Transmision Manual HDJ-80 - 2

Transmision Manual HDJ-80 - 2

Uploaded by

Pier Angelo PalumboCopyright:

Available Formats

Transmision Manual HDJ-80 - 2

Transmision Manual HDJ-80 - 2

Uploaded by

Pier Angelo PalumboOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Transmision Manual HDJ-80 - 2

Transmision Manual HDJ-80 - 2

Uploaded by

Pier Angelo PalumboCopyright:

Available Formats

MT-1

MANUAL TRANSMISSION (H14OF, H150F AND H151F TRANSMISSIONS)

Page DESCRIPTION PRECAUTIONS TROUBLESHOOTING REMOVAL AND INSTALLATION OF TRANSMISSION COMPONENTS DISASSEMBLY OF TRANSMISSION COMPONENT PARTS Input Shaft Assembly Output Shaft Assembly Counter Gear Assembly Front Bearing Retainer Oil Pump Cover Assembly ASSEMBLY OF TRANSMISSION MT-5 MT-12 MT-15 MT-25 MT-25 MT-27 MT-39 MT-42 MT-43 MT-47 MT-2 MT-4 MT-4

MT-2

MANUAL TRANSMISSION - Descriptiot

DESCRIPTION

Transmission types, H140F, H15OF and H151F are constant mesh synchronizer for forward gears and a sliding mesh reverse gear.

H140F

HM0535

H150F

HM0520

MANUAL TRANSMISSION - Description

MT-3

H151F

HM0521

Specifications Type of Transmission Type of Engine 1 st 2 nd 3 rd Gear Ratio 4 th 5 th Rev. Oil Capacity Type of Oil H140F H150F, H151F 4.313 2.7 liters (2.8 Us qts, 2.4 Imp.qts) 2.6 liters (2.7 Us qts, 2.3 Imp.qts) API GL-4 or GL-5 SAE 75W-90 4.529 2.464 1.490 1.000 0.881 H140F 3F, 1HZ H150F H151F 1HD-T 4.081 2.294

MT-4

MANUAL TRANSMISSION - Precautions, Troubleshooting

PRECAUTIONS

When working with FIPG material, you must be observe the following. Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces. Thoroughly clean all components to remove all the loose material. Clean both sealing surfaces with a non-residue solvent. Apply the seal packing in approx. 1.2 mm (0.047 in.) bead along the sealing surface. Parts must be assembled within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

TROUBLESHOOTING

Problem Hard to shift or will not shift Possible cause Splines on input shaft dirty or burred Transmission faulty Transmission jumps out of gear Transmission faulty Remedy Repair as necessary Disassemble and inspect transmission Disassemble and inspect transmission Page MT-5 MT-5 MT-5

MANUAL TRANSMISSION - Removal and Installation of Transmission

MT-5

REMOVAL AND INSTALLATION OF TRANSMISSION

COMPONENTS

MT-6

MANUAL TRANSMISSION - Removal and Installation of Transmission

REMOVAL OF TRANSMISSION

1. 2. DISCONNECT BATTERY CABLE FROM NEGATIVE TERMINAL REMOVE BATTERY AND COVER

3.

REMOVE SHIFT LEVER FROM INSIDE OF VEHICLE (a) (b) (c) (d) (e) (f) Remove the shift lever knob. Remove the two screws and remove the shift lever boot retainer. Pull up the shift lever boot. Cover the shift lever cap with a cloth. Then, pressing down on the shift lever cap rotate it counterclockwise to remove. Remove the shift lever.

4.

LOOSEN FAN SHROUD OF COOLING FAN TO AVOID DAMAGE TO FAN RAISE VEHICLE

5.

6.

DISCONNECT PROPELLER SHAFT (See page PR-2) REMOVE STARTER Remove the bolt, nut and the starter.

7.

8.

DISCONNECT SPEEDOMETER CABLE

MANUAL TRANSMISSION - Removal and Installation of Transmission 9.

MT-7

DISCONNECT BACK-UP LIGHT SWITCH CONNECTOR

10. DISCONNECT RELEASE CYLINDER FROM TRANSMISSION Remove the two mounting bolts and release cylinder alongside the engine. HINT: Do not disconnect the clutch line.

11 . REMOVE STABILIZER BRACKET Remove four stabilizer bracket set bolts.

12. SUPPORT TRANSMISSION WITH JACK 13. REMOVE CROSSMEMBER AND REAR MOUNTING (a) Remove the eight bolts, two nuts and crossmember.

(b)

Remove the four bolts and rear mounting from the transmission.

14. (1HZ, 1HD-T) REMOVE STIFFENER PLATE BOLTS Remove the four stiffener plate bolts from the transmission.

MT-8

MANUAL TRANSMISSION - Removal and Installation of Transmission 15. JACK UP FRONT SIDE OF ENGINE (a) Remove the four set bolts and engine under cover.

(b)

Jack up the front side of engine.

16. REMOVE REMAINING TRANSMISSION BOLTS 17. REMOVE TRANSMISSION Remove transmission toward the rear. 18. REMOVE TRANSFER FROM TRANSMISSION (a) (b) Remove the transfer adaptor rear mounting bolts. Remove the transfer from the transmission.

MANUAL TRANSMISSION Removal and Installation of Transmission

MT-9

INSTALLATION OF TRANSMISSION

1. INSTALL TRANSFER TO TRANSMISSION (a) (b) 2. Install the transfer to the transmission. Install the transfer adaptor rear mounting bolts.

PLACE TRANSMISSION AT INSTALLATION POSITION Align the input shaft spline with the clutch disc, and push the transmission fully into position.

3.

INSTALL TRANSMISSION BOLTS Torque: 730 kg-cm (53 ft-lb, 72 N-m)

4.

(1HZ, 1HD-T) INSTALL STIFFENER PLATES Torque: 380 kg-cm (27 ft-lb, 37 N-m)

5.

INSTALL ENGINE REAR MOUNTING AND CROSSMEMBER (a) Install the mounting with four bolts to the transmission. 600 kg-cm (43 ft-lb, 59 N-m)

Torque:

(b)

Install the crossmember with eight bolts and two nuts. 620 kg-cm (45 ft-lb, 61 N-m)

Torque:

6. 7.

REMOVE JACK INSTALL ENGINE UNDER COVER

MT-10

MANUAL TRANSMISSION Removal and Installation of Transmission 8. INSTALL STABILIZER BRACKET Install the stabilizer bracket with four bolts.

9.

INSTALL CLUTCH RELEASE CYLINDER

Install the release cylinder with two bolts.

Torque: 120 kg-cm (9 ft-lb, 12 N-m)

10. CONNECT BACK-UP LIGHT SWITCH CONNECTOR 1 1 . CONNECT SPEEDOMETER CABLE

12. INSTALL STARTER Install the starter with bolt and nut.

13. CONNECT PROPELLER SHAFT (See page PR-2) 14. LOWER VEHICLE 15. TIGHTEN FAN SHROUD

MANUAL TRANSMISSION - Removal and Installation of Transmission

MT-11

16. INSTALL SHIFT LEVER (a) Apply MP grease to the shift lever. (b) Align the groove of the shift lever cap and the pin part of case cover. (c) Cover the shift lever cap with a cloth. (d) Then, pressing down on the shift lever cap rotate it clockwise to install. (e) Install the shift lever boot and retainer with four screws. (f) Install the shift lever knob.

17. CONNECT BATTERY CABLE TO NEGATIVE TERMINAL 18. PERFORM ROAD TEST Check for abnormal noise and smooth operation.

MT-12

MANUAL TRANSMISSION - Components

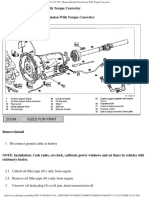

COMPONENTS (H14OF, H150F AND H151F TRANSMISSIONS)

COMPONENTS

Shift Lever Control Retainer

170 (12, 17)

Restrict Pin

Slotted Spring Pin

Reverse Restrict Pin Shift Lever Housing Shift Lever Shaft 120 (9,12) Oil Receiver

Top Switch (H150F) Clutch Housing

Back-Up Light Switch

450 (33, 44)

Transmission Case Front Bearing Retainer

170 (12, 16) 380 (27, 37)

(H150F, H151F) H140F: Back-Up Light Switch H150F: Top Switch Plug

380 (27, 37)

Intermediate Plate

120 (9,12)

380 (27, 37)

Transfer Adaptor Oil Strainer

Specified torque kg-cm (ft-lb, N-m) Non-reusable part Precoated part

MANUAL TRANSMISSION - Components

MT-13

COMPONENTS (Cont'd)

Output Shaft Assembly Input Shaft Assembly Synchronizer Ring

Hub Sleeve No. 4 Shifting Key Reverse Gear

185 (13,18)

Clutch Hub No. 4 Synchronizer Ring

Snap Ring Snap Ring

Shifting Key Spring Needle Roller Bearing Rear Bearing Retainer

Intermediate Plate Rear Bearing Outer Race Reverse Idler Gear Thrust Washer

Roller Bearing Counter Gear

Woodruff Key

Needle Roller Bearing Thrust Washer Reverse Idler Gear Shaft

kg-cm (ft-lb, N-m)

Specified torque

HM0340

MT-14

MANUAL TRANSMISSION - Components

COMPONENTS (Cont'd)

4-Speed (H140F)

Plug 190 (14,19) Spring 370 (27, 36) Ball 190 (14,19) Interlock Pin 370 (27, 36) Shift Fork No. 2 Interlock Pin Shift Fork No. 1 Interlock Pin 190(14,19) Shift Fork Shaft No. 1 Reverse Shift Fork Snap Ring Shift Fork Shaft No. 3 Shift Fork No. 2

Interlock Pin

370 (27, 36)

5-Speed(H150F, H151F)

Plug 190 (14,19) Spring Ball 370 (27, 36) 190 (14,19)

Interlock Pin Shift Fork Shaft No. 2 Interlock Pin Interlock Pin Shift Fork No. 2 Shift Fork Shaft No. 1 190 (14, 19) Interlock Ball Snap Ring

Shift Fork No. 1 Shift Fork Shaft No. 4

350 (25, 34)

Shift Fork No. 3

190 (14,19) Ball Reverse Shift Head Interlock Pin Shift Fork Shaft No. 3 370 (27, 36) Reverse Shift Fork

kg-cm (ft-lb, N-m) Precoated part

Specified torque

HMO 505 HM0341

MANUAL TRANSMISSION - Disassembly of Transmission

MT-15

DISASSEMBLY OF TRANSMISSION

(See page MT-12 to 14) 1. 2. REMOVE RELEASE FORK AND BEARING REMOVE BACK-UP LIGHT SWITCH

3.

REMOVE CLUTCH HOUSING FROM TRANSMISSION CASE Remove the ten bolts and clutch housing.

4. 5.

REMOVE TWO RESTRICT PINS REMOVE BREATHER HOSE

6.

REMOVE SHIFT LEVER CONTROL RETAINER Remove the six bolts and transmission shift lever control retainer.

7.

REMOVE REVERSE RESTRICT PIN (a) Using pliers, remove the slotted spring pin.

MT-16

MANUAL TRANSMISSION - Disassembly of Transmission (b) Remove the reverse restrict pin.

8.

REMOVE OIL PUMP COVER ASSEMBLY (a) Remove the five bolts and oil pump cover.

(b)

Using a magnetic finger, remove the two straight pins.

9.

REMOVE TRANSFER ADAPTOR Remove the eleven bolts. HINT: If necessary, tap the transfer adaptor with a plastic hammer.

10. REMOVE OIL STRAINER FROM TRANSFER ADAPTOR Remove the two bolts and oil strainer.

MANUAL TRANSMISSION - Disassembly of Transmission

MT-17

11 . REMOVE MAGNET FROM INTERMEDIATE PLATE

12. REMOVE REVERSE IDLE GEAR FROM INTERMEDIATE PLATE

13. REMOVE SHIFT LEVER SHAFT AND SHIFT LEVER HOUSING (a) Using a pin punch and a hammer, drive out the slotted spring pin from the shift lever housing.

(b)

Remove the shift lever shaft and shift lever housing.

14. REMOVE FRONT BEARING RETAINER (a) Remove the eight bolts, and front bearing retainer.

MT-18

MANUAL TRANSMISSION - Disassembly of Transmission (b) Using snap ring pliers, remove the two snap rings from the input shaft and counter gear.

15. SEPARATE TRANSMISSION CASE FROM INTERMEDIATE PLATE (a) (b) Using a brass bar and a hammer, carefully tap off the transmission case. Remove the transmission case from the intermediate plate.

16. REMOVE OIL RECEIVER FROM TRANSMISSION CASE Remove the two bolts and oil receiver. 17. REMOVE OIL RECEIVER FROM INTERMEDIATE PLATE Remove the three bolts and oil receiver.

18. MOUNT INTERMEDIATE PLATE IN VISE (a) Use two clutch housing bolts, plate washers and suitable nuts as shown.

NOTICE: Install the plate washers in reverse of normal. Increase of decrease plate washers so that the bolt tip and front tip surface of the nut are aligned. (b) Mount the intermediate plate in vise.

19. REMOVE STRAIGHT SCREW PLUGS, LOCKING BALLS AND SPRINGS (a) Using a torx socket wrench, remove the four screw plugs.

(Torx socket wrench T40 09042-00020)

MANUAL TRANSMISSION - Disassembly of Transmission

MT-19

(b) Using a magnetic finger, remove the springs and balls. 4-Speed: Three springs and balls

5-Speed:

Four springs and balls

20. REMOVE FORK SHAFT SNAP RINGS Using two screwdrivers and a hammer, tap out the snap rings. 4-Speed: One snap ring 5-Speed: Four snap rings

21. REMOVE SHIFT FORK SHAFT NO.3 OR N0.4 AND REVERSE SHIFT FORK 4-Speed: Shift fork shaft No.3 5-Speed: Shift fork shaft No.4 (a) Remove the set bolt.

(b)

(5-Speed) Remove the shift fork shaft No.4, reverse shift fork and ball. (4-Speed) Remove the shift fork shaft No.3 and reverse shift fork.

(c)

MT-20

MANUAL TRANSMISSION - Disassembly of Transmission 22. (5-Speed) REMOVE SHIFT FORK SHAFT NO.3. SHIFT FORK NO.3 AND REVERSE SHIFT HEAD (a) Using a magnetic finger, remove the interlock ball.

(b) (c)

Remove the set bolt. Remove the shift fork shaft No.3, shift fork No.3 and reverse shift head.

(d)

Using a magnetic finger, remove the interlock pin from shift fork shaft No.3.

23. REMOVE SHIFT FORK SHAFT NO.2 AND SHIFT FORK NO.1 (a) Using a magnetic finger, remove the interlock pin.

(b) (c)

Remove the set bolt. Remove the shift fork shaft No. 1 and shift fork No. 1.

MANUAL TRANSMISSION Disassembly of Transmission (d)

MT-21

Using a magnetic finger, remove the interlock pin from shift fork shaft No.1.

24. REMOVE SHIFT FORK SHAFT NO.2 AND SHIFT FORK NO.2 (a) Using a magnetic finger, remove the interlock ball.

(b) (c)

Remove the set bolt. Remove the shift fork shaft No.2 and shift fork No.2.

25. REMOVE REVERSE GEAR AND CLUTCH HUB NO.4 ASSEMBLY (w/ SERVICE HOLE) (a) Using two screwdrivers and a hammer, drive out the snap ring.

(b)

Using SST and two bolts (90101-08136), remove the clutch hub No.4 assembly.

SST 09310-17010 (09310-07010, 09310-07020)

MT-22

MANUAL TRANSMISSION - Disassembly of Transmission (c) Remove the synchronizer ring, reverse gear and needle roller bearing.

(w/o SERVICE HOLE) (a) Using two screwdrivers and a hammer, drive out the snap ring.

(b)

Using SST, remove the reverse gear with clutch hub No.4 assembly. Remove the needle roller bearing and synchronizer ring.

SST 09336-60010, 09950-20017

(c)

26. REMOVE HUB SLEEVE N0.4, SHIFTING KEYS AND SPRINGS FROM CLUTCH HUB NO.3 Using a screwdriver, remove the two springs and three shifting keys from clutch hub No.4.

27. REMOVE REAR BEARING RETAINER Remove the four bolts, and rear bearing retainer.

MANUAL TRANSMISSION - Disassembly of Transmission

MT-23

28. REMOVE TWO SNAP RINGS (a) Using snap ring pliers, remove the two snap rings.

29. REMOVE COUNTER GEAR (a) Using SST, remove the rear bearing outer race. SST 09602-35011

(b) Using a screwdriver, remove the roller bearing and counter gear.

30. REMOVE INPUT SHAFT

31. REMOVE OUTPUT SHAFT Remove the output shaft, from the intermediate plate by pulling on the output shaft and tapping on the intermediate plate with plastic hammer.

MT-24

MANUAL TRANSMISSION Disassembly of Transmission 32. INSPECT BACK-UP LIGHT SWITCH Check that there is continuity between terminals as shown.

Switch Position Push Free Specified Continuity No Continuity

If operation is not specified replace the switch.

MANUAL TRANSMISSION - Component parts (Input Shaft Assembly)

MT-25

COMPONENT PARTS Input Shaft Assembly

COMPONENTS

Roller Bearing

Input Shaft Bearing

Synchronizer Ring

Input Shaft Snap Ring

Non-reusable part

HM0387

INSPECTION OF INPUT SHAFT ASSEMBLY

INSPECT SYNCHRONIZER RING (a) Turn the ring and push it into check braking action.

Measure the clearance between the synchronizer ring back and the gear spline end. Standard clearance: 0.8 - 1.6 mm (0.0315 - 0.0630 in.) Minimum clearance: 0.6 mm (0.0236 in.)

(b)

MT-26

MANUAL TRANSMISSION - Component parts (Input Shaft Assembly)

REPLACEMENT OF BEARING

IF NECESSARY, REPLACE INPUT SHAFT BEARING (a) Using snap ring pliers, remove the snap ring.

(b)

Using a press, remove the bearing.

(c)

Using SST and a press, install a new bearing.

SST 09316-20011

(d)

Select a snap ring that will allow minimum axial play. Mark A B C D E F 2.50 2.55 2.60 2.65 2.70 2.75 Thickness 2.55 2.60 2.65 2.70 2.75 2.80 mm (in.) 0.1004) 0.1024) 0.1043) 0.1063) 0.1083) 0.1102)

(0.0984 (0.1004 (0.1024 (0.1043 (0.1063 (0.1083

(e)

Using snap ring pliers, install the snap ring.

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly)

MT-27

Output Shaft Assembly

COMPONENTS

Third Gear Synchronizer Ring Clutch Hub No. 2

Snap Ring Needle Roller Bearing Synchronizer Ring Hub Sleeve No. 2 Clutch Hub No. 3 Shifting Key Snap Ring Shifting Key Spring

Needle Roller Bearing

Fifth Gear Hub Sleeve No. 3 Shifting Key Shifting Key Spring Pin

Needle Roller Bearing Snap Ring Output Shaft Shifting Key Hub Sleeve No. 1 Second Gear

First Gear Synchronizer Ring Clutch Hub No. 1 Shifting Key Spring Synchronizer Ring Needle Roller Bearing Thrust Washer Thrust Washer Non-reusable part

HM0395

Ball Bearing Snap Ring

MT-28

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly)

DISASSEMBLY OF OUTPUT SHAFT ASSEMBLY

1. (H140F, H150F) REMOVE BALL BEARING AND FIRST GEAR (a) Using two screwdrivers and a hammer, drive out the snap ring.

