Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser.

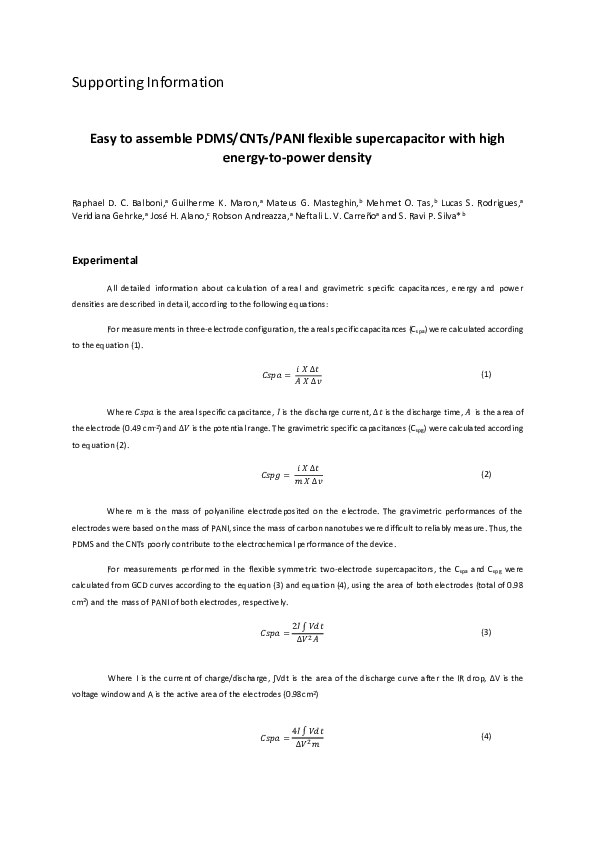

An easy to assemble PDMS/CNTs/PANI flexible supercapacitor with high energy-to-power density

An easy to assemble PDMS/CNTs/PANI flexible supercapacitor with high energy-to-power density

2022, Nanoscale

PDMS is used as matrix to produce a flexible supercapacitor based on aligned carbon nanotubes and polyaniline, which presents outstanding energy-to-power density ratio and remarkable cycling stability even at different bending angles.

Related Papers

2017 •

Journal of Power Sources

Brushed-on flexible supercapacitor sheets using a nanocomposite of polyaniline and carbon nanotubes2010 •

2021 •

The spread of wearable and flexible electronics devices has been accelerating in recent years for a wide range of applications. Development of an appropriate flexible power source to operate these flexible devices is a key challenge. Supercapacitors are attractive for powering portable lightweight consumer devices due to their long cycle stability, fast charge-discharge cycle, outstanding power density, wide operating temperatures and safety. Much effort has been devoted to ensure high mechanical and electrochemical stability upon bending, folding or stretching and to develop flexible electrodes, substrates and overall geometrically-flexible structures. Supercapacitors have attracted considerable attention and shown many applications on various scales. In this review, we focus on flexible structural design under six categories: paper-like, textile-like, wire-like, origami, biomimetics based design and micro-supercapacitors. Finally, we present our perspective of flexible supercapaci...

2021 •

Supercapacitors are energy storage devices that have received much interest in the past decade. These devices have unique characteristics, such as high energy density, fast charging, extensive life cycle, and excellent stability. Currently, wearable electronic gadgets have appeared as an interesting application for flexible supercapacitors, in which lightness and flexibility of the electrodes are two of the most important properties. In addition, the materials used as electrodes severely affect the behavior of these devices. Carbon nanomaterials are the most proficient and most studied electrode materials in flexible supercapacitors. Among them, carbon nanotubes (CNTs) have been extensively studied owing to their excellent mechanical and electrical properties. Therefore, this short review focuses on the new progress in the use of CNT materials as electrodes in flexible energy storage devices.

2013 •

2017 •

Journal of Power Sources

Flexible supercapacitor based on polyaniline nanowires/carbon cloth with both high gravimetric and area-normalized capacitance2010 •

RELATED PAPERS

2023 •

The Cartographic Journal

On The Living Black Atlas: Learning Geospatial Ethics from the African American Freedom Struggle2023 •

Eleições municipais na pandemia

As novas direitas: uma tipologia a partir dos prefeitos eleitos2022 •

Brill Encyclopedia of Early Christianity Online

Christ, Jesus, 02: Birth and Infancy Narratives2018 •

Reproductive Biology and Endocrinology

Maternal immune system adaptation to pregnancy - a potential influence on the course of diabetic retinopathy2010 •

Remote Sensing of Environment

The seasonal cycle of satellite chlorophyll fluorescence observations and its relationship to vegetation phenology and ecosystem atmosphere carbon exchange2014 •

Neuro-Oncology

P16.19 * the Effects of Bevacizumab on MR-Imaging and 1H-MR-SPECTROSCOPY (MRS) in Patients with High Grade Gliomas2014 •

1977 •

Seattle University Law Review

Foreword to Symposium on "Should the Family Be Represented as an Entity?": Reexamining the Family Values of Legal Ethics1998 •

International Journal of Current Microbiology and Applied Sciences

Genetic Divergence of Newly Developed Thirty Eight Maintainer Lines of Rice (Oryza sativa L.) for Yield and Grain Quality Characters2012 •

RELATED TOPICS

- Find new research papers in:

- Physics

- Chemistry

- Biology

- Health Sciences

- Ecology

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

S. Ravi P. Silva

S. Ravi P. Silva