Preprint

Article

Ballistic Behavior of Epoxy Composites Reinforced with Amazon’s Titica Vine Fibers (Heteropsis flexuosa) in Multilayered Armor System and as Stand-Alone Target

Altmetrics

Downloads

110

Views

35

Comments

0

A peer-reviewed article of this preprint also exists.

Abstract

Titica vine fibers (TVFs) extracted from aerial roots of Heteropsis flexuosa, from the Amazon region, were 10, 20, 30 and 40 vol% incorporated into an epoxy matrix for applications in ballistic multilayered armor systems (MASs) and stand-alone tests for personal protection against high-velocity 7.62 mm ammunition. The back-face signature (BFS) depth measured for composites with 20 and 40 vol% TVFs used as an intermediate layer in MASs was 25.6 and 32.5 mm, respectively, below the maximum limit set by the international standard. Fracture mechanisms found by scanning electron microscopy (SEM) attested the relevance of increasing the fiber fraction for applications in MASs. The results of stand-alone tests showed that the control (0 vol%) and samples with 20 vol% TVFs absorbed the highest impact energy (Eabs) (212 – 176 J), and consequently limit velocity (VL) values (213 – 194 m/s), when compared with 40 vol% fiber fractions. However, the macroscopic evaluation found that the plain epoxy, referring to control samples, shattered completely. In addition, for 10 and 20 vol% TVFs, the composites were fragmented or exhibited delamination fracture, which contributed to their physical integrity. On the other hand, the composite with 30 and 40 vol% TVFs, whose Eabs and VL varied between 166 – 130 J and 189 – 167 m/s, respectively, showed the best dimensional stability. The SEM images indicated that for composites with 10 and 20 vol% TVFs the fracture mode was predominantly brittle, due to the greater performance of the epoxy resin and the discrete action of the fibers. While for composites with 30 and 40 vol% TVFs, there was the activation of more complex mechanisms such as pullout, shearing and fiber rupture.

Keywords:

Submitted:

04 July 2023

Posted:

06 July 2023

You are already at the latest version

Alerts

A peer-reviewed article of this preprint also exists.

Submitted:

04 July 2023

Posted:

06 July 2023

You are already at the latest version

Alerts

Abstract

Titica vine fibers (TVFs) extracted from aerial roots of Heteropsis flexuosa, from the Amazon region, were 10, 20, 30 and 40 vol% incorporated into an epoxy matrix for applications in ballistic multilayered armor systems (MASs) and stand-alone tests for personal protection against high-velocity 7.62 mm ammunition. The back-face signature (BFS) depth measured for composites with 20 and 40 vol% TVFs used as an intermediate layer in MASs was 25.6 and 32.5 mm, respectively, below the maximum limit set by the international standard. Fracture mechanisms found by scanning electron microscopy (SEM) attested the relevance of increasing the fiber fraction for applications in MASs. The results of stand-alone tests showed that the control (0 vol%) and samples with 20 vol% TVFs absorbed the highest impact energy (Eabs) (212 – 176 J), and consequently limit velocity (VL) values (213 – 194 m/s), when compared with 40 vol% fiber fractions. However, the macroscopic evaluation found that the plain epoxy, referring to control samples, shattered completely. In addition, for 10 and 20 vol% TVFs, the composites were fragmented or exhibited delamination fracture, which contributed to their physical integrity. On the other hand, the composite with 30 and 40 vol% TVFs, whose Eabs and VL varied between 166 – 130 J and 189 – 167 m/s, respectively, showed the best dimensional stability. The SEM images indicated that for composites with 10 and 20 vol% TVFs the fracture mode was predominantly brittle, due to the greater performance of the epoxy resin and the discrete action of the fibers. While for composites with 30 and 40 vol% TVFs, there was the activation of more complex mechanisms such as pullout, shearing and fiber rupture.

Keywords:

Subject: Chemistry and Materials Science - Materials Science and Technology

1. Introduction

Fire-armed is a persistent problem that has been escalating in large urban centers of emerging countries. In addition armed conflicts still persist between nations and terrorist groups, demanding a pressing need for the improvement of body armor systems to ensure the safety of combatants. In this regard, the search for new materials capable of absorbing high impact energies, resisting penetration, and promoting mobility must be prioritized, taking into consideration the advancements in weapons and ammunition technology [1,2,3].

Multilayered armor systems (MASs) enable efficient personal protection against traumas caused by heavy ammunition. These systems consist of distinct layers of materials designed to withstand the impact of high-velocity projectiles (>800 m/s) [4,5,6]. A typical MAS is comprised of a ceramic front layer, which aims to fragment the projectile tip and absorb most of its energy [4,5,6,7,8,9]. The second layer is a lower-density material, often a polymer, that absorbs the residual energy of the ceramic fragments and projectile shrapnel resulting from the front layer [6,10]. Lastly, the third layer is commonly composed of a ductile metal [11], or more recently, synthetic fabrics such as aramid [12,13].

The international standard NIJ 0101.04 [14], which assesses the ballistic resistance of personal body armor, provides two methods to determine the efficiency of a MAS. The first method involves measuring the trauma (indentation) caused in a clay witness backing after being shot with 7.62 mm x 51 mm NATO ammunition. The clay witness simulates the consistency of the human body and, according to the standard, the deformation caused by the projectile cannot exceed 44 mm, as anything beyond that could be considered lethal in real-life situations. The second method is based on a probabilistic approach that calculates the limit velocity (VL), i.e., the velocity above which the projectile can penetrate the armor and below which the projectile is stopped. The criterion used is the ballistic limit V50, which determines the velocity at which the probability of perforation would be 50% [3]. However, for high-velocity projectiles (>800 m/s), it is not feasible to calculate the V50 due to limitations in shooting at low speeds. As a result, it is not possible to guarantee non-perforation of the target, as the reduction in gunpowder reaches a limit where the projectile may not leave the firing device. In such cases, VL is understood as the maximum velocity at which the target can absorb all the kinetic energy of the projectile, as described by Morye et al. [15].

Synthetic fabrics made os strong aramid fibers (e.g. Kevlar/Twaron), ultrahigh molecular weight polyethylene (e.g. Dyneema), and polybenzoxazole (e.g. Zylon) have traditionally been used in MAS. However, in recent times, natural fiber reinforced polymer composites (NFRPCs) have gained popularity as a cost-effective replacement for synthetic laminates in the second layer of a multilayered armor system (MAS) [13,17,18,19,20]. Natural lignocellulosic fibers (NLFs), such as those derived from plant sources, offer several attractive properties, including low cost, lightweight, minimal health risks during processing, good thermal and acoustic insulation characteristics, reasonably good specific strength and modulus, and wide availability, among others [21,22,23]. As a result, NFRPCs have found numerous applications in areas such as civil construction panels [24], automotive parts [25], aeronautics [26], and more recently, ballistic armor [27].

The fiber extracted from the Heteropsis flexuosa, a plant prevalent in the Amazon region, is also known as titica vine fiber (TVF). This NLF from the Araceae family [28], rarely addressed in forestry studies [29] and in engineerable composites [30], has shown promise when incorporated into polymer matrices [30,31]. A recent study on TVFs revealed favorable properties for application in NFRPCs, describing them as comparable to many NLFs previously investigated in the literature for the same purpose, as compared in Table 1.

According to Table 1, TVFs have one of the lowest densities among NLFs. In addition, the low microfibrillar angle and high crystallinity yield a comparable tensile strength for this fiber. These properties motivated for the first time a study on the use of TVFs in epoxy matrix composites both as the second layer of MASs and as stand-alone samples for the absorbed impact energy (Eabs) and limit velocity (VL). The present work evaluated the ballistic performance of a MAS consisting of an Al2O3/Nb2O5 ceramic front layer followed by a composite plate, varying between 20 and 40 vol% TVFs, supported on a panel with 12 Twaron sheets that simulate a level IIIA ballistic vest (Figure 1). The depths of indentation were measured after the shots using 7.62 mm x 51 mm NATO ammunition. Stand-alone tests were also carried out on single composite plates (0 to 40 vol% of TVFs) to determine the energy absorbed after the impact and the limit velocity of the materials. The acquired data were statistically evaluated using the Weibull distribution, analysis of variance (ANOVA), and the Tukey test to identify behaviors and alterations in the failure mechanisms, as well as to investigate the level of reliability, significance, and equality of the results obtained.

