S. Riaz Ahamed et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 5, Issue 1( Part 5), January 2015, pp.130-135

RESEARCH ARTICLE

www.ijera.com

OPEN ACCESS

Speed Control of Induction Motor by Using Intelligence

Techniques

S. Riaz Ahamed*, J. N. Chandra Sekhar**, Dinakara Prasad Reddy P***

Department of EEE, Sri Venkateswara University College of Engineering, Tirupati.

ABSTRACT

This paper gives the comparative study among various techniques used to control the speed of three phase

induction motor. In this paper, indirect vector method is used to control the speed of Induction motor. Firstly

Simulink Model is developed by using MATLAB/ Simulink software. PI controller, Fuzzy PI Hybrid controller,

Genetic Algorithm (GA) are the techniques involved in control Induction motor and the results are compared.

By converting three phase supply currents coming from stator to Flux and Torque components of current the

speed responses such as rise time, overshoot, settling time and speed regulation at load have been observed and

compared among the techniques. The PI controller parameters defined by an objective function are calculated by

using Genetic Algorithms presented good performance compared to Fuzzy PI Hybrid controller which has

parameters chosen by the human operator.

Keywords—Induction Motor, PI Controller, Fuzzy PI Hybrid Controller, Indirect Vector control, Genetic

Algorithm

I. Introduction

Now a day’s Induction motors are the work

horses of many industries which also replaced DC

machines with their various advantages like lack of

commutator, lower cost, reduced maintenance cost,

robust, less weight and rugged structure. Because of

their complex characteristics, it is not easier to

control the speed of Induction motor like DC motor,

so the vector control is used. It is introduced by

Blaschke and Hasse has resulted in remarkable

change in the field of electrical drives. Indirect vector

control is used in this paper which is one of the types

of vector control. It is very popular form of control of

Induction motor because this control strategy can

provide the same performance as achieved from a

separately excited DC Motor.

The simple structure and its good performance

has made the PI controller the best controller in the

industry. Its functions depends on two parameters

namely proportional gain Kp and Integral gain Ki.

Several methods can be used to tune PI controller.

The Fuzzy set theory, introduced by L.Zadeh is the

mathematical tool for Fuzzy Logic Controller (FLC).

It can be used in control of Induction Motor because

of its advantages such as it does not need a

mathematical model for the system, it is just based on

linguistic rules with IF-THEN general structure

which is based on human logic.

Methods such as Pole assignment method and

Ziegler-Nichols method have major inconvenience as

it is necessary to have prior knowledge of various

parameters of the Induction motor. An optimization

procedure can be developed to design the good

controller. Genetic Algorithm has been employed

www.ijera.com

successfully to solve the complex optimization

problems. The parameters of different controllers can

be determined by using Genetic Algorithm due to

their reasonable accuracy and fast convergence.

The PI controller parameters are determined by

minimizing Objective Function. The goal of this

work is to show that Optimization can be achieved by

optimization of PI Controller parameters. This can be

observed by comparing the results of Genetic

Algorithm based PI controller with PI, Fuzzy PI

Hybrid Controller.

