1. Understanding Average Age in Inventory Management

In the realm of inventory management, understanding the concept of average age is vital for optimizing the allocation and movement of goods. It plays a pivotal role in the ABC analysis method, a renowned strategy for categorizing inventory items into different classes based on their importance and value. This blog section delves deep into the intricacies of average age, shedding light on why it matters, how it's calculated, and the impact it has on your inventory management decisions.

1. Defining average Age in inventory Management:

Average age, also known as the average holding period or average age of inventory, refers to the mean time an item stays in your inventory before being sold or used. It is a crucial metric as it offers insights into the efficiency of your inventory turnover. The shorter the average age, the faster your goods are moving, which can free up capital and reduce holding costs.

2. Calculating Average Age:

Calculating average age is relatively straightforward. You sum the number of days each item spends in your inventory, and then divide this total by the number of items. Here's an example: If you have three items with ages of 10 days, 20 days, and 30 days, the average age would be (10 + 20 + 30) / 3 = 20 days.

3. Importance of Short Average Age:

Shortening the average age of inventory is often a goal for businesses aiming to optimize their inventory management. This directly impacts your cash flow by reducing the amount of capital tied up in unsold goods. It also minimizes the risk of obsolescence and spoilage, as fresher items are less likely to become outdated.

4. The Impact on Different Inventory Categories:

Different categories of inventory items are affected by average age in distinct ways. For instance, fast-moving products, categorized as "A" items in the ABC analysis, benefit from shorter average ages. This ensures that popular items remain in stock and readily available to meet customer demand. On the other hand, slow-moving items ("C" items) might have a longer average age, as they don't sell as quickly.

5. The Balance Between Average Age and Holding Costs:

While a short average age is desirable for improved cash flow, it's essential to strike a balance with holding costs. You may need to hold some items for a longer time due to seasonality, supplier lead times, or other factors. Careful analysis of each inventory item's specific requirements is necessary to optimize the average age effectively.

6. Real-Life Example:

Let's consider an electronics retailer. High-end smartphones ("A" items) should have a short average age to meet the ever-changing consumer demand. In contrast, accessories like phone cases ("C" items) can have a longer average age since they don't become obsolete as quickly.

In summary, understanding and managing the average age of inventory is a critical aspect of efficient inventory management. It impacts your cash flow, holding costs, and the availability of products to meet customer demand. Different categories of items require different average ages, and finding the right balance can be a key factor in your business's success. The ABC analysis method helps categorize items and prioritize efforts to manage average age effectively.

Understanding Average Age in Inventory Management - ABC analysis: Prioritizing Inventory Management for Average Age

2. Strategies for Managing High Average Age Inventory

In the realm of inventory management, one key metric that demands attention is the average age of inventory. This metric essentially measures the length of time that items sit in a warehouse before being sold or used. A high average age can be indicative of various issues, such as slow-moving products, inadequate demand forecasting, or ineffective inventory management practices. To tackle this challenge, businesses need to implement strategies that address the root causes and ensure efficient management of their inventory. In this section, we will delve into some effective strategies for managing high average age inventory, providing insights from different perspectives and offering practical tips for improvement.

1. Optimize demand forecasting: Accurate demand forecasting is crucial for maintaining optimal inventory levels. By analyzing historical sales data, market trends, and customer behavior, businesses can gain valuable insights into demand patterns. This enables them to make informed decisions about inventory replenishment, reducing the likelihood of overstocking or understocking. For instance, a company specializing in outdoor gear may identify a surge in demand for camping equipment during the summer months. By leveraging this information, they can adjust their inventory levels accordingly, avoiding excess inventory and potential obsolescence.

2. Implement an inventory classification system: Categorizing inventory based on its value and demand can significantly enhance inventory management efforts. One commonly used classification system is the ABC analysis, which segments inventory into three categories: A, B, and C. Category A includes high-value items with high demand, while Category C comprises low-value items with low demand. By prioritizing the management of Category A items, businesses can ensure that their most valuable products are readily available and minimize the risk of stockouts. On the other hand, a more relaxed approach can be adopted for Category C items, reducing the need for excessive storage space and excessive attention.

3. Establish effective communication channels: Collaboration and communication between different departments within a company are vital for inventory management success. Sales teams can provide valuable insights into customer preferences and market trends, enabling inventory managers to make more informed decisions. Additionally, cross-functional meetings and regular updates on inventory levels can help identify slow-moving items and take proactive measures to address them. By fostering a culture of open communication, businesses can streamline their inventory management processes and reduce the average age of inventory.

4. Implement just-in-time (JIT) inventory management: JIT is a lean inventory management approach that aims to minimize inventory holding costs by receiving goods only when they are needed for production or sale. By synchronizing the supply chain and production processes, businesses can reduce lead times and eliminate the need for excess inventory. This strategy is particularly effective for perishable or seasonal products, as it ensures freshness and minimizes the risk of obsolescence. For example, a bakery may adopt JIT inventory management for their daily bread production, ensuring that they have just enough inventory to meet customer demand while minimizing waste.

5. Leverage technology and automation: In today's digital era, technology plays a crucial role in optimizing inventory management. Inventory management software can provide real-time visibility into inventory levels, enabling businesses to track and monitor stock movements efficiently. Furthermore, automation tools can streamline various processes, such as order fulfillment and replenishment, reducing the chances of human error and improving overall efficiency. For instance, an e-commerce retailer may use automated reorder triggers based on predefined inventory thresholds to ensure timely replenishment of fast-moving products.

By implementing these strategies, businesses can effectively manage high average age inventory and optimize their overall inventory management practices. From accurate demand forecasting to leveraging technology, each approach brings its own benefits and contributes to reducing the average age of inventory. Ultimately, by prioritizing inventory management and continuously evaluating and refining their strategies, businesses can maintain a healthy balance between inventory levels and customer demand, maximizing profitability and customer satisfaction.

Strategies for Managing High Average Age Inventory - ABC analysis: Prioritizing Inventory Management for Average Age

3. Understanding the Importance of Maintaining Average Age of Inventory

Understanding the Importance of Maintaining Average Age of Inventory

When it comes to inventory management, one crucial aspect that often gets overlooked is the average age of inventory. This metric measures the average number of days it takes for a product to be sold after it has been received into the inventory. Maintaining a healthy average age of inventory is essential for businesses as it directly impacts their profitability, customer satisfaction, and overall operational efficiency. In this section, we will delve deeper into the significance of this metric and explore different perspectives on why it should be a priority for businesses.

1. Financial Implications:

Maintaining a reasonable average age of inventory is directly linked to a company's financial health. By minimizing the average age of inventory, businesses can reduce holding costs, such as storage fees, insurance, and depreciation, which can eat into their profit margins. Additionally, a lower average age of inventory allows businesses to free up working capital, enabling them to invest in other areas of the company or take advantage of new opportunities. Conversely, a high average age of inventory can tie up valuable resources, leading to cash flow issues and hindering growth.

2. Customer Satisfaction:

From a customer's perspective, having access to products promptly is crucial for a positive shopping experience. If a business frequently experiences out-of-stocks or delays in fulfilling orders due to high average age of inventory, it can result in frustrated customers who may turn to competitors. For instance, imagine a customer wanting to purchase a popular item online but finding it consistently out of stock. They are likely to seek alternative options, potentially leading to a loss of sales and loyal customers. By maintaining a healthy average age of inventory, businesses can ensure they meet customer demand promptly, enhancing customer satisfaction and loyalty.

3. Operational Efficiency:

Efficient inventory management is vital for the smooth functioning of any business. A high average age of inventory often indicates inefficiencies in the supply chain, such as inaccurate demand forecasting, procurement delays, or inadequate inventory control. These inefficiencies can result in excess inventory, leading to increased carrying costs and a higher risk of obsolescence. On the other hand, a low average age of inventory indicates a streamlined and responsive supply chain, allowing businesses to operate efficiently, reduce waste, and optimize resources.

4. Examples of Maintaining Average Age of Inventory:

To illustrate the importance of maintaining the average age of inventory, let's consider a retail clothing store. If the store fails to manage its inventory effectively and experiences a high average age of inventory, it may end up with an excess of out-of-fashion or seasonal clothing. As a result, the store would have to heavily discount these items to clear the inventory, leading to decreased profit margins. Conversely, a store that maintains a low average age of inventory can quickly respond to fashion trends and ensure that its shelves are stocked with the latest styles, attracting more customers and maximizing sales.

5. Balancing Act:

It is important to note that maintaining the average age of inventory is a delicate balancing act. While a low average age of inventory is generally desirable, businesses must also avoid the opposite extreme of carrying too little inventory. Insufficient inventory levels can lead to frequent stockouts, missed sales opportunities, and dissatisfied customers. Striking the right balance requires businesses to analyze demand patterns, optimize procurement processes, and leverage technology to improve forecasting accuracy.

By understanding the importance of maintaining the average age of inventory, businesses can make informed decisions to optimize their inventory management strategies. From financial implications to customer satisfaction and operational efficiency, this metric serves as a valuable indicator of a company's overall health and success. As we delve deeper into the topic of backordering and its impact on average age of inventory, we will explore strategies and best practices that businesses can adopt to ensure a healthy and efficient inventory management system.

Understanding the Importance of Maintaining Average Age of Inventory - Backordering: Maintaining Average Age of Inventory during Out of Stocks

4. The Impact of Out-of-Stocks on Average Age of Inventory

When a business experiences an out-of-stock situation, it can have a significant impact on its average age of inventory. Average age of inventory refers to the average amount of time it takes for a product to be sold or used up. Out-of-stocks occur when there is no inventory available to fulfill customer orders or meet internal demand. This can happen due to various reasons such as supply chain disruptions, unexpected spikes in demand, or forecasting errors. In this section, we will explore the effects of out-of-stocks on the average age of inventory and discuss strategies to mitigate these impacts.

1. Increased average age of inventory: When a product is out of stock, it remains unsold or unused, leading to an increase in the average age of inventory. This means that the overall inventory is aging, and the longer it remains unsold, the higher the average age becomes. Higher average age of inventory can have several negative consequences for a business, including increased carrying costs, reduced cash flow, and potential obsolescence of products.

2. Customer dissatisfaction and lost sales: Out-of-stocks can result in customer dissatisfaction and lost sales. When customers are unable to purchase a desired product due to it being out of stock, they may turn to competitors or seek alternative solutions. This not only leads to missed sales opportunities but also affects customer loyalty and brand reputation. In addition, customers may perceive a business as unreliable or unprepared, further damaging the relationship.

3. Inventory replenishment delays: When an out-of-stock situation occurs, it takes time to replenish the inventory and bring the product back in stock. This delay in replenishment can further contribute to an increase in the average age of inventory. The longer it takes to restock, the longer the product remains unsold, resulting in a higher average age.

