PLC, PLC Ladder, PLC Ebook, PLC Programming

Uploaded by

Amar ThakurPLC, PLC Ladder, PLC Ebook, PLC Programming

Uploaded by

Amar ThakurShare

More

Next Blog

Create Blog

We are ready to help you for learning or Training on PLC. You can learn PLC programming for Industrial Automation,Machines or Other PLC Applications.Download Free PLC Program,PLC Pdf,PLC eBooks,PLC Theory and Automation Theory,SCADA,DCS Books,Presentations.

Home Downloads Live PLC Questions and Answers SiteMap

PLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING,

Select Language

Pow ered by

Thursday, 13 June 2013

Translate

PLC & Visual Basic 6.0 Communication using MSComm Control

PLC Training

PLC Simulators

www.plcdev.com Programming made easy for all types of PLCs

www.precontraining.com PLC SCADA HMI AC DRIVES Training 100 % Practical Training &Placement

H i F riends H ere i want t o share a new post relat ed t o P L C and V isual Basic V B6.0 Communicat ion V B code is giv en below. Enjoy

Automation Training Pune

www.mpta.in/Pune/Automation-Training Job Oriented Automation Courses. Utilise Your Summers. Inquire Now.

Jobs In India

www.Quikr.com Multiple Positions Open In Your Desired Field. Apply Now. Free!

Guide to PLC Ladder Logic

engineer-and-technician.com Learn to program PLC Ladder Logic Online tutorial & ebook -only $9.95

Real Time Automated Control using PLCVB Communication

A bstract

PLC training software

EasyVeep.com Programming on your own PLC Use for all PLC, easy to learn

PLC SCADA Training -Delhi

gravityautomation.com PLC AutomationTraining in Noida NCR Automation HMI VSD Panel Design

Flats in Pune

www.namratagroup.c 1 & 2 BHK Flats at Reasonable Price to Experience The EcoLife in Pune.

This paper is to enable the Delta PLC (Programmable Logic Control) DVP14SS to communicate with the Visual Basic 6.0. The communication between DVP14SS and Visual Basic 6.0 is via Modbus Serial Protocol. Computers are used as a link between humans and PLC systems as they have more graphics and visual capabilities. These are nothing but SCADA systems widely used for determining plant set-ups and displaying plant status on high quality screens. They also record/log the system data for long period .The SCADA softwares are the software packages needs to be purchased from vendors and the cost depends on tag count. Visual Basic 6.0 platform can be used develop the SCADA application effectively. Using VB 6.0 we integrate software and hardware across spectrum of vendors easily. Here we show simple approach to communicate Delta PLC with visual Basic using MSComm control in visual basic. By means of Visual Basic cost effective solution is possible as Visual Basic we do not need to purchase licenses and is cheaper than SCADA packages. It also has the advantages like flexibility.

PLC Supplier

cminfotechnologies.co Extensive Range Of Branded & High Quality PLC Available. Enquire Now!

I . Introduction Communication has become a major part of any process control automation system. Today PLC communication is as much for data acquisition as plant control. The objective of communication is to collect or transfer large / small amount of data. Over the course of time certain interfacing standards have been generated by industry in order to make communication between systems from two different manufacturers more simple. These standards typically defined the communications medium, transmission voltages, speed of communication, (baud rate). The first such real standard was RS232. This was written by the Electronic Industries Association (EIA). The main advantage of this being cost as RS232 interfaces are very simple and thus cheap, plus of course the fact that most PCs, which are used more and more in automation systems today, have at least one RS232 (serial) interface as a standard. P rogrammable L ogic Cont rollers (PLCs) are solid state devices using integrated circuits to control process or machines. They can store instructions like sequencing counting, timing, arithmetic, data manipulation and communication [2]. A PLC is an example of a hard real time system since output results must be produced in response to input conditions within a bounded time, otherwise unintended operation will result.PLC reads the status of the external input devices, e.g. keypad, sensor, switch and pulses, and execute by the microprocessor logic, sequential, timing, counting and arithmetic operations according the status of the input signals as well as the prewritten program stored in the PLC [5]. The generated output signals are sent to output devices as the switch of a relay, electromagnetic valve, motor drive, control of a machine or operation of a procedure for the purpose of machine automation or processing procedure. V isual Basic (VB) is developed by Microsoft Corporation and is most widely used development environment in the world. Visual Basic is tool provides platform to develop new optimum Windows/SCADA applications. Visual Basic can communicate with PLC with various ways. Visual Basic does not have code for communication protocol inbuilt. User need to write code for communication protocol or need to purchase ActiveX controls which are used to develop applications. ActiveX control with Libraries can be purchased to develop application. Here we are using MSComm ActiveX control freely available in VB to establish communication with delta PLC.

Blog Archive 2013 (1) June (1) PLC & Visual Basic 6.0 Communication using MSComm ... 2012 (30) 2011 (22)

Find us on Facebook

Plc,scada,dcs & Automation

Like 2,096 people like Plc,scada,dcs & Automation.

II.M ethod of Interfacing

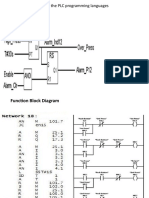

Delta DVP14SS comes with serial port and the communication protocol is serial Modbus protocol which is a open protocol. Visual Basic acts as a Modbus Master device which issues request or commands (Query) on serial bus which is received by slave. PLC acts as a Modbus slave device and responds to the Master by sending massage called response. Modbus Query and Response contains fields like device address, function code, data, and error check [1]. Figure 1 shows the system block diagram.

F acebook social plugin

Contributors Vinod2012 Automized Automized1

TABLEI Function code for Delta plc Code 01 02 03 05 Name Read Coil Status Read Input Status Read Registers Holding Description S, Y, M, T, C S, X, Y, M,T, C T, C, D S, Y, M, T, C T, C, D S, Y, M, T, C T, C, D None

Force Single Coil Preset Single Register Force Multiple Coils Preset Multiple Register Report Slave ID

Followers

Join this site

w ith Google Friend Connect

06 15 16 17

Members (21) More Table 2 shows the Query format to read Input Status of contacts Y20 to Y47from slave device address 01 TABLE II Query to Read input status y20 - y47 F ield N ame Ex ample (H ex ) Heading Slave Address Command code

Already a member? Sign in

3A 01 02 05 14 00 25 BF

Starting Address Hi Starting Address Lo Number of Points Hi Number of Points Lo

Feedjit

Error Check ( LRC )

Table 3 shows the response from slave device to Query shown above.

TABLE III Response from slave F ield N ame Slave Address Command code Bytes Count DataCoils Y033Y024 DataCoils Y043Y034 DataCoils Y053Y044 DataCoils Y063Y054 DataCoils Y070Y064 Error CheckLRC Ex ample (H ex ) 01 02 05 CD 6B B2 0E 1B E5

The PLC receives the messages without a communication error, but cannot handle it, an exception response willreturn to the master device. In the exception response, the most significant bit of the original command code is set to 1, and an exception code explains the condition that caused the exception is returned. Table 4 shows message response with exception code. [3] [4] TABLE IIV Exception response from slave F ield N ame Heading Slave Address Function Exception Code

Ex ample (H ex ) 3A 01 81 02

Error Check ( LRC )

7C

Live Traffic Feed

Table 5 shows different exception codes available in DVP14SS PLC [3] [4]. TABLE IIIV Exception codes

A visitor from Ahmedabad, Gujarat arrived from google.co.in and viewed "PLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING," 0 secs ago A visitor from Jakarta, Jakarta Raya arrived from google.com and viewed "PLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING,: Free PLC Softwares" 20 mins ago A visitor from Pune, Maharashtra arrived from plc-scadadcs.blogspot.in and viewed "PLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING,: Downloads" 33 mins ago A visitor from Bangalore, Karnataka arrived from google.co.in and viewed "PLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING," 44 mins ago A visitor from New Delhi, Delhi arrived from google.co.in and viewed "PLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING,: Typical circuit diagram of Star Delta starter" 1 hour 3 mins ago A visitor from Hyderabad, Andhra Pradesh arrived from google.co.in and viewed "PLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING,:

Code 01

M eaning Illegal command code: The command code received in the command message is not available for the PLC. Illegal device address: The device address received in the command message is not available for the PLC. Illegal device value: The device value received in the command message is not available for the PLC. Check Sum Error Check if the check Sum is correct Illegal command messages The command message is too short. Command message length is out of range.