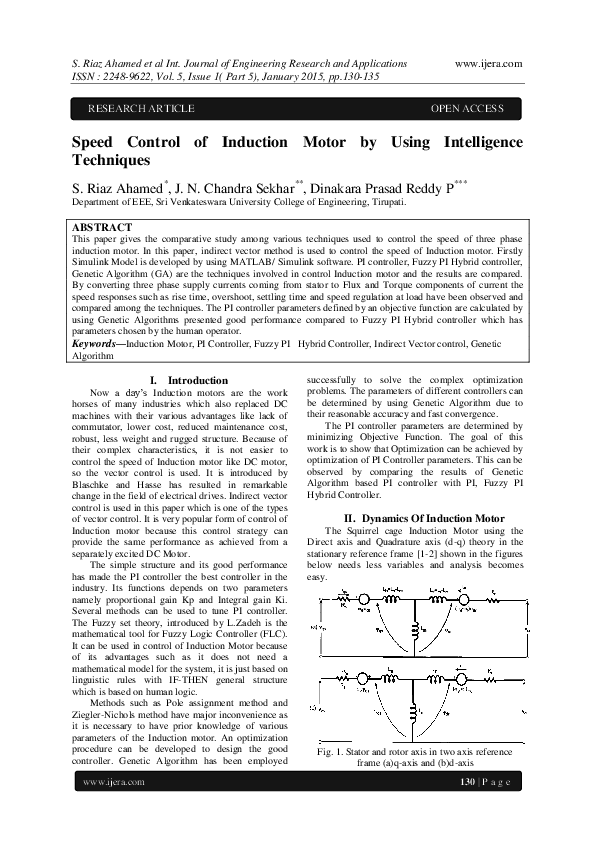

II. Dynamics Of Induction Motor

The Squirrel cage Induction Motor using the

Direct axis and Quadrature axis (d-q) theory in the

stationary reference frame [1-2] shown in the figures

below needs less variables and analysis becomes

easy.

Fig. 1. Stator and rotor axis in two axis reference

frame (a)q-axis and (b)d-axis

130 | P a g e

�S. Riaz Ahamed et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 5, Issue 1( Part 5), January 2015, pp.130-135

control induction motor drive namely Internal Pulse

Width Modulation current control loop and External

Speed control loop [3].

A. Electrical system of Induction Motor

�

�

0

0

=

R s + SLs

− Ls

SLm

− Lm

Ls

R s + SLs

Lm

SLm

SLm

− − r Lm R r + SLr − − r Lr

− r Lm

Lm

− r Lr R r + SLr

www.ijera.com

ids

iqs

idr

iqr

ϕqs = Ls iqs + Lm iqr

ϕds

= Ls ids _ + Lm idr

ϕqr = Lr iqr + Lm iqs

ϕdr

= Lr idr + Lm ids

Ls = Lls + Lm

Lr = Llr + Lm

Te =

3

2

P

2

ϕds iqs − ϕqs ids

A. Mechanical system of Induction Motor

1

d

=

T − F m − Tm

dt m 2H e

d

θ =

dt m

m

Where,

, � : Resistanceand leakage inductance of

stator

, � : Resistanceand leakage inductance of

rotor

�

: The magnetizing Inductance

Ls , Lr : Stator and rotor inductances

� , iqs : q axis component of stator voltage and

current

� , iqr :q axis component of rotor voltage and

current

� , ids :d axis component of stator voltage and

current

� , idr :d axis component of rotor voltage and

current

� , ϕds : q and d axis components of stator flux

� , ϕdr : q and d axis components of rotor flux

m : Angular velocity of rotor

θm : Angular position of rotor

P : Number of poles

�

p: Pairs of Poles ( )

2

: Electrical angular velocity ( . )

� : Electrical rotor angular position(� . )

Te : Electromagnetic Torque

Tm : Mechanical Torque on Shaft

J: Load Inertia Constant

F:Friction Coefficient

III. Indirect Vector Control

The block diagram shown below is the Indirect

Vector Control Technique. Two control loops will

www.ijera.com

Fig. 2. Block Diagram of Indirect Vector Control

Technique.

The indirect vector control method is essentially

the same as direct vector control, but the unit vector

signals (cos� and sin� ) are generated in feed

forward manner using the measured rotor speed

and the slip speed . Indirect vector control is

widely used in industrial applications. CurrentControlled PWM Inverter acts as three phase

sinusoidal current source to Induction motor. The

error between reference speed ∗ and speed

is

given to speed controller which outputs the command

Torque Te∗ .

A shown in the Block diagram above, Torque

and Rotor Flux can be independently controlled by qaxis stator current iqs and d-axis stator current ids

respectively.

The q-axis Stator Current Reference ∗ is

calculated from Command Torque Signal Te∗ as

shown in below equation.

2 2 Lr Te

i∗qs =

3 P Lm r

est

is the Estimated Rotor Flux Linkage. It can

be calculated by equation shown below.

Lm ids

=

r est

1 + τr s

L

Where τr = r is Time Constant of Rotor.

Rr

The d-axis stator current reference i∗ds

∗

.

calculated from Rotor flux reference input

i∗ds

=

r

∗

is

Lm

The rotor flux position � which is required for

coordinate transformation is calculated from slip

frequency sl and rotor speed as shown in equation

below.

