IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 24, NO. 1, MARCH 2001

33

A Voltage-Controlled Tunable Thin-Film Distributed

RC Notch Filter

Won-Youl Choi and Susan Trolier-McKinstry, Member, IEEE

Abstract—Notch filters are widely used in communication

and instrumentation systems not only for eliminating undesired

frequencies and for measuring transient harmonic distortions, but

also as central components of selective filters and oscillators in

feedback arrangements. This paper describes the characteristics

of a thin-film distributed RC (DRC) notch filter made from

Au/TaN/Y-doped BaTiO3 (Y-BT)/Pt. The dielectric (Y-BT) and

resistive (TaN) films were grown by pulsed laser deposition (PLD).

A notch frequency of 2.8 MHz and notch depth of 76.7 dB were

measured from zero with a notch resistance (

) of 34 . The

experimental optimum notch parameters of

were obtained. Tunability of the notch

and

frequency was observed with an applied dc bias voltage.

=

= 33 0

=

= 19 7

Index Terms—BaTiO3 thin film, pulsed laser deposition, RC

notch filter, TaN thin film, Y-doping.

I. INTRODUCTION

T

HE USE of distributed-RC (DRC) rather than lumped-RC

(LRC) networks as frequency-selective elements in hybrid

integrated-circuit active filters has been advocated as offering

the practical advantages of increased simplicity and reliability

[1]. For example, Kaufman [2] and Kaufman and Garrett [3]

studied a notch filter consisting of an RC transmission line

fabricated on a semiconductor substrate in conjunction with a

lumped resistance and described the effect of geometrical tapering on the characteristics of DRC substrates. Su [4] reported

an RC filter with staggered notch frequencies fabricated using

Teledetos paper and Myler film as the resistive and dielectric

films, respectively. Ahmad and Singh [5] fabricated a thin film

uniformly DRC structure consisting of Al/Al O –SiO/Ni–Cr

films using vacuum evaporation. The electrical performance of

uniformly DRC notch networks fabricated using conventional

integrated circuit (IC) thin-film vacuum deposition techniques

and a very large scale integration (VLSI) interlevel silicon

dioxide spin-on glass (SOG) dielectric planarization material

was reported by Kolesar [6].

For such a filter, the optimum null in the open-circuit

voltage-transfer function is obtained for a particular ratio of

the resistors, and the frequency of the null is then determined

by the RC product. Hence, if the capacitance of the distributed

section couldbechangedwithoutchangingtheresistance,anideal

Manuscript received July 25, 2000; revised November 3, 2000. This work

was supported by the TDK Cooperation. This paper was recommended for publication by Associate Editor A. Deutsch upon evaluation of the reviewers’ comments.

W.-Y. Choi is with the MEMS Laboratory, S&C Sector, Samsung Advanced

Institute of Technology, Suwon 440–600, Korea.

S. Trolier-McKinstry is with the Materials Research Laboratory, Pennsylvania State University, University Park, PA 16802 USA.

Publisher Item Identifier S 1521-3331(01)01381-2.

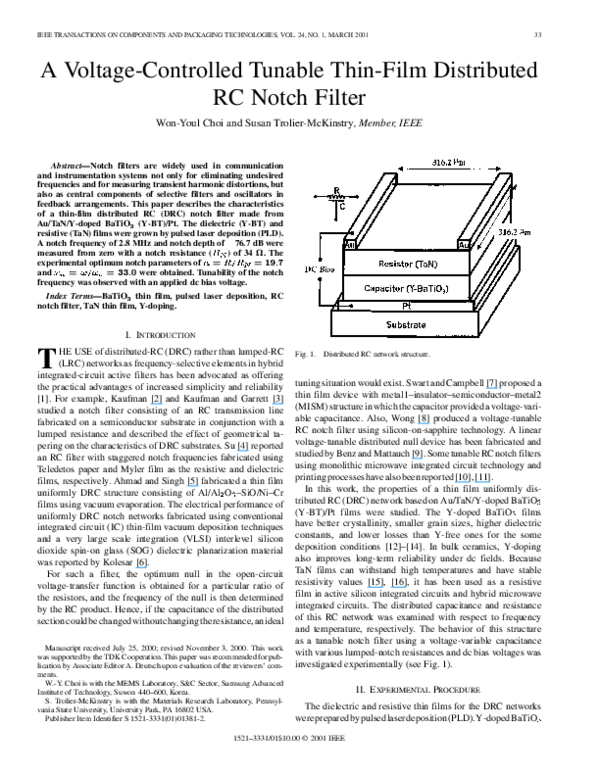

Fig. 1.