4. impact on supply chain efficiency: Out-of-stocks can disrupt the smooth functioning of the supply chain. When a product is out of stock, it can cause delays in fulfilling customer orders and result in increased lead times. This can have a domino effect on other products and inventory levels, affecting the overall efficiency of the supply chain. It is crucial for businesses to closely monitor and manage their inventory levels to minimize the impact of out-of-stocks on supply chain operations.

5. Mitigating the impact of out-of-stocks: To maintain a healthy average age of inventory during out-of-stock situations, businesses can implement several strategies. These include:

A. accurate demand forecasting: By accurately forecasting demand, businesses can ensure that they have the right amount of inventory on hand to meet customer needs. This can help in preventing out-of-stock situations and minimizing the impact on average age of inventory.

B. Safety stock management: Safety stock refers to the extra inventory kept on hand to buffer against unexpected fluctuations in demand or supply. By maintaining an appropriate level of safety stock, businesses can mitigate the impact of out-of-stocks on average age of inventory.

C. efficient supply chain management: Streamlining supply chain processes and improving communication with suppliers can help in reducing lead times and replenishment delays. This can ensure that products are restocked promptly, minimizing the impact on average age of inventory.

D. Implementing backordering: Backordering allows customers to place orders for out-of-stock products, ensuring that the demand is captured and fulfilled once the inventory is replenished. This can help in reducing lost sales and maintaining a healthy average age of inventory.

Out-of-stocks can have a significant impact on the average age of inventory. It leads to increased average age, customer dissatisfaction, lost sales, and supply chain inefficiencies. However, by implementing effective strategies such as accurate demand forecasting, safety stock management, efficient supply chain practices, and backordering, businesses can mitigate these impacts and maintain a healthy average age of inventory.

The Impact of Out of Stocks on Average Age of Inventory - Backordering: Maintaining Average Age of Inventory during Out of Stocks

5. A Solution for Maintaining Average Age of Inventory

Section 1: The Challenge of Maintaining Average Age of Inventory

In the world of inventory management, one of the critical metrics that businesses often strive to optimize is the Average Age of Inventory. It's a measure of how long, on average, items sit in the warehouse before being sold. Maintaining a healthy Average Age of Inventory is essential because it directly impacts a company's profitability, cash flow, and customer satisfaction. When items linger in the warehouse for too long, they tie up capital and increase carrying costs, making it harder to adapt to market changes. On the other hand, if inventory turnover is too rapid, it can lead to stockouts and potential revenue loss. Striking the right balance is challenging, especially during periods of high demand or supply chain disruptions.

1. Inventory Holding Costs: One perspective on this challenge comes from the financial side of the business. Holding inventory incurs costs such as storage, insurance, and depreciation. A longer Average Age of Inventory generally means higher holding costs. For instance, consider a retailer with a surplus of winter coats during the summer months. Holding onto these items for an extended period incurs storage costs without generating revenue.

2. Customer Expectations: From a customer-centric viewpoint, maintaining a reasonable Average Age of Inventory is essential to meet customer expectations. Customers today expect prompt deliveries and readily available products. When a product is consistently out of stock, it can lead to dissatisfaction and loss of customers. An example of this can be seen in the tech industry, where demand for the latest gadgets is high. Companies must ensure they have enough stock to meet demand while not overstocking on soon-to-be outdated models.

Section 2: Backordering as a Solution

So, how can businesses effectively manage their Average Age of Inventory, especially during periods of out-of-stock situations? One solution that has gained traction is backordering, a strategy that can help strike that delicate balance between inventory turnover and customer satisfaction.

1. Strategic Allocation: Backordering allows companies to strategically allocate limited inventory to fulfill orders. For example, if a popular item is temporarily out of stock, customers can still place orders for it. This ensures that the company doesn't lose potential sales and can fulfill them when new stock arrives. This approach minimizes revenue loss while maintaining a reasonable Average Age of Inventory.

2. Transparent Communication: Effective communication is key when implementing backordering. Companies must clearly communicate to customers that their desired items are temporarily out of stock but will be available soon. This transparency helps manage customer expectations and can even build trust. An example of this can be seen in the fashion industry, where pre-orders for upcoming clothing collections are common. Customers know they're reserving items in advance, and they're willing to wait.

3. Data-Driven Insights: Backordering isn't a one-size-fits-all solution. Businesses must rely on data to determine which items are suitable for backordering and how much stock to allocate. For instance, an online bookstore might allow customers to backorder a highly anticipated book release, ensuring they don't miss out on sales while controlling inventory levels for less popular titles.

4. Supply Chain Efficiency: Implementing backordering can also incentivize businesses to improve their supply chain efficiency. Knowing that customers are willing to wait for an item can reduce the pressure to maintain excessive safety stock, leading to cost savings in the long run.

Backordering is a strategic tool that can help businesses maintain their Average Age of inventory during out-of-stock situations. By leveraging this approach along with transparent communication and data-driven insights, companies can minimize revenue loss, keep customers satisfied, and strike that essential balance in inventory management.

A Solution for Maintaining Average Age of Inventory - Backordering: Maintaining Average Age of Inventory during Out of Stocks

6. Overcoming Challenges in Backordering to Maintain Average Age of Inventory

One of the biggest challenges in backordering is to maintain the average age of inventory. When a product goes out-of-stock, it can disrupt the smooth flow of operations and lead to dissatisfied customers. Backordering, which involves accepting orders for products that are temporarily unavailable, can be a useful strategy to manage inventory and keep customers happy. However, it is not without its challenges. In this section, we will discuss some of the common challenges faced in backordering and how they can be overcome to maintain the average age of inventory.

1. Communication and Transparency: Communication plays a crucial role in backordering. It is essential to keep customers informed about the status of their orders and provide realistic estimated delivery dates. Lack of transparency can lead to frustration and, ultimately, loss of customers. To overcome this challenge, implement a robust system to update customers about their backordered items regularly. Utilize automated emails or notifications to provide real-time updates on order status. Transparency builds trust and helps manage customer expectations effectively.

2. Supplier Reliability: Backordering relies heavily on suppliers' ability to deliver the products on time. However, supplier reliability can be a significant challenge. Late deliveries or failure to fulfill orders can lead to increased average age of inventory and customer dissatisfaction. To mitigate this challenge, develop strong relationships with reliable suppliers. Regularly evaluate their performance and communicate your expectations clearly. Consider having backup suppliers to ensure a steady supply of products during peak demand or unforeseen circumstances.

3. Inventory Management: Maintaining an optimal inventory level is crucial to avoid excessive backorders and long average age of inventory. It is essential to strike a balance between stocking enough inventory to meet demand and avoiding overstocking. Utilize inventory management software to track sales patterns, forecast demand, and optimize reorder points. Regularly analyze sales data and adjust inventory levels accordingly. By effectively managing inventory, you can reduce backorders and maintain a healthy average age of inventory.

4. efficient Order fulfillment: Backordered items require special attention to ensure efficient order fulfillment. It is essential to prioritize backorders and streamline the fulfillment process. Implement an order management system that allows easy tracking of backordered items and ensures timely fulfillment. Consider using a first-in, first-out (FIFO) approach to fulfill backorders, ensuring fairness and customer satisfaction. Efficient order fulfillment minimizes delays and helps maintain a reasonable average age of inventory.

5. Customer Satisfaction and Retention: Backordering can be a double-edged sword when it comes to customer satisfaction and retention. While it allows customers to place orders for out-of-stock items, it also tests their patience. To overcome this challenge, focus on providing exceptional customer service. Promptly address customer inquiries and concerns about backorders. Offer alternatives or substitutes for unavailable products whenever possible. By prioritizing customer satisfaction, you can minimize the negative impact of backordering on customer retention.

Backordering presents several challenges in maintaining the average age of inventory. However, with effective communication, reliable suppliers, robust inventory management, efficient order fulfillment, and a strong focus on customer satisfaction, these challenges can be overcome. By implementing strategies to address these challenges, you can successfully navigate the backordering process while maintaining a healthy average age of inventory.

Overcoming Challenges in Backordering to Maintain Average Age of Inventory - Backordering: Maintaining Average Age of Inventory during Out of Stocks

7. Key Factors Affecting Average Age of Inventory Accuracy

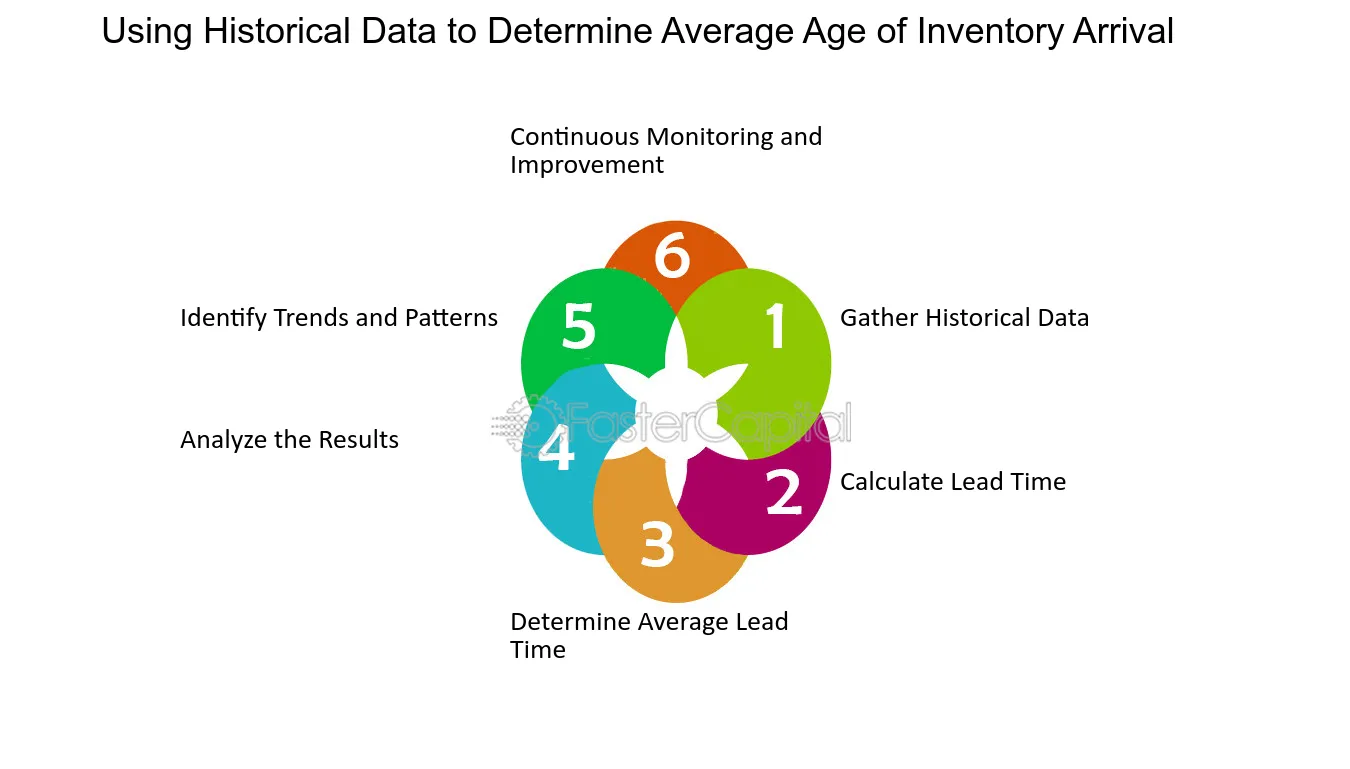

Accurate inventory management is crucial for businesses to maintain a competitive edge in today's fast-paced market. In order to meet customer demands efficiently, it is essential to have a precise understanding of inventory levels and the age of inventory. The average age of inventory accuracy is a key metric that measures how quickly inventory data reflects the actual stock on hand. Several factors can significantly impact this metric, and understanding them is vital for improving demand forecasting and inventory accuracy.

