PSZ 19:16 (Pind. 1/07)

UNIVERSITI TEKNOLOGI MALAYSIA

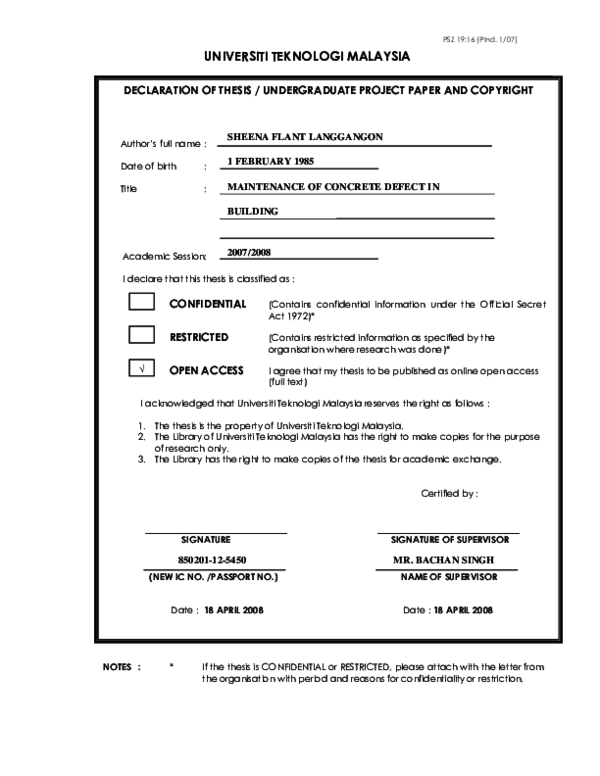

DECLARATION OF THESIS / UNDERGRADUATE PROJECT PAPER AND COPYRIGHT

Author’s full name :

SHEENA FLANT LANGGANGON

Date of birth

:

1 FEBRUARY 1985

Title

:

MAINTENANCE OF CONCRETE DEFECT IN

BUILDING

Academic Session:

2007/2008

I declare that this thesis is classified as :

√

CONFIDENTIAL

(Contains confidential information under the Official Secret

Act 1972)*

RESTRICTED

(Contains restricted information as specified by the

organisation where research was done)*

OPEN ACCESS

I agree that my thesis to be published as online open access

(full text)

I acknowledged that Universiti Teknologi Malaysia reserves the right as follows :

1. The thesis is the property of Universiti Teknologi Malaysia.

2. The Library of Universiti Teknologi Malaysia has the right to make copies for the purpose

of research only.

3. The Library has the right to make copies of the thesis for academic exchange.

Certified by :

SIGNATURE

850201-12-5450

(NEW IC NO. /PASSPORT NO.)

Date : 18 APRIL 2008

NOTES :

*

SIGNATURE OF SUPERVISOR

MR. BACHAN SINGH

NAME OF SUPERVISOR

Date : 18 APRIL 2008

If the thesis is CONFIDENTIAL or RESTRICTED, please attach with the letter from

the organisation with period and reasons for confidentiality or restriction.

�“I/we* hereby declare that I/we* have read this final year project and in my/our*

opinion this final year project is sufficient in terms of scope and quality for the

award of the Bachelor of Civil Engineering”

Signature

: ....................................................

Name of Supervisor

: MR. BACHAN SINGH

Date

: 18 April, 2008

�MAINTENANCE OF CONCRETE DEFECT IN BUILDING

SHEENA FLANT LANGGANGON

A report submitted in partial fulfillment

of the requirement for the award of the degree of

Bachelor of Civil Engineering

Faculty of Civil Engineering

Universiti Teknologi Malaysia

APRIL, 2008

�ii

“I declare that this final year project entitled “Maintenance of Concrete Defect in

Building” is the result of my own research except as cited in the references. The final

year project has not been accepted for any degree and is not concurrently submitted

in candidature of any other degree.”

Signature

: …………………………...

Name

: Sheena Flant Langgangon

Date

: 18 April 2008

�iii

To my beloved family

�iv

ACKNOWLEDGEMENT

Throughout the completion of this project, I have faced various challenges.

Without the help of people around me giving support and guidance would make it

harder to overcome these obstacles.

First and foremost, I would like to express my deepest gratitude to my

supervisor Mr. Bachan Singh for his time and unlimited guidance from the start to

the completion of this study. His advice and motivation had indeed helped me a lot

throughout this study.

I would also like to thank the Public Work Department in Kota Kinabalu and

Penampang district for their cooperation in providing me useful information and

giving insights regarding my study.

Lastly, I would like to thank my family and friends for their invaluable

support. All of you have made this study possible. Thank you very much.

�v

ABSTRACT

Malaysia is a developing country and many projects are being implemented.

Some of the projects involve construction of buildings. Nevertheless, some of the

buildings are poorly constructed and maintained. One of the components that need

attention is concrete. The concrete structure need to be inspected and maintained

regularly. Poor maintenance of concrete components will lead to the buildings being

rendered not fit for occupancy. The main objectives of this study are to determine

the types of concrete defect, the factors that cause concrete defects, the method of

repairs and the problems faced by the Public Work Department (PWD) in carrying

out the maintenance work. The study is carried out on government buildings in

Sabah. The data are collected through questionnaire and also from the records of the

PWD. The data is analyzed by using average mean index. From the study, it was

found that the main types of concrete defects are spalling and delamination. The

factors that cause the defects are inefficient maintenance and poor construction

method. The method of concrete repairs that are adapted by PWD are patching and

sealing.

�vi

ABSTRAK

Malaysia adalah negara yang membangun dengan banyak projek-projek baru

yang dilaksanakan. Antara projek ini adalah melibatkan pembinaan bangunan baru.

Namun demikian, masih terdapat bangunan yang telah dibina dan diselenggara

dengan tidak memuaskan. Salah satu komponen yang perlu diberi perhatian adalah

konkrit. Pemeriksaan dan penyenggelaraan yang tetap adalah penting untuk struktur

bangunan konkrit.

Sistem penyenggelaraan yang tidak memuaskan boleh

menyebabkan bangunan tersebut menjadi tidak sesuai untuk penghunian. Objektif

utama kajian ini adalah untuk mengenalpasti jenis kerosakan konkrit, faktor-faktor

yang menjadi punca kerosakan, teknik-teknik pembaikan dan masalah yang dihadapi

oleh Jabatan Kerja Raya (JKR) dalam sistem penyenggelaraan bangunan. Skop

kajian ini adalah pada semua bangunan kerajaan di Sabah. Data adalah dikumpul

melalui borang soal selidik serta rekod kerja penyenggelaraan daripada JKR.

Analisis data dilakukan dengan menggunakan Kaedah Purata Index. Daripada kajian

ini, didapati kerosakan utama pada bangunan adalah spalling dan pengupasan.

Faktor yang menyebabkan kerosakan ini adalah sistem penyenggelaraan yang tidak

cekap dan teknik pembinaan yang tidak sempurna. Teknik pembaikan yang paling

kerap digunakan adalah pembaikan tampalan dan sealing.

