REVIEW OF PERIPHERAL NERVE ELECTRODE

TECHNOLOGY

Dhonam Pemba

Introduction

The electrode serves as the critical component of Functional Electrical Stimulation, Brain

Machine Interfaces and Neural Prosthesis. The choice of electrode use in any stimulation system

would depend on the application. Electrode selectivity varies from measuring surface EMG

signals to signal neuron spikes, while invasiveness is inversely proportional to selectivity.

Surface electrodes are the least invasive while penetrating intraneural electrodes are the most

invasive, accordingly their respective resolution increases with proximity to the neurons.

Electrode types can be grouped according to their location; on the surface, epimysial,

intramusclar, extraneural, epineural, interfasciular, intraneural.

I.

Surface Electrodes

Surface Electrodes usually consist of stainless steel disks placed on the skin external to

the desired muscle to stimulate. The electrode are able to record motor unit action potentials and

EMG signals[1–3] and have shown promise in rehabilitation applications[4–7]. Although the

electrodes demonstrate capability of detecting muscle activity, their use in for finer motor control

would be impractical. The electrodes would require significant current to stimulate muscle for

functional motor movement which would cause muscle fatigue and tissue damage. In addition,

the large area of the electrodes would produce very low selective stimulation, and accurate

muscle recoding for finer control would require significant post signal processing and

computation to accurately differentiate motor activity readings[8], [9]. Magnetoneuraphy is an

alternative non-invasive method to record magnetic fields in the action in the peripheral

�nerves[10] but this system would again only be practical for stimulation and depend significantly

on post processing[11].

II.

Muscle Electrodes

To overcome the disabilities of surface electrodes, researchers and clinician have place

electrodes directly in contact with the muscle fiber. Methods of muscle stimulation include

epimysial electrodes surgically sutured to the muscle[12–14][15], and intramuscular electrodes

that are placed inside the muscle[11], [16–19]. The most widespread design of intramsuclar

electrodes consist of fine wire inserted into targeted muscle. A novel intramuscular electrode

system called the Bionic Neurons(BIONs) was developed to be a self-contained unit. The BIONs

are implanted into the muscle with a needled, and are individually addressable, receive power

externally and stimulate motor units.[20], [21]. Although epimysial and intramuscular electrodes

are able to stimulate and record motor unit action potential, there are several issues preventing

success in neuroprosthetic applications. Similar, to surface electrode, the muscle electrodes

possess low selectivity due to their distance from the nerve. Even though the electrodes are

placed on the muscle, the stimulation actually evokes action potential in the nerve rather thus a

higher current would be required stimulate the nerve muscle impedance as opposed to an

electrode placed on the nerve directly. In addition, due to the graded recruitment of muscle[22],

[23], muscle stimulation would result in muscle fatigue and discomfort[24], [25]. Finally, to

achieve complex and fine motor control, electrodes would need to be placed on each individual

muscle making the system inconvenient and high maintenance.

III.

Nerve Electrodes

Stimulating the nerve directly has significant advantages of surface, epimysial and

intramuscular electrodes. By directly stimulating the nerve, less current can be used while

�achieve higher selectivity, the electrode can be placed away from the contracting muscle thereby

increasing durability, and avert graded recruitment issues to reduce muscle fatigue. Electrodes

are either placed outside the epineurium, between epineurium and perineurium, insde the

perineurium or through the fascicule.

Extraneural Electrodes

Extraneural electrodes contact the nerve but are placed outside the epineurium, and including

epnineural, helical, book, and cuff electrodes.

Epineural electrodes are electrodes that are sutured outside of the nerve. The electrodes are

wires, discs or buttons and had success with less complex stimulation needs such as pain therapy

or respiration.[26–29] The disadvantages with them are their lower relative selective to other

neural electrode and more complicated surgery to ensure stable suture.

G.S Brindley pioneered the book electrodes, which have demonstrated success in bladder

control by contacting the sacral spinal roots. The device is constructed from implanting

electrodes inside channels that are cut out of block biocompatible insulation. The electrode

design resembles book, where the gaps between the pages resemble the channels[30–34].

Although the book electrode has had success with spinal root stimulation, the device is too bulky

and not designed peripheral nerve stimulation. Recently, a group has attempted to miniaturize the

book electrodes for placing individual nerve fascicles between the pages rather than spinal

roots[35]. However the miniature book electrode would require the dissection of the nerve into

individual fascicles and manual placement in the grooves.

Cuff electrodes are arguably the most widely used nerve configuration[36–56], they were

designed to improve upon the epineural electrodes by improving the signal to noise and ease of

implantation. In general the cuff design composes of an electrode in contact with the epineurium

�that is encircles the never with biocompatible insulation. Original designs did not utilize

micromachining technology and were silicon rubber tubes with a slot[37], blocks of insulating

material with a channel[36][57], or flexible insulating material wrapped around a nerve[54],

[58].Figure from Loeb et al summarizes in detail the fabrication of several other nerve cuff

deigns[59]. With the advancement of thin film micromachining technology, electrode designs

have included polyimide as the substrate material, and improved electrode materials and

designs[40], [60–65]. Most of the polyimide cuff electrodes are fabricated by depositing and

patterning metal between layers of polyimide, and then shaped into a cuff. A critical issue with

cuff electrodes is to seal the slot in which the nerve was inserted which was originally done with

a silicon elastomer[49], [50], [66],suture[54], [58] or tension[37]. Recent designs have attempted

to close the slot by using hinges[45], or advanced polymers with self-coiling abilities[51], [52].

In addition to sheets of biocompatible insulation encircle the nerve, spiral and helical cuff

electrodes have been designed[67–73]. Helical electrodes improve fitting while decreasing

compression due to self-sizing nature of the spiral. Although cuff electrodes have widely been

used, stimulation superficially[74] thus the greatest disadvantages are in the difficulty in

selective action of particular fascicles.

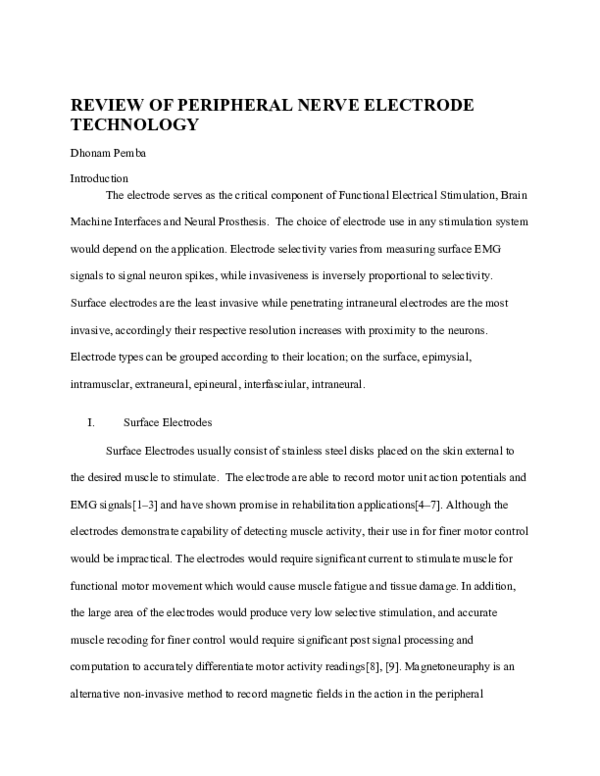

To improve of selectivity of nerve cuff electrodes, the cuff electrode was redesigned to

reshapes the nerve to bring central axon population closer to the electrodes[75], [76]. The flat

interface nerve electrode(FINE) were silicon elastomer shaped with a rectangular center opening

1.4 times the cross-sectional area of the nerve(figure [76]). The electrodes have shown

effectiveness in controlling gross movements such as knee extension[77], [78] but not complex

movements such as ankle control.[79] More recently, Poly (DL-lactic-co-glycolic) acid (PLGA)

was added to the a FINE electrode to improve control of closure[80]. The PLGA was attached to

�a stretched FINE electrode, and upon degradation the FINE electrode deformed to its original

equilibrium state.

Figure 2.1: FINE electrode (Left), SPINE electrode (Right).

Longitudinal electrodes

The inventors of the FLAT electrode had previously developed an interfasicular electrode

which makes contacts which penetrates the epinerium. The slowly penetrating interfascicular

nerve electrode (SPINE) is similar to a traditional cuff electrode but includes blunt electrodes

that penetrate epineurm. The SPINE electrode is an interfascicular electrode that is in-between

extraneural and intraneural electrodes. Electrodes that penetrate the perineurium are considered

intraneural while electrodes outside the epineurium are identified as extraneueral. Intraneural

electrodes improve selectivity and signal to noise ratio and reduce cross talk by placing the

electrodes inside the nerve and in contact with individual fascicules[81]. Intraneural electrodes

possess superior selectivity to extranenural electrodes[74], [82]and have shown the most promise

for use in complex motor control neuroprosthesis[83–89]. Restoring hand function is one of the

most complex motor movements for a neuroprothesis because high selectivity would be needed

to stimulate specific muscles without recruiting others. Success in of stimulating independent

�specific muscles along with natural hand movements has beech achieved by implanting an

intraneural electrode[87]. Intraneural electrodes have shown the ability to detect motor activity in

amputee and have helped provide tactile and proprioceptive feedback to discriminate objects

without visual cues[90]. By implanting intraneural electrodes, stimulation was able to evoke

discrete tactile and proprioceptive sensation in a missing limb.[84], [85]

Longitudinally Implanted Intrafascicular electrodes(LIFE) were originally thin insulated

wires securely inserted under the perenerium which stimulate and record from individual

fascicules. Electrode areas were exposed by heating the insulating layer and the penetrating end

was electrochemically sharpened with potassium nitrite[91]. To reduce the mechanical mismatch

between tissue and electrode, and decrease cellular encapsulation, flexible substrates were used

over the original wire[83], [92]. Polymer fiber was first as a flexible alternative to metal

wires, polymer-based longitudinal intrafascicular electrode (polyLIFE) were fabricated by

sputter deposition of metals over Kevlar fiber, and dip coating of silicone insulation[83], [93].

Although polyLIFEs improved on flexibility over traditional LIFEs, the active sites precision had

not improved. Microfabrication technology was implemented in the newest generation of LIFEs

that allowed control over electrode geometry. Fabrication of thin film LIFE (tfLIFE) was similar

to polyimide cuff electrodes, where lithography based patterning of metal was sandwiched

between two polymer layers[92], [94], [95]. LIFEs offered precise stimulation and record from

individual fascicules, but to control complex motor movements various fascicules would need to

be selectively stimulated. Thus to selectively stimulate specific fascicules within a nerve fiber

bundle would require several implanted LIFEs.

Transverse Penetrating

�Selective stimulation of various fascicules within a nerve fiber bundle would be

impractical with LIFEs and unachievable with extraneural electrodes, therefore the best option

for electrodes for complex motor function controlled would be transversely penetrating probes.

a. Wires

Hodgkin and Huxley first demonstrated that action potentials in a squid axon could be

detected with a simple wire inserted into a micro glass pipette[96], [97].The basic microwires are

easily fabricated and has demonstrated success in neural activity from cortex and peripheral

nerves [98–103]. Wire based microelectrodes are constructed from small diameter wires that are

then electrochemical sharpened, and finally insulated[99], [104]. Although, these

microelectrodes have had success recording neural activity, the fact that selective and

independent activation of different fasciculus would require several electrodes limits its

application in use with neuroprothesis.

b. MEMS Penetrating Electrodes

The advancement of MEMS has allowed for microfabrication precision and repeatability

to transfer to neural electrodes construction. By incorporating microfabrication technology such

as ebeam deposition, sputtering, metal etching and lift off, MEMS based penetrating electrodes

now have the capabilities to precisely define electrode geometry as well as a whole larger choice

of materials. Bulk and surface micromaching capabilities allow for precision probe shape design

and thin film technology allow a larger choice of dielectrics and insulation. MEMS based neural

probes were pioneered by University of Utah and University of Michigan. Integrated Circuit

technology was first implemented at Stanford by Dr. Wise[105], but Wise moved to University

of Michigan and developed with Najafi a planer probe, known famously as the Michigan

probe[106], [107]. Along the same time as the Michigan probe was developed, Dr. Norman at

�the University of Utah produced a three dimensional probe, known as the Utah Electrode

Array(UEA)[108], [109].

The Utah Electrode

Dr. Richard Norman’s group at the University of Utah fabricated an electrode array

referred to as the Utah Electrode Array or UEA[108–116]. The group fabricated a ten by ten

electrode array with overall dimensions of 4.2 mm by 4.2 mm Each electrode is needle shaped

and can range from 1 to 1.5 mm in length long, with a 80µm diameter at the base. The needles

project to a .2 mm thick glass-silicon composite base, which also serves as insulation, see figure

6d[9]. Glass insulation is poured between grooves that are made with a dicing saw in the

backside of a silicon square block. The glass/silicon base is grinded down, and patterned with

aluminum. The device is flipped over and columns are diced on the top side, and finally the

columns are sharpened and insulated. Insulation on the tips is removed by poking the arrays

through aluminum foil and etching the exposed tips. This method has been improved recently

with parylene C deposition, and a custom holder for photoresist spinning[113]. Other groups

have improved charge capabilities of the UEA by coating with new materials[117] or roughening

the tips[118].

�Figure 2. 2: Utah Electrode Array- Utah Electrode Device including circuit received in May 2008(Top),

Varying Length Utah Electrode(Bottom Left) [119], 10 by 10 Utah Electrode(Bottom Right) [111]

An improved design with varying length electrodes has also been design to allow stimulation of

different regions of a nerve bundle, see Figure 2.2 [110]The authors have also designed a

pneumatically actuated insertion method to minimize tissue damage their system was able to an

array of 100 needles electrodes into the cerebral cortex with minimal by using a minimum

insertion speed for safe entry was 8.3m/s for a depth of 1.5 mm into a cat cortex[109].

There are certain draw backs with the UEA, first of all the fabrication is tedious due to the

numerous manual dicing steps required to create one array. Preferably, a more lithography based

approach would provide The UEA lacks on chip circuitry thus requiring lead wires that bulk up

the size of the device. As can be seen in Figure 3, the electrode arrays are tiny in comparison to

the whole device. The circuit board, itself is over 8cm long; the size of this device makes long

term implantation impractical. In addition, its structural integrity is in question because it is a

composite material and thus introducing an interfacial region. One additional issue is that glass

has a lower service temperature than the silicon, which might cause processing obstructions.

The Michigan Probe

At Michigan Center for Neural Communication Technology planer iridium stimulating

arrays were fabricated using surface micromachining and thin-film technology[119–122]. The

probes are fabricated by selectively diffusing boron to define the shape of the probes. The

thickness of the devices is defined by the thickness of the boron layer. A three layer stack of

silicon dioxide, silicon nitride and another layer of silicon dioxide, serve as dielectrics and

insulation of the interconnects. Phosophorous doped polysilicon is patterned and serves as

interconnects, which is then covered with the three layer stack of dielectrics once more. Next

�bond pads are made with gold and chromium for adhesion, while electrode sites are made with

iridium with titanium for adhesion. The device is finally released by using anisotropic silicon

etch composed of ethylenediamine, pyrocatechol, and water.(EDP) Integrated ribbon cables as

thin as 2 µm and as thick as 20, as well as a sharper tip angles of less than 10 degrees can also be

fabricated using shallow boron diffusion[122]. Later improvement of the original cables was to

use polyimide which provides more flexibility and improves durability of the failure prone

silicon cables[123]. These probes were able to be integrated with CMOS[119] on chip circuitry.

Although planer they can be assembled into three dimensional arrays using orthogonal lead

transfers between the planer probes and a platform; Gold electrode plated leads are bent and then

the probes are manually inserted into a platform[120]. Despite the great improvements and

advancements on the Michigan probe, there are still problems limiting their use in neural

implants. Although, the planer geometry is defined by microfabrication capabilities, the depth is

dependent on boron diffusion, and therefore limited. In addition, the mechanical mismatch

between nerve implantation and these electrodes causes problems of chronic implantation. For

long term implantation, a wireless system must be integrated to remove the output leads. There is

also the consideration of the tissue-electrode interface. Improvements of the electrodes have been

made with bioactive coatings. These techniques have lowered the impedance caused by

unfavorable cell activity by coating the electrodes with the conducting polymer polypyrrole

(PPy) doped with biomolecules having cell adhesion[124], [125]. Although these systems have

improved the interface between electrodes and tissue, there is still the issue of chronic immune

response. Preferable drug eluting system must be incorporated to prevent this immune response.

�Figure 2.3:Michigan probe arrays-Single probes are planer(Top Left) [127], 3 dimensional integration of

planer electrodes(Top Right)[128], Cmos Integration(Bottom Left)[120], polyimide cable used instead of

silicon ribbon(Bottom Right)[124]

Silicon Penetrating Electrodes

The UEA and Michigan probe pioneered the field of MEMS based microelectrodes,

however the advancements of microfabrication processes and technology brought a whole new

era of MEMS based probes. In addition, to the UEA and Michigan probe, researchers have

developed various other probes using different materials. In our laboratory, Dr. Jian Wu

developed a three dimensional silicon intraneural electrode arrays that utilizes DRIE instead of

the dicing saw used in the UEA fabrication[126]. Further improvements by Dr. Wu included the

incorporation of a form fitting SU-8 layer to fit the electrode array with peripheral nerves[127].

In addition, Dr. Wu also fabricated a novel curvature-controlled electrode for use in cochlear

implants; the probe was made out of polypyrrole which deforms by application of electric

�field[128]. Researchers in California Institute of Technology utilized emerging parylene

technology to develop a more durable alternative to the silicon ribbon and polyimide cables of

the Michigan probe[129]. To improve on the uniformity and circuit integration, groups have

moved toward dry etching of probe shape. The first probes developed with dry etching were

limited to how deep they could etch. Therefore they used a combination of Reactive Ion Etching

to define the probe shape, and used backside wet etching to release the probes[130][131]. With

the development of deep reactive ion etching (DRIE), thicker probes could be etched. To

provide a thicker support structure groups have utilized deep reactive ion etching(DRIE) of SOI

wafers[132–134]. DRIE is a dry etching technique and has more control than the wet etching

used in the Michigan probe. In addition by using a SOI wafer, the probe thickness is defined by

the topside silicon while the support structures depth is limited to the thickness of the SOI wafer.

DRIE has also been used by our group to fabricate MEMS based alternative to UEA[126], [135]

which requires less manual fabrication with features defined by lithography instead of a dicing

saw. Chapter 2 and 3 of this will further optimize our previously fabricated three dimensional

electrodes.

Figure 2. 4:Silicon probe with parylene wire(Left)[129], Probe made by combination of dry and wet

etching (Right) [131].

�Polymer Based Probes

Silicon based probes provide excellent recording and stimulating capabilities in acute but

have not had as parallel success in chronic use. A key issue which degrades electrode charge is

the cellular response from the mechanical mismatch between tissue and electrode. Fabrication of

flexible neural probes has been a key research issue and has resulted in shift towards polymer

based probes. Polymer based probes all have a similar fabrication procedure that involves

depositing a sacrificial layer on silicon, then depositing the first polymer, next patterning metal

on the first polymer layer, then depositing another polymer layer, exposes the electrodes and

finally dissolving the sacrificial layer to release the polymer probe[65], [136–145]. Although,

there are a plethora of choices of polymers, polyimide[65], [136], [146], [147],

Benzocyclubuten[148–150] and Parylene[143–145], [151], [152] have been used most

extensively in neural probes. Along with a more cost effective and easier fabrication procedure,

polymer probes can be assembled easier than their silicon counter parts. Takeuchi et al

demonstrated three dimensional batch assembly of their polymer probes by using magnetic

force[153]. The main disadvantage of flexible probes is that they are not strong enough to

penetrate the nerve. But this can be overcome by using a microneedle to first puncture the

epineurm and perineum[140] integrate a silicon backbone with the polymer[137] or use a

biodegradable polymer to increase mechanical stiff for insertion and later dissolve to increase

flexibility[147].

Cellular Response Probes

Although flexible probes provide on improvement on long time viability over their

silicon counterparts, there still are more promising methods to further improve the lifetime of a

chronic implant. The main culprit of electrode failure is due to the host’s systems cellular

�response. However, the chronic electrode has already by developed over 20 years ago. The

neurotrophic electrode consists of gold wires and neurotrophic factors inside of a glass tip[154–

156]. By implanting autologous growth factors into the tip, the electrode integrates with the host

tissue by inducing neurite growth, and have achieved viability of 4 years in humans[155].

Although these electrodes have achieved great success in brain computer interface

applications[157–160], using them in peripheral nerve neural interfaces will be less successful

due to the difficulty in miniaturizing the electrodes and defining active sites. Researchers at the

University of Michigan developed a probe to reduce tissue encapsulation around the electrode

sites by placing them in a finer lateral area region[161–163]. They were able to increase

penetrating strength while placing the electrodes on a smaller area by incorporating an open

architecture design. Most recently, the same group utilized parylene-N covered by PEGMA to

prevent protein adoption and cellular response[164]. Unlike the neurotrophic electrode, the openarchitecture probes did not contain neurotrophic factors to induce neurite growth, but current

research has shown that neurite growth can be inducing by electrical stimulation or neural

adhesion molecular coating [165]. Groups have developed electrically stimulated nerve guidance

channels to guide nerve growth as an alternative to nerve grafts[166–168]. Although, the

guidance channels were not developed for prosthetics, the idea of regenerative electrodes for

neuroprostheses were one of the first conceived[169–172].

�Figure 2.5: Electrodes design on small surface area to reduce encapsulation[174]

Regenerative Electrodes

Regenerative Electrodes are another group of penetrating electrodes. They are also known as

sieve electrodes and implanted on severed nerves. The electrical activity and/or neurotrophic

factors induce never axon growth through the holes in the electrode[40], [171], [173–177].

Although, these electrodes provide the highest selectivity they are limited to use only severed

nerves or stumps of amputees.

�Figure 2.6:Sieve Electrode(Left)[175], Implantation Setup(Right)[177]

Fluidic Delivery Probe

Figure 2. 7: Various Fluidic Probe Fabrication Techniques-Bonding(Left), Sacrificial layer(Middle),

sealing buried channel with dielectrics(Right).

The ideal neural probe would have the highest selectivity while evoking the minimal

immune response. An electrode with fluidic delivery capabilities could combine the selectivity of

penetrating electrodes, the axon regenerative abilities of sieve electrodes and the tissue

encapsulation reduction capabilities of neurotopic electrodes. A MEMS based approach would

allow for high repeatability, scalability, and precise control over design, while a fluidic channel

could delivery either drugs and growth factors to prevent or enhance cellular responses. Figure

2.7 provides an overview of the various approaches to fabricate fluidic channels. University of

Michigan researchers have pioneered neural electrode progress, Kensall Wise and David

�Anderson developed the commercially viable Michigan probe, and their student’s Daryl Kipke

and Jamie Hetke continued the legacy and success with NeuroNexus technologies. That legacy

still continues today with David Martin leading the field in electrode materials with his startup

Biotectix. It would seem fitting that one of the first neural electrodes simultaneous fluidic and

electrical capabilities would originate at the University of Michigan[178].Chen et al, fabricated

in fluidic channel in the traditional Michigan probes by using shallow boron diffusion to define

the channel mask, RIE to etch the channel, EDP to form a continues flow channel by

undercutting the mask, and growing and depositing dielectrics to seal the channel[178].

Although, the probes were capable of delivering fluids, they are more practical in research on the

cellular response of chemicals due to the extremely shallow depth of the channels. The channels

were limited to 15 um due to the channel fabrication and sealing process. In addition, the final

release of the probes use EDP as in the Michigan probe fabrication which could potentially

destroy CMOS circuitry. To improve CMOS compatibility, UC Berkeley researchers used Deep

Reactive Ion Etching of a SOI wafers to both define and release the probes. Their fluidic channel

was defined in similar fashion but with a nitride mask, and KOH was to undercut the mask, and

low pressure chemical vapor deposition of oxide was used to seal the channels[132].

�Figure 2. 8: Silicon Fluidic Probes- Figure Michigan fluidic probe(Left)[180], Berkeley probe

(Right)[132].

To improve flexibility, Michigan researchers recently fabricated a parylene C flexible fluidic

probe by filling an etched a channel in parylene with sacrificial photoresist and then applying

another layer on top to seal the channel[152], [179]. Limitations from this method arise from

non-planar deposition of sacrificial photoresist and parylene thickness deposition. The current

fluidic probes available at NeuroNexus are made from their Michigan probe mounted to a fluidic

tube.

�Figure 2. 9: Parylene fluidic probe, channel height 5 micrometers[153]

Other groups have similarly used sacrificial layers and sealants to construct fluidic neural

probes[180–182]. Similarly to the fluidic Michigan probes, sacrificial methods to construct

fluidic probes using polyimide or parylene limit the channel depth. Most recently, Kuo et al,

inserted a wire into a parylene fluidic probe fabricated from sacrificial method, and

thermoformed the electrode into a three dimensional shape with fluidic openings up to 300

um[183]. Boer et al developed the buried channel technology to increase the dimensions of

silicon etched microfluid channels. The process involves DRIE of trench, sidewall coverage of

trench with either silicon dioxide or LPCVD silicon nitride, removing the coverage on the

bottom of trench with RIE, creating buried channel with Isotroptic dry etching, KOH, or HNA,

and sealing the channel seal trench with LPCVD of polysilicon dioxide or, silicon nitride[184].

Figure 2. 10:Silicon fluidic probe-DRIE used to make trench (Top), isotropic etching to make channel,

and sealed with dielectrics(Bottom).[186]

�An alternative to sealing the channel with dielectrics or using sacrificial materials is

bonding the channel roof to walls of microchannel. Metz et al defined channel walls with

polyimide and the channel roof was constructed by bonded and releasing an another polymide

layer that was mounted on mylar foil[138].Parker et al used thermocompression bonding Ti foils

to fabricate embedded channels[185]. The European Union funded NeuroProbes project utilized

wafer bonding to fabricate silicon probes with fluidic channels. Wafer bonding allows for

increased channel depth that is now limited to silicon thickness rather than polymer deposition or

undercutting mechanics. The NeuroProbes project used DRIE to define channels and the probe

shape in one wafer, then mounted wafer to serve as the roof of the channel, the mounted wafer

was grinded down to the desired thickness, and DRIE was used to etch out the probe shape on

the mounted wafer[186]. The probes then could be assembled into three dimensional

configuration with a PDMS based microfluidic connection[187]. Polyimide and parylene probes

have the advantage in flexibility, tissue stiffness matching, simplicity of fabrication, while

silicon based probes allow for greater control of channel depth and stiff enough for neural

penetration.

SU8 is a low cost negative resist developed by IBM with single coat spin thickness of 750nm

to 450 um[188] and has excellent biocompatibility[189]. Interestingly one of the first uses of

SU8 in neural application in 2004[190] and 2005[191] were used as a molds. Park et al

fabricated constructed double molds for biodegradable polymer needles by sharpening SU-8

cylindrical posts with RIE[191]. The SU8 molds were used to create PDMS molds which were

further used for biodegradable polymers. Kim et al created hollow metallic needles using

sacrificial SU8. Tapered SU8 posts were created by backside exposure through glass, which

subsequently was covered with metal, then polished to create a hole in posts, and plasma was

�used to remove the SU8[190]. Lu et al reported one of the first SU8 neural electrodes were in

2006[192] [193], where they fabricated planar SU8 electrodes with grooves for nerves to be

inserted. In 2011, Ribeiro et al developed a low cost, simple solution to silicon penetrating

electrodes using SU8;They deposited gold in-between two layers of SU8 with omnicoat used to

separate the probes from the silicon substrate[194]. In 2012, a Spanish research group under the

ERANET-Neuron project fabricated planar SU8 probes under a similar method to Ribeiro et al,

with the main difference being the deposition of sacrificial aluminum instead of omnicoat for

device separation[195]. In 2009, the Spanish group first demonstrated the viability of SU-8

based neural electrodes with fluidic channels[196], and most recently the same group reported in

a different approach to create SU8 embedded microchannels [197]. Their newest involves

bonding two patterned SU-8 layers, but crosslinking will increase thermal stability, and glass

transition temperature and make reflow and bonding difficult. An alternative to bonding would

allow for a simpler process, more accurate alignment, and stronger interface sealing the channels.

Summary

We presented a review of electrodes for use in neuroprosthetic, brain machine and functional

electrical stimulation devices. Intraneural electrodes are necessary to achieve the high selectivity

needed to reach central axons of nerve fibers for complex motor control. The tradeoff with

increasing selectivity is the increase in invasiveness. Current research understands the need for a

chronic electrode to make neuroprosthetic systems a reality. Table 2.1 summarizes the progress

made in multi-electrode arrays. Initially, silicon was the gold standard used for neural electrodes,

but as researchers attributed the cellular response that degrades the electrode to the mechanical

mismatch between silicon and neuronal a trend was pushed to more flexible materials. At the

same time, the demand for a probe capable of simultaneous fluidic delivery, and electrical

�abilities as created because the neurotropic electrode, and others studies demonstrated that

neurotrophic factors and drugs can extend the lifespan of probes[154][198], [199][200] while

enhance nerve regeneration[201], [202]. Research and progress suggest that the next generation

of probes could be made from SU8 as it is biocompatible with customizable flexibility, IC

compatibly, and photolithography defined.

�Table 2.1: Progress in multielectrode array fabrication

University/Company

Year

Material

Description

Recording and stimulating

Recording and stimulating electrode made with EDP

and boron diffusion

Wire enclosed with neurtrophic factors enclosed in glass

cone

Stanford University

1970

Si

University of Michigan

1985

Si

Georgia Institute of Technology

1989

Si/Glass

University of Utah

1991

Si

University of Michigan

1994

Si

University of Michigan

1997

Si/dielectrics

University of Southampton

2000

SOI

Fraunhofer-Institute

2000

Polyimide

University of Michigan

2003

Si/Polyimide

University of Tokyo

2003

Arizona State University

2004

Parylene

Benzocyclobute

ne

Arizona State University

2004

Polyimide/SI

University of Tokyo

Georgia Institute of Technology

Emory Universtiy

2004

Parylene

2005

PGA

University of Michigan

California Institute of

Technology

2005

Polyimide

2006

Si/Parylene

Universtiy of Texas at Dalas

2006

SU8

Recording and stimulating

Silicon Ribbon cables made with shallow diffusion of

Boron and EDP etching on non doped Si

Fluidic channel made by undercuting mask with wet

etchant and seal channel by growing dielectrics

Recording and stimulating

Recording and stimulating electrodes sandwiched

between polyimide

Polyimide cables made with same method as Stieglitz et

al

Recording and stimulating

Recording and stimulating

Polyimide with silicon backbone tip for stiffness

improvement

Fluidic probe made with sacrificial layer photoresist

SU8 needles used to mold PDMS. PMDS mold used for

PGA needle

Fluidic probe made by same method as Takeuci et al

Parylene Cable made with same methods as Takeuchi et

al

Reference

Wise and

Angel[105]

Najafi et

al[203]

Kennedy[154]

Campbell et

al[108]

Hetke et

a[122]

Chen et

al[204]

Ensell et

al[134]

Stieglitz et

al[139]

Hetke et

al[123]

Suzuki et

al[205]

K. Lee et

al[150]

K. Lee et

al[136]

Takeuchi et

al[144]

Park et

al[191]

Pellinen et

al[152]

Pang et

al[129]

Recording and stimulating

Lu et al[192]

SU8 shank and parylene electrode sites for reduced

Seymour et

tissue encapsulation

al[163]

University of Michigan

2006 SU8/ Parylene

University of California at Santa

Fluidic channel made by thermocompression of two Ti

Parker et

2007 Titantium

Barbara

foil layers

al[185]

SU8 fluidic probe made by embedded chrome to prevent Fernández et

crosslinking

al[196]

Spain*

2009 SU8

University of Southern

Fluidic channel made by thermoforming parylene with

California

gold wire

2012 Parylene

Kuo et al[183]

Parylene, SU8 and polyimide coated with PEG for

Cheng et

stiffness improvement

al[147]

Polymer coated with PEG

2013 PEG

Fluidic channel made by bonding of two patterned SU8

Altuna et

Spain**

2013 SU8

layers

al[197]

*Collaboration between IKERLAN, S. Coop.(Company), University of Barcelona, Ciberned, and Spanish National Research

Council

** Collaboration between IKERLAN, S. Coop.(Company) , Ciberned, Spanish National Research Council and Cajal institute

�References

[1]

A. J. Fuglevand, D. A. Winter, A. E. Patla, and D. Stashuk, “Detection of motor unit action potentials with

surface electrodes: influence of electrode size and spacing,” Biological cybernetics, vol. 67, no. 2, pp. 143–

153, 1992.

[2]

T. Masuda, H. Miyano, and T. Sadoyama, “A surface electrode array for detecting action potential trains of

single motor units,” Electroencephalography and clinical neurophysiology, vol. 60, no. 5, pp. 435–443,

1985.

[3]

T. Masuda, H. Miyano, and T. Sadoyama, “The propagation of motor unit action potential and the location

of neuromuscular junction investigated by surface electrode arrays,” Electroencephalography and Clinical

Neurophysiology, vol. 55, no. 5, pp. 594–600, 1983.

[4]

A. Kralj, T. Bajd, R. Turk, J. Krajnik, and H. Benko, “Gait restoration in paraplegic patients: a feasibility

demonstration using multichannel surface electrode FES.,” Journal of rehabilitation R&D/Veterans

Administration, Department of Medicine and Surgery, Rehabilitation R&D Service, vol. 20, no. 1, p. 3,

1983.

[5]

H. Kern, S. Salmons, W. Mayr, K. Rossini, and U. Carraro, “Recovery of long‐term denervated human

muscles induced by electrical stimulation,” Muscle & nerve, vol. 31, no. 1, pp. 98–101, 2004.

[6]

H. Kern, C. Hofer, M. Mödlin, C. Forstner, D. Raschka‐Högler, W. Mayr, and H. Stöhr, “Denervated

muscles in humans: limitations and problems of currently used functional electrical stimulation training

protocols,” Artificial organs, vol. 26, no. 3, pp. 216–218, 2002.

[7]

T. Masuda and T. Sadoyama, “Skeletal muscles from which the propagation of motor unit action potentials

is detectable with a surface electrode array,” Electroencephalography and clinical Neurophysiology, vol. 67,

no. 5, pp. 421–427, 1987.

[8]

M. Gazzoni, D. Farina, and R. Merletti, “A new method for the extraction and classification of single motor

unit action potentials from surface EMG signals.,” Journal of neuroscience methods, vol. 136, no. 2, p. 165,

2004.

[9]

G. Rau and C. Disselhorst-Klug, “Principles of high-spatial-resolution surface EMG (HSR-EMG): single

motor unit detection and application in the diagnosis of neuromuscular disorders,” Journal of

Electromyography and Kinesiology, vol. 7, no. 4, pp. 233–239, 1997.

[10]

M. Hoshiyama, R. Kakigi, and O. Nagata, “Peripheral nerve conduction recorded by a micro gradiometer

system (micro-SQUID) in humans.,” Neuroscience letters, vol. 272, no. 3, pp. 199–202, Sep. 1999.

[11]

P. R. Troyk, I. E. Brown, W. H. Moore, and G. E. Loeb, “Development of BION/spl trade/ technology for

functional electrical stimulation: bidirectional telemetry,” 2001 Conference Proceedings of the 23rd Annual

International Conference of the IEEE Engineering in Medicine and Biology Society, pp. 1317–1320, 2001.

[12]

N. Bhadra, K. L. Kilgore, and P. H. Peckham, “Implanted stimulators for restoration of function in spinal

cord injury.,” Medical engineering & physics, vol. 23, no. 1, pp. 19–28, Jan. 2001.

[13]

P. A. Grandjean and J. T. Mortimer, “Recruitment properties of monopolar and bipolar epimysial

electrodes,” Annals of biomedical engineering, vol. 14, no. 1, pp. 53–66, 1986.

�[14]

R. J. Triolo, C. Bieri, J. Uhlir, R. Kobetic, A. Scheiner, and E. B. Marsolais, “Implanted Functional

Neuromuscular Stimulation systems for individuals with cervical spinal cord injuries: clinical case reports,”

Archives of physical medicine and rehabilitation, vol. 77, no. 11, pp. 1119–1128, 1996.

[15]

J. P. Uhlir, R. J. Triolo, J. A. Davis Jr, and C. Bieri, “Performance of epimysial stimulating electrodes in the

lower extremities of individuals with spinal cord injury,” Neural Systems and Rehabilitation Engineering,

IEEE Transactions on, vol. 12, no. 2, pp. 279–287, 2004.

[16]

Y. Handa, N. Hoshimiya, Y. Iguchi, and T. Oda, “Development of percutaneous intramuscular electrode for

multichannel FES system.,” IEEE transactions on bio-medical engineering, vol. 36, no. 7, pp. 705–10, Jul.

1989.

[17]

J. Perry, C. S. Easterday, and D. J. Antonelli, “Surface versus intramuscular electrodes for electromyography

of superficial and deep muscles,” Physical therapy, vol. 61, no. 1, pp. 7–15, 1981.

[18]

W. D. Memberg, P. H. Peckham, and M. W. Keith, “A surgically-implanted intramuscular electrode for an

implantable neuromuscular stimulation system,” Rehabilitation Engineering, IEEE Transactions on, vol. 2,

no. 2, pp. 80–91, 1994.

[19]

Y. Shimada, K. Sato, H. Kagaya, N. Konishi, S. Miyamoto, and T. Matsunaga, “Clinical use of

percutaneous intramuscular electrodes for functional electrical stimulation,” Archives of physical medicine

and rehabilitation, vol. 77, no. 10, pp. 1014–1018, 1996.

[20]

M. J. Kane, P. P. Breen, F. Quondamatteo, and G. ÓLaighin, “BION microstimulators: a case study in the

engineering of an electronic implantable medical device.,” Medical engineering & physics, vol. 33, no. 1,

pp. 7–16, Jan. 2011.

[21]

G. E. Loeb, F. J. R. Richmond, and L. L. Baker, “The BION devices: injectable interfaces with peripheral

nerves and muscles.,” Neurosurgical focus, vol. 20, no. 5, p. E2, Jan. 2006.

[22]

E. Henneman, G. Somjen, and D. O. Carpenter, “Excitability and inhibitibility of motoneurons of different

sizes,” Journal of Neurophysiology, vol. 28, no. 3, pp. 599–620, 1965.

[23]

E. Henneman, G. Somjen, and D. O. Carpenter, “Functional significance of cell size in spinal motoneurons,”

J Neurophysiol, vol. 28, no. 3, pp. 560–580, 1965.

[24]

J. Chae and R. Hart, “Comparison of Discomfort Associated With Surface and Percutaneous Intramuscular

Electrical Stimulation for Persons With Chronic Hemiplegia1,” American journal of physical medicine &

rehabilitation, vol. 77, no. 6, pp. 516–522, 1998.

[25]

D. T. Yu, J. Chae, M. E. Walker, and R. L. Hart, “Pain associated with percutaneous versus surface

neuromuscular electrical stimulation for treating shoulder dysfunction in hemiplegia,” Arch Phys Med

Rehabil, vol. 79, p. 1151, 1998.

[26]

F. W. CLIPPINGER, A. V SEABER, J. H. MCELHANEY, J. M. HARRELSON, and G. MAXWELL,

“Afferent sensory feedback for lower extremity prosthesis,” Clinical Orthopaedics and Related Research,

vol. 169, p. 202, 1982.

[27]

J. Holle, M. Frey, H. Gruber, H. Kern, H. Stohr, and H. Thoma, “Functional electrostimulation of

paraplegics: experimental investigations and first clinical experience with an implantable stimulation

device,” Orthopedics, vol. 7, no. 7, pp. 1145–1160, 1984.

�[28]

H. Thoma, W. Girsch, J. Holle, and W. Mayr, “Technology and long-term application of an epineural

electrode.,” ASAIO transactions/American Society for Artificial Internal Organs, vol. 35, no. 3, p. 490,

1989.

[29]

B. S. Nashold Jr, J. B. Mullen, and R. Avery, “Peripheral nerve stimulation for pain relief using a

multicontact electrode system,” Journal of neurosurgery, vol. 51, no. 6, pp. 872–873, 1979.

[30]

G. S. Brindley, “IMPLANTABLE ELECTRODE CONNECTOR.” Google Patents, 02-Feb-1973.

[31]

G. S. Brindley, “The first 500 patients with sacral anterior root stimulator implants: general description,”

Spinal Cord, vol. 32, no. 12, pp. 795–805, 1994.

[32]

G. S. Brindley, “An implant to empty the bladder or close the urethra.,” Journal of Neurology, Neurosurgery

& Psychiatry, vol. 40, no. 4, pp. 358–369, 1977.

[33]

G. S. Brindley and D. N. Rushton, “Long-term follow-up of patients with sacral anterior root stimulator

implants,” Spinal Cord, vol. 28, no. 8, pp. 469–475, 1990.

[34]

G. S. Brindley, C. E. Polkey, D. N. Rushton, and L. Cardozo, “Sacral anterior root stimulators for bladder

control in paraplegia: the first 50 cases.,” Journal of Neurology, Neurosurgery & Psychiatry, vol. 49, no. 10,

pp. 1104–1114, 1986.

[35]

P. Koole, J. Holsheimer, J. J. Struijk, and A. J. Verloop, “Recruitment characteristics of nerve fascicles

stimulated by a multigroove electrode,” Rehabilitation Engineering, IEEE Transactions on, vol. 5, no. 1, pp.

40–50, 1997.

[36]

R. B. Banzett, “Implantable electrode pair for recording from intact small nerves,” Biomedical Engineering,

IEEE Transactions on, no. 1, pp. 53–54, 1980.

[37]

J.-F. Sauter, H.-R. Berthoud, and B. Jeanrenaud, “A simple electrode for intact nerve stimulation and/or

recording in semi-chronic rats,” Pflügers Archiv European Journal of Physiology, vol. 397, no. 1, pp. 68–69,

1983.

[38]

R. L. Testerman, N. R. Hagfors, and S. I. Schwartz, “Design and evaluation of nerve stimulating

electrodes.,” Medical research engineering, vol. 10, no. 1, p. 6, 1971.

[39]

F. C. Barone, M. J. Wayner, H. U. Aguilar-Baturoni, and R. Guevara-Aguilar, “A bipolar electrode for

peripheral nerve stimulation,” Brain research bulletin, vol. 4, no. 3, pp. 421–422, 1979.

[40]

D. Ceballos, A. Valero, E. Valderrama, T. Stieglitz, and X. Navarro, “Polyimide cuff electrodes for

peripheral nerve stimulation,” Journal of neuroscience methods, vol. 98, no. 2, pp. 105–118, 2000.

[41]

J.-U. Chu, K.-I. Song, S. Han, S. H. Lee, J. Kim, J. Y. Kang, D. Hwang, J.-K. F. Suh, K. Choi, and I. Youn,

“Improvement of signal-to-interference ratio and signal-to-noise ratio in nerve cuff electrode systems,”

Physiological Measurement, vol. 33, no. 6, p. 943, 2012.

[42]

M. A. Crampon, V. Brailovski, M. Sawan, and F. Trochu, “Nerve cuff electrode with shape memory alloy

armature: design and fabrication,” Bio-Medical Materials and Engineering, vol. 12, no. 4, pp. 397–410,

2002.

[43]

W. M. Grill and J. T. Mortimer, “Neural and connective tissue response to long‐term implantation of

multiple contact nerve cuff electrodes,” Journal of biomedical materials research, vol. 50, no. 2, pp. 215–

226, 2000.

�[44]

S. H. Lee, S. J. Park, S. H. Lim, K. S. Hwang, and J. Y. Kang, “Implantable Nerve Cuff Electrode Deposited

with Electrospun Nanofiber to Control Drug Release for Long-Term Implantation,” in Meeting Abstracts,

2012, no. 18, p. 2063.

[45]

H. Neisz, R. Cardinal, J. Shiroff, and J. J. Skubitz, “Cuff electrode having tubular body with controlled

closing force.” Google Patents, 10-Apr-2012.

[46]

J. A. Picaza, S. E. Hunter, and B. W. Cannon, “Pain suppression by peripheral nerve stimulation,”

Stereotactic and Functional Neurosurgery, vol. 40, no. 2–4, pp. 223–234, 1977.

[47]

T. Sakaguchi, A. Warashina, and A. Niijima, “Production of elastic electrodes for nerve stimulation,”

Pflügers Archiv European Journal of Physiology, vol. 380, no. 3, p. 283, 1979.

[48]

R. B. Stein, T. Gordon, J. A. Hoffer, L. A. Davis, and D. Charles, “Long-term recordings from cat peripheral

nerves during degeneration and regeneration: Implications for human nerve repair and prosthetics,” Nerve

Repair: Its Clinical and Experimental Basis, pp. 166–176, 1980.

[49]

R. B. Stein, D. Charles, L. Davis, J. Jhamandas, A. Mannard, and T. R. Nichols, “Principles underlying new

methods for chronic neural recording.,” The Canadian journal of neurological sciences. Le journal canadien

des sciences neurologiques, vol. 2, no. 3, p. 235, 1975.

[50]

R. B. Stein, D. Charles, T. Gordon, J.-A. Hoffer, and J. Jhamandas, “Impedance properties of metal

electrodes for chronic recording from mammalian nerves,” Biomedical Engineering, IEEE Transactions on,

no. 6, pp. 532–537, 1978.

[51]

T. Ware, D. Simon, K. Hearon, C. Liu, S. Shah, J. Reeder, N. Khodaparast, M. P. Kilgard, D. J. Maitland,

and R. L. Rennaker, “Three‐Dimensional Flexible Electronics Enabled by Shape Memory Polymer

Substrates for Responsive Neural Interfaces,” Macromolecular Materials and Engineering, vol. 297, no. 12,

pp. 1193–1202, 2012.

[52]

T. Ware, D. Simon, R. L. Rennaker, and W. Voit, “Smart Polymers for Neural Interfaces,” Polymer

Reviews, vol. 53, no. 1, pp. 108–129, 2013.

[53]

R. L. Waters, D. R. McNeal, and J. Tasto, “Peroneal nerve conduction velocity after chronic electrical

stimulation.,” Archives of physical medicine and rehabilitation, vol. 56, no. 6, p. 240, 1975.

[54]

R. E. Avery, “IMPLANTABLE NERVE STIMULATION.” Google Patents, 27-Nov-1973.

[55]

R. E. Avery, “IMPLANTABLE ELECTRODES FOR THE.” Google Patents, 1973.

[56]

D. J. Edell, J. N. Churchill, and I. M. Gourley, “Biocompatibility of a silicon based peripheral nerve

electrode,” Artificial Cells, Blood Substitutes and Biotechnology, vol. 10, no. 2, pp. 103–122, 1982.

[57]

S. I. Schwartz, “Implantable electrode for nerve stimulation.” Google Patents, 03-Mar-1970.

[58]

N. R. Hagfors, “IMPLATABLE ELECTRODE.” Google Patents, 03-Mar-1972.

[59]

G. E. Loeb and R. a Peck, “Cuff electrodes for chronic stimulation and recording of peripheral nerve

activity.,” Journal of neuroscience methods, vol. 64, no. 1, pp. 95–103, Jan. 1996.

�[60]

C. De Haro, R. Mas, G. Abadal, J. Munoz, F. Perez-Murano, and C. Domı́nguez, “Electrochemical platinum

coatings for improving performance of implantable microelectrode arrays,” Biomaterials, vol. 23, no. 23,

pp. 4515–4521, 2002.

