ISSN 0018-1439, High Energy Chemistry, 2015, Vol. 49, No. 1, pp. 48–52. © Pleiades Publishing, Ltd., 2015.

Original Russian Text © A.G. Ryabenko, D.P. Kiryukhin, G.A. Kichigina, O.M. Zhigalina, E.N. Nikolaev, A.N. Krasnovskii, 2015, published in Khimiya Vysokikh Energii, 2015,

Vol. 49, No. 1, pp. 51–55.

NANOSTRUCTURED SYSTEMS

AND MATERIALS

Reactions on Single-Walled Nanotubes:

1. Radiation-Stimulated Reactions in Aqueous Suspensions

of Single-Walled Carbon Nanotubes in Surfactant Solutions

A. G. Ryabenkoa, D. P. Kiryukhina, G. A. Kichiginaa, O. M. Zhigalinab,

E. N. Nikolaevc, and A. N. Krasnovskiid

a

Institute of Problems of Chemical Physics, Russian Academy of Sciences,

pr. Akademika Semenova 1, Chernogolovka, Moscow oblast, 142432 Russia

e-mail: aryabenk@icp.ac.ru

b Shubnikov Institute of Crystallography, Russian Academy of Sciences, Leninskii pr. 59, Moscow, 119333 Russia

c Talrose Institute of Energy Problems of Chemical Physics, Leninskii pr. 38, Moscow, 119334 Russia

d Moscow State Technological Institute STANKIN, Vadkovskii per. 1, Moscow, 127994 Russia

Received May 30, 2014; in final form, August 1, 2014

Abstract—Chical reactions initiated by 60Co γ-radiation in the suspensions of single-wall carbon nanotubes

(SWCNTs) in the aqueous solutions of a surfactant, cetyltrimethylammonium bromide (CTAB), have been

studied. In a pure aqueous solution of CTAB, the radiolysis of water leads to the appearance of OH radicals,

which induce the oxidation of CTAB molecules. In the suspensions, CTAB molecules are concentrated on

SWCNTs and oriented in one direction and the OH radicals induce the crosslinking of surfactant molecules.

A moss-like coating is formed on the nanotubes, and the suspension is converted into jelly. The coating does

not have covalent bonds with the nanotube walls. The formation of the polymer is due to the packing of molecules around the nanotube, rather than their chemical properties.

DOI: 10.1134/S0018143915010129

The γ-irradiation of nanotubes leads to a number of

specific features on radiation grafting. For example,

the irradiation of SWCNTs nanopaper increases its

Young’s modulus and conductivity because of the formation of defects, which can lead to the crosslinking

of nanotubes in bundles [8]. Guo et al. [9] concluded

that irradiation gives a new approach to different forms

of the modification of carbon nanotubes because γ-ray

photons generate a large amount of new defects on the

walls of multiwall nanotubes. This was repeatedly confirmed in works with multiwall nanotubes [10–14]. It

was established that γ-irradiation changes the surface

and structure of multiwall nanotubes [15, 16].

Jovanovic et al. [17] described a new method for highly

efficient functionalization of SWCNTs by DNA wrapping. Because SWCNTs are tightly packed in the bundles, the surface of the nanotubes is inaccessible to

modifying reagents. For the uniform modification of

the walls of nanotubes, it is necessary to split a nanotube from the bundle by preliminary treatment.

Jovanovic et al. [17] used γ-irradiation as this pretreatment, whereas Castell et al. [18] stimulated the formation of crosslinks between nanotubes and a polymer

using γ-irradiation. XRD analysis showed the presence

of only an α-monoclinic crystal; this fact unambiguously demonstrated that nanotubes create a preferred

orientation of polymer molecules [18]. The γ-irradia-

Single-wall carbon nanotubes (SWCNTs) possess

unique mechanical and electronic properties. However, they spontaneously stick together in the course of

synthesis and purification to form thick bundles,

which prevent the practical applications of their

unique properties. The self-assembly of nanotubes

into dense bundles occurs due to the strong van der

Waals interaction of nanotubes over a large contact

surface. This interaction can be decreased either by

the use of a surfactant (noncovalent modification) or

by the grafting of polar functional groups to the walls

of nanotubes (covalent modification). Much attention

has been devoted to the latter of these modifications

[1–7]. It is believed that, on the covalent modification, functional groups are joined to defects on the

walls of the nanotubes because the intact walls are

chemically inert. Modification enlarges these defects

to unavoidably decrease the strength of nanotubes and

change their electronic properties. Radiation-induced

grafting has a number of advantages over usual chemical modification. The products of radiolysis do not

contain initiator catalyst residues. The process can be

performed in gas, liquid, and solid phases. It is likely

that functional groups can be radiation grafted not

only onto defects on nanotube walls but also to intact

walls.