�vii

TABLE OF CONTENTS

CHAPTER

1

2

TITLE

PAGE

DECLARATION

ii

DEDICATION

iii

ACKNOWLEDGEMENTS

iv

ABSTRACT

v

ABSTRAK

vi

TABLE OF CONTENTS

vii

LIST OF TABLES

xii

LIST OF FIGURES

xiii

LIST OF SYMBOLS

xv

LIST OF APPENDICES

xvi

INTRODUCTION

1.1

Background of Study

1

1.2

Statement of Problem

3

1.3

Objectives of Study

4

1.4

Scope of Study

5

1.5

Summary of Study Methodology

5

LITERATURE REVIEW

2.1

Introduction

6

2.2

Maintenance

7

2.2.1

Planned Maintenance

8

2.2.1.1 Preventive Maintenance

8

2.2.1.2 Corrective Maintenance

8

�viii

2.2.2

Unplanned Maintenance

9

2.3

Assessment of Existing Structure

9

2.3.1

Preliminary Investigation

11

2.3.1.1 Past Records

11

2.3.1.2 Visual Inspection

11

2.3.2

Detailed Investigation

12

2.3.3

Test and Inspection Techniques

12

2.3.3.1 Structural integrity

13

2.3.3.2 Concrete Quality

13

2.3.3.3 Steel Serviceability and Condition

14

2.4

2.5

2.6

Types of Defects

14

2.4.1

Corrosion of Reinforcement Steel

15

2.4.2

Cracks

16

2.4.2.1 Longitudinal Cracks

17

2.4.2.2 Transverse Cracks

17

2.4.2.3 Shear Cracks

18

2.4.2.4 Plastic Shrinkage Crack

18

2.4.2.5 Plastic Settlement Crack

18

2.4.2.6 Crazing

18

2.4.2.7 Map Crack

19

2.4.3

Spalling

19

2.4.4

Delamination

20

2.4.5

Honeycombing

21

2.4.6

Scaling

21

2.4.7

Popouts

22

Causes of Deterioration

22

2.5.1

Excessive Concrete Mix Water

22

2.5.2

Sulphate Deterioration

23

2.5.3

Faulty Design

23

2.5.4

Construction Defects

24

2.5.5

Alkali-Aggregate Reaction

25

2.5.6

Structural Overload

26

2.5.7

Faulty Materials

26

Repair System

26

�ix

2.7

3

Repair Method

27

2.7.1

Cathodic Protection

28

2.7.2

Cathite Method

28

2.7.3

Decholorisation Technique

29

2.7.4

Crack Repair

29

2.7.4.1 Dormant Cracks

29

2.7.4.2 Live Cracks

30

2.7.5

Patch Repairs

31

2.7.6

Sealing

31

2.7.7

Sprayed Concrete

31

2.7.7.1 Dry-mix Process

32

2.7.7.2 Wet-mix Process

32

2.7.8

Pre-packed Grouting

33

2.7.9

Recasting

33

2.7.10 Dry Packing

34

2.7.11 Thin Bonded Resurfacing

34

2.7.12 Stitching

34

2.7.13 Caulking

34

METHODOLOGY

3.1

Introduction

35

3.1.1

Primary Data

35

3.1.1.1 Reports and Records

36

3.1.1.2 Questionnaire

36

3.1.1.3 Interview

36

Secondary Data

36

3.1.2

3.2

3.3

4

Data Analysis

37

3.2.1

37

Average Index

Conclusion

38

CASE STUDY

4.1

Introduction

39

4.2

Building Works Department Sabah

40

4.3

Clients

41

�x

5

4.4

Maintenance System

42

4.5

Problems Faced by PWD

43

DATA ANALYSIS AND RESULT

5.1

Introduction

45

5.2

Questionnaire Background and Number

46

Of Respondents

5.3

Party’s Involved in Carrying out Maintenance

47

Works on Government Buildings

5.4

Types of Maintenance Conducted on Government

48

Building

5.5

Types of Concrete Defect that Occur in

Government Building

5.6

Factor’s that Causes Defects in Government

Building

52

5.7

Method of Repair in Rectifying Concrete Defects

54

5.8

Factor’s Affecting Choice of Repair

56

5.9

Common Problems Faced by PWD in Building

Maintenance

6

49

57

CONCLUSION AND RECOMMENDATION

6.1

Introduction

60

6.2

Conclusion

61

6.2.1

Types of Concrete Defect that Occur

In Buildings

6.2.2

61

Factors that Causes the Concrete Defect

In Buildings

62

6.2.3

Method of Concrete Repair Carried Out

62

6.2.4

Problems Faced by PWD in Maintenance

Of Building

63

6.3

Recommendation

64

6.4

Recommendation for Further Study

64

�xi

REFERENCES

66

APPENDICES A

69

APPENDICES B

73

APPENDICES C

74

�xii

LIST OF TABLES

TABLE NO.

TITLE

PAGE

4.1

Summary of Financial Report

40

5.1

Party to Carry Out Maintenance

47

5.2

Types of Maintenance

48

5.3

Types of Defect that Occur in Government Building

50

5.4

Factors that Causes Concrete defects in Government

52

Building

5.5

Method of Repair in Rectifying Concrete Defects

54

5.6

Factors Affecting Choice of Repair

56

5.7

Common Problems Faced by PWD in Building

58

Maintenance

�xiii

LIST OF FIGURES

FIGURE NO.

TITLE

PAGE

1.1

A Flow Chart of research Methodology

5

2.1

Forms of Maintenance

7

2.2

Typical Flow Chart for Assessment Programs

10

2.3

Core Samples to Determine Chloride

13

Contents

2.4

Corrosion of Steel Reinforcement

16

2.5

Crazing on Concrete Structure

19

2.6

Heavily Rusted Reinforcement and Spalling

20

of the Concrete

2.7

Scaling in Concrete

21

4.1

Organization Chart of Building Works

41

Department

5.1

Number of Respondent on Questionnaire

46

Distributed to PWD Sabah

5.2

Party to Carry Out Maintenance

47

5.3

Types of Maintenance Conducted on

49

Government Buildings

5.4

Types of Concrete Defects that Occur in

51

Government Building

5.5

Factors that Causes Concrete Defects in

53

Government Building

5.6

Method of Repair in Rectifying Concrete

Defects

55

�xiv

5.7

Factors Affecting Choice of Repair

57

5.8

Common Problems Faced by PWD in

59

Building Maintenance

�xv

LIST OF SYMBOLS

=

-

Equal to

≤

-

Less than or equal to

<

-

Less than

∑

-

Total of

%

-

Percentage

�xvi

LIST OF APPENDICES

APPENDIX

TITLE

PAGE

A

Example Questionnaire

69

B

Computation Repair Work Form

73

C

Repair Works Description Form

74

�CHAPTER 1

INTRODUCTION

1.1

Background of Study

After almost 50 years of independence, Malaysia once known as Malaya is

going into a new era of globalization, unleashing its potential and competition

worldwide. Both federal and state government worked hand in hand to make full

utilization of the country’s source and expertise in expanding the infrastructure in

Malaysia. Most recent attribute is Northern Corridor Economic Region (NCER) in

which one of its main objectives is to promote social and community development

that will contribute greatly to Malaysia’s growth and economy. As the technology

advances and changes, the need of more infrastructures will be more apparent.

Infrastructure includes buildings, roads, bridges, utilities, water supply,

sewerage system, mechanical and electrical systems. All of these infrastructures are

important because it helps civilians to be able to live in a more systematic and ease

environment. It helps to save cost, traveling time and providing facilities that will

make life easier.

�2

Many of these infrastructures will need proper maintenance to extend the

lifespan besides promoting safety and reliability to the public. In the Malaysian

Budget 2006, a total of RM4.3 billion have been provided to public agencies for

maintenance and another RM 1 billion to the government for the maintenance of

public facilities in the year 2007. Buildings in particular are important structures and

are a main concern of the government to make sure it is maintained regularly to

prevent it from deteriorating and eventually could pose as a threat to the public.

Poor maintenance might result in structural failure and wastage in money.

For example, six roof leakages were spotted on May 9, 2007 at the Parliament

building in Malaysia. After inspection, it was found that the leakage was caused by

cracks and seepage of water through the concrete roof. There was also no sign of

maintenance done. Restoration and renovation works of the Parliament Building was

previously done in 2005 with a total budget of RM90 million executed by Public

Works Department (PWD). Although PWD had carried out a lot of repairs but there

was reoccurring damage due to absence of maintenance (Daily Express, May 20,

2007). Even though the maintenance was under the responsibility of the Parliament

building management unit and not PWD, the issue here is not who to blame but to

prove that poor maintenance will result in repeated repairs and dire consequences.

One of the major components of building that needed attention is concrete

defects.