02

03

07

Visual Basic has ActiveX MSComm control 6.0 to send andreceive ASCII characters on communication port. MSCommcontrol added through the project component menu as shown in fig 2.

MSComm control is a drag and drop tool and can be accessed, handled with its properties and event handler.

I I I . IM PLEM ENTA TIO N

Following steps are implemented to obtain desired objective. A. Knowing the Modbus Protocol for Delta PLC DVP14SS series MPU support Modbus ASCII/RTU communication format with speed of up to 115,200bps. and modification on data length (data bits, parity bits, stop bits).Modbus communication format ,CRC calculation ,Modbus addressing for various internal devices of PLC are the key factor in the interface. Communication parameters for COMcan be manipulated by writing ladder program. Here we use default protocol settings hence we do not alter PLC program. [4] B. Writing Visual Basic code for MSComm Control Designing windows form in visual basic as shown in fig 4. Form contains controls like Timer, MSComm Control, Button, textbox etc.

OnComm () event in MSComm control is used to receive response from slave PLC. Dim strRx As String Select Case MSComm1.CommEvent Case comEvReceive Case comEvEOF strRx = MSComm1.Input Similarly MSComm.output property is used to send ASCII characters through serial port. For Index = 0 To Len(txtWrite.Text) 1 sendArr(Index) = Asc(Mid(txtWrite.Text, Index + 1, 1)) Next sendArr(Index) = &HD sendArr(Index + 1) = &HA strRx = "" MSComm1.Output = sendArr Do While True If MSComm1.InBufferCount > 0 Then strRx = strRx + MSComm1.Input If Len(strRx) > 2 Then If Asc(Mid(strRx, Len(strRx) - 1, 1)) = &HD And Asc(Mid(strRx, Len(strRx), 1)) = &HA Then Text1.Text = Mid(strRx, 1, Len(strRx) - 2) Exit Do End If End If

IV. RESULTS

Fig 5 shows GUI developed using VB and results of serial communication between DVP14SS PLC and PC.

The main idea was to interface Visual Basic 6.0 and Delta PLC DVP14SS for moreeffective and efficient process control. This project ofinterfacing establishes communication between two powerful technologies used in industries. Visual Basic provides a platform where new solutions or highly customized SCADA's can be created with a richer experience than those that may be provided by standard SCADA offerings. By using Visual Basic it offers many advantages over SCADA packages as it comes free and not expensive. Also SCADA packages cost depend on the tag count and runtime licenses needs to be purchased. Thus for OEM Visual Basic offers the optimum solution. Thus the PLC has been interfaced with Visual Basic 6.0 and several real time processes have been controlled.

References

Modbus communication Manual, MTL 8000 process control for process I/O ,The MTL Instruments Group PLC, England NaregalkarAkshay.,Real Time Automated Control of Industrial Pocesses with PLC LABVIEW Communication,.Ibrahimpatnam, Hyderabad, India, Issue-1, Volume-1 ,035-038 [3] DVP PLC communication Protocol, Delta Electronics Inc,www.delta.com.tw/industrialautomation. [4] DVP PLC Application Manual, Delta Electronics Inc,www.delta.com.tw/industrialautomation. [5] T.Kalaiselvi, R.Praveena ,Aakanksha.R,, Dhanya.S, PLC Based Automatic Bottle Filling and Capping System With User Defined Volume Selection, IJETAE., Volume 2, Issue 8, August 2012. [1] [2]

Posted by Vinod2012 @ 6/13/2013 03:09:00 pm

Comments (0)

Home

Older Posts

Subscribe To Get FREE Tutorials! And More....

Enter Your email address

Submit

aristhaserenade.blogs...

tugas-tugas mata kuliah di PGSD

sdnsatuba.blogspot.co...

Blog Guru Indonesia

infoga8.com/

Welcome: Here you frequently download free PDF & E-books in different catagories...

site directory MiriBlack Web Directory Submit Express - SEO Services links to my website? Backlinks to my website? Advertising website online free at UseAds.com - Submit & add url - advertise site promotion internet & exchange text links + increase traffic

Science

Subm it Express

& improve page rank! Try us on Wibiya! Copyright 2011-2012. All rights reserved. Template images by Airyelf. Powered by Blogger.

You might also like

- PLC Ladder Logic: Nano PLC Micro PLC Mini PLC Compact PLC Small PLC Brick PLC Medium PLC Large PLC Modular PLCNo ratings yetPLC Ladder Logic: Nano PLC Micro PLC Mini PLC Compact PLC Small PLC Brick PLC Medium PLC Large PLC Modular PLC12 pages

- Identify The PLC Programming Languages: Function Block DiagramNo ratings yetIdentify The PLC Programming Languages: Function Block Diagram43 pages

- Programmable Logic Controller L T P C 1 0 0 1: Department ofNo ratings yetProgrammable Logic Controller L T P C 1 0 0 1: Department of4 pages

- Introduction To Industrial Automation in PLC100% (1)Introduction To Industrial Automation in PLC50 pages

- LAB 10: Programmable Logic Controllers and Ladder Logic: ObjectiveNo ratings yetLAB 10: Programmable Logic Controllers and Ladder Logic: Objective4 pages

- Chinhoyi University of Technology: - School of Engineering Sciences and - CUME 206No ratings yetChinhoyi University of Technology: - School of Engineering Sciences and - CUME 20633 pages

- FWD Rev Three Phase Motor Using Timer PDFNo ratings yetFWD Rev Three Phase Motor Using Timer PDF1 page

- A PLC System: CPU Module (Left) and An I/O Rack (Right) (Allen Bradley PLC-5)No ratings yetA PLC System: CPU Module (Left) and An I/O Rack (Right) (Allen Bradley PLC-5)71 pages

- PLC Manual - 1803096 - Mayank Shahabadee - FINAL67% (3)PLC Manual - 1803096 - Mayank Shahabadee - FINAL72 pages

- Industrial Automation Trainings Course Outline100% (1)Industrial Automation Trainings Course Outline7 pages

- Programmable Logic Controllers: Richard A. WyskNo ratings yetProgrammable Logic Controllers: Richard A. Wysk49 pages

- Programmable Logic Controller WhitepaperNo ratings yetProgrammable Logic Controller Whitepaper97 pages

- Index: Introduction About Automation. o o o o Inroduction To PLC o o o o o o o o o o o o o o o o o o o o o o oNo ratings yetIndex: Introduction About Automation. o o o o Inroduction To PLC o o o o o o o o o o o o o o o o o o o o o o o37 pages

- Attendance Authentication System Using Face RecognitionNo ratings yetAttendance Authentication System Using Face Recognition15 pages

- " Real Time Automated Control Using PLC-VB Communication ": June 2013No ratings yet" Real Time Automated Control Using PLC-VB Communication ": June 20135 pages

- 50 Inspiring Audiobooks To Self-Improve While You Work Out - Online College CoursesNo ratings yet50 Inspiring Audiobooks To Self-Improve While You Work Out - Online College Courses7 pages

- Automatic Vending Machine Prototype Model: ISSN: 0974-2115No ratings yetAutomatic Vending Machine Prototype Model: ISSN: 0974-21155 pages

- Proposal For Tapping Unit: Sr. Numb Er Description Unit Qty Cost Per QtyNo ratings yetProposal For Tapping Unit: Sr. Numb Er Description Unit Qty Cost Per Qty1 page

- 080M40 (EN8) Specification Chemical CompositionNo ratings yet080M40 (EN8) Specification Chemical Composition1 page