Distributed RC network structure.

tuning situation would exist. Swart and Campbell [7] proposed a

thin film device with metal1–insulator–semiconductor–metal2

(MISM) structure in which the capacitor provided a voltage-variable capacitance. Also, Wong [8] produced a voltage-tunable

RC notch filter using silicon-on-sapphire technology. A linear

voltage-tunable distributed null device has been fabricated and

studied by Benz and Mattauch [9]. Some tunable RC notch filters

using monolithic microwave integrated circuit technology and

printing processes have also been reported [10], [11].

In this work, the properties of a thin film uniformly distributed RC (DRC) network based on Au/TaN/Y-doped BaTiO

(Y-BT)/Pt films were studied. The Y-doped BaTiO films

have better crystallinity, smaller grain sizes, higher dielectric

constants, and lower losses than Y-free ones for the some

deposition conditions [12]–[14]. In bulk ceramics, Y-doping

also improves long-term reliability under dc fields. Because

TaN films can withstand high temperatures and have stable

resistivity values [15], [16], it has been used as a resistive

film in active silicon integrated circuits and hybrid microwave

integrated circuits. The distributed capacitance and resistance

of this RC network was examined with respect to frequency

and temperature, respectively. The behavior of this structure

as a tunable notch filter using a voltage-variable capacitance

with various lumped-notch resistances and dc bias voltages was

investigated experimentally (see Fig. 1).

II. EXPERIMENTAL PROCEDURE

The dielectric and resistive thin films for the DRC networks

werepreparedbypulsedlaserdeposition(PLD).Y-dopedBaTiO

1521–3331/01$10.00 © 2001 IEEE

�34

IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 24, NO. 1, MARCH 2001

TABLE I

PULSED LASER DEPOSITION PARAMETERS FOR DIELECTRIC (Y-BT) AND RESISTIVE (TaN) FILM GROWTH

Fig. 2. Dielectric constants and dissipation factors (tan� ) of the dielectric

(Y-BT) film as a function of frequency.

(Y-BT) and TaN film were used as the dielectric and resistive

films, respectively. The specific deposition parameters are given

in Table I. Y-BT and TaN films were grown in pure (99.99%)

N atmospheres from 0.2wt% Y O doped BaTiO ceramic

and a 99.95% pure Ta metal target, respectively. Pt/Ti/SiO /Si

substrates were used. In both cases, a

Hz pulsed laser

J/cm ,

repetition frequency with an energy density of

and a working pressure of 100 mtorr were found to yield good

film properties. Growth temperatures spanning 300 C to 700 C

were achieved by adhering the substrates to a stainless steel

block-style heater with silver paint. The growth temperature for

the TaN film was deliberately kept low to minimize reaction with

the underlying capacitor film. A Lambda Physik Compex 102

excimer laser operating at 248 nm was used. The top electrode

(Au)filmwasdepositedatroomtemperature bydcsputtering.Top

Å thickness were fabricated by

electrode patterns with a

photolithography and wet etching processes.

The crystallinity of the Y-BT and TaN films was examined

with an X-ray diffractometer using Cu K radiation (Scintag,

Inc.). The dielectric constants and dissipation factors (tan ) of

the Y-BT films were measured using a HP4194A impedance analyzer with a 0.03 V oscillation level or HP 4284A LCR meter.

The sheet resistance of the TaN films on the SiO /Si substrates

were measured as a function of temperature using a four-point

probe and a Fluke 8840A multimeter. A computer controlled

Fig. 3. Permittivity of the Y-BT dielectric film and sheet resistance of the TaN

resistive film as a function of temperature.