2. Materials and Methods

Titica vine fibers (TVFs) were purchased at a local market in the city of Boa-Vista, state of Roraima, Brazil, and used as reinforcement for polymeric composites. Composite plates were made by compression molding using a commercial epoxy resin, diglycidyl ether of bisphenol A (DGEBA)-type, hardened with triethylenetetramine (TETA), in stoichiometric ratio phr 13, both supplied by Epoxy Fiber (Rio de Janeiro, Brazil).

Before producing the composites, the fibers were cleaned in running water and placed in an oven at 60 °C for 24 h. Then, composites with 0, 10, 20,30 and 40 vol% TVFs, preferably aligned in the direction, incorporated into epoxy resin (TVF/E) were prepared by the hand lay-up process, in which a compression force of 5 MPa was applied in a Sky hydraulic press, Brazil, at room temperature (RT) for 24 h. The metallic mold used for processing had dimensions of 150 x 120 x 11.9 mm. For the manufacture of composites, 0.50 g/cm3 was adopted as the average density for TVFs [30] and 1.11 g/cm3 for epoxy resin [42]. Figure 2 schematically presents the processing method used.

The production of MAS targets involved the assembly of three layers: in a first layer of a 10 mm thick ceramic plate made of Al2O3 + Nb2O5; in a second layer of a 10 mm thick TVF/E composite plate; and in a third layer consisting of 12 sheets of Twaron. The Twaron fabric, which was supplied by the Teijin Aramid company, China, was cut into rectangular sheets measuring 15 x 12 x 0.01 cm. The individual sheets were then bonded together using polyurethane glue. The Al2O3 + Nb2O5 ceramic plates were manufactured using a previously described procedure [43].

The ballistic behavior of the composites was evaluated through two tests conducted at the Army Assessment Center (Caex) in Rio de Janeiro, Brazil. The first test involved placing a MAS target in front of a clay witness block supplied by Corfix, Porto Alegre, Brazil. After the shots were fired, a laser sensor (model Q4x Banner) was used to measure the back-face signature (BFS) depth of the resulting trauma. This test is commonly referred to as the BFS perforation and is described by the international standard NIJ 0101.04 [14]. In the second test, the individual performance of the TVF/E composite plates in terms of Eabs and VL was assessed. This test is known as the stand-alone test.

Both MAS and stand-alone ballistic tests used 7.62 mm caliber commercial ammunition, weighing 9.3 g, with metal coating. The velocity of the projectile before and after impact was measured using a radar model SL-520P Weibel Doppler, Denmark. For each proposed TVF volume content, five samples of MAS (20 and 40 vol% TVFs) and seven independent composite plates (0, 10, 20, 30 and 40 vol% TVFs) were tested.

For by stand-alone tests, the impact energy absorbed (Eabs) by the composite was estimated with the following equation:

Where Mp is the mass of the projectile, Vi is the velocity of the projectile just before impact, and Vr is the residual velocity of the projectile after perforating the target.

The limit velocity (VL) is a dynamic parameter of great interest in materials for ballistic applications. Assuming that the target can fully stop the projectile, i.e. Vr equals to zero, the limit velocity can be calculated with the equation:

Where M is the mass of the projectile.

The ballistic parameters, including BFS depth, absorbed energy, and limit velocity, were statistically evaluated and validated in terms of reliability and significance, through the Weibull distribution and analysis of variance (ANOVA), along with the Tukey test.

Finally, the microscopic aspects of the ballistic impacted MASs and stand-alone TVF/Epoxy composites samples were analyzed using scanning electron microscopy (SEM), in a Quanta FEG 250 FEI microscope, Switzerland, operating with secondary electrons and voltages up to 5 kV. All samples were sputter-coated with gold using a LEICA EM ACE600 equipment.

3. Results

3.1. Multilayered Armor System (MAS)

Previous studies [44] confirm the efficiency of MASs consisting of three layers (ceramic + NLFs composite + aluminum alloy) protect against level III ammunition and meet the BFS depth criteria established by the NIJ [14]. However, in the present work, armor plates were placed in front of target samples that simulate a level IIIA bulletproof vest to enhance its performance to level III protection against 7.62 mm ammunition. The results obtained for the MASs tested in this study are shown in Figure 4. The systems in which the intermediate composite plates have 20 and 40 vol% TVFs were denominated 20TVF/E and 40TVF/E, respectively.

For all samples and conditions tested there was no complete perforation of the target. In addition, for both groups, the BFS depth was less than 44 mm, the maximum limit allowed by the NIJ [14] to avoid lethal trauma. With the increase in the volume of fibers present in the second layer, the measured trauma increased from 25.57 mm to 32.51 mm. This same behavior was reported by other authors. Oliveira et al. [45] investigated the ballistic performance of both single composites of fique fabric and epoxy and their application as an intermediate layer in MASs. In their work, an increase in the BFS depth of 3.3 mm was verified when incorporating larger fractions of fique fabric (15 to 50 vol%). Demosthenes et al. [46] verified that as buriti fabrics volume content was increased in epoxy matrix composites, there was a gradual increase in the traumas measured in the clay witness, jumping from 18.9 mm for the 10% samples to 25 mm for those with 30 vol%. This behavior is probably associated with transitions in the fracture mechanisms acting on the composites, which were evaluated by means of SEM and further discussed in a following separate section.

The Weibull distribution was used to quantify the statistical reliability of the measured BFS depth results. Table 2 presents the distribution parameters related to the evaluated property (BFS depth), were β the Weibull modulus, θ the scale parameter, and R² of statistical precision.

Table 2 shows that the 40TVF/E composite had a lower β value, indicating a greater dispersion of values, as confirmed by the higher standard deviation of this group. The θ parameter followed the expected trend, correlating with the BFS depth measured in the test. Specifically, 62.3% of the tested samples in the 20TVF/E and 40TVF/E groups had a BFS depth of approximately 26.9 and 34.7 mm, respectively. The statistical precision coefficient R2 was highly representative and within an acceptable reliability range (>0.83). However, up to 17% of the samples in the 20TVF/E group and 4.5% in the 40TVF/E group could not be explained by the Weibull mathematical model.

Although the BFS depth increased with the volumetric fraction of TVFs, the standard deviations for the average measurements extracted from these groups may conceal the correlation regarding possible differences between the composites. To clarify this, ANOVA was performed on the results shown in Figure 4. The results indicate, with 95% confidence, that the values are different, as Fcalc = 7.28 > Fcritical = 5.31. Therefore, since there are only two sample conditions, it is possible to say that the volumetric fraction of fibers incorporated into the composites influenced the increase in the BFS depth exhibited by the MASs samples, with systems with 20TVF/E resisting the penetration of the projectiles better. Figure 5 depicts the appearance of the MAS target after being hit by a 7.62 mm projectile in ballistics tests using 20TVF/E and 40TVF/E as an intermediate layer.

In all samples the ceramic plate was completely destroyed (Figure 5). This occurs because this material is responsible for absorbing most of the impact energy [9]. Despite this, the composite layer plays a fundamental role in energy dissipation through the capture of ceramic fragments [19,47] that can be visualized by the presence of small white particles covering the fracture surface in the central area. This will be better explored by SEM images.

The ballistic tests showed that even though the MAS samples with an intermediate layer of 20TVF/E presented greater resistance to penetration due to their smaller BFS depth, the plates of this condition were almost completely fragmented, as seen in Figure 5a,b. In contrast, the targets with 40TVF/E showed traces of composite fragments stick to the shield, indicating an improvement in the physical integrity of the material with an increase in fiber content, as shown in Figure 5c,d. This improvement in physical integrity is an important criterion for ballistic applications, as noted by Monteiro et al. [48].