θe =

dt

sl +

131 | P a g e

�S. Riaz Ahamed et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 5, Issue 1( Part 5), January 2015, pp.130-135

The slip frequency sl is calculated from stator

∗

and motor parameters.

reference current iqs

Lm R r ∗

i

sl =

Lr qs

r

est

∗

are converted

The current references i∗qs and ids

∗

∗

∗

into three phase currents , , by using Park’s

Transformation for the current regulators. The current

regulators will use the reference currents and the

measured currents to form the inverter gating signals.

To provide a good dynamic response during

transient conditions, the speed controller should

maintain the motor speed equal to reference speed

input.

www.ijera.com

Fig. 4. Fuzzy Logic Controller.

IV. Speed Controllers

As already mentioned, the input to the speed

controller is the speed error signal, which is

difference between the reference speed and actual

speed. In this paper, three types of controllers are

used. They are PI controller, PI-Fuzzy Hybrid

Controller, Genetic Algorithm based PI controller.

Fig.5.Input Membership Functions for error speed (e)

rate of change of error speed (de)

4.1 PI Controller

Fig. 3. Block Diagram of PI Controller

Command Torque is the output signal of

controller where Kp is the proportional gain and Ki is

the integral gain.

Te n =Te n−1 + K p ∆e n + K i e(n)

If the gains of the controller exceed a certain

value, the variations in the command torque become

too high and will decrease stability of the system. To

overcome this problem, a limiter ahead of the PI

controller is used.

Temax

Temax → Te n+1

Te n+1 =

−Temax

−Temax → Te n+1

4.2 Fuzzy Logic Controller

Good Dynamic stability of induction motor is

achieved when it has a good performance under

transient stability conditions such as Sudden Load

application or sudden load removal and sudden

increase or decrease in speed. In PI controller, the

tuning parameters depend on the ratings of the motor

but Fuzzy logic Controller does not require any

model of the motor and can handle complex

nonlinearities.

The Fuzzy logic controller shown in the figure

has three functional blocks

www.ijera.com

Fig.6. Output Membership Function of Fuzzy Logic

Controller.

Table 1. Rule Matrix for Fuzzy Logic Controller

Triangular Membership functions are used to

represent input and output variablessuch as NB –

Negative Big, NM – Negative Medium, NS –

Negative Small, ZE – Zero, PS – Positive Small, PM

– Positive Medium, PB – Positive Big. Here,

Membership functions should be normalized between

-1 to +1[4].

The Fuzzy Rules are represented using IF-THEN

form. MAX-MIN Inference algorithm and Center of

Gravity Defuzzification Approach is used to get

Crisp output from Fuzzy Logic Controller. The fuzzy

132 | P a g e

�S. Riaz Ahamed et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 5, Issue 1( Part 5), January 2015, pp.130-135

rules were designed based on the dynamic behavior

of the error signal.

4.3 PI Fuzzy Hybrid Controller

Fig. 7. Block Diagram of PI Fuzzy Hybrid Controller

This controller [3-5] has the advantages of both

PI and Fuzzy Logic controller. Fuzzy logic is used

for pre-compensation of reference speed, which

changes reference speed given to PI controller in

accordance to rotor speed as shown in figure above

[3].

4.4 Genetic Algorithm based PI Controller

The simplified dynamic Model of Induction

Motor drive [6-7] is represented by the block diagram

shown below.

www.ijera.com

Mutation) to arrive at the best solution.GA maintains

and manipulates a population of solutions and

implements a “Survival of the Fittest” strategy in

their search for better solutions. This provides an

implicit as well as explicit parallelism that allows for

the exploitation of several promising areas of the

solution space at the same time. By starting at several

independent points and searching in parallel, the

algorithm avoids local minima and convergence to

sub optimal solutions. In this way, GA has been

shown to be capable of locating high performance

areas in complex domains without experiencing the

difficulties associated with high dimensionality, as

may occur with gradient descent techniques or

methods that rely on derivative information.

Genetic Algorithm [8-11] mainly consists of

three stages: Selection, Crossover and Mutation. New

individuals were created by performing these

operations which may be better than their parents.

This algorithm is repeated for many generations and

finally stops when reaching individuals that represent

optimal solution to the problem.