Delta Design oven was used to control the temperature between

100 C and 200 C.

Following the fabrication of the notch filters, the surface and

cross-sectional morphologies of the layers were observed with

optical microscopy and scanning electron microscopy (SEM).

The open-circuit voltage transfer function of the DRC notch

filter was measured using the HP 4194A impedance analyzer.

To satisfy the optimum null condition for the notch filter, a variable resistance lumped-notch resistor was used. Tunability was

) and the dc bias

examined with various notch resistances (

voltages generated by the HP4192A impedance analyzer.

III. RESULTS AND DISCUSSION

anddissipationfactors

Fig.2showsthedielectricconstants

(tan ) of Y-BT films on Pt/Ti/SiO /Si substrates as a function of

frequency.Inordertomeasurethedielectricconstantsanddissipation factors (tan ) of the Y-BT dielectric layers, 0.3 mm diameter

Pt top electrodes were sputtered through a shadow mask onto the

and

top surface of the films. Dielectric constants of

dissipationfactors (tan ) of 0.03 at 1 kHzwere observed. The temperature dependence of the permittivity for Y-BT films as well as

thesheetresistanceofTaNfilms(onSiO /Sisubstrates)areshown

inFig.3.ThedielectricconstantatroomtemperatureandtheCurie

point at 10 kHz are 1150 and 123 C, respectively. The high temperature dielectric data were fitted to the Curie–Weiss model (the

�CHOI AND MCKINSTRY: VOLTAGE-CONTROLLED TUNABLE THIN-FILM DISTRIBUTED RC NOTCH FILTER

Fig. 4.

35

(a) Surface optical microscopy image and (b) cross-sectional SEM images of distributed RC network.

where

linearrelationshipbetweentheinversedielectricconstantandtemperature above the ferroelectric transition) [17]

Curie constant;

absolute temperature;

Curie temperature.

TheCurieconstantwascalculatedfromthehightemperaturedata.

TheCurieconstantisontheorderof10 K .Thesheetresistance

of the TaN film at room temperature (20 C) is 670 , and the temperature coefficient ofresistance (TCR) is 920 ppm/ C.

Fig. 4 shows SEM micrographs of the top surface and

cross-sections of the distributed filter structure obtained by

photolithography and wet etching of the Au top electrode.

Good top electrode patterns for uniformly DRC networks were

obtained. The thicknesses of the dielectric Y-BT film and

Å and

Å, respectively.

resistive TaN film were

From the thicknesses and effective area (316.2 m 316.2 m)

of the dielectric and resistive films, a distributed capacitance of

2.8 nF and resistance of 670 were calculated, assuming no

reaction layers between the films.

It has been shown [18] that the open circuit voltage transfer

function, , of a uniformly DRC notch filter with dielectric dissipation is given by

(1)

(2)

Fig. 5. Measured open-circuit voltage transfer function of the fabricated DRC

network for various notch resistances (R ).

�36

Fig. 6.

IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 24, NO. 1, MARCH 2001

Notch frequency and depth with notch parameters (

= R=R

).

where

is expressed in terms of a freand a frequency dequency normalization parameter

. In these

pendent normalized dielectric dissipation factor

, where and , respectively, derelationships

note the distributed resistance and capacitance of the structure.

, and the parameter ( ) is given as

in terms of the lumped notch resistance (

). The zero of transmission in (2) that yields the optimum notch condition is realized when both the real and imaginary components of the numerator are zero. In particular, the optimum notch parameters

) and free of

for an ideal notch filter which is a lossless (

and

.

parasitics are

In this work, the experimentally observed open-circuit

voltage transfer function of the fabricated DRC notch filter is

,

shown in Fig. 5 together with its circuit (having

nF, and

kHz). The

values found for the notch frequency and notch depth when

were 2.8 MHz and 76.7 dB, respectively.

This gives the experimental optimum notch parameters

and

. The difference between the values of the notch parameters obtained

experimentally and those predicted theoretically may be due

to the dissipation factor (tan ) of the dielectric film (Y-BT)

and parasitics. In addition, it is possible that a tantalum oxide

(TaO ) with a low dielectric constant was unintentionally

formed between the capacitor and the resistor during the nitride

film growth. Any tantalum oxide phase present would decrease

the total distributed capacitance of the RC network and causes

the optimum notch frequency to shift to higher values.

