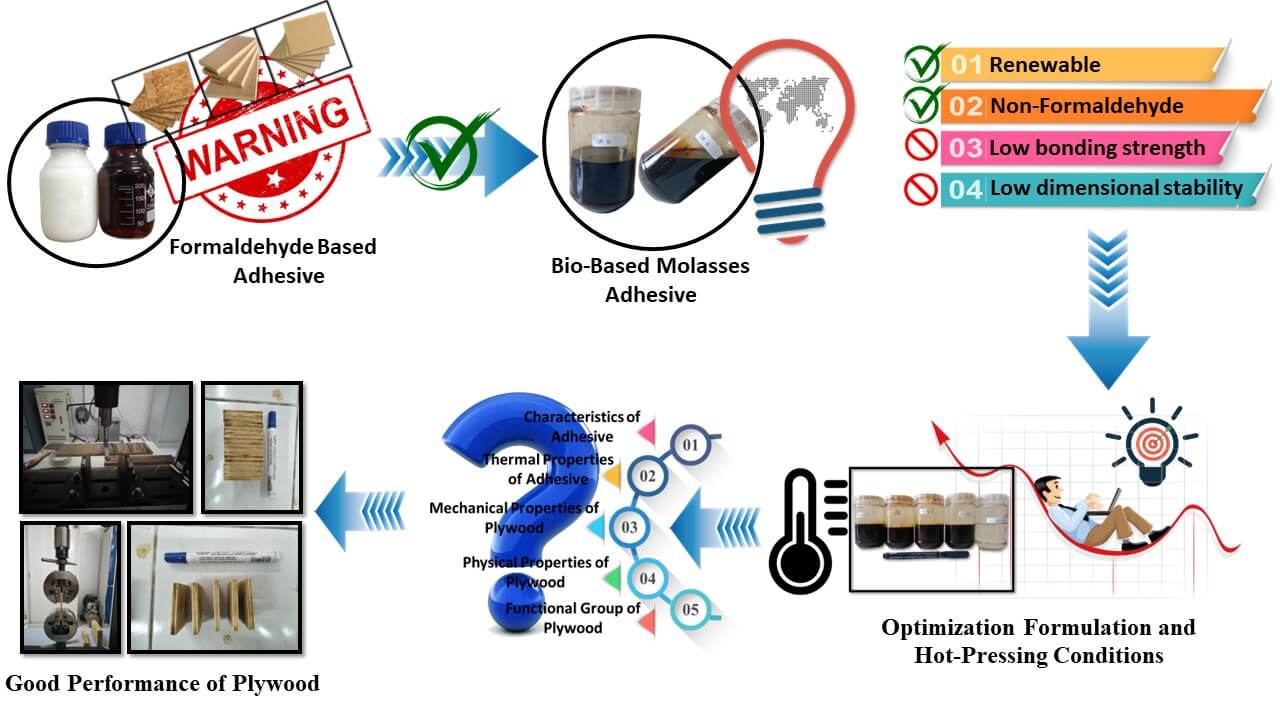

Influence of Formulation and Hot-Pressing Conditions on the Performance of Bio-Based Molasses Adhesive for Plywood

1 Research Center for Biomass and Bioproducts, National Research and Innovation Agency, Cibinong, 16911, Indonesia

2 Forest Product Department, Faculty of Forestry and Environment, IPB University, Bogor, 16680, Indonesia

3 Department of Forest Products, Faculty of Forestry, Universitas Sumatera Utara, Medan, 20155, Indonesia

4 Research Collaboration Center for Biomass and Biorefinery, BRIN and Universitas Padjadjaran, Bandung, 40600, Indonesia

5 Department of Agro-Industrial Technology, Universitas Padjadjaran, Bandung, 40600, Indonesia

* Corresponding Authors: Dede Hermawan. Email: ; Muhammad Adly Rahandi Lubis. Email:

Journal of Renewable Materials 2024, 12(8), 1383-1397. https://doi.org/10.32604/jrm.2024.052052

Received 21 March 2024; Accepted 14 June 2024; Issue published 06 September 2024

Abstract

Molasses can serve as a natural adhesive for plywood and particleboard. However, several disadvantages remain, including lower dimensional stability and low bonding strength compared to other adhesives. Therefore, modifications are needed to use molasses as an adhesive for plywood. This research aims to improve bio-based molasses (MO) adhesive for plywood using citric acid (CA) adhesive. In addition, this research aims to analyze the effect of adding citric acid and to investigate the optimum hot-pressing temperature to produce the best quality plywood. In the first stage, the molasses and citric acid were combined in a ratio of 100:0, 75:25, 50:50, 25:75, 0:100 w/w%. Then, the second stage focuses on analyzing the influences of pressing temperature based on an optimum first stage. The research demonstrated that the addition of CA altered the gelation time, solid content, viscosity, and pH of the molasses adhesives. In addition, the thermal properties of molasses adhesives were changed after mixing with citric acid. These phenomena indicate changes in characteristics, such as the curing of adhesive. Overall, the characteristics of plywood showed a steady improvement as the CA ratio increased but revealed a significant decline for the 25:75 MO-CA ratio. By raising the pressing temperature from 180°C to 200°C, the quality of plywood was effectively improved. The plywood that was bonded using adhesives with a 50:50 MO-CA ratio exhibited superior mechanical properties and improved dimensional stability compared to the plywood bonded solely with MO. Furthermore, the optimal mechanical and physical properties resulted in plywood bonded with a 50:50 MO-CA ratio when subjected to a pressing temperature of 200°C. The Thermal and FTIR measurements revealed that CA established ester bonds with both the MO and wood veneers. In conclusion, the mechanical characteristics of plywood were improved, while maintaining its excellent dimensional stability.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools