SPECIAL SECTION ON ADVANCED SENSOR TECHNOLOGIES

ON WATER MONITORING AND MODELING

Received July 25, 2018, accepted September 14, 2018, date of publication September 28, 2018, date of current version October 25, 2018.

Digital Object Identifier 10.1109/ACCESS.2018.2872506

Sensor Failure Detection and Faulty Data

Accommodation Approach for Instrumented

Wastewater Infrastructures

KARTHICK THIYAGARAJAN , (Member, IEEE), SARATH KODAGODA, (Member, IEEE),

LINH VAN NGUYEN , (Member, IEEE), AND RAVINDRA RANASINGHE, (Member, IEEE)

Centre for Autonomous Systems, University of Technology Sydney, Sydney, NSW 2007, Australia

Corresponding author: Karthick Thiyagarajan (karthick.thiyagarajan@uts.edu.au)

This work was supported by the Data Analytics on Sewers Project through in part by the Sydney Water Corporation, in part by the

Melbourne Water Corporation, in part by the Water Corporation (WA), and in part by the South Australian Water Corporation.

ABSTRACT In wastewater industry, real-time sensing of surface temperature variations on concrete sewer

pipes is paramount in assessing the rate of microbial-induced corrosion. However, the sensing systems are

prone to failures due to the aggressively corrosive environmental conditions inside sewer assets. Therefore,

reliable sensing in such infrastructures is vital for water utilities to enact efficient wastewater management.

In this context, this paper presents a sensor failure detection and faulty data accommodation (SFDFDA)

approach that aids to digitally monitor the health conditions of the sewer monitoring sensors. The SFDFDA

approach embraces seasonal autoregressive integrated moving average model with a statistical hypothesis

testing technique for enabling temporal forecasting of sensor variable. Then, it identifies and isolates

anomalies in a continuous stream of sensor data whilst detecting early sensor failure. Finally, the SFDFDA

approach provides reliable estimates of sensor data in the event of sensor failure or during the scheduled

maintenance period of sewer monitoring systems. The SFDFDA approach was evaluated by using the surface

temperature data sourced from the instrumented wastewater infrastructure and the results have demonstrated

the effectiveness of the SFDFDA approach and its applicability to surface temperature monitoring sensor

suites.

INDEX TERMS Anomalies detection, faulty data accommodation, forecasting, SARIMA model, sensor

failure detection, sensor monitoring, sewer corrosion, time series modeling, wastewater infrastructure.

I. INTRODUCTION

Sensors are essential constituents of any critical infrastructure

monitoring system. They play an important role in maintaining the system safety and reliability [1], [2]. However, in realtime systems, sensors can provide spurious data owing to

different erratic factors including the exposure of the sensor

to a harsh environment and inherent sensing malfunctions [3].

Spurious data emanating from the sensors can be momentary or long-lasting. Momentary faulty data are likely to

happen randomly due to changes in sensor characteristics

and electronics [4]. Those temporary data should not be

attributed to sensor failures. Instead, they need to be isolated

as anomalies. However, the continuous spurious data is probably an indication of a sensor failure and results in downgrading the performance of an entire monitoring system.

Therefore, early sensor failure detection is significant for

56562

pertinent intervention strategies while monitoring the environmental phenomena of critical infrastructure assets.

An urban sewerage system is an ideal example of a critical

underground infrastructure system. Presently, the concrete

pipes in sewer systems are suffering from a higher rate

of structural degradation due to hydrogen sulphide-induced

concrete corrosion [5]. Because of the increasing corrosion

in sewers, the wastewater industry around the globe incurs

economic repercussions that are estimated to be in the order

of billion dollars [6]. In order to manage the sewer infrastructure effectively, the water utilities rely on the sensor

monitoring systems that acquire information-rich data about

the corrosion. In this context, the temperature on the concrete

surface was identified as an important observation that can

provide vital data to the models predicting the rate of sewer

corrosion [7], [8].

2169-3536 2018 IEEE. Translations and content mining are permitted for academic research only.

Personal use is also permitted, but republication/redistribution requires IEEE permission.

See http://www.ieee.org/publications_standards/publications/rights/index.html for more information.

VOLUME 6, 2018

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

Currently, there is no reliable sensor system available to

monitor temporal dynamics of surface temperature under

aggressively corrosive environmental conditions of the sewer.

For that reason, this collaborative research between the University of Technology Sydney and four government-owned

water utilities aims to develop an advanced sensor suite for

monitoring surface temperature variations in sewer pipes.

In this regard, a sensor suite was developed and deployed in

sewer systems for over three months between 3rd November 2016 and 07th February 2017 in the municipal sewer

of the Sydney city in Australia. The field testing campaign

has demonstrated that the sensor suite is robust and capable

of monitoring for long-term in sewer conditions. However,

the confined sewer systems are typically hostile environments to both sensor monitoring and human inspections.

Since the sensor system cannot be physically monitored every

time, automatic sensor failure detection approaches become

a salient need of the sewer monitoring system.

The collaborative research reported in this paper focuses

on a SFDFDA approach for a sewer monitoring application.

The work motivates the development of a SFDFDA approach

that possesses the following three properties:

•

•

•

Forecasting: Forecasting is a process of predicting the

future trends of data based on the collected historical

data trends by using a mathematical model [9]. The surface temperature data measured by the sensor deployed

inside the sewer pipe is represented as a time-series

data. By using the past temporal dynamics of the surface

temperature variable, the future trends will be foreseen

by using a mathematical model. The forecast data will be

acting as a virtual sensor to compare against the actual

upcoming sensor data from the sewer systems for detecting anomalies and sensor failures. Also, in the event of

scheduled sensor maintenance, the forecast data will be

potentially used to replace the actual measurements.

Anomalies detection and isolation: Anomalies are unexpected patterns in the data that do not comply with the

normal behavioral trends [10]. So, the sensor data that

suddenly deviates or rare occurrences from the normal

pattern is flagged as an anomaly [11]. Hence, it is important to detect and isolate anomalies.

Sensor failure detection and accommodation: Sensors

are prone to fail over time. Detecting early sensor failure

will enhance the present sewer monitoring capabilities

for effective management of sewer infrastructure assets.

Also, it prevents the faulty data to train the forecasting model. Once the sensor failure has been detected,

the faulty sensor data needs to be accommodated with

the predicted data [12], [13] and this process will be

continued until operator addresses the issue.

In this paper, SFDFDA approach using Seasonal Autoregressive Integrated Moving Average (SARIMA) model is

proposed with sewer monitoring system as the application

domain. The major contributions of our proposed scheme are

enumerated as follows:

VOLUME 6, 2018

1) SARIMA model based forecasting for the surface temperature variable from sewer pipes was implemented to

form a framework for detecting anomalies and sensor

failure.

2) By using the statistical approach, anomalies present in

the sensor data were detected and isolated.

3) Sensor failure detection model was implemented by

using forecasting technique and the faulty data is

accommodated by using the forecast values.

The remainder of this paper is organized as follows:

Section II presents the brief review of related work to

the SFDFDA approach. Section III describes the sensor suite. Section IV presents the SARIMA model for

forecasting the surface temperature variable. Section V

illustrates the methodology for the proposed SFDFDA

approach. Section VI evaluates the SFDFDA approach and

finally, Section VII concludes the paper.

II. BRIEF REVIEW OF RELATED WORK

The state-of-the-art method for implementing the SFDFDA

approach through hardware redundancy has been proposed

in [14] and [15], where the measurement variable is obtained

by using several identical sensors. Then, a voting logic is used

to detect the faulty sensor [16], [17]. In the sensing applications where the sensors are expensive, analytical redundancy

approaches are popular [16]. In this approach, the signal

between the sensor model and sensor is compared to generate

the residual error. Then, the sensor failure is detected by setting a threshold logic for the generated residual error values.

In the event of detecting the sensor failure, the predicted data

is used for sensor failure accommodation [18].

Computational modeling using artificial neural networks is

widely used for detecting sensor failures mainly because of its

adaptability to dynamic environments [19], [20]. This method

works by training the neurons and developing a structure

based on the training data for comparing with the sensor

measurements to detect the sensor failure [21]. On the other

hand, time series based forecasting models that represent

sensor data as a linear time series was used for detecting early

sensor failure [22]. There are several time series forecasting

techniques available in the literature like Random Walk (RW)

method, Simple Exponential Smoothing (SES) method and

Autoregressive Moving Average (ARMA) Model [23]. In the

RW model, the variable value takes the independent random step. This method takes an assumption that past data

is not informative and only the present observation is useful [24]. The SES model is used in applications of forecasting

seasonal data. However, it is not an appropriate model in

applications where the data has trends [25]. The ARMA

method is an important method in time series forecasting [26].

This method is a stationary stochastic process that combines

the Autoregressive (AR) model and Moving Average (MA)

model.

G.E.P. Box and G.M. Jenkins extended the ARMA model

to the ARIMA model, which integrates the AR and MA

parts of the model with differencing [27], [28]. Among the

56563

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

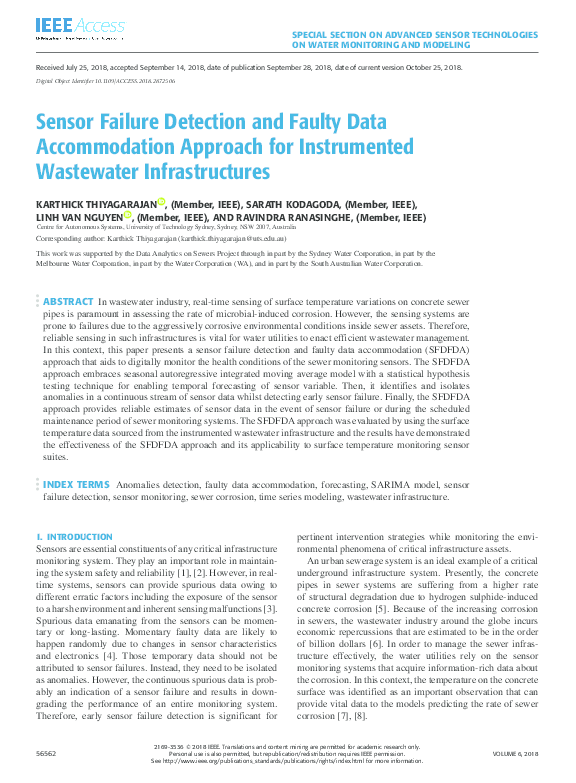

FIGURE 1. Field deployment of sensor suite displaying the sensing system installed inside the sewer pipe near the head-space and access station

constructed outside the sewer pipe for data monitoring and acquisition.

time series forecasting methods, the ARIMA model has

been widely used over the last two decades for forecasting applications [29]. The difference between the ARMA

and the ARIMA model is that the ARIMA model converts

the non-stationary data into stationary data for predicting

the linear time series [26]. For the data that shows seasonal trends, the ARIMA model is extended to the SARIMA

model [30]–[32]. Although ARIMA and SARIMA models

have been used for forecasting applications in different

sectors [33]–[37], their application in forecasting variables

inside sewer has not been reported. This work utilizes the

SARIMA for forecasting the surface temperature variable.

In order to achieve better forecasting results, the forecast

model needs to be provided with anomaly-free data during

model training. Therefore, anomaly detection is vital for the

application motivated in this work. Methods based on clustering, support vector machine and kernel functions are used for

anomalies detection [38]–[40]. However, those approaches

are dependent on static routing trees or assigning threshold

values to the data streams [3]. In contrast, our work focuses

on detecting anomalies through statistical techniques for each

sensor measurements. By using the stochastic time series

models like SARIMA, anomalies can be detected in the data

streams [41], [42]. Once the anomaly is detected, the faulty

sensor reading is isolated. Then, the faulty information needs

to be accommodated with the reliable value [43].

56564

III. SENSOR SUITE

For monitoring the diurnal variations of surface temperature in sewer pipes, a custom-built sensor suite meeting the

requirements specified by the sewer operators was designed

and developed using an infrared radiometer sensor. This

sensor was housed in a tailor-made enclosure and installed

near the head-space of the confined concrete sewer pipe. The

sensor measures the thermal radiations of the exposed sewer

surface and produces an output in the form of an electrical

signal. This signal is transmitted to the access station constructed outside the sewer pipe for processing. Fig. 1 shows

the installation of temperature sensor inside the sewer and

access station constructed outside the sewer. To the best of

our knowledge, the sensor suite used in this work is the

first one to demonstrate long-term temporal monitoring of

surface temperature dynamics inside aggressively corrosive

sewer conditions through non-contact measurements. The

SFDFDA approach proposed in this work is applied to the

aforementioned sensor suite.

IV. FORECASTING SURFACE TEMPERATURE DATA

USING SARIMA MODEL

This section elaborates the forecasting technique employed

in this paper by using the surface temperature data sourced

from the instrumented wastewater infrastructure.

VOLUME 6, 2018

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

q moving average term.

A. SURFACE TEMPERATURE DATA FROM THE SENSOR

SUITE

The surface temperature data coming from the sensor suite

can be observed as a time series St , where the values of

the data are at equally spaced times t, t − 1, t − 2, . . . by

St , St−1 , St−2 , . . .. The time interval between the two sensor

measurements is one hour.

B. FORMULATION OF THE SARIMA MODEL

The ARIMA model is a combination of two independent

models namely AR model and MA model with finite differencing of data points. Mathematically, the AR part of the

ARIMA model can be defined as in (1), which is an autoregressive process of order p. It can be succinctly expressed as

AR(p). This AR(p) regresses the evolving variable against its

prior values in the series.

St−1 + φ2e

St−2 + . . . + φpe

St−p + εt (1)

AR(p)t = c + φ1e

where AR(p)t is the actual value of AR(p) at time period

t, φ1 , φ2 , . . . , φp are the finite set of weight parameters of

the AR(p) with c as a constant and p as the order of the

model AR(p) with e

St−1 , e

St−2 , .., e

St−p as previous deviations

from the mean value. The εt is the random shock and it is

assumed to be a white noise process [44]. The εt is identically

distributed i.e. εt ∼ IN (µ, σ 2 ), where the mean µ = 0 and

a constant variance σ 2 [45]. The MA part of the ARIMA

model is mathematically defined in (2) and it can be called as

a moving average process of order q. It can be expressed as

MA(q). This MA(q) model uses its past errors as the explanatory variables.

MA(q)t = c + εt + θ1 εt−1 + θ2 εt−2 + . . . + θq εt−q

(2)

where MA(q)t is the actual value of MA(q) at time period

t, θ1 , θ2 , . . . , θq are the finite set of weight parameters of

the MA(q) with c as a constant and q as the order of the

model MA(q). Similar to AR(p), the εt of MA(q) is assumed to

be a white noise process with identically distributed random

variables with zero mean and constant variance. Both AR(p)

and MA(q) are combined together to form an ARMA model.

The model is mathematically defined in (3) and it can be

expressed as ARMA(p, q).

AR(p)t + MA(q)t = c + φ1e

St−1 + φ2e

St−2

e

+ . . . + φp St−p + θ1 εt−1

+ θ2 εt−2 + . . . + θq εt−q + εt

(3)

where the predictor is AR(p)t + MA(q)t of the ARMA(p, q)

as it includes the prior values of AR(p) and past errors of

MA(q). The AR(p)t + MA(q)t expression can be denoted as

e

St . In ARMA(p, q), the order value p of AR(p) model and q of

MA(q) model are not greater than 2 [46]. Upon simplification

(3) is reduced to (4). The constant term c is omitted for

simplicity [47] and (4) is rearranged to (5), where the order

of the models p and q denotes the p autoregressive term and

VOLUME 6, 2018

Set −

p

X

n=1

Set = c + εt +

φne

St−n = εt +

q

X

p

X

n=1

φne

St−n +

q

X

θm εt−m

(4)

m=1

(5)

θm εt−m

m=1

In time series data, the backshift operator B governs a value

in the series to produce its prior value [48]. Mathematically,

it is defined in (6), where k is the time series backward

observation of the time period.

Bk Set = e

St−k

(6)

Generally, the ARMA(p, q) model is manipulated by

using (6). By using the lag operator, the ARMA(p, q) model

equation in (5) can be expressed as in (7).

�

�

�

�

p

q

X

X

n e

m

1−

(7)

φn B St = 1 +

θm B εt

n=1

m=1

The ARMA(p, q) model is suitable only for stationary time

series data. However, the sensor data emerging from the

sewer pipes possess non-stationary behavior. In order to process the non-stationary nature of sewer data, the ARIMA

model is proposed for the application reported in this work

to forecast surface temperature measurements. This model

obtains homogeneous non-stationary behavior by supposing

a suitable d th difference value of the process to the stationary ARMA(p, q). The differencing is mathematically defined

in (8), where the (1 − B)d = 1d . Mathematically, the general

form of ARIMA model can be defined as in (9) and it can

expressed as ARIMA(p, d, q).

Set = 1d Set

�

�

�

�

q

p

X

X

θm Bm εt

φn Bn 1d Set = 1 +

1−

(8)

(9)

m=1

n=1

where the p, d and q are the integers referring to the order

of autoregressive, integrated and moving average parts of the

ARIMA(p, d, q) model. The integer d governs the level of

differencing. SARIMA is employed in applications where

the time series data presents seasonal changes [48]. The

SARIMA is denoted as SARIMA(p, d, q)(P, D, Q)Sp , where

P is the seasonal autoregressive parameter, D is the degree

of seasonal differencing parameter, Q is the seasonal moving

average parameter and the subscript Sp denotes the seasonal

period this stochastic model. The forecasts of sewer surface

temperature variable by using SARIMA(p, d, q)(P, D, Q)Sp is

given by (10), where the 8 and 2 are the weight parameters

of seasonal autoregressive term and seasonal moving average

term respectively.

�

��

�

p

P

X

X

Sp

n

1−

1−

8n B (1)d (1Sp )D Set

φn B

n=1

n=1

�

�

��

q

Q

X

X

Sp

m

= 1+

1+

2m B εt

θm B

m=1

(10)

m=1

56565

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

C. AUTOMATIC SELECTION OF ARIMA MODEL

PARAMETERS

For the SARIMA(p, d, q)(P, D, Q)Sp model, the order parameters p, d, q, P, D and Q are automatically determined by

using Hyndman and Khandakar algorithm [49] [50]. The

differencing terms d and D are computed by performing the

unit root test such as the Kwiatkowski Phillips Schmidt Shin

(KPSS) test. If the values of differencing parameters d and

D are known, then the algorithm [49] selects the values for

p, q, P and Q through minimization of an Akaike information

criterion (AIC) given in (11).

AIC = −2 log(L) + 2(p + q + P + Q + Kn )

(11)

where L is the maximized likelihood of the forecasting model

SARIMA(p, d, q)(P, D, Q)Sp , fitted to the differenced data

(1)d (1Sp )D Set and Kn is the number of parameters estimated

to compute one-step ahead forecasts.

D. COMPUTING PREDICTION INTERVALS OF THE

FORECASTS AT ANY LEAD TIME

A prediction interval is an estimate of an upper and lower

bound of an interval in which the observable variable of the

future is expected to lie with a specified probability based

on the past observed values [50], [51]. Considering that g′ s

are Gaussian distribution with standard deviation σg , then the

probability distribution (St+f |St , St−1 , St−2 , . . .) of a future

observable value St+f of the process will be normal with

mean Ŝ(f ) and standard distribution is given in (12) [46].

�1/2

�

f −1

X

2

σ (f ) = 1 +

ψj

σg

(12)

j=1

h�

� �

�i

The variate St+f − Ŝt (f ) / σ (f ) will posses a unit

normal distribution. Therefore, for St+f , Ŝf ± µλ/2 σ (f ) will

provide the bounds of the prediction interval with probability

(1−λ). µλ/2 is the deviate transcended by a proportion of λ/2

of the unit normal distribution. Mathematically, the prediction

interval for the SARIMA(p, d, q)(P, D, Q)Sp model can be

computed by using (13) [46].

�1/2

�

f −1

X

Ŝ t+f (±) = Ŝ t (f ) ± µλ/2 1 +

σg

(13)

ψj2

j=1

where µλ/2 are the percentiles of the standard normal distribution. In this paper µλ/2 = 95%. The forecast value

Ŝt+f coming from the SARIMA(p, d, q)(P, D, Q)Sp model

with the probability of 1 − λ will lie between the upper

�interval Ŝt+f (+) and lower interval Ŝt+f (−), i.e. Probability

Ŝt+f (−) < Ŝt+f < Ŝt+f (+) .

V. SFDFDA APPROACH

The SFDFDA approach proposed in this work presents

advanced data analytics solution by combining predictive

analytics and diagnostic analytics methods. The predictive analytics component of the SFDFDA approach features SARIMA(p, d, q)(P, D, Q)Sp model for forecasting the

56566

Algorithm 1 Pseudocode for the SARIMA Forecast

for all i ∈ 1 : length[R(t)i ] do

Computing p, d, q, P, D and Q

Forecasting [Ŝt+f ]i

Computing [Ŝt+f (−)]i and [Ŝt+f (+)]i

i = i + 24

end for

surface temperature variable. The forecast data Ŝt+f will

function as a virtual sensor. The forecasting process of the

SARIMA(p, d, q)(P, D, Q)Sp model involves three main steps.

The first step of the forecasting model uses the time-series

data to provide the surface temperature sensor data from

4th November 2016 to 10th November 2016 for training the

forecast model. The presence of anomalies will downgrade

the prediction performance of the forecast model. Therefore, it is important to detect the anomalies and isolate them

before supplying the data for training the forecast model.

In this work, we compared the trends of sensor data with

the benchmark sensor measurements before supplying the

data for training. The initial training data contains 168 data

points. Then, the SARIMA(p, d, q)(P, D, Q)Sp model parameters are determined in the second step by invoking the Hyndman and Khandakar algorithm for automatic selection of

p, d, q, P, D and Q, and then building a forecast model using

the determined parameters. Finally in the third step, the model

forecasts the surface temperature data Ŝt+f for the next day

containing 24 data points with Ŝt+f (−) and Ŝt+f (+) values.

The pseudocode for SARIMA forecast process is presented

in Algorithm 1.

The diagnostic analytics component of the SFDFDA

approach presents statistical techniques for detecting sensor

failure and anomalies using the data from the surface temperature sensor and SARIMA(p, d, q)(P, D, Q)Sp model forecasts. This component employs statistical hypothesis testing

for computing probability value (p-value) to detect anomalies and sensor failure. A p-value is obtained by performing Pearson’s chi-squared test, denoted as χ 2 . It determines

the divergence of the observed sensor data from the values

that would be forecasted using SARIMA(p, d, q)(P, D, Q)Sp

model under the null hypothesis of no association. The chisquared distribution χdf2 is used in the χ 2 for goodness of fit

of the observed sensor data distribution to a distribution of

SARIMA(p, d, q)(P, D, Q)Sp model data. The χdf2 is characterized by degrees of freedom df , whose value is one less than

the number of total data points in the data set used to compute

one χ 2 measure. A sliding window mechanism [16], [21] is

incorporated within the SFDFDA framework to provide a

set of data for computing p-value. This mechanism is illustrated in Fig. 2, where the sliding window of size WL data

points keeps moving as the time t progresses. In the proposed

SFDFDA approach, WL = n. So, the χdf2 of observed sensor

data and the SARIMA(p, d, q)(P, D, Q)Sp model data takes n

data points for computing χ 2 . Therefore, the df of that χ 2

VOLUME 6, 2018

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

Algorithm 3 Psuedocode - Function P-Value CALCULATOR

/* FUNCTION PARAMETERS */

[R(t)]i , [Ŝt+f ]i , WL

/* INITIALIZATION OF VARIABLES */

df = WL − 1

FIGURE 2. Illustration of the sliding window mechanism at time period t .

Algorithm 2 Pseudocode - Function CHI CALCULATOR

/* FUNCTION PARAMETERS */

[R(t)]i , [Ŝt+f ]i , WL

/* INITIALIZATION OF VARIABLES */

Total = 0

for all i ∈ 1 : (1 + �WL ) do

Total = Total + [R(t)]i − [Ŝt+f ]i

end for

return(Total)

�2

/[Ŝt+f ]i

will be WL − 1 forP

all sliding windows. The χ 2 measure for

the testing dataset

of size WL is measured using (14):

i2

h

i=W

XL (Rt )i − (Ŝt+f )i

χ2 =

(14)

(

Ŝ

)

t+f

i

i=1

where i is the instantaneous time, χ 2 is the cumulative

statistic of Pearson’s chi-squared test, Rt is the observed

surface temperature sensor data, Ŝt+f is the expected data

resulting from the SARIMA(p, d, q)(P, D, Q)Sp model. The

pseudocode for determining χ 2 of each sliding window is

presented in Algorithm 2.

Since the value of WL is static for all the computations, df

will be same for all the computations as well with the value

of df = n − 1. After computing χ 2 and df , it is therefore

important to set a critical significance level to determine the

p-value for each sliding window. The critical significance

level is denoted as α. Typically, in the proposed SFDFDA

approach α is 5% i.e., α = 0.05. Given the α and df , the contingency table that shows multivariate frequency distribution

of the variables will be referred. This table provides values

with respect to df and α. Then, by comparing the measures

of χ 2 with χdf2 p-value is given by (15).

P − value = P(χdf2 ,α ≥ χ 2 )

(15)

For the critical level of α, the statistical hypothesis testing

provides significant value only if the is χdf2 ,α greater than

the χ 2 . In case of χ 2 being greater than the χdf2 ,α , the statistical hypothesis testing provides a non-significant value. The

determination of significant and non-significant value plays

a paramount role in the SFDFDA approach for detecting the

anomalies and sensor failure.

VOLUME 6, 2018

χ 2 = chiCalculator(R(t)]i , [Ŝt+f ]i , WL )

P − value = 1 − chi2Cdf (χ 2 , df )

return(P − value)

In a sliding window, if the p-value is a significant value

i.e., p-value > 0.95, then the sensor data measurements of

that particular sliding window will be pushed to the training

dataset of the SARIMA(p, d, q)(P, D, Q)Sp model for forecasting future values. Consequently, the sliding window progresses to the next window for performing statistical testing.

This process iterates as long as the surface temperature provides measurements.

In the case of sliding window producing a non-significant

p-value i.e., p-value < 0.95, then the sensor data measurements of that particular window is examined to check the

presence of anomalies or any indications of early sensor

failure. Each surface temperature measurement within that

sliding window is evaluated with the prediction intervals.

Precisely, the condition defined in (16) is examined.

� � �� � � ��

��

��

Ŝt+f (−)

< Rt

(16)

< Ŝt+f (+)

i

i

i

where i is the instantaneous time. If the condition in (16) is not

satisfied, then there arise three scenarios. In all the scenarios,

the SFDFDA approach will look for continuity of individual

data of sensor measurements present outside of Ŝt+f (−) or

Ŝt+f (+). The three scenarios are as follows:

• In the first scenario where one or two (Rt )i present

outside of Ŝt+f (−) or Ŝt+f (+), then that respective

sensor data is regarded as an anomaly. Subsequently,

the SFDFDA approach performs data accommodation

process,

� where the value of (Rt )i is accommodated by

Ŝt+f i .

• In the second scenario where there are three or more

(Rt )i present outside of Ŝt+f (−) or Ŝt+f (+) and their

continuity is less than three successive times, (Rt )i is

still flagged as an anomaly. However, a sensor failure

warning will be issued for inspection. In addition to the

warning signal, the SFDFDA approach undergoes data

accommodation �process to replace the faulty (Rt )i with

respective Ŝt+f i .

• Finally, in the third scenario where there are more than

one (Rt )i present outside of Ŝt+f (−) or Ŝt+f (+) and

their continuity is three or more successive times in one

sliding window, then a signal of early sensor failure is

issued. In this scenario, the SFDFDA approach will also

invoke data accommodation�process to replace the faulty

(Rt )i with respective Ŝt+f i . The SFDFDA approach

56567

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

Algorithm 4 Psuedocode - Detecting Sensor Failure and

Anomalies, Data Accommodation Process

/* FUNCTION PARAMETERS */

P − value, [R(t)]i , [Ŝt+f (−)]i , [Ŝt+f ]i , [Ŝt+f (+)]i , WL

Timestamp

/* INITIALIZATION OF VARIABLES */

COUNTERS : Total = 0; Warning_Count = 0;

Failure_Count = 0; Previous_ID = 0;

FLAG : Failed = FALSE

if (!(P − value > α)) then

for all i ∈ 1 : (1 + WL ) do

if (![R(t)]i ≥ [Ŝt+f (−)]i &&[R(t)]i ≤ [Ŝt+f (+)]i )

then

/* Evaluating Sensor Failure Condition*/

if (i == Previous_ID + 1) then

(Failure_Count = Failure_Count + 1)

if (Failure_Count >= 3) then

Message: Sensor_Failure_(Timestamp)

(Failed = TRUE)

end if

end if

Previous_ID = i

/* Evaluating Sensor Warning Condition */

if (!Failed) then

(Warning_Count = Warning_Count + 1)

if (Warning_Count >= 3) then

Message: Sensor_Warning_(Timestamp)

end if

end if

/* Anomaly Detection & Data Accommodation */

Message: Anomaly_Detected_(Timestamp)

Data Accommodation: [R(t)]i = [Ŝt+f ]i

end if

end for

end if

return([R(t)]i )

iterates the data accommodation process until (Rt )i is

present within the Ŝt+f (−) and Ŝt+f (+).

VI. EXPERIMENTAL EVALUATION

This section evaluates the proposed SFDFDA approach by

using the surface temperature sensor data sourced from the

instrumented wastewater infrastructure. During the course of

the sewer monitoring campaign, the surface temperature sensor demonstrated robust behavior and did not generate prolonged spurious data. However, the sensor has produced some

spurious data in the interim of laboratory evaluation. So, for

evaluating the SFDFDA approach, we have injected anomalies based on the lab data to the time series data observed

during the field testing. In addition, we have implanted continuous spurious data on 22nd to 23rd December 2016 and 5th

to 6th February 2017 to simulate sensor failure. The size of

56568

the sliding window was heuristically chosen as 6 based on

the knowledge of sensor characteristics and therefore, each

window takes 6 sensor measurements.

Figure 3 and Fig. 4 illustrates the results of the experiments of SFDFDA approach to demonstrate sensor failure detection, anomaly detection and isolation, and data

accommodation process from 11th November 2016 to 23rd

December 2016 and from 24th December 2016 to 6th February 2017 respectively. The first plot displays the model forecast within the prediction interval and the second plot shows

the sensor data with some random and continuous spurious

measurements. By using the forecast and sensor data, the

p-value is determined and presented in the third plot along

with the critical value of 0.95. For the random and continuous

spurious data, the p-value was observed to be lower than the

critical value and finally in the last plot, the data accommodation process illustrating the replacement of faulty data is

shown.

To measure the detection performance of random and

continuous spurious data, we use successful detection

rate (SDR) [3] as our metric of accuracy. The SDR for

the injected and observed anomalies of the periods from

11th November 2016 to 23rd December 2016 and from 24th

December 2016 to 6th February 2017 were 100% and 93.34%

respectively. The reason for the slightly lower value of SDR

in the latter period is due to the closeness of anomaly to

the forecast value. In this case, the p-value remains to be

higher than the critical value. The SFDFDA approach successfully detected anomalies including the two successive

ones and thereby reported the anomalies with time-stamp

and accommodated the corresponding forecast data. In the

case of more frequent anomalies present in a single window

frame, the SFDFDA approach issues sensor failure warning

for early intervention. In this case, the p-value remains lower

than the critical value. Long-term monitoring of sensor data

for detecting sensor failure is displayed in Fig. 5. Overall for

the entire time period, the SDR is 97.06%. For the continuous

spurious data on 22nd to 23rd December 2016 and 5th to 6th

February 2017, SDR were 100% for each period, indicating

the efficacy of sensor failure detection.

The forecasting performance of ARIMA model was evaluated and compared with the other models, where ARIMA outperforms the other stochastic models [52]. In order to evaluate

the forecasting performance of the SARIMA model, we compared the forecasting data of two different periods with the

anomalies-free sensor measurements. The first period is from

25th to 30th November 2016 and the second period is from

11th to 16th January 2017. Fig. 6 presents the temporal profile of forecasted and sensor measurements data, where it

can be observed that the profiles tend to follow a similar

pattern to each other. Mean Absolute Error (MAE), Mean

Absolute Percentage Error (MAPE) and Root Mean Square

Error (RMSE) were used as statistical metrics to evaluate the

forecasting performance of the SARIMA model. The MAE,

MAPE and RMSE for the period from 25th to 30th November 2016 and from 11th to 16th January 2017 were 0.18◦ C,

VOLUME 6, 2018

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

FIGURE 3. Experiment-1: Evaluation of SFDFDA approach.

0.0086%, 0.24◦ C and 0.15◦ C, 0.0062%, 0.17◦ C respectively.

These statistical metrics demonstrate the higher accuracy of

the forecast model employed in this work.

VOLUME 6, 2018

As in Fig. 7, the data accommodation occurs once the

sensor failure is detected and the corresponding forecast

data is utilized to replace the continuous spurious data.

56569

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

FIGURE 4. Experiment-2: Evaluation of SFDFDA approach.

Performance analysis on data accommodation process was

carried out to determine MAE, MAPE and RMSE on the failure period from 22nd to 23rd December 2016 and from 5th to

6th February 2017, and were determined to be 0.28◦ C, 0.01%,

56570

0.31◦ C and 0.46◦ C, 0.02%, 0.53◦ C respectively. These results

show that the data accommodation process provides satisfactory prediction when the sensor generates spurious

data.

VOLUME 6, 2018

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

FIGURE 5. Long-term evaluation of SFDFDA approach.

VII. DISCUSSION

In this paper, we proposed a SFDFDA approach, and

its effectiveness was evaluated by utilizing the surface

temperature sensor measurements. The proposed approach

has the potential to be used for detecting failures of different

VOLUME 6, 2018

sensors, which are monitoring other essential infrastructure

parameters in distribution networks such as pH, resistivity,

conductivity etc. Besides detecting the sensor failures and

anomalies, the proposed approach can be used for forecasting

the sensor parameters.

56571

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

sensing suite, and field experimentation will be published

subsequently in a journal.

VIII. CONCLUSION

FIGURE 6. Illustration of SFDFDA approach forecasting performance.

This paper presented an approach called SFDFDA, for detecting early sensor failure based upon the real-time operational

data sourced from an urban sewer. The SFDFDA approach

utilizes SARIMA model for forecasting the sensor data to

comprehend the temporal dynamics of the variable. This

forecasting mechanism is used as a framework to provide

an alternate measure to physical sensor measurements. The

forecast data from the SARIMA model was used as a reference measure in the SFDFDA approach to perform anomaly

detection, early sensor failure detection and data accommodation. The SFDFDA approach integrates the forecasting

mechanism with statistical diagnostic method. In the event of

detecting anomalies, the algorithm isolates the spurious data

and accommodates the data with the corresponding forecast

value. Further, in case of a continuity of faulty data, the early

sensor failure is detected and data accommodation process is

invoked to provide predicted measures. Experimental evaluation demonstrates that SFDFDA approach can be used

for surface temperature monitoring in-sewer application with

high detection accuracy and efficiency.

ACKNOWLEDGMENT

The research participants are Data61 - Commonwealth Scientific and Industrial Research Organization (CSIRO), University of Technology Sydney (UTS) and The University of

Newcastle (UoN).

REFERENCES

FIGURE 7. Illustration of the data accommodation during sensor failure.

The SFDFDA approach simultaneously check for anomalies and sensor failures. In the broader context, surface temperature data has the potential to be used in sewer corrosion

predicting models. Presence of anomalies in the observed

data can affect the prediction accuracy of those models.

Hence, in the proposed approach anomaly detection and

isolation are carried out simultaneously to the process of

detecting sensor failure. The sensor failure detection of the

SFDA algorithm is set to a heuristic criterion, which is based

on the repeated observation of faulty data. The criterion was

based on the sensor characteristics, where three or more

consecutive faulty data means a sensor failure. The size of

the sliding window was heuristically chosen as 6, based on

the knowledge of sensor characteristics.

The data collection was organised during the summer season of the Sydney city in Australia. Although the ambient

temperature of the field location was high, the sewer air

temperature was between 20◦ C and 26◦ C. This can be due

to the thickness of the concrete layer and the soil layer

above the sewer pipe providing a thermal barrier. More details

about the design and development of the surface temperature

56572

[1] Y. Zhang, Y. Fu, Z. Wang, and L. Feng, ‘‘Fault detection based on modified

kernel semi-supervised locally linear embedding,’’ IEEE Access, vol. 6,

pp. 479–487, 2017.

[2] S. Yin, S. X. Ding, and D. Zhou, ‘‘Diagnosis and prognosis for complicated

industrial systems—Part I,’’ IEEE Trans. Ind. Electron., vol. 63, no. 4,

pp. 2501–2505, Apr. 2016.

[3] P.-Y. Chen, S. Yang, and J. A. McCann, ‘‘Distributed real-time anomaly

detection in networked industrial sensing systems,’’ IEEE Trans. Ind.

Electron., vol. 62, no. 6, pp. 3832–3842, Jun. 2015.

[4] W. He, P.-L. Qiao, Z.-J. Zhou, G.-Y. Hu, Z.-C. Feng, and H. Wei, ‘‘A new

belief-rule-based method for fault diagnosis of wireless sensor network,’’

IEEE Access, vol. 6, pp. 9404–9419, 2018.

[5] G. Jiang, J. Keller, and P. L. Bond, ‘‘Determining the long-term effects

of H2S concentration, relative humidity and air temperature on concrete

sewer corrosion,’’ Water Res., vol. 65, pp. 157–169, Nov. 2014.

[6] M. P. H. Brongers, P. Y. Virmani, and J. H. Payer, ‘‘Drinking water

and sewer systems in corrosion costs and preventative strategies in the

United States,’’ Federal Highway Admin. Publ., U.S. Dept. Transp.,

Washington, DC, USA, Tech. Rep. FHWA-RD-01-156, 2002.

[7] K. Thiyagarajan, S. Kodagoda, and J. K. Alvarez, ‘‘An instrumentation

system for smart monitoring of surface temperature,’’ in Proc. 14th Int.

Conf. Control, Autom., Robot. Vis. (ICARCV), Nov. 2016, pp. 1–6.

[8] K. Thiyagarajan, S. Kodagoda, and N. Ulapane, ‘‘Data-driven machine

learning approach for predicting volumetric moisture content of concrete

using resistance sensor measurements,’’ in Proc. IEEE 11th Conf. Ind.

Electron. Appl. (ICIEA), Jun. 2016, pp. 1288–1293.

[9] L. Yi, X. Ke, and S. Junde, ‘‘Research on forecasting and early-warning

methods,’’ in Proc. IEEE 9th Int. Conf. Mobile Ad-Hoc Sensor Netw., MSN,

Dec. 2013, pp. 570–576.

[10] A. Patcha and J.-M. Park, ‘‘An overview of anomaly detection techniques:

Existing solutions and latest technological trends,’’ Comput. Netw., vol. 51,

no. 12, pp. 3448–3470, Aug. 2007.

VOLUME 6, 2018

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

[11] W. Yuan, L. Zhou, D. Guan, G. Han, and L. Shu, ‘‘Anomaly detection for civil aviation pilots using step-sensors,’’ IEEE Access, vol. 5,

pp. 11236–11243, 2017.

[12] I. Samy, I. Postlethwaite, and D.-W. Gu, ‘‘Detection and accommodation of

sensor faults in UAVs—A comparison of NN and EKF based approaches,’’

in Proc. IEEE Conf. Decision Control, Dec. 2010, pp. 4365–4372.

[13] C. Aubrun and C. Leick, ‘‘Sensor fault accommodation: Application to an

activated sludge process,’’ IFAC Proc. Volumes, vol. 38, no. 1, pp. 371–375,

2005.

[14] I. Samy, I. Postlethwaite, and D. Gu, ‘‘Neural network based sensor validation scheme demonstrated on an unmanned air vehicle (UAV) model,’’

in Proc. 47th IEEE Conf. Decision Control, Dec. 2008, pp. 1237–1242.

[15] M. R. Napolitano, Y. An, and B. A. Seanor, ‘‘A fault tolerant flight control

system for sensor and actuator failures using neural networks,’’ Aircraft

Design, vol. 3, no. 2, pp. 103–128, 2000.

[16] I. Samy, I. Postlethwaite, and D.-W. Gu, ‘‘Survey and application of sensor

fault detection and isolation schemes,’’ Control Eng. Pract., vol. 19, no. 7,

pp. 658–674, 2011.

[17] P. Goupil, ‘‘AIRBUS state of the art and practices on FDI and FTC in

flight control system,’’ Control Eng. Pract., vol. 19, no. 6, pp. 524–539,

2011.

[18] Y. Zhang and J. Jiang, ‘‘Bibliographical review on reconfigurable faulttolerant control systems,’’ Annu. Rev. Control, vol. 32, no. 2, pp. 229–252,

2008.

[19] S. Toma, L. Capocchi, and G.-A. Capolino, ‘‘Wound-rotor induction generator inter-turn short-circuits diagnosis using a new digital neural network,’’

IEEE Trans. Ind. Electron., vol. 60, no. 9, pp. 4043–4052, Sep. 2013.

[20] R. Isermann and P. Ballé, ‘‘Trends in the application of model-based fault

detection and diagnosis of technical processes,’’ Control Eng. Pract., vol. 5,

no. 5, pp. 709–719, 1997.

[21] S. Hussain, M. Mokhtar, and J. M. Howe, ‘‘Sensor failure detection,

identification, and accommodation using fully connected cascade neural

network,’’ IEEE Trans. Ind. Electron., vol. 62, no. 3, pp. 1683–1692,

Mar. 2015.

[22] T. Kuzin and T. Borovicka, ‘‘Early failure detection for predictive maintenance of sensor parts,’’ in Proc. ITAT, 2016, pp. 123–130.

[23] N. S. Nalawade and M. M. Pawar, ‘‘Forecasting telecommunications data

with autoregressive integrated moving average models,’’ in Proc. 2nd Int.

Conf. Recent Adv. Eng. Comput. Sci. (RAECS), Dec. 2015, pp. 1–6.

[24] L. R. F. Simmons, ‘‘M-competition—A closer look at NAIVE2 and median

APE: A note,’’ Int. J. Forecasting, vol. 2, no. 4, pp. 457–460, 1986.

[25] E. S. Gardner, ‘‘Exponential smoothing: The state of the art—Part II,’’ Int.

J. Forecasting, vol. 22, no. 4, pp. 637–666, Oct./Dec. 2006.

[26] P. Mondal, L. Shit, and S. Goswami, ‘‘Study of effectiveness of time series

modeling (ARIMA) in forecasting stock prices,’’ Int. J. Comput. Sci., Eng.

Appl., vol. 4, no. 2, p. 13, 2014.

[27] G. E. P. Box and G. C. Tiao, ‘‘Intervention analysis with applications to

economic and environmental problems,’’ J. Amer. Statist. Assoc., vol. 70,

no. 349, pp. 70–79, 1975.

[28] G. E. P. Box, G. M. Jenkins, and G. C. Reinsel, Time Seres Analysis:

Forecasting and Control (Wiley Series in Probability and Statistics), 4th

ed. 2013.

[29] Z. Qiao, J. Zhou, F. Si, Z. Xu, and L. Zhang, ‘‘Fault diagnosis of slurry pH

data base on autoregressive integrated moving average and least squares

support vector machines,’’ in Proc. 9th Int. Conf. Natural Comput. (ICNC),

Jul. 2013, pp. 141–145.

[30] C. S. Luo, L. Y. Zhou, and Q. F. Wei, ‘‘Application of SARIMA

model in cucumber price forecast,’’ Appl. Mech. Mater., vols. 373–375,

pp. 1686–1690, 2013.

[31] T.-M. Choi, Y. Yu, and K.-F. Au, ‘‘A hybrid SARIMA wavelet transform

method for sales forecasting,’’ Decision Support Syst., vol. 51, no. 1,

pp. 130–140, 2011.

[32] H. A. Mombeni, S. Rezaei, S. Nadarajah, and M. Emami, ‘‘Estimation

of water demand in Iran based on SARIMA models,’’ Environ. Model.

Assessment, vol. 18, no. 5, pp. 559–565, 2013.

[33] K. Yunus, T. Thiringer, and P. Chen, ‘‘ARIMA-based frequencydecomposed modeling of wind speed time series,’’ IEEE Trans. Power

Syst., vol. 31, no. 4, pp. 2546–2556, Jul. 2016.

[34] A. K. Rajeevan, P. V. Shouri, and U. Nair, ‘‘ARIMA based wind speed

modeling for wind farm reliability analysis and cost estimation,’’ J. Elect.

Eng. Technol., vol. 11, no. 4, pp. 869–877, 2016.

[35] J. Contreras, R. Espinola, F. J. Nogales, and A. J. Conejo, ‘‘ARIMA models

to predict next-day electricity prices,’’ IEEE Trans. Power Syst., vol. 18,

no. 3, pp. 1014–1020, Aug. 2003.

VOLUME 6, 2018

[36] A. Geetha and G. M. Nasira, ‘‘Time series modeling and forecasting: Tropical cyclone prediction using ARIMA model,’’ in Proc. 3rd

Int. Conf. Comput. Sustain. Global Develop. (INDIACom), Mar. 2016,

pp. 3080–3086.

[37] R. N. Calheiros, E. Masoumi, R. Ranjan, and R. Buyya, ‘‘Workload prediction using ARIMA model and its impact on cloud applications’ QoS,’’

IEEE Trans. Cloud Comput., vol. 3, no. 4, pp. 449–458, Oct./Dec. 2015.

[38] S. Rajasegarar, C. Leckie, and M. Palaniswami, ‘‘Hyperspherical cluster

based distributed anomaly detection in wireless sensor networks,’’ J. Parallel Distrib. Comput., vol. 74, no. 1, pp. 1833–1847, Jan. 2014.

[39] S. Subramaniam, T. Palpanas, D. Papadopoulos, V. Kalogeraki, and

D. Gunopulos, ‘‘Online outlier detection in sensor data using nonparametric models,’’ in Proc. 32nd Int. Conf. Very Large Data

Bases (VLDB), 2006, pp. 187–198.