)

The behavior of the notch filter with notch resistance (

were observed. For

and

, the notch frequencies obtained were 2.90 MHz, 2.88

MHz, 2.83 MHz, 2.82 MHz, 2.80 MHz, and 2.76 MHz, respectively. The variation of the notch frequency and depth with notch

) is plotted in Fig. 6. The relatively high

parameter (

dB may be due to the high resistance TaN

insertion loss of

film. A lower insertion loss could probably be achieved with a

higher conductivity resistive film.

The notch filter could also be tuned with a dc bias voltage, independently of the distributed resistance. This is due to the field

dependence of the dielectric constants of the Y-BT film. Fig. 7

Fig. 7. Measured open-circuit voltage transfer function of the fabricated DRC

network for various dc bias voltages.

Fig. 8.

Dielectric constant of the Y-BT film as a function of dc bias voltage.

Fig. 9. Notch frequency and depth variation with dc bias voltage.

shows the measured open-circuit voltage transfer function of a

DRC network made with a thicker dielectric film (Y-BT) for

various dc bias voltages. Fig. 8 shows the dielectric constant

( ) of a Y-BT film as a function of dc bias voltage. Given the

decrease in the Y-BT film permittivity with field, the distributed

capacitance should drop with increased dc bias voltage, and the

�CHOI AND MCKINSTRY: VOLTAGE-CONTROLLED TUNABLE THIN-FILM DISTRIBUTED RC NOTCH FILTER

notch frequency should shift to higher values. The notch frequency and depth as a function of dc bias voltage are shown

in Fig. 9. The notch depth decreased with increasing dc bias

voltage when the notch resistance was kept constant.

The behavior of this structure as a tunable notch filter using a

voltage-variable capacitance with various lumped-notch resistances and dc bias voltage will be optimized for use in integrated-circuit network applications at radio frequencies.

IV. CONCLUSIONS

Dielectric (Y-BT) and resistive (TaN) films for distributed RC

notch filters were fabricated by pulsed laser deposition (PLD).

The dielectric constant and dissipation factor (tan ) of Y-BT

films at 10 kHz were 1150 and 0.03, respectively. TaN films

had a sheet resistance of 670 at room temperature and a temperature coefficient of resistance (TCR) of 920 ppm/ C.

A notch frequency of 2.8 MHz and depth of 76.7 dB were

) of 34 for a 316.2 m

measured at a notch resistance (

316.2 m distributed filter. Experimental optimum notch parameters of

and

were obtained. Tunability of the notch frequency with dc bias

voltage was also observed. With further optimization of the insertion loss, these characteristics of the thin film DRC notch filters should allow them to be used in integrated-circuit network

applications at radio frequencies.

REFERENCES

[1] L. P. Huelsman, “The distributed-lumped-active network,” IEEE Spectrum, vol. 6, p. 51, Aug. 1969.

[2] W. M. Kaufman, “Theory of monolithic null device and some novel circuit applications,” Proc. IRE, vol. 48, p. 1540, 1960.

[3] W. M. Kaufman and S. J. Garrett, “Tapered distributed filters,” IRE

Trans. Circuit Theory, vol. 9, p. 329, 1962.

[4] K. L. Su, “RC filters with staggered notch frequencies,” Proc. IEEE, vol.

54, p. 1199, Sept. 1966.

[5] S. Ahmad and R. Singh, “A composite dielectric thin film notch filter,”

Thin Solid Films, vol. 67, p. L63, 1980.

[6] E. S. Kolesar, “Effects of thin film spin-on glass dielectric loss on the

performance of the uniformly distributed RC notch network,” IEEE

Trans. Comp., Hybrids, Manufact. Technol., vol. 14, p. 413, June 1991.

[7] P. L. Swart and C. K. Campbell, “A voltage-controlled tunable distributed RC filter,” Solid-State Circuits, vol. SC-7, p. 306, 1972.

[8] P. H. K. Wong and L. Young, “A new voltage-tunable distributed RC

notch filter suitable for SOS realization,” Proc. IEEE, vol. 62, p. 523,

Apr. 1977.