[61]

K. Guo, W. Pei, X. Li, Q. Gui, R. Tang, J. Liu, and H. Chen, “Fabrication and characterization of

implantable silicon neural probe with microfluidic channels BT - Special Topic on Material Sciences (142),” Science China Technological Sciences, vol. 55, no. 1, pp. 1–5, 2012.

[62]

X. Navarro, A. Rodriguez, D. Ceballos, E. Valderrama, M. Schuettler, and T. Stieglitz, “Assessment of

polyimide cuff electrodes for in vivo peripheral nerve stimulation,” Exp Neurol, vol. 163, pp. 307–308,

2000.

[63]

X. Navarro, E. Valderrama, T. Stieglitz, and M. Schuttler, “Selective fascicular stimulation of the rat sciatic

nerve with multipolar polyimide cuff electrodes,” Restorative neurology and neuroscience, vol. 18, no. 1,

pp. 9–22, 2001.

[64]

T. Stieglitz, “Flexible biomedical microdevices with double-sided electrode arrangements for neural

applications,” Sensors and Actuators A: Physical, vol. 90, no. 3, pp. 203–211, 2001.

[65]

È. Beutel, M. Schuettler, T. Stieglitz, and J. Meyer, “Micromachined , Polyimide-Based Devices for

Flexible Neural Interfaces,” pp. 283–294, 2000.

[66]

L. A. Davis, T. Gordon, J.-A. Hoffer, J. Jhamandas, and R. B. Stein, “Compound action potentials recorded

from mammalian peripheral nerves following ligation or resuturing.,” The Journal of physiology, vol. 285,

no. 1, pp. 543–559, 1978.

[67]

W. F. Agnew and D. B. McCreery, “Considerations for safety in the use of extracranial stimulation for

motor evoked potentials.,” Neurosurgery, vol. 20, no. 1, p. 143, 1987.

[68]

L. A. Bullara, “Implantable electrode array.” Google Patents, 04-Mar-1986.

[69]

L. A. Bullara, “Bidirectional helical electrode for nerve stimulation.” Google Patents, 01-May-1990.

[70]

W. M. Grill Jr, M. D. Tarler, and J. T. Mortimer, “Method of manufacturing an implantable helical spiral

cuff electrode.” Google Patents, 25-Nov-1997.

[71]

G. G. Naples, J. T. Mortimer, A. Scheiner, and J. D. Sweeney, “A spiral nerve cuff electrode for peripheral

nerve stimulation,” Biomedical Engineering, IEEE Transactions on, vol. 35, no. 11, pp. 905–916, 1988.

[72]

A. L. Newman, “Implantable helical cuff.” Google Patents, 21-Nov-1989.

[73]

P. E. Zarembo and S. Ruble, “HELICALLY FORMED COIL FOR A NEURAL CUFF ELECTRODE.”

Google Patents, 05-Mar-2010.

[74]

J. Badia, T. Boretius, D. Andreu, C. Azevedo-Coste, T. Stieglitz, and X. Navarro, “Comparative analysis of

transverse intrafascicular multichannel, longitudinal intrafascicular and multipolar cuff electrodes for the

selective stimulation of nerve fascicles,” Journal of neural engineering, vol. 8, no. 3, p. 36023, 2011.

[75]

D. Tyler and D. M. Durand, “Flat interface nerve electrode and a method for use.” Google Patents, 24-Sep2002.

�[76]

D. J. Tyler and D. M. Durand, “Functionally selective peripheral nerve stimulation with a flat interface

nerve electrode,” Neural Systems and Rehabilitation Engineering, IEEE Transactions on, vol. 10, no. 4, pp.

294–303, 2002.

[77]

M. A. Schiefer, R. J. Triolo, and D. J. Tyler, “A model of selective activation of the femoral nerve with a

flat interface nerve electrode for a lower extremity neuroprosthesis,” Neural Systems and Rehabilitation

Engineering, IEEE Transactions on, vol. 16, no. 2, pp. 195–204, 2008.

[78]

M. A. Schiefer, K. H. Polasek, R. J. Triolo, G. C. J. Pinault, and D. J. Tyler, “Selective stimulation of the

human femoral nerve with a flat interface nerve electrode,” Journal of neural engineering, vol. 7, no. 2, p.

26006, 2010.

[79]

M. A. Schiefer, D. J. Tyler, and R. J. Triolo, “Probabilistic modeling of selective stimulation of the human

sciatic nerve with a flat interface nerve electrode,” in Engineering in Medicine and Biology Society, EMBC,

2011 Annual International Conference of the IEEE, 2011, pp. 4068–4071.

[80]

A. V Caparso, D. M. Durand, and J. M. Mansour, “A nerve cuff electrode for controlled reshaping of nerve

geometry,” Journal of biomaterials applications, vol. 24, no. 3, pp. 247–273, 2009.

[81]

K. Yoshida and R. B. Stein, “Characterization of signals and noise rejection with bipolar longitudinal

intrafascicular electrodes,” Biomedical Engineering, IEEE Transactions on, vol. 46, no. 2, pp. 226–234,

1999.

[82]

P. H. Veltink, B. K. Van Veen, J. J. Struijk, J. Holsheimer, and H. B. K. Boom, “A modeling study of nerve

fascicle stimulation,” Biomedical Engineering, IEEE Transactions on, vol. 36, no. 7, pp. 683–692, 1989.

[83]

S. M. Lawrence, G. S. Dhillon, and K. W. Horch, “Fabrication and characteristics of an implantable,

polymer-based, intrafascicular electrode,” Journal of Neuroscience Methods, vol. 131, no. 1–2, pp. 9–26,

Dec. 2003.

[84]

G. S. Dhillon, S. M. Lawrence, D. T. Hutchinson, and K. W. Horch, “Residual function in peripheral nerve

stumps of amputees: implications for neural control of artificial limbs,” The Journal of hand surgery, vol.

29, no. 4, pp. 605–615, 2004.

[85]

G. S. Dhillon, T. B. Krüger, J. S. Sandhu, and K. W. Horch, “Effects of short-term training on sensory and

motor function in severed nerves of long-term human amputees,” Journal of neurophysiology, vol. 93, no. 5,

pp. 2625–2633, 2005.

[86]

X. Zheng, J. Zhang, T. Chen, and Z. Chen, “Longitudinally implanted intrafascicular electrodes for

stimulating and recording fascicular physioelectrical signals in the sciatic nerve of rabbits,” Microsurgery,

vol. 23, no. 3, pp. 268–273, 2003.

[87]

N. M. Ledbetter, C. Ethier, E. R. Oby, S. D. Hiatt, A. M. Wilder, J. H. Ko, S. P. Agnew, L. E. Miller, and G.

A. Clark, “Intrafascicular stimulation of monkey arm nerves evokes coordinated grasp and sensory

responses,” Journal of Neurophysiology, vol. 109, no. 2, pp. 580–590, 2013.

[88]

S. Micera, L. Citi, J. Rigosa, J. Carpaneto, S. Raspopovic, G. Di Pino, L. Rossini, K. Yoshida, L. Denaro,

and P. Dario, “Decoding information from neural signals recorded using intraneural electrodes: toward the

development of a neurocontrolled hand prosthesis,” Proceedings of the IEEE, vol. 98, no. 3, pp. 407–417,

2010.

�[89]

R. Yang and W. Wang, “A numerical and experimental study on gap compensation and wavelength

selection in UV-lithography of ultra-high aspect ratio SU-8 microstructures,” Sensors and Actuators B:

Chemical, vol. 110, no. 2, pp. 279–288, Oct. 2005.

[90]

K. Horch, S. Meek, T. G. Taylor, and D. T. Hutchinson, “Object discrimination with an artificial hand using

electrical stimulation of peripheral tactile and proprioceptive pathways with intrafascicular electrodes,”

Neural Systems and Rehabilitation Engineering, IEEE Transactions on, vol. 19, no. 5, pp. 483–489, 2011.

[91]

M. S. Malagodi, K. W. Horch, and a a Schoenberg, “An intrafascicular electrode for recording of action

potentials in peripheral nerves.,” Annals of biomedical engineering, vol. 17, no. 4, pp. 397–410, Jan. 1989.

[92]

A. Benvenuto, S. Raspopovic, K. P. Hoffmann, J. Carpaneto, G. Cavallo, G. Di Pino, E. Guglielmelli, L.

Rossini, P. M. Rossini, and M. Tombini, “Intrafascicular thin-film multichannel electrodes for sensory

feedback: evidences on a human amputee,” in Engineering in Medicine and Biology Society (EMBC), 2010

Annual International Conference of the IEEE, 2010, pp. 1800–1803.

[93]

T. G. McNaughton and K. W. Horch, “Metallized polymer fibers as leadwires and intrafascicular

microelectrodes,” Journal of neuroscience methods, vol. 70, no. 1, pp. 103–107, 1996.

[94]

K. Yoshida, K. Hennings, and S. Kammer, “Acute performance of the thin-film longitudinal intra-fascicular

electrode,” in Biomedical Robotics and Biomechatronics, 2006. BioRob 2006. The First IEEE/RAS-EMBS

International Conference on, 2006, pp. 296–300.

[95]

K. Yoshida, D. Pellinen, D. Pivin, P. Rousche, and D. Kipke, “Development of the thin-film longitudinal

intra-fascicular electrode,” in Proceedings of the fifth Annual Conf. of the IFESS, 2000, pp. 279–284.

[96]

A. L. Hodgkin and A. F. Huxley, “Action potentials recorded from inside a nerve fibre,” Nature, vol. 144,

no. 3651, pp. 710–711, 1939.

[97]

A. L. Hodgkin and A. F. Huxley, “Resting and action potentials in single nerve fibres,” The Journal of

physiology, vol. 104, no. 2, pp. 176–195, 1945.

[98]

J. D. Green, “A simple microelectrode for recording from the central nervous system,” 1958.

[99]

W. R. Levick, “Another tungsten microelectrode,” Medical and Biological Engineering and Computing, vol.

10, no. 4, pp. 510–515, 1972.

[100]

C.-L. Li and H. Jasper, “Microelectrode studies of the electrical activity of the cerebral cortex in the cat,”

The Journal of physiology, vol. 121, no. 1, pp. 117–140, 1953.

[101]

I. Tasaki, “Nerve impulses in individual auditory nerve fibers of guinea pig,” J. Neurophysiol, vol. 17, no.

97, p. 122, 1954.

[102]

C. Welker, “Microelectrode delineation of fine grain somatotopic organization of SmI cerebral neocortex in

albino rat,” Brain research, vol. 26, no. 2, pp. 259–275, 1971.

[103]

M. L. Wolbarsht, E. F. MacNichol Jr, and H. G. Wagner, “Glass Insulated Platinum Microelectrode.,”

Science (New York, NY), vol. 132, no. 3436, p. 1309, 1960.

[104]

E. G. Merrill and A. Ainsworth, “Glass-coated platinum-plated tungsten microelectrodes,” Medical and

Biological Engineering and Computing, vol. 10, no. 5, pp. 662–672, 1972.

�[105]

K. D. Wise, J. B. Angell, and A. Starr, “An integrated-circuit approach to extracellular microelectrodes,”

Biomedical Engineering, IEEE Transactions on, no. 3, pp. 238–247, 1970.

[106]

K. L. Drake, K. D. Wise, J. Farraye, D. J. Anderson, and S. L. BeMent, “Performance of planar multisite

microprobes in recording extracellular single-unit intracortical activity,” Biomedical Engineering, IEEE

Transactions on, vol. 35, no. 9, pp. 719–732, 1988.

[107]

R. A. Normann, P. K. Campbell, and K. E. Jones, “Three-dimensional electrode device.” Google Patents,

01-Jun-1993.

[108]

P. K. Campbell, K. E. Jones, R. J. Huber, K. W. Horch, and R. a Normann, “A silicon-based, threedimensional neural interface: manufacturing processes for an intracortical electrode array.,” IEEE

transactions on bio-medical engineering, vol. 38, no. 8, pp. 758–68, Aug. 1991.

[109]

P. J. Rousche and R. A. Normann, “A method for pneumatically inserting an array of penetrating electrodes

into cortical tissue,” Annals of biomedical engineering, vol. 20, no. 4, pp. 413–422, 1992.

[110]

A. Branner, R. B. Stein, and R. A. Normann, “Selective stimulation of cat sciatic nerve using an array of

varying-length microelectrodes,” Journal of neurophysiology, vol. 85, no. 4, pp. 1585–1594, 2001.

[111]

E. M. Maynard, C. T. Nordhausen, and R. a Normann, “The Utah intracortical Electrode Array: a recording

structure for potential brain-computer interfaces.,” Electroencephalography and clinical neurophysiology,

vol. 102, no. 3, pp. 228–39, Mar. 1997.

[112]

A. Branner and R. A. Normann, “A multielectrode array for intrafascicular recording and stimulation in

sciatic nerve of cats,” Brain research bulletin, vol. 51, no. 4, pp. 293–306, 2000.

[113]

R. Bhandari, S. Negi, L. Rieth, R. a Normann, and F. Solzbacher, “A novel masking method for high aspect

ratio penetrating microelectrode arrays,” Journal of Micromechanics and Microengineering, vol. 19, no. 3,

p. 035004, Mar. 2009.

[114]

A. Branner, R. B. Stein, and R. A. Normann, “Selective Stimulation of Cat Sciatic Nerve Using an Array of

Varying-Length Microelectrodes Selective Stimulation of Cat Sciatic Nerve Using an Array of VaryingLength Microelectrodes,” pp. 1585–1594, 2013.

[115]

K. E. Jones, P. K. Campbell, and R. a Normann, “A glass/silicon composite intracortical electrode array.,”

Annals of biomedical engineering, vol. 20, no. 4, pp. 423–37, Jan. 1992.

[116]

a Branner and R. a Normann, “A multielectrode array for intrafascicular recording and stimulation in sciatic

nerve of cats.,” Brain research bulletin, vol. 51, no. 4, pp. 293–306, Mar. 2000.

[117]

R. a Parker, S. Negi, T. Davis, E. W. Keefer, H. Wiggins, P. a House, and B. Greger, “The use of a novel

carbon nanotube coated microelectrode array for chronic intracortical recording and microstimulation.,”

Conference proceedings : ... Annual International Conference of the IEEE Engineering in Medicine and

Biology Society. IEEE Engineering in Medicine and Biology Society. Conference, vol. 2012, pp. 791–4,

Aug. 2012.

[118]

S. Negi, R. Bhandari, and F. Solzbacher, “A novel technique for increasing charge injection capacity of

neural electrodes for efficacious and safe neural stimulation.,” Conference proceedings : ... Annual

International Conference of the IEEE Engineering in Medicine and Biology Society. IEEE Engineering in

Medicine and Biology Society. Conference, vol. 2012, pp. 5142–5, Aug. 2012.

�[119]

C. Kim and K. D. Wise, “A 64-site multishank CMOS low-profile neural stimulating probe,” Solid-State

Circuits, IEEE Journal of, vol. 31, no. 9, pp. 1230–1238, 1996.

[120]

Q. Bai, K. D. Wise, J. F. Hetke, and D. J. Anderson, “Microassembly structure for intracortical threedimensional electrode arrays BT - Proceedings of the 1996 18th Annual International Conference of the

IEEE Engineering in Medicine and Biology Society. Part 2 (of 5), October 31, 1996 - November 3, 1996,”

1996, no. 1, pp. 264–265.

[121]

K. L. Drake, K. D. Wise, J. Farraye, D. J. Anderson, and S. L. BeMent, “Performance of planar multisite

microprobes in recording extracellular single-unit intracortical activity.,” IEEE transactions on bio-medical

engineering, vol. 35, no. 9, pp. 719–32, Sep. 1988.

[122]

J. F. Hetke, J. L. Lund, K. Najafi, K. D. Wise, and D. J. Anderson, “Silicon ribbon cables for chronically

implantable microelectrode arrays,” Biomedical Engineering, IEEE Transactions on, vol. 41, no. 4, pp. 314–

321, 1994.

[123]

J. F. Hetke, J. C. Williams, D. S. Pellinen, R. J. Vetter, and D. R. Kipke, “3-D silicon probe array with

hybrid polymer interconnect for chronic cortical recording,” in Neural Engineering, 2003. Conference

Proceedings. First International IEEE EMBS Conference on, 2003, pp. 181–184.

[124]

X. Cui, V. A. Lee, Y. Raphael, J. A. Wiler, J. F. Hetke, D. J. Anderson, and D. C. Martin, “Surface

modification of neural recording electrodes with conducting polymer/biomolecule blends,” Journal of

biomedical materials research, vol. 56, no. 2, pp. 261–272, 2001.

[125]

X. Cui, J. F. Hetke, J. A. Wiler, D. J. Anderson, and D. C. Martin, “Electrochemical deposition and

characterization of conducting polymer polypyrrole/PSS on multichannel neural probes,” Sensors and

Actuators A: Physical, vol. 93, no. 1, pp. 8–18, 2001.

[126]

J. Wu and W. C. Tnag, “Microfabrication of High-Density Microelectrode Arrays for Peripheral Intraneural

Applications,” in Nano/Micro Engineered and Molecular Systems, 2007. NEMS’07. 2nd IEEE International

Conference on, 2007, pp. 1085–1088.

[127]

J. Wu, L. Yan, W. C. Tang, and F.-G. Zeng, “Micromachined Electrode Arrays with Form-Fitting Profile for

Auditory Nerve Prostheses,” in Engineering in Medicine and Biology Society, 2005. IEEE-EMBS 2005. 27th

Annual International Conference of the, 2006, pp. 5260–5263.

[128]

J. Wu, L. Yan, H. Xu, W. C. Tang, and F. G. Zeng, “A curvature-controlled 3D micro-electrode array for

cochlear implants,” in Solid-State Sensors, Actuators and Microsystems, 2005. Digest of Technical Papers.

TRANSDUCERS’05. The 13th International Conference on, 2005, vol. 2, pp. 1636–1639.

[129]

C. Pang, S. Musallam, Y.-C. Tai, J. W. Burdick, and R. A. Andersen, “Novel monolithic silicon probes with

flexible parylene cables for neural prostheses BT - 2006 International Conference on Microtechnologies in

Medicine and Biology, May 9, 2006 - May 12, 2006,” 2006, pp. 64–1424403383.

[130]

D. T. Kewley, M. D. Hills, D. A. Borkholder, I. E. Opris, N. I. Maluf, C. W. Storment, J. M. Bower, and G.

T. A. Kovacs, “Plasma-etched neural probes,” Sensors and Actuators A: Physical, vol. 58, no. 1, pp. 27–35,

1997.

[131]

T. H. Yoon, E. J. Hwang, D. Y. Shin, S. I. Park, S. J. Oh, S. C. Jung, H. C. Shin, and S. J. Kim, “A

micromachined silicon depth probe for multichannel neural recording.,” IEEE transactions on bio-medical

engineering, vol. 47, no. 8, pp. 1082–7, Aug. 2000.

�[132]

K. C. Cheung, K. Djupsund, Y. Dan, and L. P. Lee, “Implantable multichannel electrode array based on soi

technology,” Journal of Microelectromechanical Systems, vol. 12, no. 2, pp. 179–184, Apr. 2003.

[133]

P. Norlin, M. Kindlundh, A. Mouroux, K. Yoshida, and U. G. Hofmann, “A 32-site neural recording probe

fabricated by DRIE of SOI substrates,” Journal of Micromechanics and Microengineering, vol. 12, no. 4,

pp. 414–419, 2002.

[134]

G. Ensell, D. J. Banks, P. R. Richards, W. Balachandran, and D. J. Ewins, “Silicon-based microelectrodes

for neurophysiology, micromachined from silicon-on-insulator wafers.,” Medical & biological engineering

& computing, vol. 38, no. 2, pp. 175–9, Mar. 2000.

[135]

J. Wu, W. Feng, W. C. Tang, and F. G. Zeng, “A microsystem with varying-length electrode arrays for

auditory nerve prostheses,” in Engineering in Medicine and Biology Society, 2006. EMBS’06. 28th Annual

International Conference of the IEEE, 2006, pp. 3166–3169.

[136]

K.-K. Lee, J. He, A. Singh, S. Massia, G. Ehteshami, B. Kim, and G. Raupp, “Polyimide-based intracortical

neural implant with improved structural stiffness,” Journal of Micromechanics and Microengineering, vol.

14, no. 1, pp. 32–37, Jan. 2004.

[137]

K. Lee, A. Singh, J. He, S. Massia, B. Kim, and G. Raupp, “Polyimide based neural implants with stiffness

improvement,” Sensors and Actuators B: Chemical, vol. 102, no. 1, pp. 67–72, Sep. 2004.

[138]

S. Metz, a Bertsch, D. Bertrand, and P. Renaud, “Flexible polyimide probes with microelectrodes and

embedded microfluidic channels for simultaneous drug delivery and multi-channel monitoring of bioelectric

activity.,” Biosensors & bioelectronics, vol. 19, no. 10, pp. 1309–18, May 2004.

[139]

T. Stieglitz, H. rg Beutel, M. Schuettler, and J.-U. Meyer, “Micromachined, polyimide-based devices for

flexible neural interfaces,” Biomedical Microdevices, vol. 2, no. 4, pp. 283–294, 2000.

[140]

T. Boretius, J. Badia, A. Pascual-Font, M. Schuettler, X. Navarro, K. Yoshida, and T. Stieglitz, “A

transverse intrafascicular multichannel electrode (TIME) to interface with the peripheral nerve.,” Biosensors

& bioelectronics, vol. 26, no. 1, pp. 62–9, Sep. 2010.

[141]

T. Suzuki, S. Takeuchi, D. Ziegler, O. Fukayama, Y. Morishita, D. Frutiger, K. Ishii, and K. Mabuchi,

“Development of flexible neural probes and their application to rat brain interfaces BT - SICE Annual

Conference 2004, August 4, 2004 - August 6, 2004,” 2004, pp. 1931–1934.

[142]

S.-C. Chuang, C.-H. Chen, H.-C. Su, S.-R. Yeh, and D.-J. Yao, “Design and fabrication of flexible neural

microprobe for three dimensional assembly BT - 23rd IEEE International Conference on Micro Electro

Mechanical Systems, MEMS 2010, January 24, 2010 - January 28, 2010,” 2010, pp. 1003–1006.

[143]

D. Egert, R. L. Peterson, and K. Najafi, “Parylene microprobes with engineered stiffness and shape for

improved insertion BT - 2011 16th International Solid-State Sensors, Actuators and Microsystems

Conference, TRANSDUCERS’11, June 5, 2011 - June 9, 2011,” 2011, pp. 198–201.

[144]

S. Takeuchi, Y. Yoshida, D. Ziegler, K. Mabuchi, and T. Suzuki, “Parylene flexible neural probe with micro

fluidic channel BT - 17th IEEE International Conference on Micro Electro Mechanical Systems (MEMS):

Maastricht MEMS 2004 Technical Digest, January 25, 2004 - January 29, 2004,” 2004, pp. 208–211.

[145]

C. Pang, “Parylene Technology for Neural Probes Applications,” vol. 2008, 2008.

�[146]

P. J. Rousche, D. S. Pellinen, D. P. Pivin Jr, J. C. Williams, and R. J. Vetter, “Flexible polyimide-based

intracortical electrode arrays with bioactive capability,” Biomedical Engineering, IEEE Transactions on,

vol. 48, no. 3, pp. 361–371, 2001.

[147]

M. Y. Cheng, K. L. Tan, T. B. Yee, and M. Y. Je, “Three-Dimensional Flexible Polyimide Based Probe

Array with Stiffness Improvement by Using Biodegradable Polymer,” Advanced Materials Research, vol.

651, pp. 517–522, 2013.

[148]

K. Lee, J. He, and L. Wang, “Benzocyclobutene (bcb) based neural implants with microfluidic channel,” in

Engineering in Medicine and Biology Society, 2004. IEMBS’04. 26th Annual International Conference of

the IEEE, 2004, vol. 2, pp. 4326–4329.

[149]

K. Lee, S. Massia, and J. He, “Biocompatible benzocyclobutene-based intracortical neural implant with

surface modification,” Journal of Micromechanics and Microengineering, vol. 15, no. 11, p. 2149, 2005.

[150]

K. Lee, J. He, R. Clement, S. Massia, and B. Kim, “Biocompatible benzocyclobutene (BCB)-based neural

implants with micro-fluidic channel,” Biosensors and Bioelectronics, vol. 20, no. 2, pp. 404–407, 2004.

[151]

Z. Fan, J. M. Engel, J. Chen, C. Liu, and S. Member, “Parylene Surface-Micromachined Membranes for

Sensor Applications,” vol. 13, no. 3, pp. 484–490, 2004.

[152]

D. Pellinen, T. Moon, R. Vetter, R. Miriani, and D. Kipke, “Multifunctional flexible parylene-based

intracortical microelectrodes.,” Conference proceedings : ... Annual International Conference of the IEEE

Engineering in Medicine and Biology Society. IEEE Engineering in Medicine and Biology Society.

Conference, vol. 5, pp. 5272–5, Jan. 2005.

[153]

S. Takeuchi, T. Suzuki, K. Mabuchi, and H. Fujita, “3D flexible multichannel neural probe array,” Journal

of Micromechanics and Microengineering, vol. 14, no. 1, pp. 104–107, 2004.

[154]

P. R. Kennedy, “Implantable neural electrode.” Google Patents, 01-Aug-1989.

[155]

J. Bartels, D. Andreasen, P. Ehirim, H. Mao, S. Seibert, E. J. Wright, and P. Kennedy, “Neurotrophic

electrode: method of assembly and implantation into human motor speech cortex.,” Journal of neuroscience

methods, vol. 174, no. 2, pp. 168–76, Sep. 2008.

[156]

P. R. Kennedy, “The cone electrode: a long-term electrode that records from neurites grown onto its

recording surface,” Journal of neuroscience methods, vol. 29, no. 3, pp. 181–193, 1989.

[157]

J. S. Brumberg, E. J. Wright, D. S. Andreasen, F. H. Guenther, and P. R. Kennedy, “Classification of

intended phoneme production from chronic intracortical microelectrode recordings in speech-motor cortex,”

Frontiers in Neuroscience, vol. 5, 2011.

[158]

F. H. Guenther, J. S. Brumberg, E. J. Wright, A. Nieto-Castanon, J. A. Tourville, M. Panko, R. Law, S. A.

Siebert, J. L. Bartels, and D. S. Andreasen, “A wireless brain-machine interface for real-time speech

synthesis,” PloS one, vol. 4, no. 12, p. e8218, 2009.

[159]

P. Kennedy, D. Andreasen, J. Bartels, P. Ehirim, H. Mao, M. Velliste, T. Wichmann, and J. Wright,

“Making the lifetime connection between brain and machine for restoring and enhancing function.,”

Progress in brain research, vol. 194, p. 1, 2011.

[160]

B. Matthews and M. Clements, “Joint waveform and firing rate spike-sorting for continuous extracellular

traces,” in Signals, Systems and Computers (ASILOMAR), 2011 Conference Record of the Forty Fifth

Asilomar Conference on, 2011, pp. 1689–1693.

�[161]

J. P. Seymour and D. R. Kipke, “MICROELECTRODE WITH LATERALLY EXTENDING PLATFORM

FOR REDUCTION OF TISSUE ENCAPSULATION.” US Patent 20,120,323,103, 20-Dec-2012.

[162]

J. P. Seymour and D. R. Kipke, “Neural probe design for reduced tissue encapsulation in CNS.,”

Biomaterials, vol. 28, no. 25, pp. 3594–607, Sep. 2007.

[163]

J. P. Seymour, S. Member, and D. R. Kipke, “for Reduced Tissue Encapsulation,” no. 1, pp. 4606–4609,

2006.

[164]

T. D. Yoshida Kozai, N. B. Langhals, P. R. Patel, X. Deng, H. Zhang, K. L. Smith, J. Lahann, N. a. Kotov,

and D. R. Kipke, “Ultrasmall implantable composite microelectrodes with bioactive surfaces for chronic

neural interfaces,” Nature Materials, vol. 11, no. 12, pp. 1065–1073, Nov. 2012.

[165]

E. Azemi, C. F. Lagenaur, and X. T. Cui, “The surface immobilization of the neural adhesion molecule L1

on neural probes and its effect on neuronal density and gliosis at the probe/tissue interface,” Biomaterials,

vol. 32, no. 3, pp. 681–692, 2011.

[166]

N. Gomez and C. E. Schmidt, “Nerve growth factor‐immobilized polypyrrole: Bioactive electrically

conducting polymer for enhanced neurite extension,” Journal of Biomedical Materials Research Part A, vol.

81, no. 1, pp. 135–149, 2007.