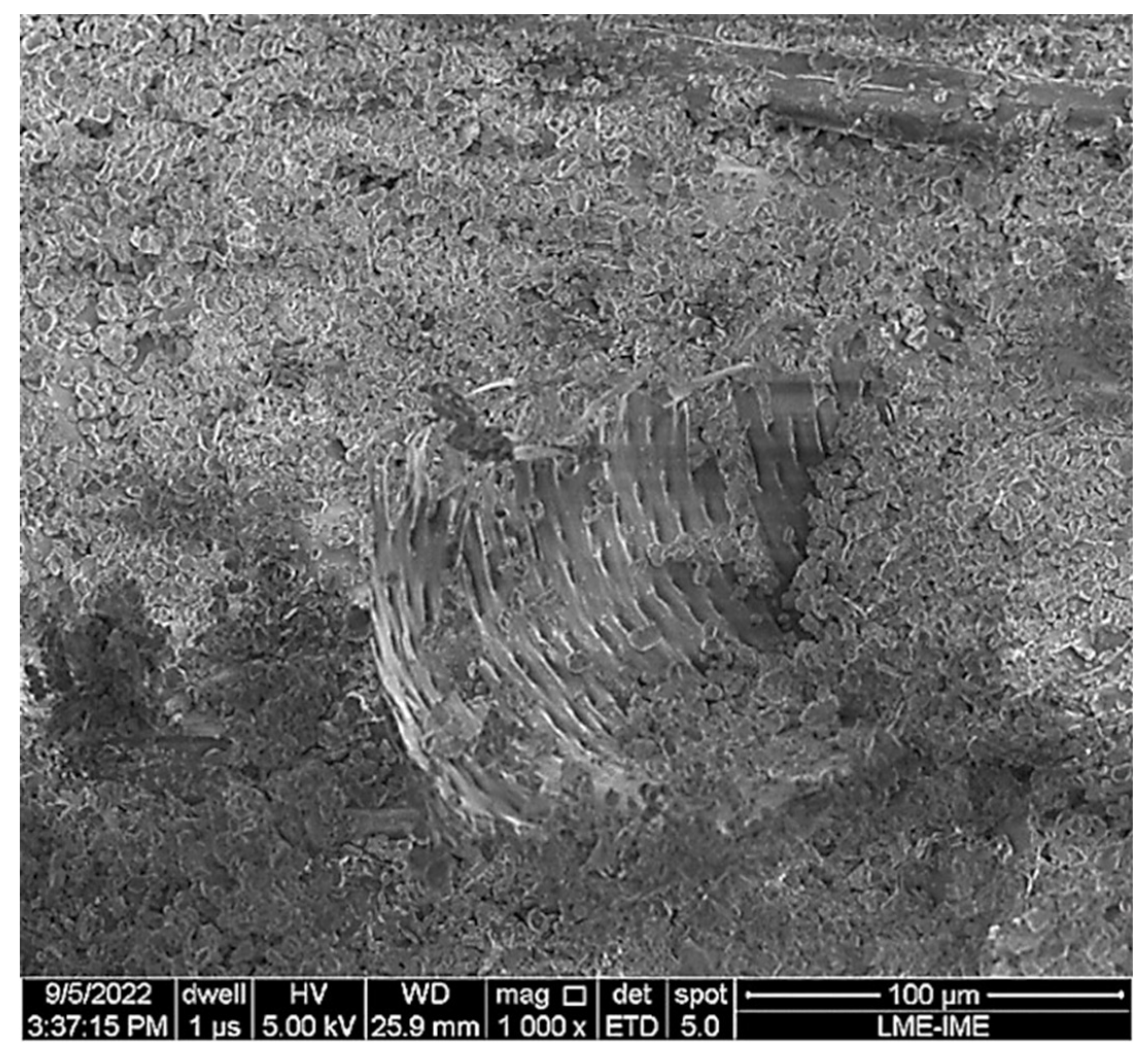

The SEM image illustrated in Figure 6 shows the surface of a 20TVF/E composite covered by ceramic material. Note that the intermediate layer absorbed the kinetic energy of the fragments through mechanical encrustation. This is due to electrostatic charges and van der Walls forces acting on the surface of the composite [11].

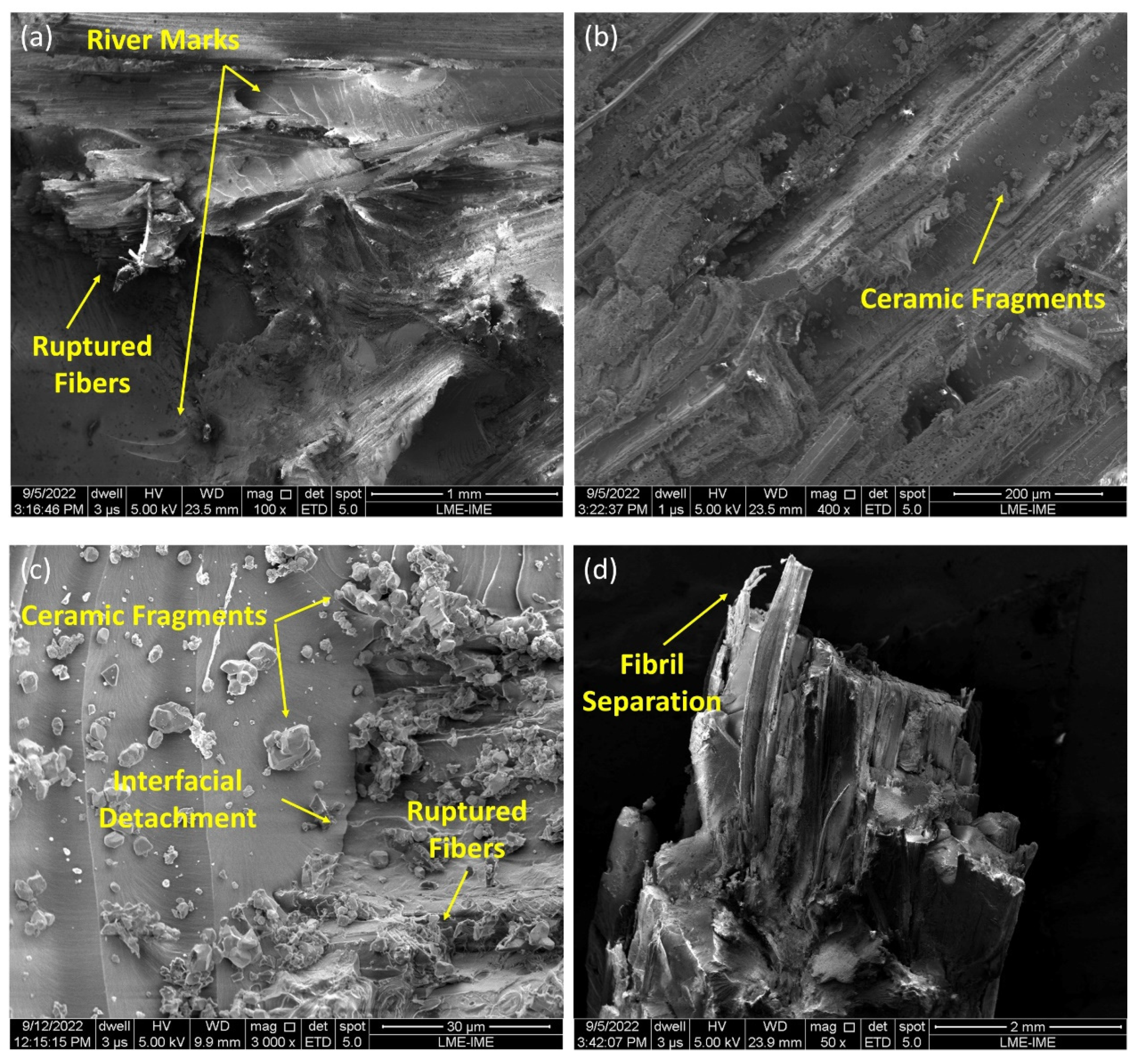

To better understand the fracture and energy absorption mechanisms at work, SEM images were taken on the surface of the target samples after the 7.62 mm shootings, as shown in Figure 7.