Defects in concrete, if not repaired, will eventually lead to major

maintenance. Failure to provide necessary maintenance will cause more expensive

repairs or replacement of otherwise useful structures. Besides that, any negligence in

any of the phases of its maintenance would lead to its deterioration and ultimately

failure to perform its intended function.

Therefore a proper and systematic

maintenance management is required to reduce possible occurrence of disaster that

may cause life injury due to structural failure.

�3

1.2

Statement of Problem

Concrete is a very high durable and versatile material as it can be cast in place

with or without reinforcement and precast or prestressed for achieving any required

strength. Therefore it is a very popular construction building material. Under normal

conditions, concrete buildings are expected to have a long life service.

However, concrete members can deteriorate due to several factors such as

aggressive environment, faulty design and construction defects etc.

Inadequate

maintenance will leave these defects unattended thus compromising the integrity of

the building.

Many reasons can contribute to poor maintenance of concrete buildings such

as local authorities as they often lack manpower when being confronted or

challenged to check the safety of structures (Lee, 2004). The economical aspect is

also a decisive factor on types of repair works that might be conducted. There is

usually more than one method of repair in concrete defects. These techniques vary

from each other in terms of cost, execution time and effectiveness. The more higher

the cost, it would deter many building owners from executing essential repair works.

Other than that, remedial works are only done on areas where the damage is

visible. This is to avoid stability problems in the structure. Unfortunately what

usually happens is reoccurrence of the damage shortly after the previous remedial

work has been carried out and leads to repeated repairs. This only contributes to

wastage in money and time besides compromising the safety factor of the structure.

In Sabah, maintenance of many government buildings, schools and hospitals

is under the custody of Public Work Department (PWD). The biggest challenge

faced is conducting effective maintenance. As stated by Prime Minister Datuk Seri

�4

Abdullah Badawi, the weakness of government department was that they lack a

building maintenance culture. He also added that they will not see the need to

inspect if they think it is a new building (The Star, April 13, 2007).

A preliminary survey is conducted on government buildings in the district of

Kota Kinabalu, Sabah. From the survey, it was found that the problems faced are

poorly maintained buildings. Buildings have become an eyesore or a danger to

general public. There were even cases of pieces of concrete falling from canopies,

ceilings, pillars and walls of unattended buildings in Commercial Business District

(CDB) areas and rainwater chute collapsing onto a car (Daily Express, April 16,

2006).

The repair works for concrete defects will be carried eventually.

Some

defects are only visually disturbing and will not affect the structural integrity of the

whole structure.

Some on the other hand can be dangerous and lead to major

failures. Hence, a study will be carried out as stated in the objectives in section 1.3.

1.3

Objectives of Study

The objectives of carrying out this study are as follow:

i.

To study the types of concrete defects that occurs in buildings

ii.

To identify the factors that causes the concrete defects in buildings

iii.

To identify the method of concrete repair carried out

iv.

To identify the problems faced by PWD in maintenance of buildings

�5

1.4

Scope of Study

In relation with the objectives of the study, this study is carried out on

buildings in Sabah under the supervision of Public Work Departments (PWD). All

government buildings under PWD are taken into count.

1.5

Summary of Study Methodology

Exploration of sources

Problem Identification

Discussion with supervisor

Title

Objective and Scope

Data Collection

Primary Data

-Records

-Questionnaire

-Interviews

-Observation

Secondary Data

-Reference books

-Journals

-Newspaper

-Magazines

Compile and organize

Analyze

-Using average mean index

Conclusion and recommendation

Figure 1.1: A Flow Chart of Research Methodology

�CHAPTER 2

LITERARURE REVIEW

2.1

Introduction

Maintenance is a very important element for concrete structures. Although

concrete is a very high durable building material, concrete can deteriorate and

become defective under certain circumstances such as environmental conditions. To

further probe this problem is poor maintenance.

Improper maintenance work could lead to repetition repairs that can be more

costly and wastage in materials. Therefore maintenance plays an important role as it

sustains the building serviceability up to its required and expected standard.

Maintenance works in Malaysia are under the concern of Public Work Department

(PWD). PWD is in charge of inspection and performing maintenance on all for state

and federal buildings.

A through inspection on concrete structures would be

determining the cause of defect, having adequate knowledge regarding the extent of

the problem and carrying appropriate repair works that could minimize or eliminate

the problem altogether.

�7

2.2

Maintenance

According to BS3811:1993 British Standard Glossary of Maintenance Terms

in Terotechnology, the term maintenance is the combination of all technical and

administrative actions, including supervision actions, intended to retain an item in, or

restore it to, a state which it can perform its required function.”

Generally, there are two process of building maintenance activities. There are

rehabilitation and repair.

i.

Rehabilitation

An activity to make sure the building is up to current acceptable functional

conditions, often involving improvements.

ii.

Repair

An action that is intended to restore a building back to its original appearance

or state by renewal, replacement and restoration.

Meanwhile maintenance can be divided into two main categories which is

planned maintenance and unplanned maintenance.

Maintenance

Planned

Maintenance

Preventive

Maintenance

Unplanned

Maintenance

Corrective

Maintenance

Figure 2.1: Forms of Maintenance (BS3811, 1993)

�8

2.2.1

Planned Maintenance

As stated in BS3811(1993), planned maintenance can be described as the

maintenance organized and carried out with forethought, control and the use of

records to a predetermined plan.

There are two sub categories of planned

maintenance which is preventive and corrective maintenance.

2.2.1.1 Preventive Maintenance

Preventive maintenance is the maintenance carried out at predetermined

intervals or according to predescribed criteria and intended to reduce the probability

of failure or the degradation of the functionality of an item. There are two different

types of preventive maintenance which is scheduled maintenance and conditionbased maintenance. Scheduled Maintenance is the preventive maintenance carried

out in accordance with an established time schedule. Meanwhile condition-based

Maintenance is the maintenance carried out according to the need indicated by

condition monitoring (BS3811, 1993).

2.2.1.2 Corrective Maintenance

The type of maintenance carried out after fault recognition and intended to

put an item into a state in which it can perform a required function. Scope of work

comprises repair, restoration, rehabilitation or replacements of components (BS3811,

1993).

�9

2.2.2

Unplanned Maintenance

Unplanned maintenance is maintenance carried out to no predetermined plan.

It consists of any maintenance activity that has no predetermined plan in all aspects

including labor, materials, tools and equipment to perform the task (BS3811, 1993).

2.3

Assessment of Existing Structure

The purpose of inspection is not only to document the type(s) and extent of

deterioration but also to investigate the cause(s) of the deterioration and provide

guidance on remedial action to prevent or mitigate against its occurrence.

Assessment on existing structures is a systematic process of evaluating the condition

and strength of the structure. This process includes two levels which is preliminary

investigation followed by detailed investigation. The need to assess structures is due

to (Singh, 1991):

Age of structure

The more the age causes a decrease in concrete strength and corrosion related

problems.

Change in occupancy

Make sure structure is sound for additional loading.

Presents of defects

Presents of cracks and other deformation may affect the overall performance

of the structure.

Statutory requirements

�10

Mandatory requirements to check on the structural integrity and safety of

existing structure.

Other factors

Accidental overloading, fire damage, seismic movements and etc.

VISUAL INSPECTION

GENERAL

INFORMATION

PLAN

INVESTIGATION

LOCATE ACCESS

OVERALL SURVEY

AND SELECTION OF

AREAS FOR

DETAILED STUDY

INFORMATION

FROM

CONSTRUCTION

RECORDS BLUE

DETAILED MAPPING

AND N.D.T OF

SPECIFIED AREAS

SAMPLING-CORING

AND DRILLING

INFORMATION

FROM

MAINTENANCE

RECORDS

LABORATORY TEST

AND ANALYSIS

ANALYSIS AND

INTERPRETATION

OF RESULTS

REPORT AND

RECOMMANDATION

Figure 2.2: Typical flow chart for assessment program (Singh, 1991)

�11

2.3.1

Preliminary Investigation

Before planning an investigation, it is recommended to conduct a site visit

first. Initial visual inspection is normally done by client representative and the

consulting engineer.

2.3.1.1 Past Records

The survey done in preliminary level is observation and identifying the

existing defects, loading, conditions and alterations in the structure. Information

could be obtained from past drawings, past records and other documents related.

Past records will be able to provide important information regarding layout and

sectional views, past weather and climatic records, original design which include

architectural, structural, mechanical, electrical, structural design calculations and type

of construction materials. Service history such as maintenance record will provide

information about previous defects and remedial work done.

2.3.1.2 Visual Inspection

Visual inspection is a visual survey on the whole structure. All apparent

signs of distress, deterioration and damage can be detected.

The outcome of

conducting a visual survey is to provide a general picture of existing structure so that

more detailed investigation may be planned to assess the structure. It is important

that these surveys are conducted by experienced personnel capable of making careful

observations and record findings in a systematic manner.

Engineers may take

photographic survey and non-destructive test measurements to assess the structures

structural integrity.

�12

2.3.2

Detailed Investigation

After visual survey is conducted and there are signs of defects, deformation

and deterioration a more detailed investigation is conducted. It is a thoroughly

examination on al members to determine the cause and then to propose a suitable

remedial work.

The detailed inspection will identify the crack size, extent of spalling, depth

of carbonation and extent of corrosion besides basic geometry on existing members

such as shape, size, cross section and location of embedded elements such as steel

bars. Destructive and non-destructive testing will be conducted to check on the

structural capacity of every key member and foundation. Analysis of the result will

be conducted and engineers for further action.

2.3.3

Test and Inspection Techniques

There are various methods and techniques available for in situ during

inspection or on samples removed from the structure for laboratory testing. There are

three categories on test and inspection techniques (Mays, 1992):

i.

Those dealing with determination of structural integrity

ii.

Those dealing with determination of concrete quality

iii.

Those dealing with determination of steel serviceability and condition

�13

2.3.3.1 Structural integrity

As mentioned previously, visual survey is important as it provides

information on the condition of the structure. Tapping survey is an in situ testing

whereas a small hammer is used to sound the concrete surface to detect spalls and

delaminations over the reinforcement.

For deeper delaminations, more suitable

equipments can be used such as ‘Delamtech’ and instrumental delamination device

(IDD). Through these techniques, the main and secondary reinforcement, minimum

cover and location of reinforcing steel can be determined. Other than that, acoustic

emissions, thermograph, dynamic response and radar can yield information on

structural integrity of concrete structure.

2.3.3.2 Concrete Quality

Core sampling is capable of producing sample most suitable for the use of

laboratory testing. To obtain a core sample, usually water cooled diamond bits are

used. Diameter of sample ranges from 40mm to over 200mm and the depth of core is

equivalent to the diameter.

Figure 2.3: Core samples to determine chloride content (Strecker, 1988)

�14

To determine the chloride content and sulphate profiles in concrete, powder

drilled samples of hardened concrete are taken at various depths usually at 5-25mm.

25-50mm, 50-75mm and 75-100mm. However this technique is not recommended

for determining alkali content due to alkali-silica reaction.

To investigate the depth of carbonation, phenolphthalein indicator is sprayed

upon fractured surface of concrete. The indicator will give a measurement of total

carbonation in concrete.

2.3.3.3 Steel Serviceability and Condition

Corrosion of steel reinforcement is most common symptom of defective

concrete.

However what actually affects the mechanical stability of concrete

structure is spalls and cracking as a result of corrosion. Half-cell potential mapping

can be used to delineate anodic and cathodic areas of reinforcement. Potential of

steel in concrete is expressed by the potential developed by common current flow

that is normally potential from both anodic and cathodic corrosion processing. The

rate of corrosion is measured by determining the conductivity or resistivity

particularly using surface contact probes.

2.4

Types of Defects

Design and construction defects can at the least cause minor cracking or

spalling leading to a major source of a structural failure. Many other causes of

deficiencies such as alkali-aggregate reaction, sulphate deterioration and structural

overloading can lead to defects in concrete structures. Following are common types

of defects in reinforced concrete structures.

�15

2.4.1

Corrosion of reinforcement steel

Numerous concrete structures have been repaired due to corrosion problems

of steel reinforcement. There are several causes that trigger this problem which are

irregular and insufficient concrete cover of the reinforcement, unsuitable concrete

mixture proportions for outdoor structure and insufficient concrete curing (Raupach,

2006).

The corrosion of steel in concrete is generally initiated by a chemical reaction

related to the composition of the constituent parts and the influence of one or more of

the following (Berkeley, 2001):

(i) Chloride concentration

(ii) Carbonation penetration

(iii) Other acid radicals

(iv) Oxygen concentration

(v) Degree of moisture ingress

(vi) Bacterial action

The alkalinity of the Portland cement used in concrete normally creates a

passive, basic environment (pH of about 12) around the reinforcing steel which

protects it from corrosion. When that passivity is lost or destroyed, or when the

concrete is cracked or delaminated sufficiently to allow free entrance of water,

corrosion can occur. Corrosion at reinforcement can occur provided that sufficient

oxygen and moisture are available.

Corrosion of steel reinforcement may only be revealed only after years of

exposure. It can be due to the concrete cover being too thin or by cracks that makes

it exposed to aggressive environment that can penetrate through the reinforcement

�16

and rust it. If not properly repaired, it will gradually deteriorate to the extent that the

reinforcement is completely exposed.

Figure 2.4: Corrosion of reinforcement steel

2.4.2

Cracks

Cracking is the most common phenomenon in concrete defects. Cracking can

be the result of one or a combination of factors, such as drying shrinkage, thermal

contraction, restraint (external or internal) to shortening, and applied loads. Cracks

can also be a sign of corroded reinforcement. Cracking can be significantly reduced

when the causes are taken into account and preventative steps are utilized. Cracks

are divided into two groups which are structural cracks and non-structural cracks.

Structural cracks are cracks that are caused by dead loads, applied forces or

other totally external influences. It can develop on structure element such as beam,

slab, column and foundation. Structural is much more critical compared to nonstructural cracks because it interferes with stability and safety factor of the building.

It is fundamental that hardened reinforced concrete cracks in the tensile zone when

�17

subjected to externally imposed loadings such as false in design, false in

construction, overloading and accident such as fire and earthquake.

There are three common structural cracks which are tensile cracks,

compressive cracks and shear cracks (See Shiou Ling, 2006). Tensile cracks happen

when the structural element fails to resist imposed tensile load. It usually occurs on

beams and slab. These elements are also subjected to shear cracks. Meanwhile

compressive cracks are cracks when compressive strength of material is less than

imposed loads. Concrete column are more open to this problem.

Concrete is also liable to crack in both plastic and hardened state due to

stresses sustain by the nature of its constituents materials. Concrete containing them

may often be summarily and unjustifiably condemned. There are various types of

cracks in concrete structures that appear such as plastic cracks, early thermal

contraction, and long term drying shrinkage, longitudinal and transverse cracks, map

cracks and surface crazing.

2.4.2.1 Longitudinal Cracks

Longitudinal cracks are cracks directly over reinforcing bars. This type of

cracks occurs due to rust forming on the reinforcement leading to spalling and

complete loss of cover.

2.4.2.2 Transverse Cracks

Transverse cracks form after the concrete hardened and is caused by

shrinkage, thermal condition, thermal contraction or structural loading. If there is an

�18

absence of secondary reinforcement, cracks will only transverse to main

reinforcement and are harmless except if it is very wide.

2.4.2.3 Shear Cracks

Shear cracks form due to structural loading or movement. Cracks develop

when the shear capacity of element is less than shear force acting on it.

2.4.2.4 Plastic Shrinkage Crack

Plastic shrinkage cracks form during construction if rapid evaporation causes

a large moisture loss from the surface. It is harmless unless the cracks are exposed

to salts or contaminated dust.

2.4.2.5 Plastic Settlement Crack

Plastic settlement crack form during construction if there is a high amount of

bleeding and there is some restraint. If the concrete mix is workable, solids can settle

and allow water to bleeds at the top. This type of crack forms longitudinally over the

reinforcement.

2.4.2.6 Crazing

Crazing is a pattern of fine cracks. It does not penetrate below the surface

and usually is cosmetic problem only. Crazing is barely visible except when the

concrete is drying after the surface is wet. Cracking of the surface layer into small

�19

irregular shaped areas depend on the environmental condition and not necessarily

affected by time.

Figure 2.5: Crazing on concrete structure

2.4.2.7 Map Crack

Map crack is caused by alkali-aggregate reaction. This type of concrete

deterioration occurs when the active mineral constituents of some aggregates react

with the alkali hydroxides in the concrete. Alkali-aggregate reactivity occurs in two

forms—alkali-silica

reaction

(ASR)

and

alkali-carbonate

reaction

(ACR).

Indications of the presence of alkali-aggregate reactivity may be a network of cracks,

closed or spalling joints, or displacement of different portions of a structure.

2.4.3

Spalling

Spalling is commonly known as concrete cancer. Steel reinforcing rods that

are affected by moisture or salt from the environment cause the steel to rust and

�20

expend. Thus pushing off surface that encases the reinforcement steel. Carbonation

that triggers corrosion in reinforcement and insufficient concrete cover also cause

spalling.

Figure 2.6: Heavily rusted reinforcement and spalling of the concrete

2.4.4

Delamination

There are many reasons that can contribute delamination in concrete. It can

be a result from bleed water and bleed air being trapped below the prematurely

densified mortar surface. Disruptive stresses from chloride-induced corrosion of

steel reinforcement results delamination that are deeper called spalls. This defect can

be detected by using sounding method by dragging a chain on the surface of tapping

using a hammer. Hollow sounds produced indicate delaminated areas.

�21

2.4.5

Honeycombing

Formation of honeycombing is due to the presence of air and bubble at the

surface of the formwork and results a separation between aggregates and cement

mixture.

Other than that, improper consolidation during construction process such

as not properly vibrating the concrete mixture will cause honeycombing to occur.

2.4.6

Scaling

Scaling is quite similar to spalling however not as serious. Scaling happens

when water is added to increase workability of concrete. The rate of water cement

ratio in the concrete will increase and further reduce the strength and durability of the

concrete.

Figure 2.7: Scaling in concrete

�22

2.4.7

Popouts

Popout is a conical fragment that breaks out of the surface of concrete thus

leaving a hole usually displaying fractured aggregate particle at the bottom of the

hole. Contributory factors to popouts in concrete can be either due to pieces of

porous rocks having a high rate of absorption and relatively low specific gravity or

swelling of aggregates under moisture conditions. It forms a pressure that ruptures

the concrete surface.

2.5

Causes of Deterioration

There are many causes of deterioration in concrete structures. This problem

can bring defects such as cracking, corrosion of steel reinforcement, spalling of the

concrete and blemishes such as popouts, scalling, honeycombing etc.

2.5.1

Excessive Concrete Mix Water.

The use of excessive water in concrete mixtures is the single most common

cause of damage to concrete. Excessive water reduces strength, increases curing and

drying shrinkage, increases porosity, increases creep, and reduces the abrasion

resistance of concrete. High durability is associated with low water-cement ratio and

the use of entrained air. Damage caused by excessive mix water can be difficult to

correctly diagnose because it is usually masked by damage from other causes.

Freezing and thawing cracking, abrasion erosion deterioration, or drying shrinkage

cracking, for example, is often blamed for damage to concrete when, in reality,

�23

excessive mix water caused the low durability that allowed these other causes to

attack the concrete. Extreme cases of excessive mix water in hardened concrete can

sometimes be detected by the presence of bleed water channels or water pockets

under large aggregate.

2.5.2

Sulphate Deterioration.

Sodium, magnesium, and calcium sulfates are salts commonly found in the

alkali soils and ground waters. These sulfates react chemically with the hydrated

lime and hydrated aluminate in cement paste and form compounds that have volume

greater than initial volume. The volume of these reaction byproducts results in

tensioning and cracking, causing disruption of the concrete from expansion.

2.5.3

Faulty Design

Design faults can create many types of concrete damage. One type of design

fault that is somewhat common is positioning embedded metal such as electrical

conduits or outlet boxes too near the exterior surfaces of concrete structures. Cracks

form in the concrete cover and around such metal features and allow accelerated

freeze-thaw deterioration to occur. Bases of handrails or guardrails are placed too

near the exterior corners of walls, walkways, and parapets with similar results. These

bases or intrusions into the concrete expand and contract with temperature changes at

a rate different from the concrete.

Tensile stresses, created in the concrete by

expanding metal cause cracking and subsequent freeze thaw damage.

�24

Insufficient concrete cover over reinforcing steel is also a common cause of

damage. Reclamation usually requires a minimum of 3 inches of concrete cover over

reinforcing steel, but in corrosive environments, this can be insufficient. Concrete

exposed to the corrosive effects of sulfates, acids, or chlorides should have a

minimum of 4 inches of cover to protect the reinforcing steel. Insufficient cover

allows corrosion of the reinforcing steel to begin. The iron oxide byproducts of this

corrosion require more space in the concrete than the reinforcing steel and result in

cracking and delaminating in the concrete.

2.5.4

Construction Defects

Some of the more common types of damage to concrete caused by

construction defects are rock pockets and honeycombing, form failures, dimensional

errors, and finishing defects. Honeycomb and rock pockets are areas of concrete

where voids are left due to failure of the cement mortar to fill the spaces around and

among coarse aggregate particles.

More likely, the resulting defect is either simply accepted by the owner, or the

contractor is required to remove the defective concrete and reconstruct that portion of

the structure. Whenever possible, it usually is best to accept the resulting deficiency

rather than attempt to repair it. If the nature of the deficiency is such, that it cannot be

accepted, then complete removal and reconstruction is probably the best course of

action. Occasionally, dimensional errors can be corrected by removing the defective

concrete and replacing it with epoxy-bonded concrete or replacement.

Finishing defects usually involve over finishing or the addition of water

and/or cement to the surface during the finishing procedures. In each instance, the

�25

resulting surface is porous and permeable and has low durability. Poorly finished

surfaces exhibit surface spalling early in their service life.

2.5.5

Alkali-Aggregate Reaction.

Certain types of sand and aggregate, such as opal, chert, and flint, or

volcanics with high silica content, are reactive with the alkalis of Portland cement

released during hydration. Some concrete containing alkali reactive aggregate shows

immediate evidence of destructive expansion and deterioration.

However other

concrete might remain undisturbed for many years. The product of alkali-aggregate

reaction shows that a gel will form around the reactive aggregate. This gel undergoes

extensive expansion in the presence of water or water vapor (a relative humidity of

80 to 85 percent is all the water required), creating tension cracks around the

aggregate and expansion of the concrete.

Usually, some type of whitish exudation will be evident in and around the

cracked concrete. In extreme instances, these cracks have opened 1.5 to 2 inches. In

large concrete structures, alkali-aggregate reaction may occur only in certain areas of

the structure. Only portions of the structure constructed with concrete containing

alkali reactive sand and/or aggregate will exhibit expansion due to alkali-aggregate

reaction.

�26

2.5.6

Structural Overload

Defects as a result of structural overload will be obvious and easy to detect.

It will show distinctive patterns of cracking that indicates the source and cause of

excessive loading and point load application. Overloading can weaken the concrete

and make it incapable of carrying the design loads. Damage can be repaired with the

expectation that the cause of damage neither will nor reoccur in the future.

2.5.7

Faulty Materials

Concrete that is contaminated with a significant level of chloride from the

original mix materials or as a result of chloride penetration from salty environment

must be cut away and replaced with uncontaminated concrete wherever it is close to

the reinforcement (Strecker, 1988).

2.6

Repair System

It is essential to have a solid plan and specifications for repair works.

Improper planning will lead to more tedious and unnecessary works besides not

being cost effective.

Therefore a systematic and detailed system is important.

Among the important criteria are (Emmons, 1993):

Diagnosis of the causes(s) of damage

The cause of damage must be correctly determined to prevent unsuitable

repairs that may further provoke the damage on the structure.

�27

Diagnosis of the extent of the damage

It is wise to know the effect of existing deterioration on current and future

structural efficiency. Engineers will have to investigate the progression of

the

damage and the possibility of the damage to aggravate further.

Investigative methods are mentioned in the earlier part which is by

preliminary and detailed investigation.

The need of repair

Repair is required if the damage effects the structural stability and safety

operation of the structure. Non-structural cracks due to drying shrinkage can

be justified for cosmetic purpose. Meanwhile structural cracks will usually

require repair.

However the precise evaluation on the current status is

extremely difficult and depends on a more subjective appraisal of an

experienced engineer. Clients on the other hand might delay repair to fit their

maintenance plan or to avoid disruption at difficult times (Grantham, 1997).

Costs

There is no clear guideline on what the costs of repairs will be as data for

basing estimates of cost are sparse. In repair works, the economic decision is

usually made on whether a regular sequence of local repairs is needed or a

more expensive corrective measure that will be less costly in the future.

Besides that early detection of damage will allow orderly budgeting of

funds for the cost of repair.

2.7

Repair Method

The concrete repair industry is both specialized and huge. Many of the repair

methods, when applied correctly are perfectly adequate for the purpose for which

they are intended. However the types of repair method are crucial as choosing the

wrong technique will be more costly and further deteriorates the concrete structure.

�28

There are various factors affecting choice of repairs such as degree of deterioration,

available budget and cost of repair, accessibility to site (Singh, 1991).

2.7.1

Cathodic Protection

Cathodic protection is another option for repairing corroded reinforcement.

This process will be able to nullify the corrosion current thus stopping corrosion

process (Ho N Y, 1991). An external will receive external current from a direct

current source and forcing the current into or on the concrete. Induced current

generated opposes the electrochemical reaction that is responsible for corrosion

problems.

Cathodic protection may not necessarily be the only acceptable method of

controlling corrosion at a specific location but it will always remain the only

technique which is capable of totally reversing the chemical and electrical

phenomena causing reinforcement corrosion. On the other hand, it is probably one of

the less economical techniques for small isolated repairs (Berkeley, 1990).

2.7.2

Cathite Method

Cathite method is suitable to repair concrete that has been damaged by

corroded reinforcement.

reinforcement.

It acts by halting the electrolytic action within the

This process will offer high electrical resistance between anode

(steel) and cathode (envelopes between the bars).

�29

2.7.3

Decholorisation Technique

This process is based on electomosis principle (Ho N Y, 1991) which is the

extraction of chlorides electrochemically and realkalised the affected area.

The

affected area is the area with corroded reinforcement. Concrete surface is covered

with mesh electrode that is covered with alkaline gel. Electrical connection between

electrode and existing reinforcement will cause the hydroxyl ions to migrate into

carbonated zones thus increasing its pH. The cost is low compared to cathodic

protection.

2.7.4

Crack Repair

There are two purpose of deciding the most suitable repair for cracks. Before

proposing repair works, it should be determine if it is dormant cracks or live cracks.

2.7.4.1 Dormant Cracks

Dormant cracks are unlikely to open, close or extend further. There are three

categories of dormant cracks (Turton et al, 1992):

i.

Fine cracks

- up to 1 mm wide

ii.

Wide cracks

- from 1-6 mm wide

iii.

Fractures

- over 6 mm wide

�30

The common method of repair for fine cracks is by injecting the crack with

epoxy resin or other suitable synthetic resin. Epoxy resins will displace water from a

crack and adhere well to damp surface. However it is hard to seal the reverse face of

cracked structure for structures such as slabs or retaining walls. Sealing of the

reverse surface will prevent the resin from flowing out. The usage of thixotropic

resins will eliminate this problem as it will cease to flow when the injection pressure

is released. (Turton et al, 1992)

Wide cracks can occur on vertical or horizontal surfaces. Injection of epoxy

resin is an option for both conditions. There is a more other simpler option for

horizontal wide cracks that can be treated by sealing the underside (Turton et al,

1992). A slight ‘V’ opening is done on the upper surface and repair material is

poured in. The materials that can be used are epoxy resins or cement grouts such as

ordinary Portland and fast hardening cement.

Usually the repair method for fractures relies more on the economic factor.

Epoxy resin mortar or grout will be a suitable option for shallow fractures. Another

option is to open out the fracture and pour mortar or concrete mix.

However,

precautions should be taken to prevent premature drying out and to ensure proper

curing.

2.7.4.2 Live Cracks

Live cracks can be subjected to more movement from external loadings.

Therefore it is important to choose the right method of repair in relation to the crack

movement. Flexible resin can only be used on live cracks with a certain movement.

In cases of large and rapid cyclic movement, the cracks should be treated as

movement joints. Repair works should cater anticipated movement, cut along the

line of crack then sealed with appropriate sealant (Turton et al, 1992). Whereas if the

�31

concrete is carbonated or contaminated with chlorides, it must be broken out and

replaced.

2.7.5

Patch Repairs

Patch repairs is an option for repairing spalled concrete or honeycombing.

Concrete mix can be used in cases of large voids. It is important to make sure that

the concrete surface is clean and free from dusty materials that can interfere with the

bond between patching materials and existing surface. Coats are used as bonding

agent. Epoxy mortar and epoxy concrete can be used on relatively small damage of

corrosion besides insufficient cover to steel.

2.7.6

Sealing

When a concrete member is generally porous it is not suitable to use patching

method. The whole surface must be sealed. There are various sealant materials such

as silicone or a propriety deep penetration compound.

2.7.7

Sprayed Concrete

Sprayed concrete, or gunite, is not a new convention.

Today the term

“sprayed concrete” and “shortcrete” are commonly used (Bernard, 2001). It is a

�32

repair method for corrosion problems, fire-damaged concrete members and distressed

structure requiring large area of reconstruction. Air pressure is an important element

as it ‘shoots’ mixed concrete. The high velocity will deposit layers of concrete on the

surface and each layer gets compacted as a result of impacting action of subsequent

layering. The main advantage of guniting is producing a high strength concrete with

low permeability without formwork. Sprayed concrete can be divided into two

categories which are dry process spraying and wet process spraying.

2.7.7.1 Dry-mix Process

Dry-mix process is a technique in which the content and aggregate are

batched either at site based plant or pre-batched. Dry mix system virtues is a simple

system and few mechanical and mix design issues that can go wrong. However,

every process has its drawbacks. For dry-mix method (Bernard, 2001):

(i) Low equipment performance

(ii) In terms of quality control, sprayed concrete, materials have a great degree of

variance due to the inadequate mixing between the nozzles of the substrate.

2.7.7.2 Wet-mix Process

The wet-mix sprayed concrete process uses concrete that is batched in a

similar way to conventional concrete, making it possible to check and control the

water content ratio and thus the quality at any time. The advantages of wet-mix

method are its ability to produce homogeneous product with uniform quality

throughout the process.

Other advantages are low dust levels, effective use of

admixing material and better total economy for applied sprayed concrete.

The

disadvantages are higher demands on mix design, cleaning cost and limited open

time/workability (Bernard, 2001).

�33

2.7.8

Pre-packed Grouting

Plate bonding can strengthen members that are under strength or require

accepting greater loading. In this process, steel plates are bonded onto the structural

members using bolts and epoxy adhesive. Epoxy is used to bond two different

surfaces which is the steel and concrete. Plate bonding is very economical and

effective at the same time. After repair works is conducted, the cross section size is

not altered drastically.

2.7.9

Recasting

Recasting is a method recommended when exposed concrete finish needs

maintenance and is done by ordinary manpower. In large replacement concrete,

ordinary Portland cement is an economical option. Concrete is mixed in ordinary

mixers to ensure that the mix obtained is workable and achieve required slump.

2.7.10 Dry Packing

Dry packing is appropriate for vertical members with cavities that have

greater depth than width. Concrete surface should be cleaned before hand. Only after

it is free from dust, bonding agent is applied. Dry pack mortar is added with certain

amount of water so that the mix can be rammed into the place without slumping.

�34

2.7.11 Thin Bonded Resurfacing

Improvement of surfaces that have deteriorated through impact of heavy

loading or displaying uneven profile can be repaired by thin bonded resurfacing.

Mortar is applied uniformly on the prepared surface. It is important to make sure that

each layer is cured properly to make sure there is a strong bond between each layer.

2.7.12 Stitching

Stitching is a technique to provide structural continuity in repairs. In tension

cracks, U-shaped anchors are placed inside drilled holes on both sides of the crack.

These holes will then be filled with a non-shrink grout.

2.7.13 Caulking

Caulking is suitable for small or medium width crack repair. Plastic material

is used to fill the narrow raptures in the concrete member. Materials usually used for

dormant cracks are Portland cement mortar or expanding mortar.

elastomeric caulking materials are used for live cracks.

Meanwhile,

�CHAPTER 3

RESEARCH METHODOLOGY

3.1

Introduction

In order to achieve the objectives of this research, it is important to have a

planned and structured study methodology.

This is to ensure smoothness and

effectiveness while conducting the study process. Data collection is an important

element of research to provide more knowledge and information for this study.

There are two types of data which is primary and secondary data.

3.1.1

Primary Data

Primary data refers to all real data collected within the study area. These data

can be obtained through questionnaires, interviews, observations and many more.

�36

3.1.1.1 Reports and records

By collecting reports and records from Public Work Department (PWD),

Sabah will give an overview on the maintenance done by PWD. In doing so it will

help to accomplish the objectives of this study such as to identify what are the most

common defects in concrete building under PWD, cause of deterioration and the

method of repair.

3.1.1.2 Questionnaire

The purpose of a questionnaire is to obtain answers and opinions for

questions that are made in relation to the objectives of the study. Questionnaires are

prepared beforehand by referring to information and sources gathered in literature

review.

3.1.1.3 Interview

Interview sessions are two-way communication which permits exchange in

ideas and information. It is conducted with professional and experienced officers

from PWD regarding concrete building maintenance. These sessions will provide

important ideas and opinions from officers on the common practice of maintenance

done by PWD that cannot be collected through questionnaires.

3.1.2

Secondary Data

Secondary data are data collected from references books, journals,

newspapers, magazines, conference papers, unpublished materials etc.

�37

3.2

Data Analysis

All the data and information that have been collected through reports,

questionnaires, interviews and literature review will need to be organized,

summarized and analyzed. Information that will be analyzed is conclusive of type of

defects in concrete structures, cause of these defects and the most common practice

of repair. Results will be analyzed using frequency counts and other descriptive

statistics method. It is then presented in a clearer manner by using graphs such as

histogram, frequency polygon, pie charts etc. Tables and pictures are attached to

give illustration of the result obtained.

3.2.1

Average Index

The average index is calculated based on the following formula:

a x

i i

Average Index =

x

i

Where:

ai = Constant expressing the weight given to i

xi = Variable expressing the frequency of respondent, for i = 1, 2, 3, 4, 5

�38

Average index method is used to determine the frequency of adoption of

defects occurrence and method of repair. The categories of scales are:

3.3

1 = least frequent

1.00 ≤ min index < 1.50

2 = less frequent

1.50 ≤ min index < 2.50

3 = average

2.50 ≤ min index < 3.50

4 = frequent

3.50 ≤ min index < 4.50

5 = very frequent

4.50 ≤ min index ≤ 5.00

Conclusion

This research utilizes various types of data collection technique. After the

data have been analyzed and tabulated for easy reference, conclusions will be made

by the results obtained in conjunction with the objectives of the study.

Recommendations will be made for future study as well as improvements in

maintenance for defective concrete.

�CHAPTER 4

CASE STUDY

4.1

Introduction

Sabah is one of a state in east Malaysia. It is a part of Borneo which consists

of Sabah and Sarawak. Also known as the land below the wind, Sabah is now vast

developing with implementations of various projects.

Many developments of

facilities and infrastructure are set up to improve the quality of life of residents in

Sabah. In line with that, many new buildings are being built as well as maintaining

old ones. Government buildings in Sabah can also be classified into state and federal

building. Public Work Department (PWD) is in charge of maintaining government

buildings throughout the districts in Sabah. Owners of government buildings are

considered as clients in whom they are also partly responsible in conducting

maintenance upon buildings with the supervision of PWD.

Table 5.1 shows the

summary of financial report of building projects implemented from the year 20022004.

�40

Table 4.1: Summary of Financial Report (Laporan Tahunan, 2002-2004)

Year Project Total Allocation (RM) Total Expenditure (RM) Number of Projects

2002 State

21,799,648.29

17,967,038.48

18

Federal

49,569,862.00

39,946,393.98

31

2003 State

28,983,501.00

14,093,932.75

18

Federal

38,681,725.15

33,852,725.15

29

2004 State

86,243,000.00

40,850,653.00

15

Federal

43,577,200.00

18,621,283.00

8

4.2

Building Works Department Sabah

In the year 2005, Building Works Department or previously known as

Building Department was established in Public Work Department (PWD), Sabah.

The main objectives of this department are (Laporan Tahunan 2005):

Planning, budgeting, implementation and monitoring of all building projects

of state and federal government.

Coordinating, monitoring and reporting of all buildings under Public Work

Department (PWD) while construction to handing over.

Managing PWD building maintenance system

Inspecting and maintaining all state and federal buildings

�41

Next is the organization chart of Building Works Department (PWD) Sabah.

KETUA PENOLONG PENGARAH

ARKITEK KANAN

PEMELIHARAAN

PERANCANGAN

DAN PEMANTAUAN

JURUTERA

JURUTERA

PENTADBIRAN

DAN AKAUN

PEMBANTU

TADBIR

Figure 4.1: Organization Chart of Building Works Department (Laporan Tahunan

2004)

4.3

Clients

Clients will either request Public Work Department (PWD) to inspect their

building or conduct maintenance. Below are among the lists of PWD clients in Sabah

(Laporan Tahunan 2002-2005):

1. Jabatan Arkib Negara

2. Jabatan Bomba

3. Jabatan Hidupan Liar

4. Jabatan Hutan Sabah

5. Jabatan Imigresen

6. Jabatan Kastam, Malaysia

�42

7. Jabatan Kebajikan

8. Jabatan Kerja Raya (JKR)

9. Jabatan Ketua Menteri

10. Jabatan Perhutanan

11. Jabatan Pertanian dan Industri Makanan

12. Jabatn Perpustakaan Negara

13. Kementerian Kebudayaan, Belia dan Sukan

14. Kementerian Kehakiman

15. Kementerian Kesihatan

16. Kementerian Pelancongan, Kebudayaan dan Alam Sekitar

17. Kementerian Pembangunan dan Luar Bandar

18. Kementerian Pembangunan Infrastruktur

19. Marine Polis

20. Pejabat Daerah

21. Perpustakaan Negeri

4.4

Maintenance System

Building maintenance upon government buildings should be conducted

annually.

Upon request from clients, Public Work Department (PWD) personnel

will conduct inspection. PWD from the related district will send request and visual

pictures of the defects to PWD Headquarters in Kota Kinabalu, Sabah. Then, PWD

lab department will be informed to conduct investigation.

PWD team which consists of engineers and technician will go to the site and

do visual inspection.

Recordings of defects and its severity will be reported.

Meanwhile Schmidt Hammer test will be conducted to determine the structural

integrity of the concrete structure.

More detailed and close-up photographs are

taken. The engineer will then prepare a report which consists of findings including

�43

defects, test results, comments and recommendation.

Structural Department will

receive this report and do assessment on the structural integrity of the building.

After full validation by both lab department and structure department,

recommendations will be sent back to District PWD and thereafter to the clients.

Clients then will decide whether or not they will conduct maintenance and also by

whom.

If the client agrees to conduct repair work, PWD Headquarter will be

informed. Cost and estimates will be done and the maintenance work will be open

out for tender if the total cost is more than RM50, 000.00. If the total cost is less, it

will proceed with quotation. Sometimes PWD conduct maintenance by themselves,

however it must comply with certain term and conditions.

Elected contractor will conduct the maintenance work but with the

supervision of PWD superintending officer (S.O).

The contractor carrying out

concrete repairs must comply with the J.K.R. General Specification for Building

Works (September 1974, revised April 1989 edition) except if indicated in the

specification provided by Public Work Department itself. After all repair work is

completed, a joint checking between PWD, contractor and client will be done.

4.5

Problems Faced by Public Work Department (PWD)

There are various problems faced by PWD in building maintenance. The

responsibilities of making sure the building is safe for occupancy lies in the hand of

both clients and PWD.

However, the building maintenance culture is still not

efficient enough. Clients do not usually conduct yearly maintenance. They will only

see the need to inspect and maintain the building when there are serious defects and

reports of major failure in other buildings. Meanwhile PWD faces challenges in the

delay of maintenance procedure.

�44

In Sabah, the problem defective concrete is still prominent in some

government buildings. According to several cases from previous reports, the use of

sea sand in concrete mix in which it is widely used as fine aggregate for construction

in 1980’s have further aggravated the problem of steel reinforcement corrosion in

buildings. However there are some building that use sea sand are still in perfect

condition. The main factor is poor treatment and site workmanship that has elevated

the problem.

The maintenance of these buildings can be tedious and could

eventually lead to major failure.

For most concrete defect, patching is the most common repair technique that

is adapted.

According to J.K.R. General Specification for Building Works

(September 1974, revised April 1989 edition), mortar patching will be used to repair

horizontal repairs. Meanwhile for overhead and vertical repairs will use free flow

cementitious grout and also patch repair mortar.

However, some defects have

reoccurred even though maintenance has been done. This can be due to many

factors. Insufficient previous maintenance such as plastering of spalling concrete and

others usually causes the problem to reoccur. This eventually led to more repetitive

repairs.

�CHAPTER 5

DATA ANALYSIS AND RESULT

5.1

Introduction

Maintenance is an important part in a building to ensure it is safe for

occupancy and is able to function at its intended function. Poor maintenance will

result in repetitive, expensive repairs and replacement of otherwise useful structures.

Federal and state building in Sabah are under the supervision of Public Work

Department (PWD.

In this chapter, analysis have been carried out to study the type of

maintenance done by PWD, types of concrete defects that occur in building, factors

that causes these defects, method of repair to rectify defects and also problems faced

by PWD in building maintenance.

All the data analysis are collected through

questionnaires to PWD personnel and supported by PWD records.

Primary data are collected from questionnaires, interview and observation on

government building in Sabah.

Meanwhile secondary data are obtained from

reference books, journals and unpublished materials. All collected data are analyze

�46

by using average mean index method by using statistical software and are presented

in the form of tables, charts and graphs to make it easier for interpretation.

5.2

Questionnaire Background and Number of Respondents

A total of 40 questionnaires have been sent to district engineers, engineers at

building department and lab investigation department throughout the districts of

Sabah. These questionnaires have been manually distributed to the district office in

Kota Kinabalu and Penampang. Other questionnaires are distributed through email

to the other districts in Sabah. However, out of 40 questionnaire forms, there were

only 20 completed replies returned and is used for this study. Figure 5.1 shows 50%

of forms returned and the other 50% not replied.

Questionnaire Respondent

60%

50%

50%

Replied

Not Replied

Percentage (%)

50%

40%

30%

20%

10%

0%

Figure 5.1: Number of respondents on questionnaire distributed to Public Work

Departments (PWD) Sabah

�47

5.3

Party’s Involved in Carrying out Maintenance Works on Government

Buildings

Government buildings needs to be maintained to ensure its reliability and is

safe for occupancy.

There are two parties involved in the maintenance of

government building. The two parties are Public Work Department (PWD) and

contractor.

From the questionnaire analysis, it is known that most maintenance works are

conducted very frequently by contractor under the supervision of Public Work

Department (PWD). This is shown by an average index of 4.50 from Table 5.1.

However it is up to the client (building owner) to whether contractor or PWD will

conduct the maintenance works. PWD does conduct maintenance works but under

certain terms and condition only.

However, it is quite seldom as compared to

contractor with a mean index of 2.05. The average means index can also be seen in

Figure 5.2 which shows the plotted distribution of party to carry out maintenance.

Table 5.1: Party to Carry Out Maintenance

Number of Respondents

Party to Carry out

Min

Maintenance

1

2

3

4

5

Index

a. Public Work Department

4

14

1

1

0

2.05

b. Contractor

0

0

2

6

12

4.50

1 – Least frequent 2 – less frequent 3 – average 4–frequent 5- Very frequent

Party to Carry Out Maintenance

Public Work

Departm ent,

2.05

Contractor, 4.5

Figure 5.2: Party to Carry Out Maintenance

�48

5.4

Types of Maintenance Conducted On Government Building

Government buildings consist of federal and state building. It is both under

the custody of Public Work Department (PWD) to inspect and maintain these

buildings. There are two types of maintenance which is planned maintenance which

is both preventive and corrective and unplanned maintenance.

The type of maintenance with the highest average mean index is unplanned

maintenance (3.35). Meanwhile the average index for corrective maintenance and

preventive maintenance is 3.10 and 2.65 respectively. This shows that maintenance

that is done the most is done without any predetermined plans.

Through the

interview conducted with district engineer at Kota Kinabalu, he stated that all

government buildings are required to conduct yearly maintenance. However, in

Sabah most maintenance action is only done when the defects have already occurred

to certain extent. Table 5.2 shows the mean index for each type of maintenance.

Table 5.2: Type of Maintenance

Types of Maintenance

1

Number of Respondents

2

3

4

a) Planned Maintenance

(i) Preventive Maintenance

3

6

(ii)Corrective Maintenance

0

6

b) Unplanned maintenance

1

2

1 – Least frequent 2 – less frequent 3 – average

5

Min

Index

6

5

0

2.65

10

4

0

3.10

6

11

0

3.35

4–frequent 5- Very frequent

Figure 5.3 shows the rating for each type of maintenance. For unplanned

maintenance is average with a mean index of 3.35. For corrective maintenance is

also in the rank of average (3.10). Lastly is preventive maintenance which is average

but with a lower mean index (2.65).

�49

Type of Maintenance Conducted on Government Building

Average Mean Index

4

3.5

3

3.35

3.1

2.65

2.5

2

1.5

1

0.5

0

Preventive

Maintenance

Corrective

Maintenance

Unplanned

Maintenance

Figure 5.3: Type of Maintenance Conducted on Government Buildings

5.5

Types of Concrete Defect that Occur in Government Buildings

There are many types of concrete defects that can occur in building. Various

types of concrete defects have been studied in literature review and are listed down in

the questionnaire. The frequency of these defects to occur in government building is

as analyzed and the mean index is as follows.

Table 5.3 and Figure 5.4 both shows that the average means index for

concrete defects ranges from 1.90 to 3.45.

The list of defects through the

questionnaire shows that the most frequent defect that occurs is spalling of concrete

with an average mean index of 3.45. This is followed by delamination with 3.25.

Other defects such as cracks have an average mean index ranging from 2.85 to 2.00.

The highest for cracks is plastic shrinkage crack (3.00) followed by longitudinal

crack (2.85), plastic settlement crack (2.55), transverse crack (2.50), shear crack

(2.25) and crazing map crack (2.00). Scaling has an average mean index of 2.65. The

�50