Crosslinking and Swelling Properties of pH-Responsive Poly(Ethylene Glycol)/Poly(Acrylic Acid) Interpenetrating Polymer Network Hydrogels

Abstract

:1. Introduction

2. Experimental Methods

2.1. Chemicals

2.2. Preparation of Hydrogels

2.2.1. PEG Single Network Hydrogel (PEG-SN)

2.2.2. PEG/PAA IPN Hydrogels (PEG/PAA-IPNs)

2.3. Characterizations

2.3.1. Raman Spectroscopy

2.3.2. Thermogravimetric Analysis (TGA)

2.3.3. Differential Scanning Calorimetry (DSC)

2.3.4. Rheological Measurements for UV Crosslinking of Hydrogels

2.4. Swelling Ratio

2.5. Mechanical Tests

2.5.1. Nano-Scratch Tests

2.5.2. Measurements of Shear Storage Modulus (G′) and Compression Modulus (E)

3. Results and Discussion

3.1. Variation of C=C Double Bonds during UV Irradiation

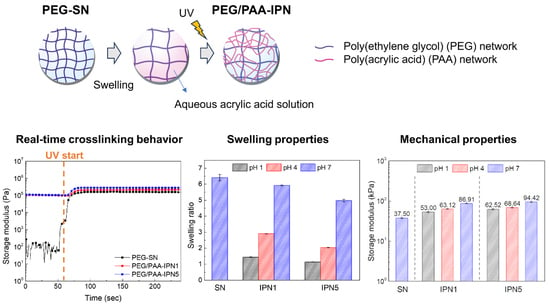

3.2. Real-Time Crosslinking Behavior during UV Irradiation

3.3. Thermal Properties of PEG-SN and PEG/PAA-IPNs

3.4. Surface Mechanical Properties of PEG-SN and PEG/PAA-IPNs

3.5. pH-Dependent Swelling and Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, Z.; Huang, K.; Luo, Y.; Zhang, L.; Kuang, T.; Chen, Z.; Liao, G. Double Network Hydrogel for Tissue Engineering. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2018, 10, e1520. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Wang, Z.; Xiao, Y.; Zhang, S.; Wang, J. Advances in Crosslinking Strategies of Biomedical Hydrogels. Biomater. Sci. 2019, 7, 843–855. [Google Scholar] [CrossRef] [PubMed]

- Aswathy, S.H.; Narendrakumar, U.; Manjubala, I. Commercial Hydrogels for Biomedical Applications. Heliyon 2020, 6, e03719. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Cid, P.; Jiménez-Rosado, M.; Romero, A.; Pérez-Puyana, V. Novel Trends in Hydrogel Development for Biomedical Applications: A Review. Polymers 2022, 14, 3023. [Google Scholar] [CrossRef] [PubMed]

- Suhail, M.; Fang, C.W.; Chiu, I.H.; Hung, M.C.; Vu, Q.L.; Lin, I.L.; Wu, P.C. Designing and In Vitro Characterization of pH-Sensitive Aspartic Acid-Graft-Poly (Acrylic Acid) Hydrogels as Controlled Drug Carriers. Gels 2022, 8, 521. [Google Scholar] [CrossRef] [PubMed]

- Dreiss, C.A. Hydrogel Design Strategies for Drug Delivery. Curr. Opin. Colloid Interface Sci. 2020, 48, 1–17. [Google Scholar] [CrossRef]

- Briggs, F.; Browne, D.; Asuri, P. Role of Polymer Concentration and Crosslinking Density on Release Rates of Small Molecule Drugs. Int. J. Mol. Sci. 2022, 23, 4118. [Google Scholar] [CrossRef]

- Hunt, J.A.; Chen, R.; van Veen, T.; Bryan, N. Hydrogels for Tissue Engineering and Regenerative Medicine. J. Mater. Chem. B 2014, 2, 5319–5338. [Google Scholar] [CrossRef] [PubMed]

- Crosby, C.O.; Stern, B.; Kalkunte, N.; Pedahzur, S.; Ramesh, S.; Zoldan, J. Interpenetrating Polymer Network Hydrogels as Bioactive Scaffolds for Tissue Engineering. Rev. Chem. Eng. 2022, 38, 347–361. [Google Scholar] [CrossRef]

- Huang, X.; Li, J.; Luo, J.; Gao, Q.; Mao, A.; Li, J. Research Progress on Double-Network Hydrogels. Mater. Today Commun. 2021, 29, 102757. [Google Scholar] [CrossRef]

- Nonoyama, T.; Gong, J.P. Tough Double Network Hydrogel and Its Biomedical Applications. Annu. Rev. Chem. Biomol. Eng. 2021, 12, 393–410. [Google Scholar] [CrossRef] [PubMed]

- Haraguchi, K.; Takehisa, T. Nanocomposite Hydrogels: A Unique Organic–Inorganic Network Structure with Extraordinary Mechanical, Optical, and Swelling/De-Swelling Properties. Adv. Mater. 2002, 14, 1120–1124. [Google Scholar] [CrossRef]

- Gong, J.P.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-Network Hydrogels with Extremely High Mechanical Strength. Adv. Mater. 2003, 15, 1155–1158. [Google Scholar] [CrossRef]

- Gong, J.P. Why Are Double Network Hydrogels So Tough? Soft Matter 2010, 6, 2583–2590. [Google Scholar] [CrossRef]

- Nakayama, A.; Kakugo, A.; Gong, J.P.; Osada, Y.; Takai, M.; Erata, T.; Kawano, S. High Mechanical Strength Double-Network Hydrogel with Bacterial Cellulose. Adv. Funct. Mater. 2004, 14, 1124–1128. [Google Scholar] [CrossRef]

- Myung, D.; Koh, W.; Ko, J.; Hu, Y.; Carrasco, M.; Noolandi, J.; Ta, C.N.; Frank, C.W. Biomimetic Strain Hardening in Interpenetrating Polymer Network Hydrogels. Polymer 2007, 48, 5376–5387. [Google Scholar] [CrossRef]

- Weng, L.; Gouldstone, A.; Wu, Y.; Chen, W. Mechanically Strong Double Network Photocrosslinked Hydrogels from N, N-Dimethylacrylamide and Glycidyl Methacrylated Hyaluronan. Biomaterials 2008, 29, 2153–2163. [Google Scholar] [CrossRef] [PubMed]

- Jayaramudu, T.; Raghavendra, G.M.; Varaprasad, K.; Reddy, G.V.S.; Reddy, A.B.; Sudhakar, K.; Sadiku, E.R. Preparation and Characterization of Poly (Ethylene Glycol) Stabilized Nano Silver Particles by a Mechanochemical Assisted Ball Mill Process. J. Appl. Polym. Sci. 2016, 133, 43027. [Google Scholar] [CrossRef]

- Jung, K.I.; Lee, D.G.; Bong, K.W.; Noh, S.M.; Um, M.S.; Choi, W.J.; Kim, B.; Jung, H.W. Effects of Solvents on Rheological and Crosslinking Properties of Photo-Polymerized Poly (Ethylene Glycol) Hydrogels. Korean J. Chem. Eng. 2017, 34, 1517–1523. [Google Scholar] [CrossRef]

- Sabel-Grau, T.; Tyushina, A.; Babalik, C.; Lensen, M.C. UV-VIS Curable PEG Hydrogels for Biomedical Applications with Multifunctionality. Gels 2022, 8, 164. [Google Scholar] [CrossRef]

- Hu, X.; Wei, W.; Qi, X.; Yu, H.; Feng, L.; Li, J.; Wang, S.; Zhang, J.; Dong, W. Preparation and Characterization of a Novel pH-Sensitive Salecan-g-Poly (Acrylic Acid) Hydrogel for Controlled Release of Doxorubicin. J. Mater. Chem. B 2015, 3, 2685–2697. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Jin, L. Hydrolysis-Induced Large Swelling of Polyacrylamide Hydrogels. Soft Matter 2020, 16, 5740–5749. [Google Scholar] [CrossRef] [PubMed]

- Myung, D.; Farooqui, N.; Waters, D.; Schaber, S.; Koh, W.; Carrasco, M.; Noolandi, J.; Frank, C.W.; Ta, C.N. Glucose-Permeable Interpenetrating Polymer Network Hydrogels for Corneal Implant Applications: A Pilot Study. Curr. Eye Res. 2008, 33, 29–43. [Google Scholar] [CrossRef] [PubMed]

- Myung, D.; Farooqui, N.; Zheng, L.L.; Koh, W.; Gupta, S.; Bakri, A.; Noolandi, J.; Cochran, J.R.; Frank, C.W.; Ta, C.N. Bioactive Interpenetrating Polymer Network Hydrogels That Support Corneal Epithelial Wound Healing. J. Biomed. Mater. Res. Part A 2009, 90, 70–81. [Google Scholar] [CrossRef] [PubMed]

- Yim, E.S.; Zhao, B.; Myung, D.; Kourtis, L.C.; Frank, C.W.; Carter, D.; Smith, R.L.; Goodman, S.B. Biocompatibility of Poly (Ethylene Glycol)/Poly (Acrylic Acid) Interpenetrating Polymer Network Hydrogel Particles in RAW 264.7 Macrophage and MG-63 Osteoblast Cell Lines. J. Biomed. Mater. Res. Part A 2009, 91, 894–902. [Google Scholar] [CrossRef] [PubMed]

- Waters, D.J.; Engberg, K.; Parke-Houben, R.; Ta, C.N.; Jackson, A.J.; Toney, M.F.; Frank, C.W. Structure and Mechanism of Strength Enhancement in Interpenetrating Polymer Network Hydrogels. Macromolecules 2011, 44, 5776–5787. [Google Scholar] [CrossRef]

- Naficy, S.; Razal, J.M.; Whitten, P.G.; Wallace, G.G.; Spinks, G.M. A pH-Sensitive, Strong Double-Network Hydrogel: Poly (Ethylene Glycol) Methyl Ether Methacrylates–Poly (Acrylic Acid). J. Polym. Sci. Part B Polym. Phys. 2012, 50, 423–430. [Google Scholar] [CrossRef]

- Tan, X.W.; Hartman, L.; Tan, K.P.; Poh, R.; Myung, D.; Zheng, L.L.; Waters, D.; Noolandi, J.; Beuerman, R.W.; Mehta, J.S. In Vivo Biocompatibility of Two PEG/PAA Interpenetrating Polymer Networks as Corneal Inlays Following Deep Stromal Pocket Implantation. J. Mater. Sci. Mater. Med. 2013, 24, 967–977. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.W.; Noh, S.M.; Kim, B.; Jung, H.W. Gelation and Crosslinking Characteristics of Photopolymerized Poly (Ethylene Glycol) Hydrogels. J. Appl. Polym. Sci. 2015, 132, 41939. [Google Scholar] [CrossRef]

- Park, J.; Kim, N.; Jung, K.I.; Yoon, S.; Noh, S.M.; Bang, J.; Jung, H.W. Effect of Silica Nanoparticles Blocked with Epoxy Groups on the Crosslinking and Surface Properties of PEG Hydrogel Films. Polymers 2021, 13, 3296. [Google Scholar] [CrossRef]

- Sung, J.; Lee, D.G.; Lee, S.; Park, J.; Jung, H.W. Crosslinking Dynamics and Gelation Characteristics of Photo-and Thermally Polymerized Poly (Ethylene Glycol) Hydrogels. Materials 2020, 13, 3277. [Google Scholar] [CrossRef] [PubMed]

- Myung, D.; Waters, D.; Wiseman, M.; Duhamel, P.E.; Noolandi, J.; Ta, C.N.; Frank, C.W. Progress in the Development of Interpenetrating Polymer Network Hydrogels. Polym. Adv. Technol. 2008, 19, 647–657. [Google Scholar] [CrossRef] [PubMed]

- Wen, X.; Cao, X.; Yin, Z.; Wang, T.; Zhao, C. Preparation and Characterization of Konjac Glucomannan–Poly (Acrylic Acid) IPN Hydrogels for Controlled Release. Carbohydr. Polym. 2009, 78, 193–198. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Z.; Zeng, Z.; Chen, Y. Chain-Extended Polyurethane–Acrylate Ionomer for UV-Curable Waterborne Coatings. J. Appl. Polym. Sci. 2002, 84, 1818–1831. [Google Scholar] [CrossRef]

- Dave, V.J.; Patel, H.S. Synthesis and Characterization of Interpenetrating Polymer Networks from Transesterified Castor Oil Based Polyurethane and Polystyrene. J. Saudi Chem. Soc. 2017, 21, 18–24. [Google Scholar] [CrossRef]