The performance of the target MASs can be explained through an evaluation of the fracture surface of these samples. Figure 7a,b confirms the brittle fracture tendency of the 20TVF/E composites. Although mechanisms of fracture and energy dissipation are observed, such as TVFs rupture and capture of ceramic fragments, the micrographs point to the strong influence of the epoxy resin which is predominant throughout the composite. In addition, there is a significant presence of river marks.

When checking the images in Figure 7c,d, mechanisms similar to those evidenced in the 20TVF/E samples are also present. However, others can still be identified, such as interfacial detachment and fibril separation. These same mechanisms of energy dissipation were reported by Costa et al. [12] when evaluating the ballistic performance of epoxy composites reinforced with curaua fibers.

The 40TVF/E samples exhibited more complex mechanisms due to the action of TVFs, as evidenced by a more disturbed fracture surface and better physical integrity. However, the greater BFS depth after impact on the MASs samples with larger fiber volumes suggests these mechanisms were not sufficient to improve the ballistic behavior. This could be attributed to the weak compatibilization at the TVF/E interface, which is often associated with the hydrophobic nature of the matrix and the hydrophilic nature of the fibers. Additionally, the presence of impurities on the surface of the TVFs such as waxes and oils can make it difficult to anchor with the matrix. Furthermore, the fibers have lower mechanical properties compared to the epoxy resin, which has a tensile strength of 38 MPa and an elastic modulus of 1.38 GPa [30]., whereas TVFs have 26 MPa and 1.02 GPa, respectively, as described elsewhere [49].

Table 3 compares the materials used as an intermediate layer in MAS available in the literature and those investigated in the current work.

According to the data presented in Table 3, it is observed that the results of the composites with 20 vol% of TVFs are similar to those obtained using NLFs traditionally known as buriti and coir reinforcing the intermediate layer of MASs. Increasing the TVF fraction to 40 vol% leads to BFS depth measurements closer to those obtained with 30 vol% of coir and guaruman fibers, indicating that higher TVF fractions are more effective in enhancing ballistic performance. Interestingly, the MASs with 40TVF/E exhibit superior ballistic performance compared to those with bagasse/E (at a lower fraction) and a Dyneema plate. It should be noted that the systems with bagasse and coconut fibers used an aluminum plate (ρal=2.66 g/cm3) [50] as the third layer, while in this study, 12 sheets of Twaron fabric (ρTwaron= 1.44 g/cm3) [51] were used, resulting in a lighter and more mobile individual.

3.2. Stand-Alone Ballistic Tests

Table 4 presents the results of impact velocity (Vi) and residual velocity (Vr) that enabled the calculations of the absorbed ballistic impact energy (Eabs) and limit velocity (VL), according to Equations 1 and 2, for the stand-alone tests with 7.62 mm ammunition.

From the values calculated for Eabs and VL, the Weibull distribution was performed to determine the degree of dispersion and the level of precision associated with the ballistic results obtained, as shown in Table 5.

Based on the results shown in Table 4 and Table 5, higher values of Eabs and VL can be noted for the 0TVF/E (plain epoxy) condition. In general, the data show a downward trend as the content of TVFs increases in the composite. This behavior can be explained by the brittle characteristic of the epoxy matrix, which tends to dissipate energy by generating fracture surfaces [52,53]. Garcia Filho et al. [53] noticed a decrease of 80J in the energy absorbed by the 40 vol% compared to the 10 vol% fiber-reinforced composites, when investigating the ballistic potential of epoxy composites with piassava fibers. Similarly, Pereira et al. [54] reported in their research the same decrease trend with the increase of the volumetric fraction of fique fibers and fabric inserted in a polyester matrix.

According to the Weibull distribution, it is possible to infer that out of the seven (7) samples tested for each condition, four (4) will present Eabs and VL with values close to the θ calculated for their respective group. Additionally, the 20TVF/E group stands out as the least homogeneous of all the conditions evaluated. This can be better explained by the low β obtained, which characterizes a less narrow distribution, i.e., with little repeatability of the results. It is suggested that this fact is related to processing defects, such as the presence of voids and bubbles acting as stress concentrators and faults. In addition, the R2 correlation coefficient showed good adjustment (> 0.85), therefore demonstrating high data accuracy.

According to Table 6, in view of the results of the ANOVA of the absorbed energy and limit velocity, it can be stated with a confidence level of 95% that the results are statistically different, since Fcal > Fcritical.

To determine the significance of the differences in mean values between the treatments, a Tukey test was performed, and the results are presented in Table 7. With 5 treatments and 30 degrees of freedom, the studentized amplitude (q) was calculated to be 4.1. From this, an honestly significant difference (HSD) of 34.62 J for absorbed Eabs and 19.71 m/s for VL was determined. The mean values that are significantly different from the others are highlighted in Table 7.

The comparison between the averages presented in Table 7 indicates that plain epoxy demonstrated the best performance in terms of energy absorption compared to the other conditions. The composites with 10 vol% were statistically equal to those with 20 and 30 vol% since the calculated difference between the means was smaller than the HSD. Formulations with 0, 10, 20 and 30 vol% were found to be statistically different from the 40 vol% condition. This explains the higher mean values calculated for the latter and the sharp decrease in absorbed energy observed in Table 4. In terms of VL, the comparison between the averages shows a similar trend.

Once again, the physical integrity of the materials must be considered. If on the one hand, the plain epoxy and samples with higher epoxy matrix percentages showed higher Eabs and VL values, on the other, they either shattered completely or had long cracks propagating throughout, corrupting their physical integrity. In contrast, increasing the content of TVFs managed to contain such problems. In fact, materials for ballistic shielding application should not be destroyed after the first shot but must be able to support other impacts and continue to dissipate energy after several shots. Used as an intermediate layer in a MASs, a plain epoxy plate would not reach this requirement. Figure 8 presents composite plates with 0, 10, 20, 30 and 40 vol% of TVFs after the ballistic impact of a 7.62 mm projectile.

Analysis of the post impact aspects shows the complete fragmentation of the plain epoxy plate (Figure 8a). After incorporating a small amount of TVFs (10 vol%) this effect is attenuated, but partial fragmentation of materials is still observed (Figure 8b). When inserting 20 vol% of fibers, the composite has greater dimensional stability compared to the two previous conditions. However, it is possible to notice the presence of cracks that propagated from end to end in the material (Figure 8c). For condition 30TVF/E, the samples display smaller cracks and its propagation interrupted due to the greater performance of TVFs (Figure 8d). The group that stood out in terms of physical integrity was 40TVF/E (Figure 8e). In the tests test of this condition, it can be highlighted only the presence of broken fibers in the region where the shooting occurred, with absence of cracks and deformations on the surface of the material that could be seen macroscopically. Therefore, this condition showed the best potential for ballistic applications as an intermediate layer. Although it did not have the best results of Eabs and VL, it had its integrity best preserved. In addition, when employed in conjunction with other materials that constitute an MAS, it proved its efficiency by presenting a BFS depth below the limit established by the NIJ standard of 44 mm [14].

Composite samples of 10, 20, 30 and 40 vol% of TVFs exhibited failure mechanisms that were best verified after fractographic analysis by SEM. The images obtained are illustrated in Figure 9.

When evaluating the behavior presented by the 10TVF/E and 20TVF/E composites (Figure 9a,b), several common failure mechanisms are identified. These samples obtained the highest Eabs values after the impact of the projectile, this characteristic being associated with a greater performance of the brittle fracture mechanisms of the epoxy resin. This was evidenced by the strong presence of river marks. Despite this, the discreet action of the fibers can be visualized by the appearance of broken fibers and delamination on the surface of the material. Thus, when considering the post fracture aspects presented by these two groups, it is possible to perceive that the TVFs were not efficient in these fractions, as they did not induce a change in behavior, predominantly brittle fracture, nor the triggering of more complex fracture mechanisms.

When observing Figure 9c,d, it is noted that the areas close to the occurrence of the shooting became more rugged and with difficult analysis of the mechanisms present. However, the absence of both river marks and the propagation of long cracks on the surface of the material is noticeable. In addition, mechanisms such as pullout, shearing and fiber rupture are more frequent in the micrographs, giving evidence that more complex fracture mechanisms were activated and those that already existed were intensified, despite the fracture mode persisting as brittle.

Even with the inferior ballistic performance of the 30TVF/E and 40TVF/E samples, the action of the TVFs is quite evident in the images, being efficient in the sense of promoting barriers against the propagation of cracks and fissures and, consequently, keeping the integrity of the material. On the other hand, it is inefficient in terms of raising the energy absorbed by the plate.

Table 7 shows a comparison of Eabs and VL for the TVFs and epoxy composites tested as a stand-alone and previous results available in the literature, in which several natural fibers were used, including when incorporated into polyester resin.

When evaluating the ballistic performance of the TVFs and epoxy composites, it is noticeable that these presented Eabs and VL values higher than any other composites of polyester matrix, as well as the plates with 30 vol% curaua and epoxy and the aramid fabric, all with the same thickness of 10 mm, as shown in Table 7. Furthermore, the composites with 20 and/or 30 vol% TVFs are comparable to buriti fabric [46] and C. malaccensis fibers [18], both incorporated in an epoxy matrix. It is worth noting that the composites with buriti fabric and C. malaccensis fibers showed higher standard deviations compared to those in the present work. Indicating greater homogeneity of samples with TVFs.

The greatest decay of the parameters listed in Table 7 occurs from samples of 30 vol%. The condition with 40 vol% TVFs exhibited 62 J less compared to piassava in the same fraction of fiber and resin. A portion of this result can be justified by poor fiber/matrix adhesion, pressing with excessive load during sample processing, which may have enabled the generation of microcracks in the material, but mainly, as previously mentioned, to the mechanical properties of TVFs lower than that of the epoxy matrix. Despite this, when applied to MASs, none of the samples underwent total perforation and all showed BFS depth smaller than 44 mm, with the 40TVF/E condition that better maintained the physical integrity of the composite. Therefore, together with the 30TVF/E group it is suggested as the most efficient for applications in ballistic protection.

5. Summary and Conclusions

For the first time, composites with titica vine fibers (TVFs) from the Amazon incorporated into a polymeric epoxy matrix were ballistically tested. In both ballistic tests, i.e., BFS and stand-alone, these materials revealed promising results for application in personal protection vests.

The MAS targets, with an intermediate layer composed of composites containing 20 and 40 vol% TVFs, presented a back-face signature (BFS) depth in the clay witness of 25.6 mm and 32.5 mm, respectively. Both values were well below the maximum limit of 44mm established by the NIJ standard. Unlike the 20% condition, where the composite almost completely fragmented, the samples with 40 vol% of TVFs exhibited better integrity after impact, as recommended by the standard.

The investigation of micrographs obtained by scanning electron microscopy (SEM) of MAS targets with a 20% TVF composite after fracture showed the predominance of brittle epoxy fracture and the presence of fracture mechanisms and energy dissipation such as fiber rupture and the capture of ceramic fragments. Upon increasing the percentage to 40%, additional features such as interfacial detachment and fibril separation were observed.

Composite samples with fiber volume fractions ranging from 0, 10, 20, 30 and 40 vol% were tested through stand-alone ballistics tests. The results showed a decreasing trend in the absorbed impact energy (Eabs) and limit velocity (VL) parameters with increasing fiber volume fraction in the matrix. The values of Eabs ranged from 212 to 131 J, and the VL values ranged from 213 to 167 m/s. Despite this decline, the plates with 30 vol% of TVFs showed superior performance when compared to polyester composites reinforced with fique and sisal fibers. Furthermore, the composites with 40 vol% of TVFs outperformed the aramid fabric ply and curaua fibers (30 vol%) in an epoxy matrix.

The plates with 30 and 40 vol% of TVFs showed better dimensional stability after the shots and stood out in comparison to other materials available in the literature. Even though the matrix exhibited brittle fracture, failure mechanisms such as pullout, shear, and fiber ruptures were observed in the fibers, and these mechanisms were efficient in preventing the propagation of cracks and fissures on the material surface and maintaining its physical integrity. However, they were not as efficient in terms of Eabs and VL as seen previously, but their measures were comparable and even superior to those of other materials reported in the literature.

Author Contributions

Conceptualization, J.d.S.C.d.C. and L.F.C.N.; methodology, J.d.S.C.d.C. and L.F.C.N.; validation, L.F.C.N., M.S.O., U.O.C and S.N.M.; formal analysis, J.d.S.C.d.C.; investigation, J.d.S.C.d.C.; resources, S.N.M. and M.d.F.V.M.; data curation, J.d.S.C.d.C., M.S.O. and A.P.S.S.; writing—original draft preparation, J.d.S.C.d.C.; writing—review and editing, W.B.A.B and S.N.M.; visualization, L.F.C.N. and U.O.C.; supervision, L.F.C.N.; project administration, S.N.M.; funding acquisition, S.N.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thanks the Brazilian agencies CAPES, CNPq, FAPERJ and FAPEAM for their support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mudzi, P.; Wu, R.; Firouzi, D.; Ching, C.Y.; Farncombe, T.H.; Selvaganapathy, P.R. Use of patterned thermoplastic hot film to create flexible ballistic composite laminates from UHMWPE fabric. Mater. Des. 2022, 214, 110403. [Google Scholar] [CrossRef]

- Braga, F.O.; Bolzan, L.T.; Lima, É.P., Jr.; Monteiro, S.N. Performance of natural curaua fiber-reinforced polyester composites under 7.62 mm bullet impact as a stand-alone ballistic armor. J Mater. Res. Technol. 2017, 6, 323–328. [Google Scholar] [CrossRef]

- Wang, L.; Kanesalingam, S.; Nayak, R.; Padhye, R. Recent Trends in Ballistic Protection. Text. Light Ind. Sci. Technol. 2014, 3, 37. [Google Scholar] [CrossRef]

- Medvedovski, E. Ballistic performance of armour ceramics: Influence of design and structure. Part 1. Ceram. Int. 2010, 36, 2103–2115. [Google Scholar] [CrossRef]

- Medvedovski, E. Ballistic performance of armor ceramics: Influence of design and structure. Part 2. Ceram. Int. 2010, 36, 2117–2127. [Google Scholar] [CrossRef]

- Benzait, Z.; Trabzon, L. A review of recent research on materials used in polymer–matrix composites for body armor application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Louro, L.HL.; Meyers, M.A. Effect of stress state and microstructural parameters on impact damage of alumina-based ceramics. J. Mater. Sci. 1989, 1989. 24, 2516–2532. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Javadpour, G.H. Penetration analysis of a projectile in ceramic composite armor. Compos. Struct. 2008, 82, 269–276. [Google Scholar] [CrossRef]

- Tasdemirci, A.; Tunusoglu, G.; Guden, M. The effect of the interlayer on the ballistic performance of ceramic/composite armors: Experimental and numerical study. Int. J. Impact Eng. 2012, 44, 1–9. [Google Scholar] [CrossRef]

- Da Luz, F.S.; Monteiro, S.N.; Lima, E.S.; Lima, É.P. Ballistic application of coir fiber reinforced epoxy composite in multilayered armor. Mater. Res. 2017, 20, 23–28. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Louro, L.H.L.; Trindade, W.; Elias, C.N.; Ferreira, C.L.; Sousa Lima, E.; Da Silva, L.C. Natural curaua fiber-reinforced composites in multilayered ballistic armor. Metall. Mater. Trans. A 2015, 46, 4567–4577. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Bezerra, W.B.A.; Neves, P.P.; Huaman, N.R.C.; Monteiro, S.N.; Pinheiro, W.A. Dynamic and Ballistic Performance of Graphene Oxide Functionalized Curaua Fiber-Reinforced Epoxy Nanocomposites. Polymers 2022, 14, 1859. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; da Luz, F.S.; Candido, V.S.; da Silva, A.C.R.; Monteiro, S.N. Ballistic performance of guaruman fiber composites in multilayered armor system and as single target. Polymers 2021, 13, 1203. [Google Scholar] [CrossRef] [PubMed]

- National Criminal Justice Reference Service; US Department of Justice, & National Institute of Justice. NIJ 0101.04. Ballistic Resistance of Body Armor. 2000. Available online: https://nij.ojp.gov/library/publications/ballistic-resistance-personal-body-armor-nij-standard-010104 (accessed on 24 March 2023).

- Morye, S.S.; Hine, P.J.; Duckett, R.A.; Carr, D.J.; Ward, I.M. Modeling of the energy absorption by polymer composites upon ballistic impact. Compos. Sci. Technol. 2000, 60, 2631–2642. [Google Scholar] [CrossRef]

- da Luz, F.S.; Filho, F.d.C.G.; Oliveira, M.S.; Nascimento, L.F.C.; Monteiro, S.N. Composites with natural fibers and conventional materials applied in a hard armor: A comparison. Polymers 2020, 12, 1920. [Google Scholar] [CrossRef] [PubMed]

- Salman, S.D.; Leman, Z.B. Physical, mechanical and ballistic properties of kenaf fiber reinforced poly vinyl butyral and its hybrid composites. In Natural Fiber Reinforced Vinyl Ester and Vinyl Polymer Composites: Development, Characterization and Applications; Woodhead Publishing: Amsterdam, The Netherlands, 2018; pp. 249–263. ISBN 9780081021613. [Google Scholar] [CrossRef]

- De Mendonça Neuba, L.; Pereira, A. C.; Junio, R.F.P.; Souza, A.T.; Chaves, Y.S.; Oliveira, M.P.; Monteiro, S.N. Ballistic performance of Cyperus malaccensis sedge fibers reinforcing epoxy matrix as a standalone target. J. mater. Res. Technol. 2023, 23, 4367–4375. [Google Scholar] [CrossRef]

- Da Cruz, R.B.; Junior, E.P.L.; Monteiro, S.N.; Louro, L.H.L. Giant bamboo fiber reinforced epoxy composite in multilayered ballistic armor. Mater. Res. 2015, 18, 70–75. [Google Scholar] [CrossRef]

- Nascimento, L.F.C.; Louro, L.H.L.; Monteiro, S.N.; Lima, E.P., Jr.; Luz, F.S. Mallow Fiber-Reinforced Epoxy Composites in Multilayered Armor for Personal Ballistic Protection. JOM 2017, 69, 2052–2056. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Sultan, M.T.B.H.; Shenoy, S.T.; Kini, C.R.; Samant, R.; Md Shah, A.U.; Amuthakkannan, P. Potential of Natural Fibers in Composites for Ballistic Applications—A Review. J. Nat. Fibers (Online) 2020. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Yang, X.; Wang, K.; Tian, G.; Liu, X.E.; Yang, S. Evaluation of chemical treatments to tensile properties of cellulosic bamboo fibers. Eur. J. Wood Prod. 2018, 76, 1303–1310. [Google Scholar] [CrossRef]

- Islam, M.S.; Ahmed, S.J.U. Influence of jute fiber on concrete properties. Constr. Build. Mater. 2018, 189, 768–776. [Google Scholar] [CrossRef]

- Kumar, R.; Ul Haq, M.I.; Raina, A.; Anand, A. Industrial applications of natural fibre-reinforced polymer composites–challenges and opportunities. Int. J. Sustain. Eng. 2019, 12, 212–220. [Google Scholar] [CrossRef]

- Scarponi, C. Hemp fiber composites for the design of a Naca cowling for ultra-light aviation. Compos. Part B Eng. 2015, 81, 53–63. [Google Scholar] [CrossRef]

- Wambua, P.; Vangrimde, B.; Lomov, S.; Verpoest, I. The response of natural fibre composites to ballistic impact by fragment simulating projectiles. Compos. Struct. 2007, 77, 232–240. [Google Scholar] [CrossRef]

- Soares, M.L.; Mayo, S.J.; Gribel, R. A preliminary taxonomic revision of Heteropsis (Araceae). Syst. Bot. 2013, 38, 925–974. [Google Scholar] [CrossRef]

- Temponi, L.G.; Garcia, F.C.P.; Sakuragui, C.M.; Carvalho-Okano, R.M.D. Diversidade morfológica e formas de vida das Araceae no Parque Estadual do Rio Doce, Minas Gerais. Rodriguésia 2013, 56, 3–13. [Google Scholar] [CrossRef]

- Cunha, J.S.C.; Nascimento, L.F.C.; Luz, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Monteiro, S.N. Titica vine Fiber (Heteropsis flexuosa): A hidden Amazon Fiber with Potential Application as Reinforcement in Polymer Matrix Composites. J. Compos. Sci. 2022, 6, 251. [Google Scholar] [CrossRef]

- Cunha, J.S.C.; Nascimento, L.F.C.; da Luz, F.S.; Monteiro, S.N.; Lemos, M.F.; da Silva, C.G.; Simonassi, N.T. Physical and Mechanical Characterization of Titica Vine (Heteropsis flexuosa) Incorporated Epoxy Matrix Composites. Polymers 2021, 13, 4079. [Google Scholar] [CrossRef]

- Vinod, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.R.; Siengchin, S.; Moure, M.M. Characterization of untreated and alkali treated natural fibers extracted from the stem of Catharanthus roseus. Mater. Res. Express 2019, 6, 085406. [Google Scholar] [CrossRef]

- Dittenber, D.B.; Gangarao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Guimarães, J.L.; Wypych, F. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- Vijay, R.; Lenin Singaravelu, D.; Vinod, A.; Sanjay, M.R.; Siengchin, S.; Jawaid, M.; Khan, A.; Parameswaranpillai, J. Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int. J. Biol. Macromol. 2019, 125, 99–108. [Google Scholar] [CrossRef] [PubMed]

- Prithiviraj, M.; Muralikannan, R. Investigation of optimal alkali-treated perotis indica plant fibers on physical, chemical, and morphological properties. J. Nat. Fibers 2022, 19, 2730–2743. [Google Scholar] [CrossRef]

- Prithiviraj, M.; Muralikannan, R.; Senthamaraikannan, P.; Saravanakumar, S.S. Characterization of New Natural Cellulosic Fiber from the Perotis Indica Plant. Int. J. Polym. Anal. Charact. 2016, 21, 669–674. [Google Scholar] [CrossRef]

- Hossain, M.K.; Karim, M.R.; Chowdhury, M.R.; Imam, M.A.; Hosur, M.; JeelAppani, S.; Farag, R. Comparative mechanical and thermal study of chemically treated and untreated single sugarcane fiber bundle. Ind. Crop. Prod. 2014, 58, 78–90. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J. Mater. Res. Technol. 2020, 9, 200–211. [Google Scholar] [CrossRef]

- Vijay, R.; Singaravelu, D.L.; Vinod, A.; Sanjay, M.R.; Siengchin, S. Characterization of alkali-treated and untreated natural fibers from the stem of parthenium hysterophorus. J. Nat. Fibers. 2021, 18, 80–90. [Google Scholar] [CrossRef]

- Ganapathy, T.; Sathiskumar, R.; Senthamaraikannan, P.; Saravanakumar, S.S.; Khan, A. Characterization of raw and alkali treated new natural cellulosic fibres extracted from the aerial roots of banyan tree. Int. J. Biol. Macromol. 2019, 138, 573–581. [Google Scholar] [CrossRef]

- Ribeiro, M.P.; de Mendonça Neuba, L.; da Silveira, P.H.P.M.; da Luz, F.S.; da Silva Figueiredo, A.B.H.; Monteiro, S.N.; Moreira, M.O. Mechanical, thermal and ballistic performance of epoxy composites reinforced with Cannabis sativa hemp fabric. J. Mater. Res. Technol. 2021, 12, 221–233. [Google Scholar] [CrossRef]