1. Demand Variability: One of the primary factors affecting the average age of inventory accuracy is demand variability. Fluctuations in customer demand can lead to stockouts or overstock situations, resulting in inaccurate inventory records. For instance, if a sudden surge in demand occurs for a particular product, and the inventory system fails to capture this change promptly, it can lead to stockouts and dissatisfied customers. Implementing advanced demand forecasting techniques, such as analyzing historical sales data and market trends, can help businesses anticipate demand fluctuations and adjust inventory levels accordingly.

2. Supply Chain Delays: Delays in the supply chain can have a significant impact on inventory accuracy. If there are delays in receiving goods from suppliers or production delays within the business, it can lead to outdated inventory data. For example, if a shipment is delayed due to unforeseen circumstances, such as weather conditions or transportation issues, the inventory system may still reflect the expected arrival time, resulting in inaccurate stock levels. Collaborating closely with suppliers, monitoring lead times, and having contingency plans in place can help mitigate supply chain delays and improve inventory accuracy.

3. Inefficient Data Management: Poor data management practices can also contribute to inaccuracies in inventory records. manual data entry, outdated systems, or inadequate training of employees can lead to errors and discrepancies in inventory data. For instance, if a warehouse worker fails to update the inventory system after fulfilling an order, it can result in inaccuracies in stock levels. Adopting automated inventory management systems, implementing regular data audits, and providing comprehensive training to employees can help minimize data management errors and improve inventory accuracy.

4. Lack of real-Time visibility: Limited visibility into inventory levels and movements can hinder accurate inventory management. Without real-time information, businesses may struggle to make informed decisions, resulting in outdated inventory records. For example, if a company operates multiple warehouses or has a complex distribution network, it becomes crucial to have real-time visibility into inventory levels across all locations. Implementing inventory tracking technologies, such as RFID or barcode systems, can provide real-time visibility and enable businesses to maintain accurate inventory records.

5. Ineffective Communication: Poor communication between different departments or stakeholders can lead to discrepancies in inventory data. For instance, if sales and operations teams do not communicate effectively, it can result in inaccurate demand forecasts and inventory levels. Collaborative communication platforms and regular cross-functional meetings can help align different departments and ensure accurate information exchange. By fostering effective communication, businesses can improve demand forecasting accuracy and maintain inventory records that reflect the actual stock on hand.

Several key factors affect the average age of inventory accuracy, including demand variability, supply chain delays, inefficient data management, lack of real-time visibility, and ineffective communication. By addressing these factors, businesses can enhance demand forecasting accuracy and maintain precise inventory records. Embracing advanced technologies, improving data management practices, and fostering collaboration between departments are essential steps towards improving the average age of inventory accuracy and achieving operational excellence.

Key Factors Affecting Average Age of Inventory Accuracy - Demand forecasting: Improving Average Age of Inventory Accuracy

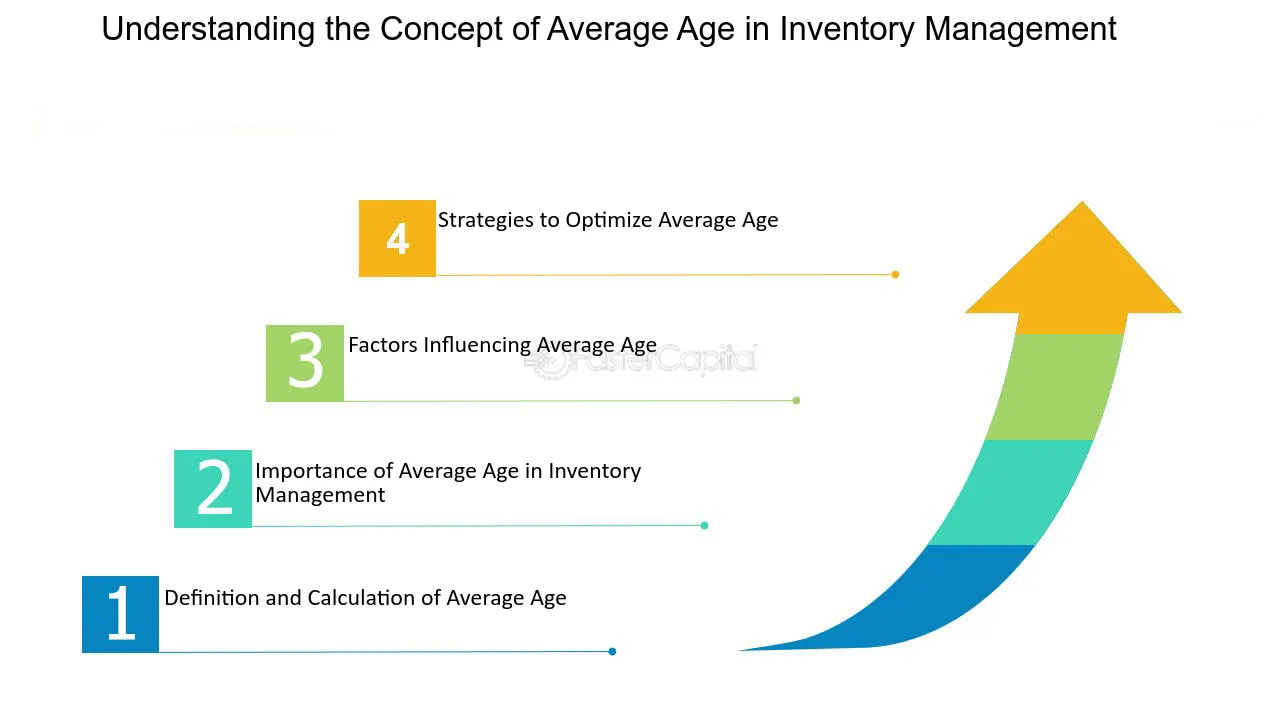

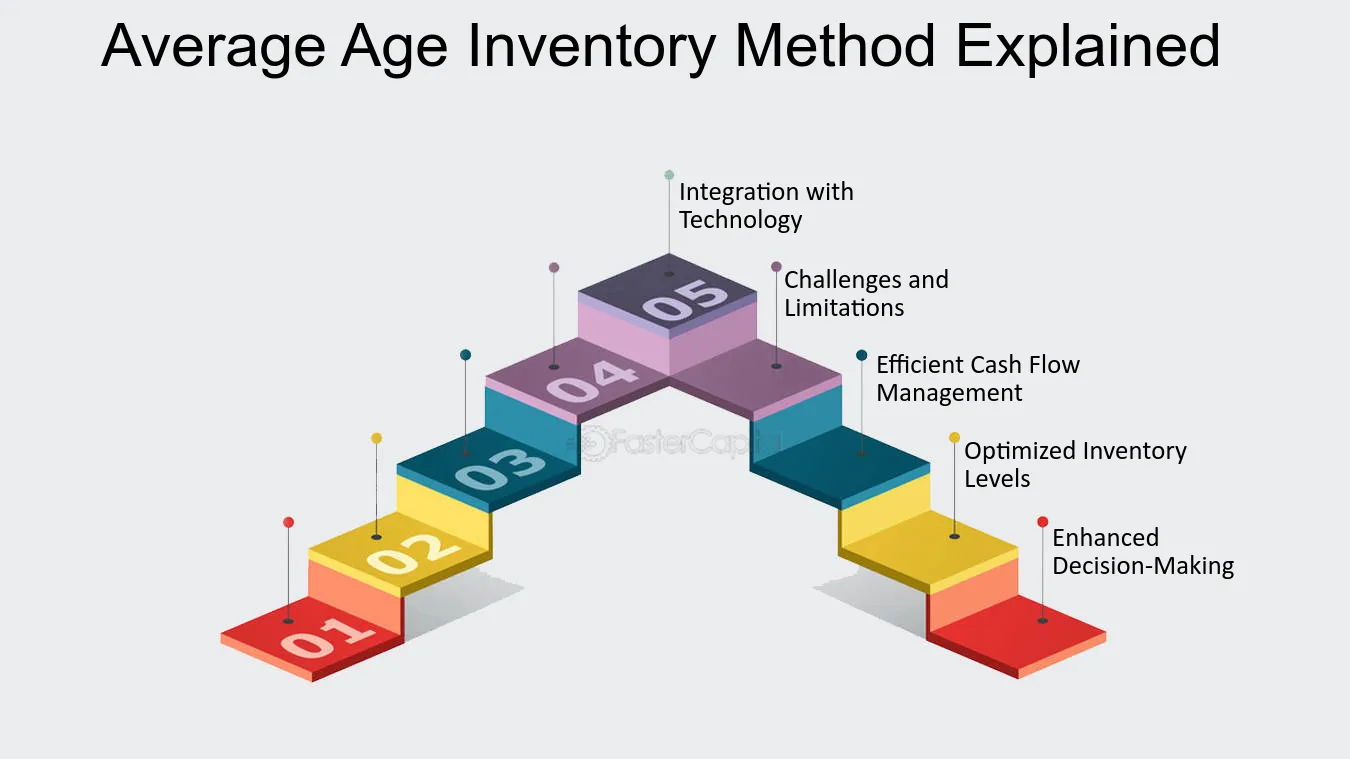

8. Understanding the Concept of Average Age of Inventory

In the world of inventory management, one key metric that is often used to evaluate the efficiency of a company's inventory system is the average age of inventory. This metric provides valuable insights into how long, on average, a company holds onto its inventory before it is sold or used. By understanding and optimizing the average age of inventory, businesses can effectively manage their supply chain, reduce costs, and improve overall operational efficiency.

1. Definition and Calculation: The average age of inventory is a measure that quantifies the average time it takes for inventory to be sold or used. It is calculated by dividing the total value of inventory by the cost of goods sold (COGS) and multiplying the result by 365 (the number of days in a year). For example, if a company has $500,000 worth of inventory and its COGS is $1,000,000, the average age of inventory would be 182.5 days.

2. Importance of Managing Average Age of Inventory: Keeping inventory for an extended period can tie up valuable working capital, increase carrying costs, and potentially lead to obsolescence or spoilage. On the other hand, maintaining too low of an average age of inventory can result in stockouts, lost sales, and dissatisfied customers. Therefore, finding the ideal average age of inventory is crucial for balancing cost-efficiency and customer satisfaction.