(b)

Remove the thrust washer and pin.

(c)

Using SST, remove the ball bearing.

SST 09950-20017

(d)

Remove the thrust washer and pin.

(e)

Remove the first gear, synchronizer ring No.1 and needle roller bearing.

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly)

MT-29

(H151F) REMOVE BALL BEARING AND FIRST GEAR (a) Using two screwdrivers and a hammer, drive out the snap ring.

(b)

Remove the thrust washer and pin.

(c) Using SST and a press, remove the ball bearing, thrust washer and first gear.

SST 09555-55010

(d) Remove the pin and needle roller bearing.

2.

REMOVE HUB SLEEVE NO. 1 ASSEMBLY, SYNCHRONIZER RING N0.1, SECOND GEAR AND NEEDLE ROLLER BEARING (a) Using two screwdrivers and a hammer, drive out the snap ring.

(b) Using a press, remove the hub sleeve No.1 assembly, synchronizer ring No.1, and second gear. (c) Remove the needle roller bearing.

MT-30

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly) 3. REMOVE HUB SLEEVE NO.1, SHIFTING KEYS AND SPRINGS FROM CLUTCH HUB NO.1 Using a screwdriver, remove the three shifting keys and two springs from the clutch hub No.1.

4.

REMOVE HUB SLEEVE NO.2 ASSEMBLY, SYNCHRONIZER RING, THIRD GEAR AND NEEDLE ROLLER BEARING (a) Remove two screwdrivers and a hammer, drive out the snap ring.

(b)

(H15OF,H151F) Shift hub sleeve No.3 onto the fifth gear.

(c)

(H140F) Using a press, remove the hub sleeve No.2 assembly, synchronizer ring and third gear.

(H15OF,H151F) Using SST and a press, remove the hub sleeve No.2 assembly, synchronizer ring and third gear. SST 09555-55010 (d) Remove the needle roller bearing.

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly) 5.

MT-31

(H150F,H151F) REMOVE HUB SLEEVE NO.2, SHIFTING KEYS AND SPRINGS FROM CLUTCH HUB NO.2 Using a screwdriver, remove the three shifting keys and two springs from the clutch hub No.2.

6.

(H150F.H151F) REMOVE HUB SLEEVE NO.3 ASSEMBLY, SYNCHRONIZER RING, FIFTH GEAR AND NEEDLE ROLLER BEARING (a) Using two screwdriver, and a hammer, drive out the snap ring.

(b) Using SST and a press, remove the hub sleeve No.3 assembly, synchronizer ring.

SST 09950-00020

(c) Remove the needle roller bearing.

7.

(H150F,H151F) REMOVE HUB SLEEVE NO.3 SHIFTING KEYS AND SPRINGS FROM CLUTCH HUB NO.3 Using a screwdriver, remove the three shifting keys and two springs from the clutch hub No.3.

MT-32

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly)

INSPECTION OF OUTPUT SHAFT ASSEMBLY

1. MEASURE EACH GEAR THRUST CLEARANCE Measure the thrust clearance of each gear. Standard clearance: 1st and 3rd gear 2nd and 5th gear Maximum clearance: 1st and 3rd gear 2nd and 5th gear 2. 0.1 0.45 mm (0.0039 - 0.0177 in.) 0.1 0.35 mm (0.0039 - 0.0138 in.) 0.45 mm (0.0177 in.) 0.35 mm (0.0138 in.)

MEASURE EACH GEAR OIL CLEARANCE Using a dial indicator, measure the oil clearance of each gear. Standard clearance: 1st and 3rd gear 0.020 (0.0008 2nd and 5th gear 0.015 (0.0006 0.073 mm - 0.0029 in.) 0.068 mm - 0.0027 in.)

Maximum clearance: 1 st and 3rd gear 2nd and 5th gear 3.

0.073 mm (0.0029 in.) 0.068 mm (0.0027 in.)

(H150F,H151F) INSPECT OUTPUT SHAFT (a) Using calipers, measure the output shaft flange thickness. 4.725 mm (0.1860 in.)

Minimum thickness:

(b)

Using a dial indicator, check the shaft runout. 0.05 mm (0.0020 in.)

Maximum runout:

(c)

Using a micrometer, measure the outer diameter of the output shaft journal. diameter: 49.979 mm 57.984 mm 37.979 mm 45.984 mm (1.9677 (2.2828 (1.4952 (1.8104 in.) in.) in.) in.)

Minimum 1st 2nd 3rd 5th

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly) 4.

MT-33

INSPECT SYNCHRONIZER RINGS (a) Turn the ring and push it in to check the braking action.

Measure the clearance between the synchronizer ring back and the gear spline end. (H140F, H150F) Standard clearance: 1st and 2nd gear 1.1 1.9 mm (0.043 - 0.075 in.) 3rd and reverse gear 0.8 1.6 mm (0.031 - 0.063 in.) Minimum clearance: 1st and 2nd gear 1.1 mm (0.043 in.) 3rd and reverse gear 0.8 mm (0.031 in.) (H151F) Standard clearance: 1st and 2nd gear 0.85 1.4 mm (0.0335 - 0.0551 in.) 3rd gear 0.75 1.3 mm (0.0295 - 0.0512 in.) Minimum clearance: 1st and 2nd gear 0.85 mm (0.0335 in.) 3rd gear 0.75 mm (0.0295 in.)

(b)

5.

MEASURE CLEARANCE OF SHIFT FORKS AND HUB SLEEVES Using a feeler gauge, measure the clearance between the hub sleeve and shift fork. Maximum clearance: 0.35 mm (0.0138 in.)

MT-34

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly)

ASSEMBLY OF OUTPUT SHAFT ASSEMBLY

1. INSERT CLUTCH HUB NO. 1, NO.2 AND NO.3 INTO HUB SLEEVE (a) Install the clutch hub and shifting keys to the hub sleeve.

(b)

Install the springs under the shifting keys.

NOTICE: Install the key springs positioned so that their end gaps are not in line.

2.

INSTALL FIFTH GEAR AND HUB SLEEVE NO.3 ASSEMBLY ON OUTPUT SHAFT (a) (b) (c) Apply gear oil to the shaft and needle roller bearing. Place the synchronizer ring on the gear and align the ring slots with the shifting keys. Install the needle roller bearing in the fifth gear.