- Gomes, A.V.; Louro, L.H.L.; Costa, C.R.C. Ballisctic behavior of alumina with niobia additions. J. Phys. 2006, 134, 1009–1014. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Drelich, J.W.; Lopera, H.A.C.; Nascimento, L.F.C.; da Luz, F.S.; da Silva, L.C.; dos Santos, J.L.; da Costa Garcia Filho, F.; de Assis, F.S.; Lima, É.P.; et al. Natural Fibers Reinforced Polymer Composites Applied in Ballistic Multilayered Armor for Personal Protection—An Overview. The Minerals, Metals and Materials Series; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Pereira, A.C.; Nunes, L.F.; Luz, F.S.; Braga, F.O.; Colorado, H.A.; Monteiro, S.N. Ballistic performance and statistical evaluation of multilayered armor with epoxy-fique fabric composites using the Weibull analysis. J. Mater. Res. Technol. 2019, 8, 5899–5908. [Google Scholar] [CrossRef]

- Demosthenes, L.C.D.C.; Luz, F.S.D.; Nascimento, L.F.C.; Monteiro, S.N. Buriti Fabric Reinforced Epoxy Composites as a Novel Ballistic Component of a Multilayered Armor System. Sustainability, 2022, 14, 10591. [Google Scholar] [CrossRef]

- Neves Monteiro, S.; de Oliveira Braga, F.; Pereira Lima, E.; Henrique Leme Louro, L.; Wieslaw Drelich, J. Promising curaua fiber-reinforced polyester composite for high-impact ballistic multilayered armor. Polym. Eng. Sci. 2017, 57, 947–954. [Google Scholar] [CrossRef]

- Monteiro, S.; Pereira, A.; Ferreira, C.; Pereira Júnior, É. Performance of Plain Woven Jute Fabric-Reinforced Polyester Matrix Composite in Multilayered Ballistic System. Polymers 2018, 10, 230. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvalho, J.P.R.G.; Vieira, C.M.F.; Lopes, F.P.D.; Tonini Simonassi, N.; Da Luz, F.S.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2020, 9. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Candido, V.S.; Braga, F.O.; Bolzan, L.T.; Weber, R.P.; Drelich, J.W. Sugarcane bagasse waste in composites for multilayered armor. Eur. Polym. J. 2016, 78, 173–185. [Google Scholar] [CrossRef]

- PARA-ARAMID, A. True All-Round. Performer, Teijin, 2018.

- Oliveira, M.S.; Luz, F.S.; Souza, A.T.; Demosthenes, L.C.C.; Pereira, A.C.; Garcia Filho, F.C.; Braga, F.O.; Figueiredo, A.B.S.; Monteiro, S.N. Tucum Fiber from Amazon Astrocaryum vulgare Palm Tree: Novel Reinforcement for Polymer Composites. Polymers 2020, 12, 2259. [Google Scholar] [CrossRef]

- Garcia Filho, F.C.; Oliveira, M.S.; Pereira, A.C.; Nascimento, L.F.C.; Matheus, J.R.G.; Monteiro, S.N. Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition. J. Mat. Res. Technol. 2020, 9, 1734–1741. [Google Scholar] [CrossRef]

- Pereira, A.C.; Assis, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Lima, E.S.; Lopera, H.A.C.; Monteiro, S.N. Evaluation of the projectile’s loss of energy in polyester composite reinforced with fique fiber and fabric. Mater. Res. 2019, 22. [Google Scholar] [CrossRef]

- Braga, F.O.; Bolzan, L.T.; Ramos, F.J.H.T.V.; Monteiro, S.N.; Lima, E.P., Jr.; Silva, L.C. Ballistic efficiency of multilayered armor systems with sisal fiber polyester composites. Mater. Res. 2018, 20, 767–774. [Google Scholar] [CrossRef]

Figure 1.

Components of the MAS used in the ballistic tests. (1) TVFs’ source plant; (b) TVFs; (3) MAS target; (4) Twaron fabric layers; (5) TVF/epoxy composite; (6) ceramic plates and (7) bulletproof vest with the proposed armor plate.

Figure 1.

Components of the MAS used in the ballistic tests. (1) TVFs’ source plant; (b) TVFs; (3) MAS target; (4) Twaron fabric layers; (5) TVF/epoxy composite; (6) ceramic plates and (7) bulletproof vest with the proposed armor plate.

Figure 2.

Manufacture of TVF/E boards. (a) schematic of the compression molding process; (b) hydraulic press used for force application.

Figure 2.

Manufacture of TVF/E boards. (a) schematic of the compression molding process; (b) hydraulic press used for force application.

Figure 3.

Schematic diagram of ballistic tests. (a) MAS target placement; (b) placement of the “stand-alone” sample.

Figure 3.

Schematic diagram of ballistic tests. (a) MAS target placement; (b) placement of the “stand-alone” sample.

Figure 4.

Backface signature of the MAS using epoxy composites with 20 and 40 vol% TVFs incorporated as second layer.

Figure 4.

Backface signature of the MAS using epoxy composites with 20 and 40 vol% TVFs incorporated as second layer.

Figure 5.

Frontal view of MAS target samples after ballistic testing: (a,b) 20TVF/E; (c,d) 40TVF/E.

Figure 6.

Fracture surface of the 20TVF/E composite illustrating ceramic fragments on the fiber.

Figure 7.

Fracture surface aspect of the different composite formulations: (a,b) 20TVF/E; (c,d) 40TVF/E.

Figure 7.

Fracture surface aspect of the different composite formulations: (a,b) 20TVF/E; (c,d) 40TVF/E.

Figure 8.

Macroscopic analysis of the samples after the stand-alone ballistic test using ammunition 7.62 mm: (a) Pure epoxy; (b) 10TVF/E; (c) 20TVF/E; (d) 30TVF/E; (e) 40TVF/E.

Figure 8.

Macroscopic analysis of the samples after the stand-alone ballistic test using ammunition 7.62 mm: (a) Pure epoxy; (b) 10TVF/E; (c) 20TVF/E; (d) 30TVF/E; (e) 40TVF/E.

Figure 9.

Microscopic analysis of the fracture surface of composites after stand-alone tests: (a) 10TVF/E; (b) 20TVF/E; (c) 30TVF/E; (d) 40TVF/E.

Figure 9.

Microscopic analysis of the fracture surface of composites after stand-alone tests: (a) 10TVF/E; (b) 20TVF/E; (c) 30TVF/E; (d) 40TVF/E.

Table 1.

Reported properties for TVFs when compared to other NLFs.

| Fiber | Apparent Density (g/cm3) | Microfibrillar Angle (Degree) | Crystallinity Index (%) | Tensile Strenght (MPa) | Young’s modulus (GPa) | Reference |

|---|---|---|---|---|---|---|

| Titica vine | 0.50 ± 0.07 | 7.95 | 78 | 25.92 ± 6.69 | 1.02 ± 0.22 | [30] |

| Catharanthus roseus | 1.34 ± 0.57 | - | 25.09 | 27.02 ± 1.1 | 1.23 ± 0.04 | [32] |

| Coir | 1.20 ± 0.24 | 30 - 49 | 43.50 | 44.0 ± 8 | 2.0 ± 0.3 | [32,33,34] |

| Tridax procumbens | 1.16 ± 0.12 | 13.4 | 34.46 | 25.75 ± 2.45 | 0.94 ± 0.09 | [35] |

| Perotis indica | 0.79 | 8.45 – 15.87 | 48.3 | 32.3 | 69.61 | [36,37] |

| Sugar cane | 1.28 | - | 35 | 169.51 ± 18.65 | 5.18 ± 0.63 | [38,39] |

| Parthenium Hysterophorus | 1.25 | - | 40.68 | 24 ± 2 | - | [40] |

| Aerial roots of banyan tree | 1.23 | 10.88 | 72.47 | 19.37 ± 7.72 | 1.8 ± 0.40 | [41] |

Table 2.

Weibull parameters for the BFS depth of the samples.

| Sample | BFS (mm) | β | ϴ | R² |

|---|---|---|---|---|

| 20TVF/E | 25.57 ± 2.89 | 8.725 | 26.92 | 0.8347 |

| 40TVF/E | 32.51 ± 4.98 | 6.509 | 34.73 | 0.9559 |

Table 3.

Comparison between the BFS depths exhibited by natural fiber reinforced epoxy composites (10 mm thick) and a Dyneema plate (25 mm thick) for application as second layer in MASs.

Table 3.

Comparison between the BFS depths exhibited by natural fiber reinforced epoxy composites (10 mm thick) and a Dyneema plate (25 mm thick) for application as second layer in MASs.

| Material in Ballistic Armor for Protection against Level III Ammunition | BFS (mm) | Last Layer | Reference |

|---|---|---|---|

| 20TVF/E | 25.57 ± 2.89 | Twaron | PW |

| 40TVF/E | 32.51 ± 4.98 | Twaron | PW |

| 20Buriti/E | 21 ± 1,9 | Al Plate | [46] |

| 20Coir/E | 22 ± 2 | Al Plate | [10] |

| 30Coir/E | 31.6 ± 2.7 | Al Plate | [10] |

| 30Guaruman/E | 32.9 ± 1.6 | Kevlar | [13] |

| 30Sugarcane bagasse/E | 39 ± 8 | Al Plate | [50] |

| Dyneema plate | 41.5 ± 1.8 | Kevlar | [16] |

Table 4.

Parameters and results from the stand-alone ballistic tests with 7.62 mm ammunition for the epoxy composites reinforced with TVFs.

Table 4.

Parameters and results from the stand-alone ballistic tests with 7.62 mm ammunition for the epoxy composites reinforced with TVFs.

| Sample | Vi (m/s) | Vr (m/s) | Eabs (J) | VL (m/s) |

|---|---|---|---|---|

| 0TVF/E | 814.40 ± 8.54 | 785.96 ± 7.01 | 211.69 ± 21.56 | 213.27 ± 6.94 |

| 10TVF/E | 805.55 ± 8.45 | 782.28 ± 7.89 | 171.82 ± 15.88 | 192.06 ± 8.80 |

| 20TVF/E | 813.91 ± 4.69 | 790.28 ± 6.95 | 176.19 ± 31.41 | 193.88 ± 17.75 |

| 30TVF/E | 820.17 ± 4.16 | 797.74 ± 4.94 | 166.51 ± 23.36 | 188.84 ± 13.08 |

| 40TVF/E | 815.68 ± 11.14 | 798.26 ± 12.69 | 130.53 ± 19.50 | 167.14 ± 12.60 |

Table 5.

Weibull parameters for absorbed energy and limit velocity of the samples.

| Eabs | Sample | β | ϴ | R² | VL | Sample | β | ϴ | R² |

| 0TVF/E | 15.98 | 218.1 | 0.9354 | 0TVF/E | 32.02 | 216.6 | 0.9373 | ||

| 10TVF/E | 11.28 | 179.1 | 0.9040 | 10TVF/E | 22.55 | 196.3 | 0.9035 | ||

| 20TVF/E | 5.268 | 190.9 | 0.9215 | 20TVF/E | 10.53 | 202.6 | 0.9212 | ||

| 30TVF/E | 7.292 | 177.1 | 0.8538 | 30TVF/E | 14.58 | 195.1 | 0.8533 | ||

| 40TVF/E | 6.599 | 139.6 | 0.8619 | 40TVF/E | 13.21 | 173.3 | 0.8624 |

Table 6.

ANOVA of the absorbed energy and limit velocity of composites from 0 – 40 vol% TVFs.

| Eabs | VL | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Variation Causes | DF | SS | MS | Fcalc | Fcritical | DF | SS | MS | Fcalc | Fcritical |

| Treatment | 4 | 23385.50 | 5846.38 | 11.71 | 2.69 | 4 | 7555.31 | 1888.83 | 11.68 | 2.69 |

| Residue | 30 | 14977.49 | 499.25 | 30 | 4851.86 | 161.73 | ||||

| Total | 34 | 38362.99 | 34 | |||||||

Table 7.

Results obtained for the differences (HSD) between the average values of the impact Eabs and the VL, in the volumetric fractions of 0, 10, 20, 30 and 40 vol% TVFs, after the Tukey test.

Table 7.

Results obtained for the differences (HSD) between the average values of the impact Eabs and the VL, in the volumetric fractions of 0, 10, 20, 30 and 40 vol% TVFs, after the Tukey test.

| Eabs | VL | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample | 0TVF/E | 10TVF/E | 20TVF/E | 30TVF/E | 40TVF/E | 0TVF/E | 10TVF/E | 20TVF/E | 30TVF/E | 40TVF/E |

| 0TVF/E | 0 | 39.87 | 35.50 | 45.19 | 81.16 | 0 | 21.22 | 19.40 | 24.43 | 46.13 |

| 10TVF/E | 39.87 | 0 | 4.37 | 5.32 | 41.29 | 21.22 | 0 | 1.82 | 3.21 | 24.92 |

| 20TVF/E | 35.50 | 4.37 | 0 | 9.68 | 45.66 | 19.40 | 1.82 | 0 | 5.03 | 26.74 |

| 30TVF/E | 45.19 | 5.32 | 9.68 | 0 | 35.98 | 24.43 | 3.21 | 5.03 | 0 | 21.70 |

| 40TVF/E | 81.16 | 41.29 | 45.66 | 35.98 | 0 | 46.13 | 24.92 | 26.74 | 21.70 | 0 |

Table 8.

Comparison of absorbed energy and limit velocity for the composite plates reinforced with titica vine fibers and other composites with incorporated natural fibers, as well as the aramid fabric plate.

Table 8.

Comparison of absorbed energy and limit velocity for the composite plates reinforced with titica vine fibers and other composites with incorporated natural fibers, as well as the aramid fabric plate.

| Conditions | Matrix | Eabs (J) | VL (m/s) | Reference |

|---|---|---|---|---|

| TVF - 0% | Epoxy | 211.69 ± 21.56 | 213.27 ± 6.94 | PW |

| TVF - 10% | Epoxy | 171.82 ± 15.88 | 192.06 ± 8.80 | PW |

| TVF - 20% | Epoxy | 176.19 ± 31.41 | 193.88 ± 17.75 | PW |

| TVF - 30% | Epoxy | 166.51 ± 23.36 | 188.84 ± 13.08 | PW |

| TVF - 40% | Epoxy | 130.53 ± 19.50 | 167.14 ± 12.60 | PW |

| Fique fiber - 20% | Polyester | 121 ± 11 | − | [54] |

| Fique fiber - 30% | Polyester | 113 ± 4 | − | [54] |

| Fique fabric - 20% | Polyester | 156 ± 12 | − | [54] |

| Fique fabric - 30% | Polyester | 97 ± 7 | − | [54] |

| Buriti fabric - 20% | Epoxy | 178 ± 54 | 190 ± 30 | [46] |

| Buriti fabric - 30% | Epoxy | 189 ± 50 | 194 ± 97 | [46] |

| C. Malaccensis - 20% | Epoxy | 222.11 ± 22.38 | 213.74 ± 10.56 | [18] |

| C. Malaccensis - 30% | Epoxy | 167.18 ± 39.05 | 184.40 ± 21.58 | [18] |

| Piassava fiber - 40% | Epoxy | 192 ± 13 | 198 ± 6 | [53] |

| Sisal fiber - 20% | Polyester | 116 | − | [55] |

| Sisal fiber - 30% | Polyester | 139 | − | [55] |

| Curaua - 30% | Epoxy | 106 ± 11 | − | [11] |

| Aramid fabric | − | 58 ± 29 | 109 ± 7 | [11] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

Ballistic Behavior of Epoxy Composites Reinforced with Amazon’s Titica Vine Fibers (Heteropsis flexuosa) in Multilayered Armor System and as Stand-Alone Target

Juliana dos Santos Carneiro da Cunha

et al.

,

2023

Numerical and Experimental Results on Charpy Tests for Blends Polypropylene + Polyamide + Ethylene Propylene Diene Monomer (PP+PA+EDPM)

Catalin Pirvu

et al.

,

2020

Open-Source Flexible Materials Tensile Testing Apparatus

Morgan C. Woods

et al.

,

2023

MDPI Initiatives

Important Links

© 2024 MDPI (Basel, Switzerland) unless otherwise stated