3. Factors Affecting Average Age of Inventory: Several factors influence the average age of inventory. Demand variability, lead time, order quantity, and production cycle time are some of the key factors that can impact the average age of inventory. For instance, a company with high demand variability may need to hold more inventory to ensure customer demands are met, resulting in a longer average age of inventory.

4. inventory Turnover ratio: The inventory turnover ratio is closely related to the average age of inventory. It measures the number of times inventory is sold or used during a specific period. The formula for calculating inventory turnover ratio is COGS divided by average inventory. A high turnover ratio indicates that inventory is moving quickly, resulting in a lower average age of inventory.

5. Optimizing the Average Age of Inventory: To optimize the average age of inventory, companies can employ various strategies. One such strategy is implementing a just-in-time (JIT) inventory system, where inventory is ordered and received just in time for production or sale. This approach minimizes the time inventory spends in storage, reducing the average age of inventory. Additionally, forecasting demand accurately, improving supply chain management, and implementing efficient inventory control systems can also help optimize the average age of inventory.

6. Examples: Let's consider two companies, Company A and Company B. Company A has an average age of inventory of 90 days, while Company B has an average age of inventory of 180 days. Despite having similar sales volumes, Company B's longer average age of inventory indicates potential inefficiencies in its inventory management. By analyzing the factors affecting the average age of inventory, such as demand variability and lead time, Company B can identify areas for improvement and work towards reducing its average age of inventory.

Understanding the concept of average age of inventory is essential for businesses to effectively manage their inventory levels and improve operational efficiency. By analyzing this metric, companies can make informed decisions regarding inventory ordering, storage, and replenishment. Ultimately, optimizing the average age of inventory allows businesses to strike a balance between reducing costs and meeting customer demands.

Understanding the Concept of Average Age of Inventory - Economic order quantity: EOQ: Finding the Ideal Average Age of Inventory

9. Importance of Finding the Ideal Average Age of Inventory

The importance of finding the ideal average age of inventory cannot be overstated in the context of economic order quantity (EOQ). This crucial metric allows businesses to strike a delicate balance between holding too much inventory, which ties up valuable capital, and holding too little inventory, which can lead to stockouts and missed opportunities. By determining the optimal average age of inventory, companies can minimize costs, maximize efficiency, and ensure smooth operations. In this section, we will delve into the significance of finding the ideal average age of inventory and explore various perspectives to shed light on this critical aspect of inventory management.

One of the primary reasons for determining the ideal average age of inventory is to minimize holding costs. Holding costs include expenses such as warehousing, insurance, maintenance, and obsolescence. Holding excess inventory for an extended period can significantly increase these costs. On the other hand, holding too little inventory can result in frequent replenishment orders, leading to increased ordering costs. By finding the optimal average age of inventory, businesses can strike a balance between these costs, ensuring that they neither tie up excessive capital nor incur unnecessary expenses.

Example: A clothing retailer must carefully manage its average age of inventory to minimize holding costs. If the retailer holds excessive inventory of a particular style for an extended period, it risks being left with unsold items as fashion trends change. Conversely, if the retailer holds too little inventory, it may face stockouts, leading to missed sales opportunities. By analyzing historical sales data and market trends, the retailer can determine the ideal average age of inventory for each product category, minimizing holding costs while meeting customer demand.

2. Optimizing production and supply chain efficiency:

Another crucial aspect of finding the ideal average age of inventory is optimizing production and supply chain efficiency. By understanding the average age of inventory, businesses can align their production schedules and supply chain operations accordingly. This alignment ensures that production is neither underutilized nor overwhelmed, leading to a more efficient and cost-effective operation.

Example: An automobile manufacturer must carefully manage its average age of inventory to optimize production efficiency. Holding excessive inventory for an extended period ties up capital and increases holding costs. On the other hand, holding too little inventory can disrupt the production line and lead to delays. By analyzing demand forecasts, production capacity, and lead times, the manufacturer can determine the ideal average age of inventory, ensuring a smooth production process and minimizing costs.

3. Meeting customer demand and reducing stockouts:

Finding the ideal average age of inventory is crucial for meeting customer demand while minimizing stockouts. By analyzing historical sales data, market trends, and customer preferences, businesses can determine the optimal inventory levels required to fulfill customer orders promptly. maintaining the right average age of inventory helps ensure that products are available when customers need them, enhancing customer satisfaction and loyalty.

Example: An e-commerce platform must carefully manage its average age of inventory to meet customer demand and avoid stockouts. Holding excessive inventory for an extended period ties up capital and increases the risk of inventory becoming obsolete. Conversely, holding too little inventory may result in stockouts, leading to dissatisfied customers and potential loss of sales. By analyzing customer buying patterns, seasonality, and lead times, the e-commerce platform can determine the ideal average age of inventory for each product, ensuring high customer satisfaction and minimizing stockouts.

Finding the ideal average age of inventory is of utmost importance in the context of economic order quantity (EOQ). It enables businesses to minimize holding costs, optimize production and supply chain efficiency, and meet customer demand while reducing stockouts. By carefully analyzing historical data, market trends, and customer preferences, companies can strike the perfect balance between holding too much or too little inventory, ensuring a smooth and profitable operation.

Importance of Finding the Ideal Average Age of Inventory - Economic order quantity: EOQ: Finding the Ideal Average Age of Inventory

10. Factors Affecting the Average Age of Inventory

The average age of inventory is a crucial metric for businesses to monitor and optimize. It represents the average length of time that inventory items remain in stock before being sold or used. understanding the factors that influence this metric is essential for achieving efficiency in inventory management and maximizing profitability. In this section, we will delve into the various factors that affect the average age of inventory, exploring insights from different perspectives and providing in-depth information to help businesses make informed decisions.

1. Demand Variability: One of the primary factors influencing the average age of inventory is demand variability. Fluctuations in customer demand can significantly impact how quickly inventory items are sold or used. When demand is stable and predictable, businesses can maintain lower inventory levels, leading to a shorter average age of inventory. Conversely, if demand is highly variable, businesses may need to hold higher levels of inventory to avoid stockouts, resulting in a longer average age of inventory. For example, a retailer selling seasonal products like swimwear may experience high demand during the summer months and minimal demand during the rest of the year, leading to a longer average age of inventory.

2. Lead Time: Lead time, which refers to the time it takes for inventory to be replenished after it has been ordered, is another critical factor affecting the average age of inventory. Longer lead times generally result in a longer average age of inventory, as it takes more time for new stock to arrive and be sold or used. Businesses that rely on international suppliers or manufacturers located far away may face longer lead times due to shipping and transportation delays. Conversely, businesses with shorter lead times can maintain lower inventory levels and achieve a shorter average age of inventory. For instance, a company that sources inventory from local suppliers can benefit from shorter lead times, enabling them to replenish stock more quickly and reduce the average age of inventory.

3. Ordering Frequency and Batch Size: The frequency of orders placed and the batch size of each order can significantly impact the average age of inventory. Ordering more frequently with smaller batch sizes allows businesses to keep inventory levels low, resulting in a shorter average age of inventory. On the other hand, ordering less frequently with larger batch sizes can lead to higher inventory levels and a longer average age of inventory. The trade-off lies in finding the optimal balance between ordering costs and holding costs. For example, a restaurant that orders fresh produce daily in small quantities can maintain a shorter average age of inventory compared to a restaurant that orders large quantities once a week.

4. Seasonality and Trends: Seasonal fluctuations and trends in consumer behavior can also influence the average age of inventory. Businesses that experience predictable seasonal demand patterns may adjust their inventory levels accordingly, resulting in shorter average age of inventory during peak seasons. Additionally, staying abreast of trends can help businesses proactively manage inventory levels to meet changing customer preferences and avoid obsolescence. For instance, a fashion retailer that accurately predicts upcoming trends can stock inventory accordingly, reducing the average age of inventory during the peak trend period.

5. Product Shelf Life: The shelf life of products is a crucial factor when considering the average age of inventory. Perishable or time-sensitive goods require careful inventory management to minimize waste and obsolescence. Businesses dealing with such products must consider the expiration dates or product lifecycles to ensure timely sales or usage. In industries like food and pharmaceuticals, where product quality and safety are paramount, managing the average age of inventory becomes even more critical. For example, a bakery specializing in fresh bread must carefully monitor the average age of inventory to prevent spoilage and maintain customer satisfaction.

Understanding and managing these factors can help businesses optimize their average age of inventory, leading to improved efficiency, reduced holding costs, and increased profitability. By analyzing demand variability, lead time, ordering frequency and batch size, seasonality and trends, and product shelf life, businesses can make informed decisions about inventory management strategies. Striking the right balance between these factors while considering industry-specific requirements will enable businesses to find their ideal average age of inventory and thrive in a competitive market.

Factors Affecting the Average Age of Inventory - Economic order quantity: EOQ: Finding the Ideal Average Age of Inventory