(d)

Using SST and a press, install the fifth gear and hub sleeve No.3.

SST 09316-60010 (09316-00010)

3.

INSTALL SNAP RING (a) Select a snap ring that will allow minimum axial play.

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly)

MT-35

(b) Using a brass bar and hammer, drive in the snap ring.

4.

MEASURE FIFTH GEAR THRUST CLEARANCE Using a feeler gauge, measure the fifth gear thrust clearance. Standard clearance: 0.1 0.35 mm (0.0039 - 0.0138 in.) Maximum clearance: 0.35 mm (0.0138 in.)

5.

INSTALL THIRD GEAR AND HUB SLEEVE NO.2 ASSEMBLY (a) Apply gear oil to the shaft and needle roller bearing. (b) Place the synchronizer ring on the gear and align the ring slots with the shifting keys. (c) Install the needle roller bearing in the third gear.

(d) Using SST and a press, install the third gear and hub sleeve No.2. SST 09316-60010 (09316-00010)

6.

INSTALL SNAP RING (a) Select a snap ring that will allow minimum axial play. Mark 4 5 6 7 8 9 Thickness mm - 1.95 (0.0748 - 2.00 (0.0768 - 2.05 (0.0787 - 2.10 (0.0807 - 2.15 (0.0827 - 2.20 (0.0847 (in.) - 0.0768) - 0.0787) - 0.0807) - 0.0827) - 0.0847) - 0.0866)

1.90 1.95 2.00 2.05 2.10 2.15

MT-36

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly) (b) Using a brass bar and a hammer, drive in a new snap ring.

7.

MEASURE THIRD GEAR THRUST CLEARANCE Using a feeler gauge, measure the third gear thrust clearance. Standard clearance: Maximum clearance: O.I 0.45 mm (0.0039 - 0.0138 in.) 0.45 mm (0.0138 in.)

8.

INSTALL SECOND GEAR AND HUB SLEEVE NO.1 ASSEMBLY (a) (b) (c) Apply gear oil to the shaft and needle roller bearing. Place the synchronizer ring on the gear and align the ring slots with the shifting keys. Install the needle roller bearing in the second gear.

(d)

Using a press, install the second gear and hub sleeve No.1 assembly.

9.

INSTALL SNAP RING (a) Select a snap ring that will allow minimum axial play.

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly)

MT-37

(b) Using a brass bar and a hammer, drive in a new snap ring.

10. MEASURE SECOND GEAR THRUST CLEARANCE Using a feeler gauge, measure the second gear thrust clearance. Standard clearance: 0.1 0.35 mm (0.0039 - 0.0138 in.) Maximum clearance: 0.35 mm (0.0138 in.)

11. INSTALL FIRST GEAR (a) Apply gear oil to the shaft and needle roller bearing. (b) Place the synchronizer ring on the gear and align the ring slots with the shifting keys. (c) Install the needle roller bearing in the first gear.

12. INSTALL BALL BEARING (a) Install the pin and thrust washer.

(b) Using SST and a press, install the ball bearing. SST 09316-60010 (09316-00010), 09523-36010

MT-38

MANUAL TRANSMISSION - Component parts (Output Shaft Assembly) (c) Install the pin and thrust washer.

13. INSTALL SNAP RING (a) Select a snap ring that will allow minimum axial play.

(b)

Using a brass bar and a hammer, drive in a new snap ring.

MANUAL TRANSMISSION - Component Parts (Counter Gear Assembly)

MT-39

Counter Gear Assembly

COMPONENTS

1H engine

Counter Gear Snap Ring Inner Race Counter Gear Front Bearing

Counter Gear Rear Bearing

Side Race

Non-reusable part

DISASSEMBLY OF COUNTER GEAR ASSEMBLY

IF NECESSARY, REPLACE COUNTER GEAR FRONT BEARING AND SIDE RACE (a) Using snap ring pliers, remove the snap ring.

(b)

Using SST and socket wrench, press out the bearing.

SST 09950-00020

MT-40

MANUAL TRANSMISSION - Component Parts (Counter Gear Assembly) (c) Remove the side race.

INSPECTION OF COUNTER GEAR ASSEMBLY

INSPECT COUNTER GEAR Using a micrometer, measure the outer diameter of needle roller bearing race. Standard diameter: 35.957 35.970 mm (1.4156 - 1.4161 in.)

Maximum diameter: 35.970 mm (1.4161 in.)

ASSEMBLY OF COUNTER GEAR ASSEMBLY

INSTALL SIDE RACE AND COUNTER GEAR FRONT BEARING (a) (b) Apply gear oil to the side race. Install the side race.

(c) (d)

Apply gear oil to the bearing. Using SST and a press, install the bearing.

SST 09316-60010 (09316-00010, 09316-00020)

(e)

Select a snap ring that will allow minimum axial play. Mark A B C D E F 2.45 2.50 2.55 2.60 2.65 2.70 Thickness 2.50 2.55 2.60 2.65 2.70 2.75 mm (in.) 0.0984) 0.1004) 0.1024) 0.1043) 0.1063) 0.1083)

(0.0970 (0.0984 (0.1004 (0.1024 (0.1043 (0.1063

MANUAL TRANSMISSION - Component Parts (Counter Gear Assembly) (f)

MT-41

Using snap ring pliers, install a new snap ring.

MT-42

MANUAL TRANSMISSION - Component Parts (Front Bearing Retainer)

Front Bearing Retainer

COMPONENTS

Oil Seal

Front Bearing Retainer

Non-reusable part

REPLACEMENT OF OIL SEAL

IF NECESSARY REPLACE FRONT BEARING RETAINER OIL SEAL (a) Using a screwdriver, pry out the oil seal.

HM0455

(b)

Using SST and a press in a new oil seal. 15.4 - 16.2 mm (0.606 - 0.638 in.)

SST 09608-20012 (09608-03020, 09608-00040) Oil seal depth:

HM0456

MANUAL TRANSMISSION - Component Parts (Oil Pump Cover Assembly)

MT-43

Oil Pump Cover Assembly

COMPONENTS

Screw Plug 185(13,18) O-Ring Spring Ball Oil Seal Valve Seat

Oil Pump Drive Rotor Oil Pump Driven Rotor Oil Pump Cover kg-cm (ft-lb, N-m) Non-reusable part Precoated part Specified torque

DISASSEMBLY OF OIL PUMP COVER ASSEMBLY

1. 2. REMOVE OIL SEAL REMOVE OIL PUMP DRIVE ROTOR

3. 4.