Fig. 8.Block diagram of speed system controller

If TL =0, then the Transfer Function is,

P

Kp S + Ki

J

G S =

f+K p

K

S2 +

S+ i

Lr

J

The characteristic Equation is given as follows

f + Kp P

Ki P

P S = S2 +

S+

=0

J

J

By the imposition of two poles complex

combined with real part negative, 1,2 = �(−1 ± ),

we get the equations to find Kp , Ki values

2Jρ2

Ki =

P

2ρJ − f

Kp =

P

Where � is a Positive Constant.

Genetic Algorithms have been used to solve

difficult problems with objective functions that do

not possess “nice” properties such as continuity,

differentiability, satisfaction of the Lipchitz condition

etc. An objective Function is developed by above

equations and minimized using Genetic Algorithm to

find Kp, Ki values.

Genetic Algorithm was first developed by John

Holland and his colleagues in 1975. It is a stochastic

global search method that mimics the process of

Natural Evolution. The Genetic Algorithm starts with

no knowledge of the correct solution and depends

entirely on responses from its environment and

evolution operators(i.e. Reproduction, Crossover and

www.ijera.com

Fig. 9. Genetic Algorithm Architecture

In every generation, the genetic operators are

applied to selected individuals from present

population in order to create new population.

Generally, the three main genetic operators of

reproduction, crossover and mutation are performed.

To apply these operators, different probabilities are

chosen so that speed of convergence can be

controlled.

Reproduction is creation of new population by

simply copying the selected individuals without

changing them. Also there is a probability of

selection from new population by already developed

solution. There are number of selection methods

available based on same principle i.e. giving large

probability selection for fitter chromosomes.

Once the selection process is completed,

crossover operation is initiated which swaps certain

parts of the two individuals in a bid to capture the

good parts of old population and create better new

133 | P a g e

�S. Riaz Ahamed et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 5, Issue 1( Part 5), January 2015, pp.130-135

ones. The crossover probability indicates how often

crossover is performed. Typically this operator is

applied at a probability range of 0.6 to 0.8. The

mutation operator plays a secondary role in the

evolution .It helps to keep diversity in the population

by discovering new or restoring lost genetic materials

by searching the neighborhood solution space.

Mutation occurs with a small probability rate of 0.1%

to 10% of the entire population.

Genetic Algorithm can be used to tune the gains

of PI Speed Controller as shown in figure below.

www.ijera.com

10N-m is applied suddenly to motor at 2sec and

removed at 2.5sec. Here speed regulation at load is

calculated for all controllers.

Fig.11. Speed Response with PI controller

Fig.10. Structure of the technique of optimization of

the PI controller by GA

The Objective Function can be written as shown

below

t

t

e2 t dt =

Fitness =

o

0

∗

t −

t

2

dt

Fig. 12. Speed Response with PI-Fuzzy Hybrid

Controller

The block of the objective function is used to

estimate the performances of the PI controller by

minimizing this function.

The genetic algorithm parameters chosen for the

tuning purpose are shown below.

Table 2. Parameters of Genetic Algorithm

GA Property

Value

Population Size

60

Maximum no. of Generations

100

Crossover Probability

0.8

Mutation Probability

0.1

Tolerance

10−6

After giving the above parameters to GA, the PI

controller can be easily tuned and thus system

performance can be improved. The parameters of the

PI speed controller obtained according to the

procedure of optimization by the technique of the GA

are given as Kp = 11.3006, Ki = 0.5609.

V. Simulation Results

The Simulation results for Sudden Speed

variation, sudden application and removal load are

observed. Initially, motor is running 120rad/sec,

suddenly speed is changed to 160rad/sec at 0.2sec.

Here Rise time, Peak overshoot, settling time is

observed for all controllers. The Load Torque of

www.ijera.com

Fig.13. Speed Response with GA based PI

Controller.

From the simulation results of speed responses,

the rise time, peak overshoot, settling time and speed

regulation are better with GA based PI controller

compared to PI and PI-Fuzzy Hybrid Controller.

Table.3. Parameters using different Controllers.