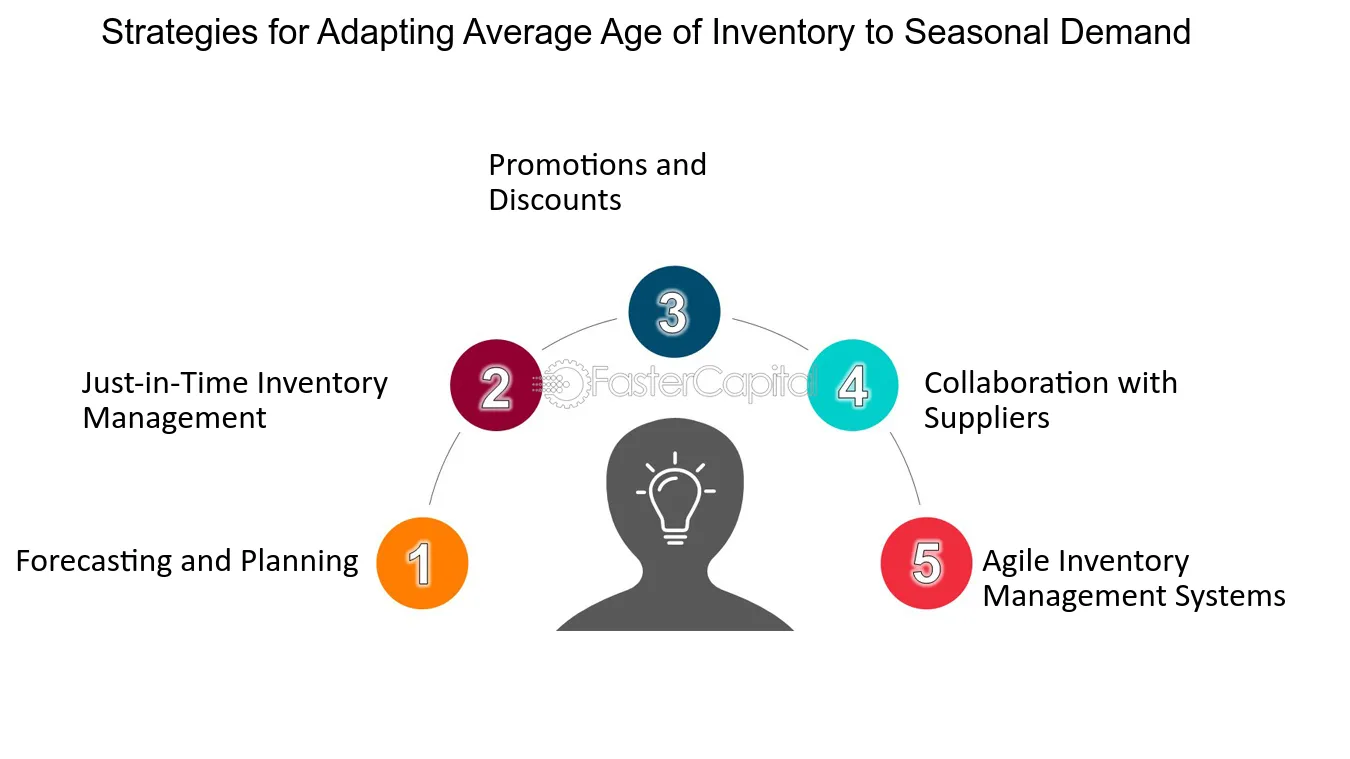

11. Strategies for Optimizing Average Age of Inventory

In the world of inventory management, finding the ideal average age of inventory is crucial for businesses to maintain a healthy balance between stock availability and cost efficiency. The average age of inventory refers to the average amount of time it takes for inventory to be sold or consumed. A longer average age of inventory can result in higher carrying costs, increased risk of obsolescence, and potential loss of sales due to stockouts. On the other hand, a shorter average age of inventory may lead to higher ordering costs and missed opportunities for bulk purchasing discounts. To strike the right balance, businesses need effective strategies for optimizing the average age of inventory.

From a supply chain perspective, it is important to consider factors such as lead time, demand variability, and customer expectations when developing strategies to optimize the average age of inventory. By implementing the following strategies, businesses can streamline their inventory management practices and achieve optimal results:

1. accurate demand forecasting: A key aspect of inventory optimization is accurately predicting customer demand. By utilizing historical data, market trends, and customer insights, businesses can forecast demand more accurately. This enables them to adjust their inventory levels accordingly, reducing the risk of excess stock or stockouts. For example, a retailer can use point-of-sale data and market research to forecast demand for seasonal products, ensuring they have the right amount of inventory on hand to meet customer demands during peak periods.

2. Implementing just-in-time (JIT) inventory management: JIT is a popular inventory management strategy that aims to minimize carrying costs and improve cash flow by receiving inventory just in time for production or customer delivery. By implementing JIT practices, businesses can reduce their average age of inventory and minimize the risk of obsolescence. For instance, a manufacturer can establish strong relationships with suppliers and receive raw materials only when needed, eliminating the need for excessive inventory storage.

3. Optimal order quantities: Determining the optimal order quantity is crucial for balancing inventory carrying costs and ordering costs. The economic order quantity (EOQ) formula helps businesses calculate the ideal order quantity that minimizes total inventory costs. By considering factors such as holding costs, ordering costs, and demand patterns, businesses can optimize their order quantities and maintain a healthy average age of inventory. For instance, a wholesaler can use the EOQ formula to determine the most cost-effective order quantity for a particular product, ensuring they have enough stock to meet customer demand without incurring unnecessary costs.

4. Efficient inventory replenishment: Streamlining the inventory replenishment process is vital for maintaining an optimal average age of inventory. Businesses can utilize technologies such as automated inventory management systems and barcode scanning to improve accuracy and efficiency in the replenishment process. By closely monitoring inventory levels and setting up automated reorder points, businesses can ensure timely replenishment and minimize stockouts or overstock situations. For example, an e-commerce company can integrate its online store with an inventory management system that automatically triggers reorder notifications when stock levels reach a certain threshold.

5. Regular inventory analysis and optimization: Continuous evaluation and optimization of inventory levels are essential for maintaining a healthy average age of inventory. By conducting regular inventory analysis, businesses can identify slow-moving or obsolete items and take appropriate actions such as discounting, liquidation, or discontinuation. Additionally, businesses can leverage data analytics tools to identify trends, patterns, and seasonality in customer demand, enabling them to adjust inventory levels accordingly. For instance, a fashion retailer can analyze sales data to identify trends in color preferences or styles, allowing them to optimize their inventory assortment for maximum sales and minimal aging.

By implementing these strategies, businesses can optimize their average age of inventory, ensuring they have the right amount of stock at the right time. Achieving the ideal balance between stock availability and cost efficiency is a continuous process that requires ongoing monitoring, analysis, and adjustment. Embracing technology, leveraging data analytics, and staying attuned to market dynamics can empower businesses to make informed decisions and maintain a competitive edge in today's fast-paced business environment.

Strategies for Optimizing Average Age of Inventory - Economic order quantity: EOQ: Finding the Ideal Average Age of Inventory

12. Successful Implementation of EOQ and Average Age of Inventory

Case Studies: Successful Implementation of EOQ

Implementing the economic order quantity (EOQ) model can be a game-changer for businesses looking to optimize their inventory management. By finding the ideal average age of inventory, companies can ensure that they maintain optimal stock levels, minimize holding costs, and maximize profitability. In this section, we will explore some real-life case studies that demonstrate the successful implementation of EOQ and the benefits it brings.

1. Case Study 1: Company A, a manufacturing firm, was facing challenges with inventory management, resulting in frequent stockouts and excess inventory. By implementing the EOQ model, they were able to determine the optimal order quantity that minimized holding costs and eliminated stockouts. As a result, the company experienced a significant reduction in carrying costs and improved customer satisfaction due to better product availability.

2. Case Study 2: Retailer B was struggling with overstocking certain products while running out of others. By applying EOQ principles, they analyzed demand patterns, lead times, and holding costs to determine the ideal order quantity and reorder point for each item. This enabled them to maintain optimal stock levels, reduce excess inventory, and avoid stockouts. Consequently, the retailer saw an increase in sales and a reduction in holding costs, leading to improved profitability.

3. Case Study 3: Distributor C, operating in a highly competitive market, faced challenges related to inventory turnover. By implementing EOQ, they were able to strike a balance between holding costs and ordering costs, resulting in efficient inventory management. This allowed them to replenish stock at the right time, avoid excess inventory, and reduce the risk of obsolescence. As a result, the distributor experienced improved cash flow, reduced storage costs, and increased customer satisfaction.

Average Age of Inventory: A Key Metric for Success

Determining the average age of inventory is crucial for businesses aiming to optimize their inventory management practices. This metric provides valuable insights into how quickly inventory is sold, how efficiently it is replenished, and how effectively it aligns with customer demand. In this section, we will delve into the significance of average age of inventory and how it can be calculated and interpreted.

1. Calculation: The average age of inventory is calculated by dividing the total value of inventory by the cost of goods sold (COGS) and multiplying the result by 365 (the number of days in a year). This provides an estimate of the number of days it takes for the inventory to be sold.

2. Interpretation: A lower average age of inventory indicates that products are selling quickly, implying efficient inventory turnover. This suggests that the business is responsive to customer demand and can avoid excess inventory and potential obsolescence. On the other hand, a higher average age of inventory may indicate slow-selling products, poor demand forecasting, or ineffective inventory management practices.

3. Importance: Monitoring the average age of inventory helps businesses identify potential issues in their supply chain and inventory management processes. It enables them to make data-driven decisions to optimize stock levels, reduce holding costs, and improve overall profitability. By adjusting order quantities, reorder points, and production schedules based on the average age of inventory, companies can align their operations with customer demand and avoid unnecessary inventory-related expenses.

These case studies highlight the successful implementation of EOQ and the benefits it brings to businesses. By optimizing inventory management practices and finding the ideal average age of inventory, companies can improve customer satisfaction, reduce holding costs, and enhance profitability. Understanding the significance of average age of inventory and leveraging it as a key metric for success empowers businesses to make informed decisions and stay ahead in today's competitive market.

Successful Implementation of EOQ and Average Age of Inventory - Economic order quantity: EOQ: Finding the Ideal Average Age of Inventory

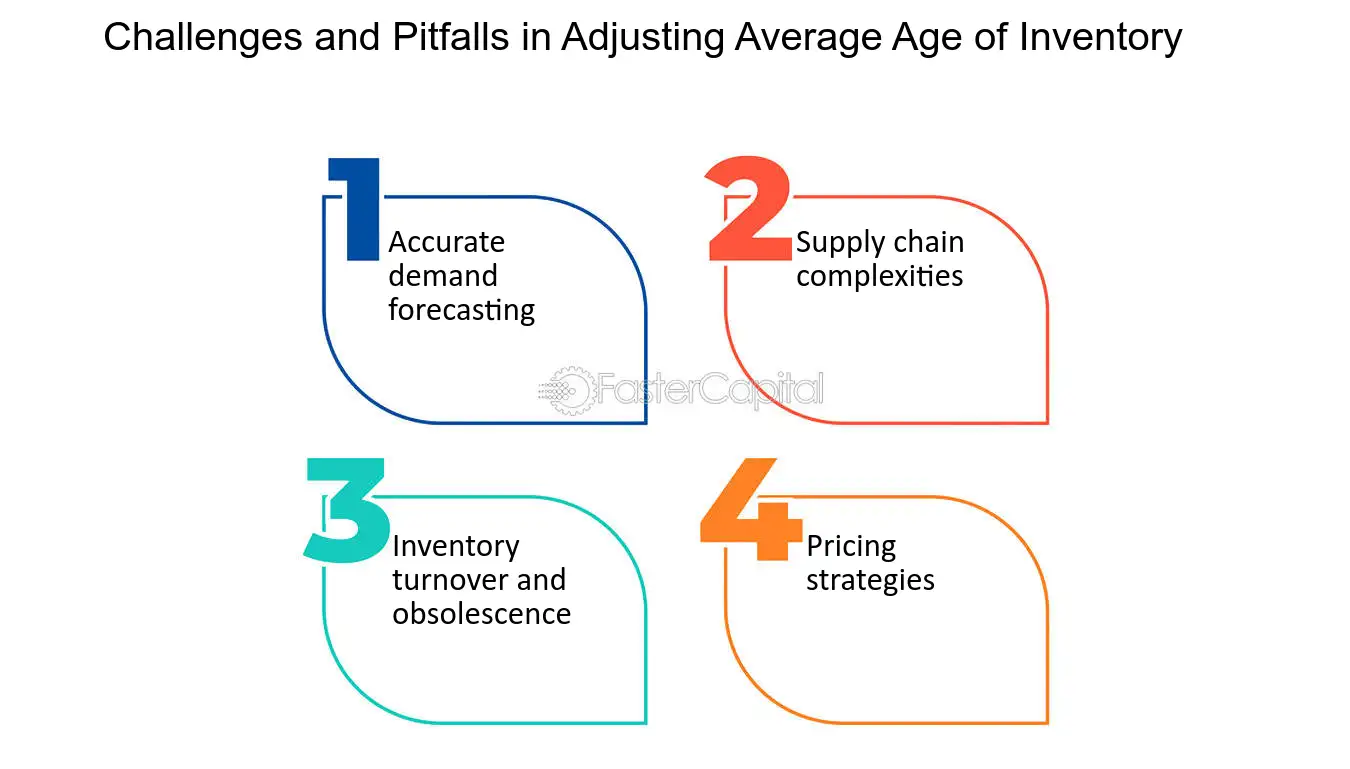

13. Potential Challenges and Solutions in Managing Average Age of Inventory

Managing the average age of inventory is a critical aspect of inventory management that directly impacts a company's profitability and operational efficiency. The average age of inventory refers to the average number of days it takes for inventory to be sold or used within a specified time period. This metric is crucial because it helps businesses determine the optimal level of inventory to hold, avoiding stockouts or excess inventory that can lead to financial losses. However, there are several challenges that organizations may encounter when trying to manage the average age of inventory effectively. In this section, we will explore these challenges and propose potential solutions to overcome them.