REMOVE OIL PUMP DRIVEN ROTOR REMOVE O-RING

MT-44

MANUAL TRANSMISSION - Component Parts (Oil Pump Cover Assembly) 5. REMOVE SCREW PLUG, SPRING, BALL AND VALVE SEAT (a) Using a hexagon wrench, remove the screw plug.

(b)

Using a magnetic finger, remove the spring.

(c)

Using a magnetic finger, remove the ball.

(d) (e)

Using a magnetic finger, remove the valve seat. Remove the O-ring from the valve seat.

INSPECTION OF OIL PUMP COVER ASSEMBLY

1. CHECK BODY CLEARANCE OF DRIVEN ROTOR Push the driven rotor to one side of the cover. Using a feeler gauge, measure the clearance. Standard clearance: Maximum clearance: 0.075 0.170 mm (0.0030 - 0.0067 in.) 0.170 mm (0.0067 in.)

If the clearance more than the limit, replace the driven rotor or pump cover.

MANUAL TRANSMISSION - Component Parts (Oil Pump Cover Assembly) 2.

MT-45

CHECK TIP CLEARANCE OF BOTH ROTORS Using a feeler gauge, measure the clearance between both rotor tips. Standard clearance: 0.10 0.22 mm (0.0039 - 0.0087 in.) Maximum clearance: 0.22 mm (0.0087 in.) If the clearance more than the limit, replace the drive rotor or driven rotor.

ASSEMBLY OF OIL PUMP COVER ASSEMBLY

1. INSTALL VALVE SEAT, BALL, SPRING AND SCREW PLUG (a) (b) (c) Install the O-ring to valve seat. Apply gear oil to the valve seat. Install the valve seat.

(d) (e)

Apply gear oil to the ball. Install the ball.

(f)

Install the spring.

(g) Using a hexagon wrench, install and torque the screw plug. Torque: 185 kg-cm (13 ft-lb, 18 N-m)

MT-46

MANUAL TRANSMISSION - Component Parts (Oil Pump Cover Assembly) 2. INSTALL OIL PUMP DRIVEN ROTOR (a) (b) Aplly gear oil to the driven rotor. Install the oil pump driven rotor.

3.

INSTALL OIL PUMP DRIVE ROTOR (a) (b) Apply gear oil to the drive rotor. Install the oil pump drive rotor.

4. 5.

INSTALL NEW O-RING INSTALL NEW OIL SEAL

MANUAL TRANSMISSION - Assembly of Transmission

MT-47

ASSEMBLY OF TRANSMISSION

(See page MT-12 to 14) 1. INSTALL OUTPUT SHAFT ASSEMBLY TO INTERMEDIATE PLATE (a) Install the output shaft assembly into the intermediate plate by pulling on the output shaft assembly and tapping on the intermediate plate.

(b) Using snap ring pliers, install the snap ring.

2.

INSTALL INPUT SHAFT (a) Apply MP grease to the 12-needle roller bearing and install them into the input shaft. (b) Install the input shaft to the output shaft with the synchronizer ring slots aligned with the shifting keys.

3.

INSTALL COUNTER GEAR (a) Install the counter gear into the intermediate plate and install the roller bearing.

(b) Using snap ring pliers, install the snap ring to outer race.

MT-48

MANUAL TRANSMISSION - Assembly of Transmission (c) Install the counter gear rear bearing outer race with a brass bar and hammer.

4.

INSTALL REAR BEARING RETAINER Install and torque the bolts. Torque: 185 kg-cm (13 ft-lb, 18 N-rn)

5.

INSTALL REVERSE GEAR, REVERSE SYNCHRO ASSEMBLY AND NEEDLE ROLLER BEARING (a) (b) Apply gear oil to the needle roller bearing. Install the needle roller bearing and reverse gear with synchronizer ring.

(c) (d)

Install the clutch hub No.4 and shifting keys to the hub sleeve No.4. Install the spring under the shifting keys.

NOTICE: Install the key springs positioned so that their end gaps are not in line.

Front

(e)

Using SST and a hammer, install the reverse synchro assembly.

SST 09316-60010 (09316-00010)

MANUAL TRANSMISSION - Assembly of Transmission 6.

MT-49

INSTALL SNAP RING (a) Select a snap ring that will allow minimum axial play. Mark A B C D E F Thickness mm - 2.45 (0.0945 - 2.50 (0.0965 - 2.55 (0.0984 - 2.60 (0.1004 - 2.65 (0.1024 - 2.70 (0.1044 (in.) - 0.0965) - 0.0984) - 0.1004) - 0.1024) - 0.1044) - 0.1063)

2.40 2.45 2.50 2.55 2.60 2.65

(b) Using a brass bar and a hammer, install the snap ring.

7.

MEASURE REVERSE GEAR THRUST CLEARANCE Using a feeler gauge, measure the reverse gear clearance. Standard clearance: 0.1 0.67 mm (0.0039 - 0.0264 in.) Maximum clearance: 0.67 mm (0.0264 in.)

8.

INSTALL SHIFT FORK SHAFT NO.2 AND SHIFT FORK NO.2 (a) Place shift fork No.2 into the grove of hub sleeve No.2. (b) Install shift fork shaft No.2 to shift fork No.2 and intermediate plate. (c) Install and torque the set bolt. Torque: 370 kg-cm (27 ft-lb, 36 N-m)

9.

INSTALL SHIFT FORK SHAFT NO.1 AND SHIFT FORK NO.1 (a) Using a magnetic finger, install the interlock pin into the intermediate plate.

MT-50

MANUAL TRANSMISSION - Assembly of Transmission (b) Install the interlock pin into the shaft hole.

(c) (d) (e)

Place shift fork No.1 into the groove of hub sleeve No.1. Install shift fork shaft No.1 to shift fork No.1 and intermediate plate. Install and torque the bolt. 370 kg-cm (27 ft-lb, 36 N-m)

Torque:

10. INSTALL SHIFT FORK SHAFT NO.3, REVERSE SHIFT HEAD AND SHIFT FORK NO.3 (a) Using a magnetic finger, install the interlock pin into the intermediate plate.

(b)

Install the interlock pin into the shaft hole.

(c) (d)

Place shift fork No.3 into the groove of hub sleeve No.3. Install shift fork shaft No.3 to shift fork No.3, reverse shift head and shift fork through the intermediate plate. Install and torque the set bolt. 370 kg-cm (27 ft-lb, 36 N-m)

(e)

Torque:

MANUAL TRANSMISSION - Assembly of Transmission

MT-51

11. INSTALL SHIFT FORK SHAFT NO.3 OR N0.4 AND REVERSE SHIFT FORK (a) Using a magnetic finger, install the locking ball into the intermediate plate.