PIControllers

GA

PI

Fuzzy

Parameters

based PI

Hybrid

Rise Time(sec)

0.231 0.225

0.219

Peak Overshoot(rad/sec) 165

160.2

160.05

Settling Time(sec)

Speed Regulation (%)

0.225

0.75

0.222

0.31

1.5

4.36

134 | P a g e

�S. Riaz Ahamed et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 5, Issue 1( Part 5), January 2015, pp.130-135

VI. Conclusion

In this paper Indirect Vector Control is used to

control the speed of Induction Motor. The simulation

is carried out using MATLAB/Simulink Software.

The GA based PI controller showed better

performance compared to PI and PI-Fuzzy Hybrid

Controllers in terms of Rise time, Peak overshoot and

Settling time as well as Speed Regulation.

Appendix: Induction Motor Specifications.

Rated power

1.5 kW

Voltage

220V

Frequency

50Hz

Rotor Type

Squirrel Cage

Stator resistance(Rs)

4.85Ω

Rotor resistance(Rr)

3.805Ω

Stator inductance(Ls)

0.274H

Rotor inductance(Lr)

0.274H

Mutual inductance(Lm)

0.258H

Moment of inertia(J)

0.031kg-m2

Friction Coefficient(f)

0.00114Nm/rad

[8]

[9]

[10]

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Bose, B. K, Power Electronics and AC

Drives, Prentice-Hall, Englewood Cliffs,

N.J, 1986.

Rajesh Kumar, R.A.Gupta, S.V.Bhangale,

“Indirect Vector Controlled Induction Motor

Drive with Fuzzy Logic Based Intelligent

Controller”, IETECH Journal of Electrical

Analysis, Vol: 2, No: 4, 211-216, 2008.

HosseinEbadi Kalhoodasthti, Dr.Mehdi

Shahbazian, “Hybrid Speed Control of

Induction Motor using PI and Fuzzy

Controller”, International Journal of

Computer Applications, Vol: 30, No: 11,

2011.

SoudElabed.H, MailefAli.M, Abdulmalek

Jamal.S, “Indirect Field Oriented Control of

Induction motor drive using fuzzy logic

controller”, IEEE 8th Conference on

Industrial

Electronics

and

Applications,2013.

MuawiaA.Magzoub,NordinB.Saad,Rosdiazli

B.Ibrahim, “An Intelligent Speed control for

indirect field oriented induction motor

drives”, IEEE conference on Clean Energy

and Technology, 2013.

MhamedChebre,

AbdelkaderMeroufel,

Yessema Bendaha, Speed control of

Induction Motor using Genetic Algorithm

based PI Controller, Acta polytechnic

Hungarica, Vol: 8, No: 6, 2011.

R. Anulmozhiyal and Dr. K. Baskarn,

“Speed Control of Induction Motor Using

Fuzzy PI and Optimized Using GA”,

www.ijera.com

[11]

www.ijera.com

International Journal of Recent Trends in

Engineering, Vol. 2, No. 5, November 2009.

Reddy P, Dinakara Prasad. "Application of

Loss sensitivity Factor and Genetic

Algorithm for Capacitor placement for

Minimum Loss in radial distribution system"

International Journal of Engineering

Sciences & Research Technology (2013):

2400-2403.

Dinakara Prasad Reddy P, C. Hari Prasad, M

C V Suresh, "Capacitor Placement Using

Bat Algorithm for Maximum Annual Savings

in Radial Distribution systems"Vol. 4 - Issue

12 (December - 2014), International Journal

of Engineering Research and Applications

(IJERA)

,

ISSN:

2248-9622

,

www.ijera.com

Sunil Kumar J, P.Dinakara Prasad Reddy,

V.Leela, V.Rajanikanth."Improvement Of

Voltage Profile In Power System Network

With SVC And UPFC By Using Optimal

Genetic Algorithm." International Journal

Of Electrical, Electronics and Computer

Systems (IJEECS) 1.2 (2011): 61-65.

Dinakara Prasad Reddy P, Sreenivasulu A.

" Optimal Capacitor Placement for Loss

Reduction in Distribution Systems Using

Fuzzy and Hybrid Genetic Algorithm ",

Vol.2 - Issue 11 (November - 2013),

International Journal of Engineering

Research & Technology (IJERT) , ISSN:

2278-0181 , www.ijert.org

135 | P a g e

�

Dinakara Prasad Reddy

Dinakara Prasad Reddy