1. Demand Forecasting Accuracy:

One of the primary challenges in managing the average age of inventory is accurately forecasting demand. Inaccurate demand forecasts can result in either stockouts or excess inventory. If demand is underestimated, it may lead to stockouts, disappointing customers and potentially losing sales. On the other hand, overestimating demand can result in excess inventory, tying up valuable capital and increasing carrying costs. To address this challenge, businesses can employ advanced demand forecasting techniques, such as statistical models or machine learning algorithms, which analyze historical sales data, market trends, and other relevant factors to improve forecast accuracy.

Example: A retail clothing company experienced stockouts during the holiday season due to underestimating customer demand for a popular winter jacket. To overcome this challenge, the company implemented a demand forecasting system that considered historical sales data, weather patterns, and social media sentiment analysis to predict future demand accurately. This helped them avoid stockouts and meet customer demand efficiently.

2. Seasonality and Trends:

Seasonality and trends in consumer behavior can significantly impact the average age of inventory. Some products may have higher demand during specific times of the year, such as holiday-themed items or seasonal clothing. On the other hand, certain products may experience declining demand due to changing trends or technological advancements. Managing inventory effectively requires businesses to anticipate these fluctuations and adjust their ordering and production schedules accordingly.

Example: A toy manufacturer faced challenges in managing the average age of inventory for their seasonal products. They implemented a just-in-time manufacturing approach, where production was ramped up closer to the holiday season based on demand forecasts. This helped them reduce excess inventory and minimize carrying costs while ensuring they could meet customer demand during peak periods.

3. Supplier and Lead Time Variability:

Supplier reliability and lead time variability can pose challenges in managing the average age of inventory. Delays in receiving raw materials or finished goods from suppliers can disrupt production schedules and lead to stockouts or excess inventory. Businesses need to establish strong relationships with reliable suppliers and negotiate favorable lead times to mitigate this challenge. Additionally, maintaining safety stock levels can help buffer against unexpected delays or disruptions in the supply chain.

Example: A manufacturing company faced lead time variability from their overseas suppliers, resulting in inconsistent inventory levels. To address this challenge, they diversified their supplier base, identifying local suppliers who could provide faster lead times. They also established safety stock levels to ensure continuity of production even during unforeseen delays.

4. Obsolescence and Perishability:

For businesses dealing with products that have a limited shelf life or are prone to obsolescence, managing the average age of inventory becomes even more critical. Perishable goods, such as fresh produce or pharmaceuticals, require careful inventory management to minimize waste and maximize profitability. Similarly, industries characterized by rapid technological advancements, like electronics or fashion, need to stay ahead of trends and avoid holding obsolete inventory.

Example: A grocery store implemented a first-in, first-out (FIFO) inventory management system for perishable goods. This ensured that older products were sold first, reducing the risk of spoilage and minimizing waste. Additionally, they closely monitored market trends and collaborated with suppliers to introduce new products and discontinue slow-moving items, effectively managing the average age of inventory in a rapidly changing industry.

Managing the average age of inventory presents several challenges that require proactive solutions. Accurate demand forecasting, considering seasonality and trends, addressing lead time variability, and effectively managing obsolescence and perishability are crucial for maintaining optimal inventory levels. By employing appropriate strategies and leveraging advanced technologies, businesses can overcome these challenges and achieve efficient inventory management, ultimately driving profitability and customer satisfaction.

Potential Challenges and Solutions in Managing Average Age of Inventory - Economic order quantity: EOQ: Finding the Ideal Average Age of Inventory

14. Understanding Average Age of Inventory

When it comes to managing inventory, one key metric that businesses often track is the average age of inventory. This metric provides valuable insights into the freshness of products and helps businesses make informed decisions about restocking, promotions, and pricing strategies. By understanding the average age of inventory, businesses can maximize freshness, reduce waste, and ultimately improve customer satisfaction.

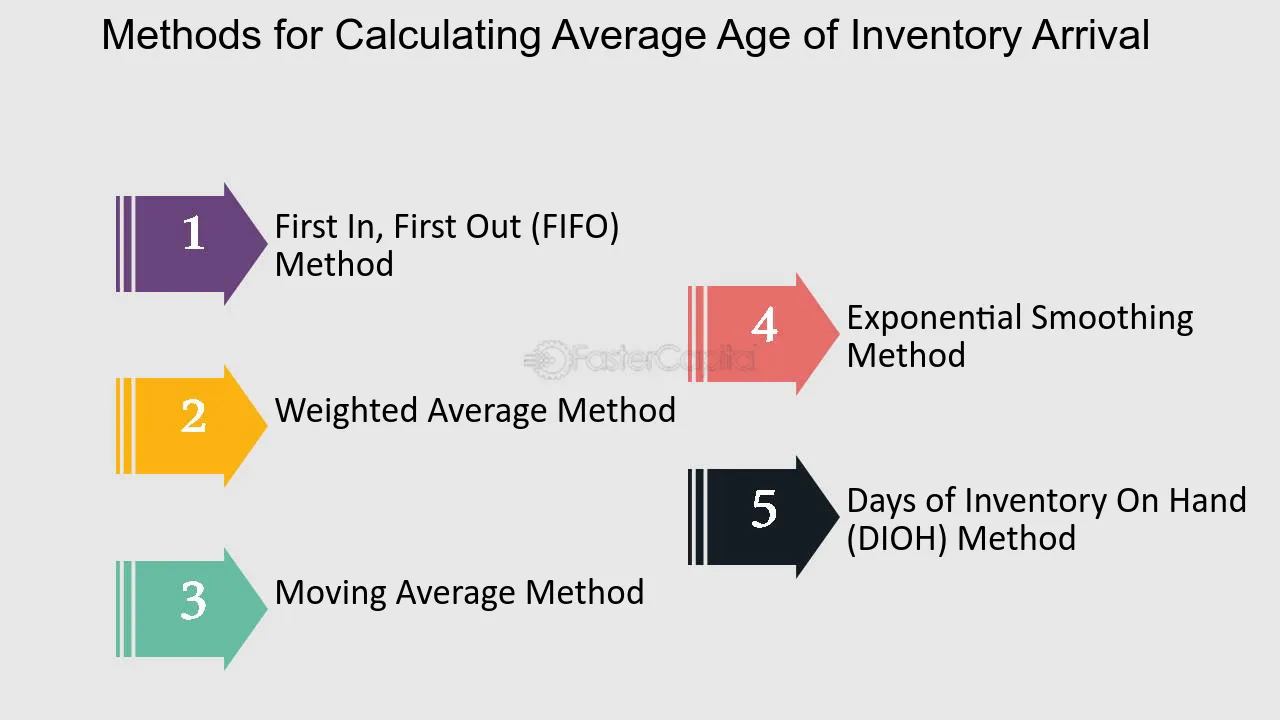

1. Definition and Calculation:

The average age of inventory is calculated by dividing the total number of days that all inventory items have been held in stock by the total number of inventory items. This calculation provides a snapshot of how long, on average, products have been sitting in the inventory before being sold. The lower the average age of inventory, the fresher the products are and the higher the chances of selling them before they become obsolete or expire.

2. Importance of Monitoring:

Monitoring the average age of inventory is crucial for businesses, especially those dealing with perishable goods or products with limited shelf life. By keeping a close eye on this metric, businesses can identify slow-moving items and take necessary actions to prevent overstocking or spoilage. Additionally, tracking the average age of inventory helps businesses assess the efficiency of their supply chain and identify potential bottlenecks.

3. Impact on Pricing and Promotions:

The average age of inventory directly influences pricing and promotional strategies. Products with a higher average age may need to be discounted or included in special promotions to incentivize customers to purchase them before they become outdated or less desirable. On the other hand, products with a lower average age can be priced higher, reflecting their freshness and premium quality.

For example, a bakery that specializes in freshly baked goods may track the average age of its bread inventory. If the average age starts to increase, indicating that bread is not being sold as quickly as before, the bakery may decide to offer a "buy one, get one free" promotion to encourage customers to purchase more bread and prevent waste.

4. Inventory Turnover:

The average age of inventory is closely related to inventory turnover, which measures how quickly inventory is sold and replaced within a specific period. High inventory turnover, accompanied by a low average age of inventory, indicates efficient inventory management and a healthy business. On the other hand, low turnover and a high average age of inventory may suggest issues with demand forecasting, purchasing decisions, or product quality.

5. Strategies to Reduce Average Age of Inventory:

To minimize the average age of inventory, businesses can employ various strategies. These include optimizing demand forecasting to ensure accurate inventory levels, implementing a first-in, first-out (FIFO) inventory management system to prioritize the sale of older products, and establishing strong relationships with suppliers to ensure timely deliveries. Additionally, implementing just-in-time (JIT) inventory management can help businesses reduce excess inventory and keep products fresh.

Understanding the average age of inventory is crucial for businesses aiming to maximize freshness and minimize waste. By monitoring this metric, businesses can make informed decisions about pricing, promotions, and inventory management strategies. Ultimately, a lower average age of inventory leads to increased customer satisfaction, reduced waste, and improved profitability.