[40] J. Branch, C. Giannella, B. Szymanski, R. Wolff, and H. Kargupta, ‘‘Innetwork outlier detection in wireless sensor networks,’’ Knowl. Inf. Syst.,

vol. 34, no. 1, pp. 23–54, 2013.

[41] M. R. Saybani, T. Y. Wah, A. Amini, and S. R. A. S. Yazdi, ‘‘Anomaly

detection and prediction of sensors faults in a refinery using data mining techniques and fuzzy logic,’’ Sci. Res. Essays, vol. 6, no. 27,

pp. 5685–5695, 2011.

[42] H. Z. Moayedi and M. A. Masnadi-Shirazi, ‘‘Arima model for network

traffic prediction and anomaly detection,’’ in Proc. Int. Symp. Inf. Technol. (ITSim), vol. 4, Aug. 2008, pp. 1–6.

[43] X. He, Z. Wang, Y. Liu, L. Qin, and D. Zhou, ‘‘Fault-tolerant control for an

Internet-based three-tank system: Accommodation to sensor bias faults,’’

IEEE Trans. Ind. Electron., vol. 64, no. 3, pp. 2266–2275, Mar. 2017.

[44] K. W. Hipel and A. I. McLeod, Time Series Modelling of Water Resources

and Environmental Systems, vol. 45. Amsterdam, The Netherlands:

Elsevier, 1994.

[45] J. C. Paul, S. Hoque, and M. M. Rahman, ‘‘Selection of best ARIMA

model for forecasting average daily share price index of pharmaceutical

companies in Bangladesh: A case study on square pharmaceutical Ltd,’’

Global J. Manage. Bus. Res., vol. 13, no. 3-C, Mar. 2013.

[46] G. E. P. Box, G. M. Jenkins, G. C. Reinsel, and G. M. Ljung, Time Series

Analysis: Forecasting and Control. Hoboken, NJ, USA: Wiley, 2015.

[47] R. Adhikari and R. K. Agrawal. (2013). ‘‘An introductory study

on time series modeling and forecasting.’’ [Online]. Available:

https://arxiv.org/abs/1302.6613

[48] I. I. Permanasari, A. E. Hidayah, and I. A. Bustoni, ‘‘SARIMA (Seasonal ARIMA) implementation on time series to forecast the number of

Malaria incidence,’’ in Proc. Int. Conf. Inf. Technol. Elect. Eng. (ICITEE),

Oct. 2013, pp. 203–207.

[49] R. J. Hyndman and Y. Khandakar, ‘‘Automatic time series forecasting: The

forecast package for R,’’ J. Statist. Softw., vol. 27, no. 3, pp. 1–22, 2008.

[50] R. J. Hyndman and G. Athanasopoulos, Forecasting: Principles and

Practice. Otexts.org., 2014. [Online]. Available: https://robjhyndman.

com/uwafiles/fpp-notes.pdf

[51] R. D. Snyder, J. K. Ord, and A. B. Koehler, ‘‘Prediction intervals for

ARIMA models,’’ J. Bus. Econ. Statist., vol. 19, no. 2, pp. 217–225, 2001.

[52] K. Thiyagarajan, S. Kodagoda, and L. Van Nguyen, ‘‘Predictive analytics

for detecting sensor failure using autoregressive integrated moving average model,’’ in Proc. 12th IEEE Conf. Ind. Electron. Appl., Jun. 2017,

pp. 1923–1928.

KARTHICK THIYAGARAJAN (M’18) received

the B.E. degree in electronics and instrumentation

engineering from Anna University, Chennai, India,

in 2011, the M.Sc. degree in mechatronics from

the University of Newcastle Upon Tyne, Newcastle

Upon Tyne, U.K., in 2013, and the Ph.D. degree in

smart sensor technologies from the University of

Technology Sydney, Sydney, Australia, in 2018.

He is currently a Research Fellow with the Centre for Autonomous Systems, University of Technology Sydney. His current research interests includes sensing technologies,

predictive analytics, and infrastructure robotics. His Ph.D. research work was

awarded with the Student Water Prize 2018 from the NSW–Australian Water

Association.

56573

�K. Thiyagarajan et al.: SFDFDA Approach for Instrumented Wastewater Infrastructures

SARATH KODAGODA (M’10) received the

B.Sc. (Eng.) degree (Hons.) in electrical engineering from the University of Moratuwa, Sri

Lanka, in 1995, and the M.Eng. and Ph.D.

degrees in robotics from Nanyang Technological University, Singapore, in 2000 and 2004,

respectively.

He was a Design Engineer in a reputed multinational company. He is currently an Associate

Professor, the Deputy Director of teaching and

research integration with the Centre for Autonomous Systems, the Founder

of the iPipes Lab, and a Program Coordinator of the Degree in mechanical

and mechatronics engineering with the University of Technology Sydney,

Ultimo, NSW, Australia. His current research interests include infrastructure

robotics, sensors and perception, machine learning, and human robot interaction.

Dr. Kodagoda has served as a keynote speaker, a general chair, an associate

editor, and a program committee member in number of top robotic conferences. He is currently serving as the Secretary to the Australian Robotics

and Automation Association and a Co-Chair of the ‘A Robotic Roadmap for

Australia.’

RAVINDRA RANASINGHE (M’97) received the

B.Sc. (Eng.) degree (Hons.) in computer science

and engineering from the University of Moratuwa,

Moratuwa, Sri Lanka, in 1995, and the Ph.D.

degree in wireless communication protocols from

the University of Melbourne, Parkville, VIC, Australia, in 2002.

Before joining the Centre for Autonomous Systems, University of Technology Sydney, Ultimo

NSW, Australia, he was in several technology

startup companies in the USA, Australia, and Sri Lanka. He is currently a

Senior Research Fellow with the Centre for Autonomous Systems, University of Technology Sydney. His current research interests include perception

for robotic systems, robotics and autonomous systems, machine learning,

mobile robotics networks, and sensor network.

LINH VAN NGUYEN (M’15) received the

Ph.D. degree in robotics from the University

of Technology Sydney, Ultimo, NSW, Australia,

in 2015.

He was with the University of Technology

Sydney as a Post-Doctoral Research Associate

until 2015. In 2016, he was as a Research Fellow with the School of Electrical and Electronic

Engineering, Nanyang Technological University,

Singapore. He rejoined the Centre for Autonomous

Systems, University of Technology Sydney, as a Research Fellow, in 2016.

His research interest includes robotics, Internet of Things, sensor placement,

artificial intelligence, machine learning, signal processing, embedded systems, and non-destructive testing.

56574

VOLUME 6, 2018

�

Linh Nguyen

Linh Nguyen