(b)

Place reverse shift fork into the groove of hub sleeve No.3 or No.4. (c) Install shift fork shaft No.3 or No.4 to reverse shift fork and shift fork through the intermediate plate. (d) Using a magnetic finger, install the locking ball into the reverse shift head.

(e) Install and torque the set bolt. Torque: 4-Speed 350 kg-cm (25 ft-lb, 34 N-m) 5-Speed 370 kg-cm (27 ft-lb, 36 N-m)

12. INSTALL FORK SHAFT SNAP RINGS Using a brass bar and hammer, tap in the snap rings. 4-Speed: One snap ring 5-Speed: Four snap rings.

13. INSTALL LOCKING BALLS, SPRINGS AND SCREW PLUGS (a) Install the locking balls, springs and screw plugs. 4-Speed: Three locking balls and springs 5-Speed: Four locking balls and springs

MT-52

MANUAL TRANSMISSION - Assembly of Transmission (b) Apply liquid sealer to the plug threads. Part No.08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

Sealant: (c)

Using a torx socket wrench, torque the screw plug. 190 kg-cm (14 ft-lb, 19 N-m)

(Torx socket wrench T40 09042-00020) Torque:

14. INSTALL REVERSE IDLER GEAR TO INTERMEDIATE PLATE

15. DISMOUNT INTERMEDIATE PLATE FROM VISE (a) (b) Dismount the intermediate plate from the vise. Remove the bolts, nuts and plate washers.

16. INSTALL OIL RECEIVER TO INTERMEDIATE PLATE (a) (b) Install the oil receiver. Install and torque the three bolts. 185 kg-cm (13 ft-lb, 18 N-m)

Torque:

17. INSTALL MAGNET TO INTERMEDIATE PLATE

18. INSTALL OIL RECEIVER TO FRONT CASE

Install and torque the two bolts.

Torque: 120 kg-cm (9 ft-lb, 12 N-m)

MANUAL TRANSMISSION - Assembly of Transmission

MT-53

19. ASSEMBLE TRANSMISSION CASE AND INTERMEDIATE PLATE Remove any packing material and be careful not to drop oil on the contacting surface of the transmission case. (b) Apply seal packing to the transmission case as shown in the figure. Seal packing: Part No.08826-00090, THREE BOND 1281 or equivalent HINT: Install the transmission case as soon as the seal packing is applied. (c) Align each bearing outer race, each fork shaft end and reverse idler gear shaft end with the case installation holes, and install the case. (d) Using a plastic hammer, tap on the case to install it. (a)

20. INSTALL BEARING SNAP RINGS Using snap ring pliers, install the two snap rings to the input shaft bearing and counter gear front bearing.

Seal Packing

21. INSTALL FRONT BEARING RETAINER (a) Remove any packing material and be careful not to drop oil on the contacting surfaces of the front bearing retainer. (b) Apply seal packing to the retainer as shown in the figure and install it to the transmission case. Seal packing: Part No.08826-00090, THREE BOND 1281 or equivalent HINT: Install the front bearing retainer as soon as the seal packing is applied. (c) Apply liquid sealer to the bolt threads.

Part No.08833-00080. THREE BOND 1344, LOCTITE 242 or equivalent (d) Install and torque the eight bolts. Torque: 170 kg-cm (12 ft-lb, 16 N-m)

Sealant:

MT-54

MANUAL TRANSMISSION - Assembly of Transmission 22. INSTALL SHIFT LEVER SHAFT AND SHIFT LEVER HOUSING (a) Install the shift lever shaft and shift lever housing.

(b)

Using a pin punch and hammer, drive in the slotted spring pin.

23. INSTALL OIL STRAINER TO TRANSFER ADAPTOR (a) (b) Install the oil strainer. Install and torque the two bolts. 120 kg-cm (9 ft-lb, 12 N-m)

Torque:

24. INSTALL TRANSFER ADAPTOR (a) Remove any packing material and be careful not to drop oil on the contacting surfaces of the transfer adaptor. Apply seal packing to the transfer adaptor as shown. Part No.08826-00090, THREE BOND 1281 or equivalent

(b)

Seal packing:

HINT: Install the transfer adaptor as soon as the seal packing is applied. (c) (d) Install the transfer adaptor. Install and torque the eleven bolts. 380 kg-cm (27 ft-lb, 37 N-m)

Torque:

MANUAL TRANSMISSION - Assembly of Transmission 25. INSTALL OIL PUMP BODY (a) Apply MP grease to the straight pin. (b) Install the two straight pins.

MT-55

(c) Install the oil pump body. (d) Apply liquid sealer to the bolt threads. Sealant: Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent. (e) Install and torque the five bolts. Torque: 170 kg-cm (12 ft-lb. 17 N-m)

26. (H150F, H151F) INSTALL REVERSE RESTRICT PIN (a) Install the reverse restrict pin to the shift control retainer.

(b) Using a hammer, tap in the slotted spring pin as shown.

Seal Packing

27. INSTALL SHIFT LEVER CONTROL RETAINER (a) Remove any packing material and be careful not to drop oil on the contacting surfaces of the shift lever control retainer as shown. (b) Apply seal packing to the shift lever control retainer. Seal packing: Part No.08826-00090, THREE BOND 1281 or equivalent HINT: Install the shift lever control retainer as soon as the seal packing is applied.

MT-56

MANUAL TRANSMISSION - Assembly of Transmission (c) Install and torque the six bolts. 170 kg-cm (12 ft-lb, 17 N-m)

Torque:

28. INSTALL TWO RESTRICT PINS Torque: 380 kg-cm (27 ft-lb, 37 N-m)

29. INSTALL BREATHER HOSE

30. INSTALL CLUTCH HOUSING (a) (b) Install the clutch housing. Install and torque the ten bolts. 380 kg-cm (27 ft-lb, 37 N-m)

Torque:

3 1 . INSTALL BACK-UP LIGHT SWITCH Torque: 450 kg-cm (33 ft-lb, 44 N-m)

32. INSTALL RELEASE FORK AND BEARING

You might also like

- 1kd FTV OverhaulDocument37 pages1kd FTV OverhaulJehuty8898% (40)

- C50 Manual TransaxleDocument105 pagesC50 Manual Transaxleciscojd100% (2)

- 2008+2009 CBR1000RR Clutch Update InstructionsDocument36 pages2008+2009 CBR1000RR Clutch Update InstructionsClyson McWilliams100% (10)

- Toyota Corolla+c52 Shift ManualDocument221 pagesToyota Corolla+c52 Shift Manualdaswine100% (4)