Understanding Average Age of Inventory - First Out: Maximizing Freshness: Average Age of Inventory and FIFO

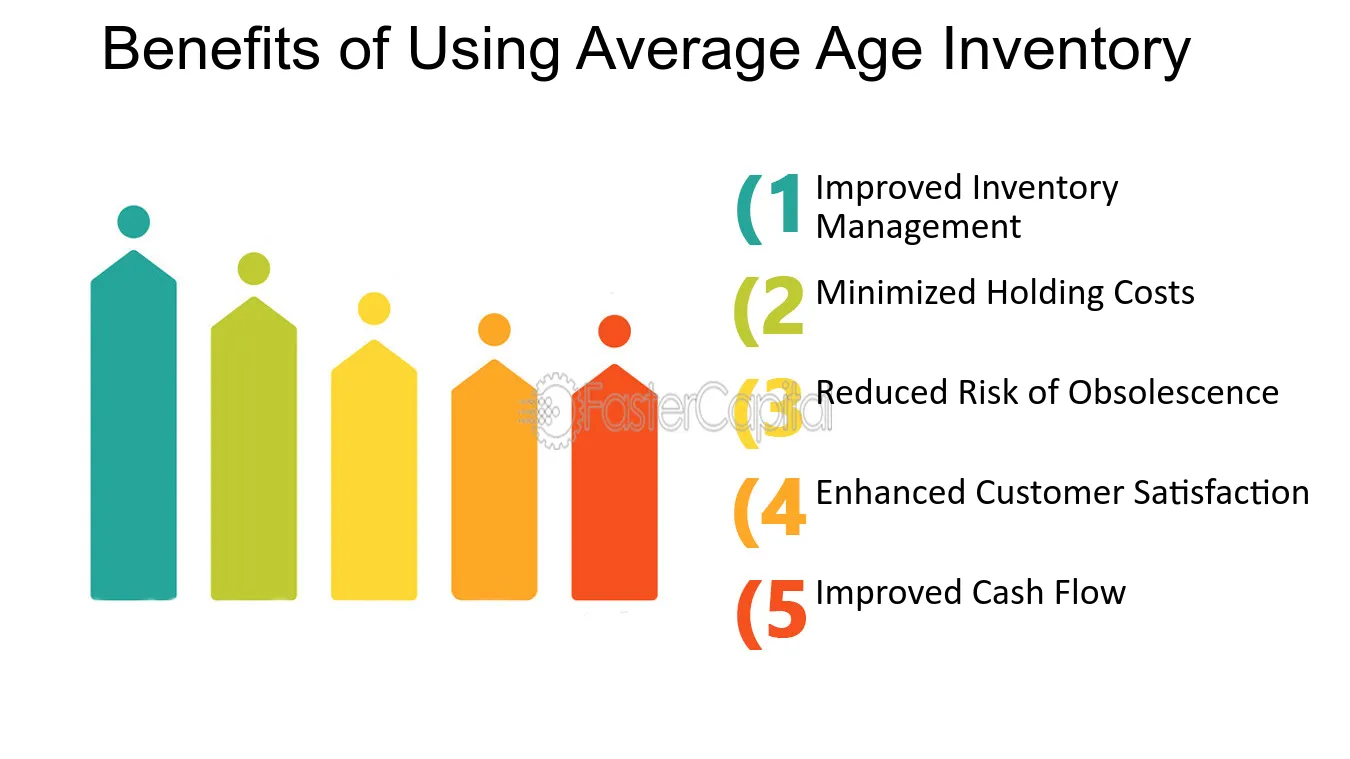

15. The Significance of Average Age of Inventory in Minimizing Holding Costs

The average age of inventory is a crucial factor when it comes to minimizing holding costs in any business. Holding costs refer to the expenses incurred by a company to store and maintain its inventory until it is sold or used. These costs can include storage fees, insurance, obsolescence, and the opportunity cost of tying up capital in inventory. Therefore, reducing the average age of inventory is essential to reduce holding costs and improve overall profitability.

From the perspective of a business owner or manager, minimizing holding costs is a top priority. By reducing the average age of inventory, businesses can free up valuable resources that can be utilized elsewhere. This not only helps to lower storage costs but also minimizes the risk of inventory becoming obsolete or unsellable. By efficiently managing inventory turnover, businesses can ensure that they always have the right amount of stock on hand, avoiding excess inventory that can lead to increased holding costs.

From a financial point of view, the average age of inventory plays a significant role in determining a company's profitability. Holding costs directly impact a company's bottom line, as they eat into the potential profit margins. By reducing the average age of inventory, businesses can increase inventory turnover and generate more sales. This, in turn, leads to higher revenue and improved profitability.

To better understand the significance of the average age of inventory in minimizing holding costs, let's delve into the following points:

1. efficient inventory management: By closely monitoring and managing inventory levels, businesses can reduce the average age of inventory and minimize holding costs. Implementing inventory control systems, such as just-in-time (JIT) inventory management, can help ensure that inventory is replenished only when needed. This prevents excess stock from piling up and reduces the risk of obsolescence.

2. Demand forecasting: Accurate demand forecasting is crucial in minimizing holding costs. By analyzing historical sales data and market trends, businesses can predict future demand and adjust inventory levels accordingly. This helps to prevent overstocking or understocking, both of which can result in increased holding costs.

3. Supplier relationships: Maintaining strong relationships with suppliers is essential in reducing the average age of inventory. Timely deliveries and reliable suppliers can help businesses manage their inventory levels effectively. By working closely with suppliers to streamline the supply chain, companies can ensure that they receive inventory on time, reducing the need for excess stock.

4. Automated inventory tracking: Utilizing inventory management software or systems can greatly aid in reducing the average age of inventory. These tools provide real-time visibility into inventory levels, allowing businesses to make informed decisions about restocking and reducing holding costs. Automated tracking also helps identify slow-moving items or potential stockouts, enabling proactive measures to be taken.

In practice, let's consider a retail clothing store. By closely monitoring sales patterns and demand trends, the store manager can adjust inventory levels accordingly. For instance, if a particular style of jeans is selling rapidly, the manager can reorder more to meet the demand. On the other hand, if a certain type of shirt is not selling well, the manager can take necessary actions to prevent excess stock from accumulating. By implementing these strategies, the store can reduce the average age of inventory, minimize holding costs, and improve overall profitability.

The average age of inventory plays a significant role in minimizing holding costs for businesses. By implementing efficient inventory management techniques, accurately forecasting demand, maintaining strong supplier relationships, and utilizing automated inventory tracking systems, companies can effectively reduce holding costs and improve profitability. keeping a close eye on the average age of inventory is a vital aspect of successful inventory management and should be a priority for any business looking to optimize its operations.

The Significance of Average Age of Inventory in Minimizing Holding Costs - First Out: Minimizing Holding Costs: Average Age of Inventory and LIFO

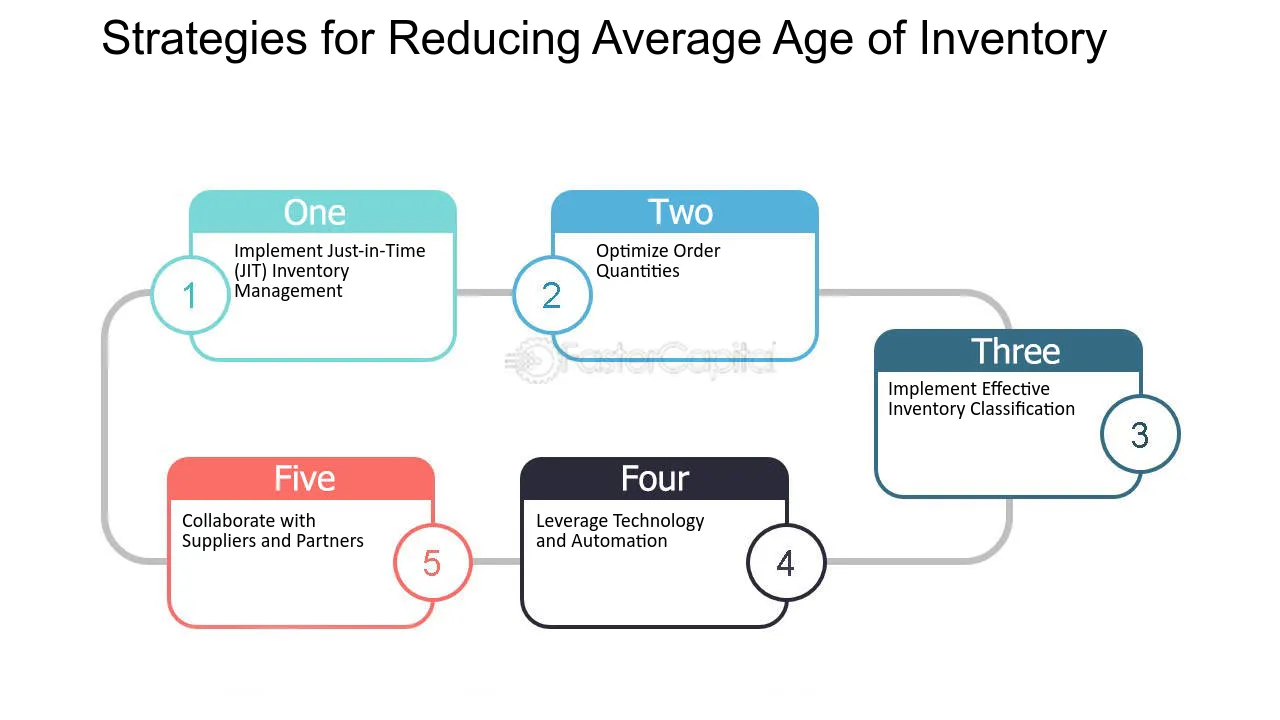

16. Strategies for Reducing Average Age of Inventory

One of the key challenges that businesses face in managing their inventory is the need to minimize the average age of inventory. The longer inventory sits in storage, the higher the holding costs become, resulting in increased expenses for the company. Additionally, older inventory is more likely to become obsolete or lose value, further adding to the financial burden. Therefore, it is crucial for businesses to implement effective strategies that can help reduce the average age of inventory and optimize their operations.

From a supply chain perspective, adopting a proactive approach is essential to reduce the average age of inventory. This involves closely monitoring the demand patterns and customer preferences to ensure that the right products are available at the right time. By accurately forecasting demand and aligning production and procurement activities accordingly, businesses can minimize the time it takes for inventory to move through the supply chain. This not only reduces holding costs but also improves customer satisfaction by ensuring timely product availability.

1. Implement Just-in-Time (JIT) Inventory Management: JIT is a strategy that aims to minimize inventory levels by receiving goods from suppliers just in time for production or customer demand. By reducing the buffer stock, businesses can significantly reduce the average age of inventory. For example, a car manufacturing company can work closely with its suppliers to receive components only when they are needed on the assembly line. This eliminates the need for extensive storage and reduces the risk of inventory becoming obsolete.

2. Optimize Order Quantities: Another strategy to reduce the average age of inventory is to optimize order quantities. By ordering in smaller quantities more frequently, businesses can ensure that inventory turnover is higher, resulting in fresher products and reduced holding costs. However, it is crucial to strike a balance between frequent orders and economies of scale to avoid increasing procurement costs. Advanced inventory management systems can help analyze historical data and forecast demand accurately, enabling businesses to determine the optimal order quantities.

3. Implement Effective Inventory Classification: Not all inventory items have the same level of importance or demand. By classifying inventory based on their value, demand, or criticality, businesses can prioritize their efforts to reduce the average age of inventory. For example, a retail store can categorize products as fast-moving, slow-moving, or seasonal items. By focusing on reducing the average age of slow-moving items through targeted promotions or discounts, businesses can free up valuable storage space and minimize holding costs.