- Ratna, D. Thermal Properties of Thermosets. In Thermosets; Guo, Q., Ed.; Woodhead Publishing: Amsterdam, The Netherlands, 2012; pp. 62–91. ISBN 9780857090867. [Google Scholar] [CrossRef]

- Gómez Ribelles, J.L.; Monleón Pradas, M.; Meseguer Dueñas, J.M.; Torregrosa Cabanilles, C. Glass Transition in Homogeneous and Heterogeneous Interpenetrating Polymer Networks and Its Relation to Concentration Fluctuations. J. Non-Cryst. Solids 2002, 307–310, 731–737. [Google Scholar] [CrossRef]

- Moon, H.; Noh, S.M.; Jung, H.W. Thermal Crosslinking Characteristics of Dual-Curable Isocyanate Blocked with Methacrylate-Functionalized Amine Derivatives for Eco-Friendly Automotive Clearcoats. Appl. Surf. Sci. 2023, 607, 155058. [Google Scholar] [CrossRef]

- June, Y.G.; Jung, K.I.; Lee, D.G.; Jeong, S.; Lee, T.H.; Park, Y.I.; Noh, S.M.; Jung, H.W. Influence of Functional Group Content in Hydroxyl-Functionalized Urethane Methacrylate Oligomers on the Crosslinking Features of Clearcoats. J. Coat. Technol. Res. 2021, 18, 229–237. [Google Scholar] [CrossRef]

- Ninciuleanu, C.M.; Ianchiş, R.; Alexandrescu, E.; Mihăescu, C.I.; Scomoroşcenco, C.; Nistor, C.L.; Preda, S.; Petcu, C.; Teodorescu, M. The Effects of Monomer, Crosslinking Agent, and Filler Concentrations on the Viscoelastic and Swelling Properties of Poly (Methacrylic Acid) Hydrogels: A Comparison. Materials 2021, 14, 2305. [Google Scholar] [CrossRef]

- Sorkhabi, T.S.; Samberan, M.F.; Ostrowski, K.A.; Majka, T.M. Novel Synthesis, Characterization and Amoxicillin Release Study of pH-Sensitive Nanosilica/Poly (Acrylic Acid) Macroporous Hydrogel with High Swelling. Materials 2022, 15, 469. [Google Scholar] [CrossRef]

- Li, T.; Yang, Q.S.; Ma, L.H.; Zhang, Y.X. A Non-Gaussian Model for the Chemo-Mechanical Coupling Behavior of Largely Deformed Hydrogels. Soft Mater. 2019, 17, 126–136. [Google Scholar] [CrossRef]

| Sample | Weight Fraction (wt%) | ||||

|---|---|---|---|---|---|

| PEGDA | AA | PEGDMA | DI Water | PI | |

| PEG-solution | 49.75 | - | - | 49.75 | 0.5 |

| PAA-solution 1 | - | 50.676 | 0.536 | 48.263 | 0.525 |

| PAA-solution 5 | - | 49.558 | 2.730 | 47.198 | 0.513 |

| Hydrogels | Tmax,1 (°C) | Tmax,2 (°C) |

|---|---|---|

| PEG-SN | 414.16 ± 1.00 | - |

| PEG/PAA-IPN1 | 301.85 ± 2.11 | 432.14 ± 0.99 |

| PEG/PAA-IPN5 | 307.13 ± 0.76 | 431.37 ± 2.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, U.; Moon, H.; Park, J.; Jung, H.W. Crosslinking and Swelling Properties of pH-Responsive Poly(Ethylene Glycol)/Poly(Acrylic Acid) Interpenetrating Polymer Network Hydrogels. Polymers 2024, 16, 2149. https://doi.org/10.3390/polym16152149

Hwang U, Moon H, Park J, Jung HW. Crosslinking and Swelling Properties of pH-Responsive Poly(Ethylene Glycol)/Poly(Acrylic Acid) Interpenetrating Polymer Network Hydrogels. Polymers. 2024; 16(15):2149. https://doi.org/10.3390/polym16152149

Chicago/Turabian StyleHwang, Uijung, HoYeon Moon, Junyoung Park, and Hyun Wook Jung. 2024. "Crosslinking and Swelling Properties of pH-Responsive Poly(Ethylene Glycol)/Poly(Acrylic Acid) Interpenetrating Polymer Network Hydrogels" Polymers 16, no. 15: 2149. https://doi.org/10.3390/polym16152149