[9] H. F. Benz and R. J. Mattauch, “A linear voltage-tunable distributed null

device,” IEEE J. Solid-State Circuits, vol. SC-7, p. 499, Dec. 1972.

[10] S. Lucyszyn and I. D. Robertson, “MMIC tunable active notch filter,”

Electron. Lett., vol. 32, p. 980, 1996.

[11] P. S. A. Evans, B. J. Ramsey, P. M. Harrey, and D. J. Harrison, “Printed

analogue filter structures,” Electron. Lett., vol. 35, p. 306, 1999.

[12] W. Choi, Y. Tsur, C. A. Randall, and S. Trolier-McKinstry, “Effect of

Y-doping on the dielectric properties of BaTiO films deposited in reducing atmospheres using pulsed laser deposition,” in Proc. MRS, 1999,

to be published.

37

[13] S. Sato, Y. Nakano, A. Sato, and T. Nonura, “Effect of Y-doping on resistance degradation of multilayer ceramic capacitors with Ni electrodes

under the highly accelerated life test,” Jpn. J. Appl. Phys., vol. 36, p.

6016, 1997.

[14] Y. Nakano, A. Sato, A. Hitomi, and T. Nonura, “Microstructure and related phenomena of multilayer ceramic capacitors with Ni-electrode,”

Ceramic Trans., vol. 32, p. 119, 1993.

[15] K. Radhakrishnan, N. Geok Ing, and R. Gopalakrishnan, “Reactive

sputter deposition and characterization of tantalum nitride thin films,”

Mater. Sci. Eng., vol. B57, p. 224, 1999.

[16] C. Au, W. Anderson, D. Schmitz, J. Flassayer, and F. Collins, “Stability

of tantalum nitride thin film resistors,” J. Mater. Res., vol. 5, no. 6, p.

1224, 1990.

[17] B. Jaffe, W. R. Cook Jr., and H. Jaffe, Piezoelectric Ceramics. New

York: Academic, 1971.

[18] J. A. Carson, C. K. Campbell, P. L. Swart, and F. J. Vallo, “Effects of

dielectric losses on the performance of evaporated thin film distributed

RC notch filters,” IEEE J. Solid-State Circuits, vol. SC-6, p. 120, June

1971.

Won-Youl Choi received the B.S. degree from

Hanyang University, Seoul, Korea, and the M.S. and

Ph.D. degrees in materials science and engineering

from the Korean Advanced Institute of Science and

Technology, Taejon.

He was a Postdoctoral Researcher with the

Materials Research Laboratory, Pennsylvania State

University, University Park. In 2000, he joined

the Samsung Advanced Institute of Technology,

Suwon, Korea, as a Special Researcher. His main

research interests include ferroelectric thin films for

dielectric applications, the characterization of the electrical and mechanical

properties of thin films, and micromachining technology for microsensors and

microactuators.

Susan Trolier-McKinstry (M’92) received the M.S.

and Ph.D. degrees in ceramic science from Pennsylvania State University (PSU), University Park.

She is an Associate Professor of Ceramic Science

and Engineering and Associate Director of the Materials Research Laboratory, PSU. Her main research

interests include ferroelectric thin films for actuator

and dielectric applications, the development of texture in bulk ceramic piezoelectrics, and spectroscopic

ellipsometry. She has held visiting appointments at

Hitachi Central Research Laboratory, the Army Research Laboratory, and the Ecole Polytechnique Federale de Lausanne.

Dr. Trolier-McKinstry received the Robert Coble Award of the American Ceramic Society, the Wilson Award for Outstanding Teaching in the College of

Earth and Mineral Sciences, and an NSF CAREER grant. She is a member

of the American Ceramic Society, the Materials Research Society, ASM, and

ASEE. She is co-chair of the committee revising the IEEE Standard on Ferroelectricity. She is an Elected Member of the IEEE Ultrasonics, Ferroelectrics,

and Frequency Control Society Advisory Committee. She is past-President of

Keramos and Treasurer for the Ceramics Education Council.

�

Susan Trolier-McKinstry

Susan Trolier-McKinstry