4. Leverage Technology and Automation: Technology plays a vital role in optimizing inventory management and reducing the average age of inventory. Implementing inventory management software can provide real-time visibility into stock levels, demand patterns, and lead times. Automation tools can streamline order processing, reduce manual errors, and speed up the movement of inventory. For instance, an e-commerce business can integrate its inventory management system with its online store, ensuring accurate stock updates and minimizing the risk of overselling or stockouts.

5. Collaborate with Suppliers and Partners: Establishing strong relationships with suppliers and partners can significantly contribute to reducing the average age of inventory. By sharing demand forecasts, production plans, and inventory levels, businesses can work together to streamline the supply chain and reduce lead times. For example, a fashion retailer can collaborate with its suppliers to implement a vendor-managed inventory (VMI) system, where suppliers are responsible for managing inventory levels at the retailer's stores. This ensures that inventory is constantly replenished based on demand, reducing the average age of inventory and improving overall operational efficiency.

Reducing the average age of inventory is crucial for businesses to minimize holding costs and optimize their operations. By implementing strategies such as JIT inventory management, optimizing order quantities, effective inventory classification, leveraging technology, and collaborating with suppliers, businesses can ensure that inventory turnover is high, reducing the risk of obsolescence and improving their bottom line. Proactive inventory management not only saves costs but also enhances customer satisfaction, making it a critical aspect of successful supply chain management.

Strategies for Reducing Average Age of Inventory - Inventory holding cost: Minimizing Expenses through Average Age Reduction

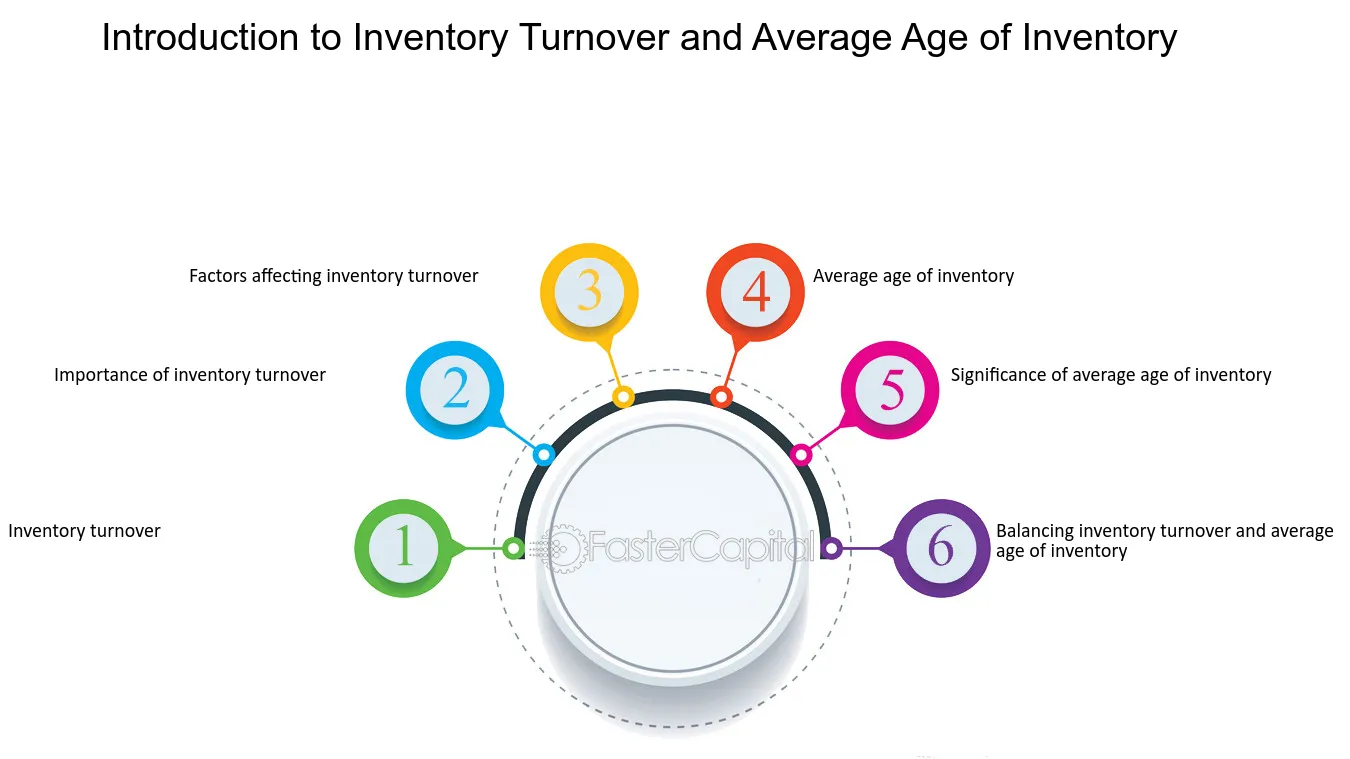

17. Introduction to Inventory Turnover and Average Age of Inventory

Inventory turnover and average age of inventory are two important metrics that businesses use to manage their inventory effectively and maximize profitability. These metrics provide insights into how efficiently a company is managing its inventory and can help identify areas for improvement. In this section, we will delve into the concept of inventory turnover and average age of inventory, and explore how businesses can use these metrics to optimize their inventory management strategies.

1. Inventory turnover:

Inventory turnover, also known as stock turnover, is a measure of how quickly a company sells its inventory and replaces it with new stock. It is calculated by dividing the cost of goods sold (COGS) by the average inventory value. A high inventory turnover indicates that a company is selling its inventory quickly, while a low turnover suggests that inventory is sitting on the shelves for a longer period.

2. Importance of inventory turnover:

Understanding inventory turnover is crucial for businesses as it directly impacts their profitability. A high inventory turnover means that a company is able to generate revenue from its inventory more frequently, thus reducing the risk of obsolete or expired stock. On the other hand, a low turnover can tie up valuable capital in unsold inventory, leading to increased carrying costs and potentially reduced cash flow.

3. Factors affecting inventory turnover:

Several factors can influence a company's inventory turnover rate. These include industry trends, seasonality, demand fluctuations, and supply chain efficiency. For example, a retailer selling seasonal products like swimwear may experience higher turnover rates during the summer months but lower turnover during the rest of the year. Understanding these factors helps businesses make informed decisions about inventory management, such as adjusting procurement strategies or implementing promotional activities.

4. Average age of inventory:

While inventory turnover measures how quickly inventory is sold, the average age of inventory provides additional insights by calculating the average number of days it takes for inventory to be sold. This metric is calculated by dividing the number of days in a specific period by the inventory turnover ratio. For instance, if the inventory turnover ratio is 5, the average age of inventory would be 73 days (365 days divided by 5).

5. Significance of average age of inventory:

The average age of inventory helps businesses assess the efficiency of their inventory management practices. A lower average age indicates that inventory is being sold quickly, reducing the risk of obsolescence and minimizing carrying costs. Conversely, a higher average age suggests that inventory is staying on the shelves for a longer time, potentially tying up capital and increasing the likelihood of obsolete or expired stock.

6. Balancing inventory turnover and average age of inventory:

Achieving an ideal balance between inventory turnover and average age of inventory is crucial for maximizing profitability. While a high inventory turnover is generally desirable, it should be accompanied by a reasonable average age of inventory. For example, a company with a very high turnover but a very low average age may struggle to meet customer demand or risk stockouts. On the other hand, a company with a low turnover but a high average age may face increased carrying costs and potential obsolescence.

Understanding inventory turnover and average age of inventory is vital for effective inventory management. By analyzing these metrics, businesses can identify areas for improvement, optimize their inventory levels, and ultimately enhance profitability. By striking the right balance between inventory turnover and average age of inventory, companies can ensure that their inventory is efficiently managed, reducing costs and maximizing revenue.

Introduction to Inventory Turnover and Average Age of Inventory - Inventory turnover: Maximizing Profitability with Average Age of Inventory

18. The Significance of Average Age of Inventory in Profitability

In the world of business, inventory turnover plays a crucial role in determining the profitability of a company. It is a measure of how efficiently a company manages its inventory and converts it into sales. While inventory turnover is an important metric to consider, it is equally important to delve deeper into the concept of average age of inventory. The average age of inventory refers to the average number of days it takes for a company to sell its entire inventory. Understanding the significance of average age of inventory can provide valuable insights into the profitability of a business.

1. optimizing Cash flow: One of the primary reasons why the average age of inventory is significant for profitability is its impact on cash flow. When inventory sits idle for a longer period, it ties up valuable capital that could be utilized elsewhere in the business. By reducing the average age of inventory, companies can free up cash flow, enabling them to invest in growth opportunities, pay off debts, or even distribute dividends.

2. minimizing Holding costs: Holding costs, also known as carrying costs, are the expenses incurred by a company to store and maintain its inventory. These costs include warehousing, insurance, utilities, and depreciation. The longer inventory remains unsold, the higher the holding costs. By reducing the average age of inventory, companies can minimize these expenses, ultimately improving profitability.

3. Reducing Obsolescence: In today's fast-paced business environment, product obsolescence is a constant challenge. As technology advances and consumer preferences change, the value of certain inventory items may diminish over time. The longer inventory sits on the shelves, the higher the risk of obsolescence. By closely monitoring the average age of inventory and taking proactive measures to sell or liquidate slow-moving items, companies can mitigate the risk of obsolescence and protect their profitability.

4. enhancing Customer satisfaction: Another significant aspect of the average age of inventory is its impact on customer satisfaction. Customers expect businesses to have readily available products, and delays in fulfilling orders can lead to dissatisfaction and lost sales. By reducing the average age of inventory and ensuring a steady supply of popular items, companies can meet customer demands promptly, fostering loyalty and repeat business.

5. Identifying Operational Inefficiencies: Analyzing the average age of inventory can provide valuable insights into the efficiency of a company's operations. A high average age of inventory may indicate issues such as poor demand forecasting, ineffective inventory management systems, or slow order processing. By identifying these inefficiencies, companies can implement corrective measures to streamline their operations, reduce costs, and improve profitability.

For instance, let's consider a retail clothing store that has a high average age of inventory due to slow sales of a particular clothing line. By closely monitoring the average age of inventory, the store manager can identify this issue and take action. They may decide to offer discounts or promotions to boost sales of the slow-moving clothing line, preventing it from becoming obsolete and potentially improving overall profitability.

The average age of inventory is a crucial metric that significantly impacts the profitability of a business. By optimizing cash flow, minimizing holding costs, reducing obsolescence, enhancing customer satisfaction, and identifying operational inefficiencies, companies can leverage this metric to make informed decisions and maximize their profitability. Understanding and actively managing the average age of inventory can help businesses thrive in today's competitive marketplace.

The Significance of Average Age of Inventory in Profitability - Inventory turnover: Maximizing Profitability with Average Age of Inventory

19. Identifying the Factors Affecting Average Age of Inventory