- Statement: SR Bill No Customer Bill Date Bill Amount Status 1 Not 2 Not 3 Not Not 5 Not Not 7 Not 8 Not 9 NotNo ratings yetStatement: SR Bill No Customer Bill Date Bill Amount Status 1 Not 2 Not 3 Not Not 5 Not Not 7 Not 8 Not 9 Not1 page

- Price List-Cum-Order Form: S. No. Particulars Amount (RS)No ratings yetPrice List-Cum-Order Form: S. No. Particulars Amount (RS)2 pages

- Brahmand Solutions: Performance Review TestNo ratings yetBrahmand Solutions: Performance Review Test3 pages

- Price List-Cum-Order Form: S. No. Particulars Amount (RS)No ratings yetPrice List-Cum-Order Form: S. No. Particulars Amount (RS)2 pages

- Convention & CNC: Conventional Vs CNC Manual Work Accuracy Time Complex Machining Skill Person InvestmentNo ratings yetConvention & CNC: Conventional Vs CNC Manual Work Accuracy Time Complex Machining Skill Person Investment6 pages

- PLC Ladder Logic: Nano PLC Micro PLC Mini PLC Compact PLC Small PLC Brick PLC Medium PLC Large PLC Modular PLCPLC Ladder Logic: Nano PLC Micro PLC Mini PLC Compact PLC Small PLC Brick PLC Medium PLC Large PLC Modular PLC

- Identify The PLC Programming Languages: Function Block DiagramIdentify The PLC Programming Languages: Function Block Diagram

- Programmable Logic Controller L T P C 1 0 0 1: Department ofProgrammable Logic Controller L T P C 1 0 0 1: Department of

- LAB 10: Programmable Logic Controllers and Ladder Logic: ObjectiveLAB 10: Programmable Logic Controllers and Ladder Logic: Objective

- Chinhoyi University of Technology: - School of Engineering Sciences and - CUME 206Chinhoyi University of Technology: - School of Engineering Sciences and - CUME 206

- A PLC System: CPU Module (Left) and An I/O Rack (Right) (Allen Bradley PLC-5)A PLC System: CPU Module (Left) and An I/O Rack (Right) (Allen Bradley PLC-5)

- Index: Introduction About Automation. o o o o Inroduction To PLC o o o o o o o o o o o o o o o o o o o o o o oIndex: Introduction About Automation. o o o o Inroduction To PLC o o o o o o o o o o o o o o o o o o o o o o o

- Attendance Authentication System Using Face RecognitionAttendance Authentication System Using Face Recognition

- " Real Time Automated Control Using PLC-VB Communication ": June 2013" Real Time Automated Control Using PLC-VB Communication ": June 2013

- 50 Inspiring Audiobooks To Self-Improve While You Work Out - Online College Courses50 Inspiring Audiobooks To Self-Improve While You Work Out - Online College Courses

- Automatic Vending Machine Prototype Model: ISSN: 0974-2115Automatic Vending Machine Prototype Model: ISSN: 0974-2115

- Proposal For Tapping Unit: Sr. Numb Er Description Unit Qty Cost Per QtyProposal For Tapping Unit: Sr. Numb Er Description Unit Qty Cost Per Qty

- Statement: SR Bill No Customer Bill Date Bill Amount Status 1 Not 2 Not 3 Not Not 5 Not Not 7 Not 8 Not 9 NotStatement: SR Bill No Customer Bill Date Bill Amount Status 1 Not 2 Not 3 Not Not 5 Not Not 7 Not 8 Not 9 Not

- Price List-Cum-Order Form: S. No. Particulars Amount (RS)Price List-Cum-Order Form: S. No. Particulars Amount (RS)

- Price List-Cum-Order Form: S. No. Particulars Amount (RS)Price List-Cum-Order Form: S. No. Particulars Amount (RS)

- Convention & CNC: Conventional Vs CNC Manual Work Accuracy Time Complex Machining Skill Person InvestmentConvention & CNC: Conventional Vs CNC Manual Work Accuracy Time Complex Machining Skill Person Investment