48

�REACTIONS ON SINGLE-WALLED NANOTUBES

As noted above, the surface of SWCNTs in bundles

is inaccessible to modifying agents. The ultrasonic

treatment of SWCNTs in the solutions of surfactants is

a standard method for splitting the bundles. In such

suspensions, the average thickness of the bundles

noticeably decreases; a portion of the tubes occurs in

an individual state, and the surfactant molecules are

concentrated on the surface of the nanotubes. In our

opinion, γ-irradiation will lead to the grafting of these

molecules to the walls of the nanotubes. In this work,

we studied the products of the radiolysis of the aqueous

suspensions of SWCNTs in the solutions of CTAB in

comparison with the radiolysis of the pure solutions

and the radiolysis of SWCNTs in water.

EXPERIMENTAL

The nanotubes were prepared by an electric arc

method with the use of a Ni/Y catalyst. The tubes

were purified to a 95% concentration by gas-phase

oxidation [22]. The suspensions were prepared by the

20-min ultrasonication of a 0.25% solution of CTAB,

which contained 1 mg of SWCNTs in 6 mL of the solution [22]. Nanopaper, which was used for determining

the radiation stability of the nanotubes, was prepared

by the filtration of this solution through a filter with

0.1-µm pores. All of the samples were irradiated with

60Co γ-rays on a Gammatok-100 source (dose rate,

0.15 Gy/s). Electron microscopy was performed on a

HIGH ENERGY CHEMISTRY

Vol. 49

No. 1

2015

284.331

CTAB

3500

N+ (CH3)3 = C19H42N + O

290

310

342.269

344.284

346.301

500

C19H42N + 3O–6H

C19H42N + 2O–4H + O

C19H42N + O–2H + 2O

C19H42N + 3O

326.274

328.288

330.304

332.321

1000

115 kGy

312.292

314.308

316.324

1500

H

C

H

C19H42N + 2O–4H

C19H42N + O–2H + O

C19H42N + 2O

2500

2000

CH3

H

C N+ CH3 = C19H42N

H

CH3

H

+

C N (CH3)3 = C19H42N + O–2H

H

H H

H O C C

H H

75 kGy

3000

H

HC

H

+

O

H

C C

H

35 kGy

4000

298.312

300.328

301.333

However, the reactions of the covalent modification of nanotubes can also be accompanied by reactions between the molecules of a grafted reagent. It is

reasonable to assume that some molecules, especially

long ones, can temporarily adhere and thus become

fixed on the walls of nanotubes due to van der Waals

interaction. Reactions between the adhered molecules

are limited by a specific orientation to the axis of a thin

nanotube on a molecular scale. This can produce

products that are strongly different from those formed

upon free reactions in a liquid and accelerate reactions

between the adhered molecules. This can be of special

importance for understanding the processes of the

production of a SWCNT/polymer composite by in situ

polymerization. As far as we know, this problem was

not studied in detail. Let us note two publications

where it was noted that the presence of nanotubes in a

reaction medium changes the structure of the resulting

polymer [18, 20]. Rance et al. [21] found an effect of

SWCNTs on chiral chemical reactions. That is, a

chiral nanosized carbon surface can control the chirality of the products of organic reactions.

C16

285.335

tion of threads woven from carbon nanotubes in an

atmosphere of air increases their tensile strength and

Young’s modulus, probably, because of an increase in

interactions between individual nanotubes [19]. All of

the cited publications were dedicated to reactions

between nanotubes or between a grafted reagent and a

nanotube.

49

330

350 m/z

Fig. 1. Electrospray mass spectra of a 0.1% CTAB aqueous

solution after γ-irradiation at doses of 35, 75, and 115 kGy.

Philips EM430ST instrument with an operating voltage of 200 kV.

RESULTS AND DISCUSSION

γ-Irradiation of SWCNT in Water

The irradiation of the nanopaper in water to a dose

of 7000 kGy did not change the UV–Vis–NIR spectrum of the nanotubes. The Raman spectrum did not

reveal changes with reference to the initial sample.

The IR spectrum of the nanopaper after irradiation

exhibited a considerable decrease in the absorption of

CTAB residues without changes in the spectrum of the

nanotubes. All the above suggests the high radiation

stability of the nanotubes in water; the OH radicals

resulting from the radiolysis of water did not interact

with the nanotubes. Consequently, unlike published

data [8, 10–17, 20, 21], radiation had no effect on the

structure of nanotube walls in water under the conditions of our experiments. At the same time, the irradiation of the nanopaper in air impaired the UV–Vis–

NIR spectrum; this is consistent with conclusions

made by Skakalova et al. [8]. We assume that this was

caused by ozone formed upon irradiation.

γ-Irradiation of CTAB Solutions

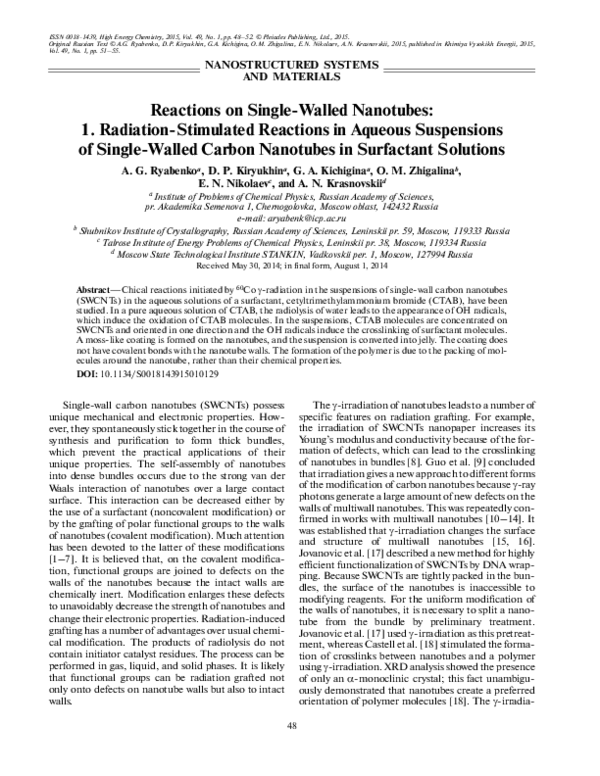

Figure 1 shows the electrospray mass spectra of a

0.1% solution of CTAB after γ-irradiation at doses of

35, 75, and 115 kGy. The degree of oxidation of CTAB

molecules increased with dose. From Fig. 1, it is evident that double bonds were formed on irradiation to

cause the appearance of additional absorption in the

UV range (Fig. 2a). Figure 2b shows the dependence

of this absorption on radiation dose and on the initial

�50

RYABENKO et al.

(а)

500 kGy

3.0

320 kGy

250 kGy

2.5

15

2.0

1.5

Total absorption, arb. units

Absorption, arb. units

(b)

120 kGy

1.0

40 kGy

0.5

0

0

237

262

Wavelength, nm

212

287

312

0.3%

0.2%

10

0.1%

5

0

100

200

300 400 500

Dose, kGy

600 700

Fig. 2. (a) Changes in the spectrum of a 0.3% CTAB solution with γ-irradiation dose. (b) The dose dependence of the accumulation of products with double bonds in solutions with different CTAB concentrations.

concentration of CTAB. It is evident that, at the initial

stage, the product was linearly accumulated with dose

regardless of the initial concentration. Consequently,

possible micelle formation (critical micelle concentration (CMC) = 0.25%) does not influence the rate of

oxidation. The CTAB content of the solution rapidly

decreased with γ-irradiation dose (see Fig. 1), and the

concentration of products also began to fall after the

initial linear increase (Fig. 2b). At high doses, CTAB

was completely oxidized.

7.5 Mrad

CTAB + SWCNTs

250

615.304

500

750

996.524

800.450

687.363

284.331

7.5 Mrad

11.5 Mrad

543.244

504.370

11.5 Mrad

127.123

45

40

35

30

25

20

15

10

5

C20H39O6NH2 ?

391.285

1000 m/z

Fig. 3. Electrospray mass spectra of the soluble fraction of

suspensions after γ-irradiation at doses of 75 and 115 kGy

and settling for eight months.

γ-Irradiation of SWCNT Suspensions

Other results were obtained upon the irradiation of

the suspensions of SWCNTs. Doses of 75 and 115 kGy

led to the loss of the long-time stability of the suspensions, and the nanotubes settled down after several

months. Figure 3 shows the mass spectrum of transparent liquid above these sediments. A comparison

between Figs. 1 and 3 indicates that, in the presence of

the nanotubes, free CTAB in solution was consumed

more rapidly, and the peaks of products in the solution

with the nanotubes were several times higher than the

peak of the parent substance (a peak at 284.331); the

products were very different, and their molecular

weights were noticeably higher; the fraction of heavy

masses increased with dose. Several peaks with distances of ~110 dalton between them stand out; that is,

a molecule of ~110 amu was formed in the process of

radiolysis in water, and these molecules were consecutively added to the CTAB molecule. At a dose of 200–

300 kGy, the suspension was converted into jelly,

which was insoluble in water and organic solvents.

Figure 4 shows a micrograph of a film of this jelly from

a transmission electron microscope (TEM). The

insert shows that the nanotubes were covered with a

moss-like coating, which was nonuniform in thickness

but no more than 1.5 nm thick (the thickness of the

coating was comparable with or smaller than the

thickness of a nanotube). In the suspension, the concentrations of water, CTAB, and SWCNTs were 99.73,

0.25, and 0.02 wt %, respectively. The only difference

of the suspension from pure solution was that CTAB

molecules in the suspension were concentrated at the

HIGH ENERGY CHEMISTRY

Vol. 49

No. 1

2015

�REACTIONS ON SINGLE-WALLED NANOTUBES

51

the latter version because the CTAB molecule is too

long to be arranged in the visible outgrowths according

to the former two versions. Figure 5 shows a hypothetical diagram of the formation of a coating. Note that,

in the course of irradiation (at the stages of 10, 20, 30,

and 50 kGy when the suspension remained stable), the

UV–Vis–NIR spectrum of the suspension did not

deteriorate; therefore, the SWCNTs did not undergo

chemical alteration in the course of the growth of the

coating. Nanotubes served as a catalyst for the formation of a polymer. Our preliminary experiments with

other surfactants (such as Triton-100 and sodium

dodecylbenzenesulfonate) showed that jelly was also

formed in the suspensions prepared based on these

surfactants under the action of γ-radiation. This fact

suggests that the formation of polymers was caused by

the packing of molecules around the nanotube rather

than their chemical properties.

25 nm

150 nm

CONCLUSIONS

Fig. 4. TEM image of a film of the jelly formed after the

irradiation of a suspension of SWCNTs at a dose of

250 kGy. Insert: a thin bundles and a separate nanotube

(marked with an arrow).

walls of SWCNTs. It is likely that, for this reason, the

OH radicals crosslinked the molecules; thus, a polymer was formed.

There is no general agreement on the packing of

surfactant molecules around a nanotube. O’Connell

et al. [23] and Shin et al. [24] assumed surfactant organization as a cylindrical micelle or micellar hemispheres, respectively, whereas Wallace and Sansom

[25] proposed the possibility of the stacking of surfactant molecules along the nanotube. Our data confirm

CTAB molecule

The presence of SWCNTs radically changes the

rate and direction of the reactions of OH radicals with

CTAB molecules; however, the addition of these latter

to the nanotube walls does not occur. In the presence

of the nanotubes, the OH radicals crosslink the molecules of CTAB with the formation of a polymer coating around the nanotubes and their bundles. The rate

of CTAB consumption increases.

ACKNOWLEDGMENTS

This work was supported by the Ministry of Education and Science of the Russian Federation within the

framework of a scientific state contract.

E.N. Nikolaev acknowledges the support of the

Russian Foundation for Basic Research, project

nos. 13-04-40110-N and 13-08-01445, and the Rus-

2.5 nm

2.5 nm

N

O

N

C

C

N

O

Carbon nanotube

Fig. 5. Illustration of polymer formation around a nanotube. Insert: TEM image of polymer outgrowths on the nanotube, which

shows that CTAB molecules concentrated at the nanotubes are arranged along the nanotube.

HIGH ENERGY CHEMISTRY

Vol. 49

No. 1

2015

�52

RYABENKO et al.

sian Science Foundation, grant no. 14-24-00114) for

the development of mass spectrometry methods.

REFERENCES

1. Mickelson, E.T., Chiang, I.W., Zimmerman, J.L.,

Boul, P.J., Lozano, J., Liu, J., Smalley, R.E.,

Hauge, R.H., and Margrave, J.L., J. Phys. Chem. B,

1999, vol. 103, no. 24, p. 4318.

2. Dyke, C.A. and Toiur, J.M., Nano-Lett., 2003, vol. 3,

no. 9, p. 1215.

3. Paloniemi, H., Aaritalo, T., Laiho, T., Liuke, H.,

Kocharova, N., Haapakka, K., Terzi, F., Seeber, R.,

and Lukkari, J., J. Phys. Chem. B, 2005, vol. 109,

no. 18, p. 8634.

4. Burghard, M., Surf. Sci. Rep., 2005, vol. 58, nos. 1–4,

p. 1.

5. Ciraci, S., Dag, S., Yildirim, T., Gulseren, O., and Senger, R.T., J. Phys.: Condens. Matter, 2004, vol. 16,

no. 29, p. Ð.901.

6. Tasis, D., Tagmatarchis, N., Bianco, A., and Prato, M.,

Chem. Rev., 2006, vol. 106, no. 3, p. 1105.

7. Kim, S.W., Kim, T., Kim, Y.S., Choi, H.S., Lim, H.J.,

Yang, S.J., and Park, C.R., Carbon, 2012, vol. 50, no. 1,

p. 3.

8. Skakalova, V., Dettlaff-Weglikowska, U., and Roth, S.,

Diamond Relat. Mater., 2004, vol. 13, no. 2, p. 296.

9. Guo, J., Li, Y., Wu, S., and Li, W., Nanotechnology,

2005, vol. 16, no. 10, p. 2385.

10. Xu, H.X., Wang, X.B., Zhang, Y.F., and Liu, S.Y.,

Chem. Mater., 2006, vol. 18, no. 13, p. 2929.

11. Chen, S.M., Wu, G.Z., Liu, Y.D., and Long, D.W.,

Macromolecules, 2006, vol. 39, no. 1, p. 330.

12. Wu, W.-T., Shi, L., Wang, Y., Pang, W., and Zhu, Q.,

Nanotechnology, 2008, vol. 19, no. 12, p. 125607.

13. Karim, M.R., Yeum, J.H., Lee, M.S., and Lim, K.T.,

Mater. Chem. Phys., 2008, vol. 112, no. 3, p. 779.

14. Jung, C.H., Kim, D.K., and Choi, J.H., Curr. Appl.

Phys., 2009, vol. 9, p. 85.

15. Xu, Z., Chen, L., Liu, L., Wu, X., and Chen, L., Carbon, 2011, vol. T.49, p. C.339.

16. Safibonab, B., Reyhani, A., Nozadgolikand, A., Mortazavi, S.Z., Mirershadi, S., and Ghoranneviss, M.,

Appl. Surf. Sci., 2011, vol. 258, no. 2, p. 766.

17. Jovanovic, S.P., Markovic, Z.M., Kleut, D.N., Romcevic, N.Z., Trajkovic, V.S., and Dramicanin, M.D.,

and Todorovic Markovic, B.M., Nanotechnology, 2009,

vol. 20, no. 44, p. 4456021.

18. Castell, P., Medel, F., Martinez, M., and Puertolas, J.,

J. Nanosci. Nanotechnol., 2009, vol. 9, no. 10, p. 6055.

19. Miao, M., Hawkins, S.C., Cai, J.Y., Gengenbach, T.R.,

Knott, R., and Huynh, C.P., Carbon, 2011, vol. 49,

no. 14, p. 4940.

20. Estrin, Ya.I., Badamshina, E.R., Grishchuk, A.A.,

Kulagina, G.S., Lesnichaya, Yu.A., Ol’khov, V.A., Ryabenko, A.G., and Sul’yanov, S.N., Polym. Sci., Ser. A,

2012, vol. 54, no. 4, p. 290.

21. Rance, G.A., Miners, S.A., Chamberlain, T.W., and

Khlobystov, A.N., Chem. Phys. Lett., 2013, vol. 557,

p. 10.

22. Ryabenko, A.G., Dorofeeva, T.V., and Zvereva, G.I.,

Carbon, 2004, vol. 42, no. 8/9, p. 1523.

23. O’Connell, M.J., Bachilo, S.M., Huffman, C.B.,

Moore, V.C., Strano, M.S., Haroz, E.H., Rialon, K.L.,

Boul, P.J., Noon, W.H., Kittrell, C., Ma, J.,

Hauge, R.H., Weisman, R.B., and Smalley, R.E., Science, 2002, vol. 297, p. 593.

24. Shin, Ji-Y., Premkumar, T., and Geckeler, K.E., Chem.

Eur. J., 2008, vol. 14, p. 6044.

25. Wallace, E.J. and Sansom, M.S.P., Nanotechnology,

2009, vol. 20, no. 4, p. 045101.

Translated by V. Makhlyarchuk

HIGH ENERGY CHEMISTRY

Vol. 49

No. 1

2015

�

Evgeny N Nikolaev

Evgeny N Nikolaev