- 2 - TransmissionDocument137 pages2 - TransmissionHugo Mendes100% (3)

- Testing and AdjustingDocument20 pagesTesting and AdjustingAlexandra Yupanqui sarmiento100% (2)

- NV146 Tcase Removal DisassemblyDocument34 pagesNV146 Tcase Removal DisassemblyMarcus RafaeliNo ratings yet

- Motor F4RDocument64 pagesMotor F4RPablo OrtizNo ratings yet

- Adjustment of The Valve Lash and The Valve Bridge With The 147-5482Document8 pagesAdjustment of The Valve Lash and The Valve Bridge With The 147-5482victor.cipriani50% (2)

- RA61 Manual TransaxleDocument77 pagesRA61 Manual TransaxlelogammicNo ratings yet

- Assembly Removal and Installation: G58 Manual TransmissionDocument9 pagesAssembly Removal and Installation: G58 Manual TransmissionPannie Ng100% (1)

- w58 RebuildDocument49 pagesw58 Rebuildtfphoenix100% (1)

- 42 - ClutchDocument24 pages42 - ClutchArif WidayuniNo ratings yet

- Clutch Accumulator Assy (1Cd-Ftv) : ComponentsDocument29 pagesClutch Accumulator Assy (1Cd-Ftv) : ComponentsMusat Catalin-Marian100% (1)

- GearboxDocument48 pagesGearboxBob DesmetNo ratings yet

- Parking Brake Assy: ComponentsDocument19 pagesParking Brake Assy: ComponentsMusat Catalin-Marian100% (2)

- Desmonte de Bomba de Inyeccion 3406cDocument5 pagesDesmonte de Bomba de Inyeccion 3406cAnderson CamachoNo ratings yet

- SLK Trans RemovalDocument3 pagesSLK Trans RemovalMarl Dominic M. BonbonNo ratings yet

- Mercury Commander Side Mount ControlDocument18 pagesMercury Commander Side Mount ControlTab Sedgwick100% (1)

- A32 MTDocument47 pagesA32 MTLevin Tan HtNo ratings yet

- 34-1 Shift Linkage ServiceDocument18 pages34-1 Shift Linkage Servicemefisto06cNo ratings yet

- Precione de Trasmicion D6eDocument14 pagesPrecione de Trasmicion D6efranklin oliverosNo ratings yet

- ZJ Trans&XferDocument356 pagesZJ Trans&Xferoğuzhan_tekceNo ratings yet

- Remove Fuel Injection Pump Housing and GovernorDocument7 pagesRemove Fuel Injection Pump Housing and GovernorAnonymous cS9UMvhBqNo ratings yet

- D Transmission2010Document37 pagesD Transmission2010Akrae AcrNo ratings yet

- Transmision Automatica CorollaDocument50 pagesTransmision Automatica Corollajavier guardiaNo ratings yet

- Powershit CatDocument36 pagesPowershit CatFrancisco Mariños100% (1)

- Pages From FJ HDJ Hzj-80 Series Chassis-TransferDocument92 pagesPages From FJ HDJ Hzj-80 Series Chassis-TransferNimesh EdirisingheNo ratings yet

- Remove TransmissionDocument8 pagesRemove TransmissionWilfredo BuesoNo ratings yet

- Rear AxleDocument108 pagesRear AxleGreg HannaNo ratings yet

- Lincoln Navigator Transmission-RemovalDocument5 pagesLincoln Navigator Transmission-RemovalemilioostiNo ratings yet

- Engine - Repair - 1997-2000 EV Repair ManualDocument327 pagesEngine - Repair - 1997-2000 EV Repair ManualJorge Sepulveda100% (1)

- Engine, Removing and Installing: Special Tools and EquipmentDocument20 pagesEngine, Removing and Installing: Special Tools and Equipmentifu62319No ratings yet

- Suspension: General Procedures Wheel AlignmentDocument18 pagesSuspension: General Procedures Wheel Alignmentpavel35No ratings yet

- 3406C Generator Set 4ZR00001-UP (SEBP2547 - 45) - Systems & ComponentsDocument5 pages3406C Generator Set 4ZR00001-UP (SEBP2547 - 45) - Systems & ComponentsAmine SabiriNo ratings yet

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- Fuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Document9 pagesFuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Hammam al HammamNo ratings yet

- Camshaft TimingDocument8 pagesCamshaft TimingHarol Ariel Sanchez MezaNo ratings yet

- Caterpillar Cat 245D EXCAVATOR (Prefix 7ZJ) Service Repair Manual (7ZJ00001 and Up)Document29 pagesCaterpillar Cat 245D EXCAVATOR (Prefix 7ZJ) Service Repair Manual (7ZJ00001 and Up)rpoy9396615No ratings yet

- Desmontaje Paquete de Embrague d7g2Document11 pagesDesmontaje Paquete de Embrague d7g2cristian chuquicondor torres100% (2)

- Pruebas y Ajustes Caja D7HDocument83 pagesPruebas y Ajustes Caja D7HAlfredo GuzmánNo ratings yet

- Repair Guides - Automatic Transmission - Transmission Removal & InstallationDocument17 pagesRepair Guides - Automatic Transmission - Transmission Removal & InstallationJayD505No ratings yet

- 32 BrakeDocument63 pages32 BrakeTung NguyenNo ratings yet

- Transmission and Transfer CaseDocument6 pagesTransmission and Transfer CaseawemetalNo ratings yet

- Transmission Removal and Installation at PDFDocument4 pagesTransmission Removal and Installation at PDFOskars ŠtālsNo ratings yet

- Diagram Cat Starter and Selenoid 4n241 - InfoDocument11 pagesDiagram Cat Starter and Selenoid 4n241 - InfoMatz D2No ratings yet

- Diagram Cat Starter and Selenoid 4n241 - InfoDocument11 pagesDiagram Cat Starter and Selenoid 4n241 - InfoMatz D2No ratings yet

- Automatic Timing AdvanceDocument9 pagesAutomatic Timing AdvanceАлександрNo ratings yet

- Automatic Transaxle System: PrecautionDocument21 pagesAutomatic Transaxle System: PrecautionJorge NegrettiNo ratings yet

- AssemblyDocument8 pagesAssemblyGregory YoungNo ratings yet

- 016 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - Off VehicleDocument106 pages016 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - Off VehicleGedas GvildysNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- The Red Baron’s Ultimate Ducati Desmo Manual: BELT-DRIVEN CAMSHAFTS L-TWINS 1979 TO 2017From EverandThe Red Baron’s Ultimate Ducati Desmo Manual: BELT-DRIVEN CAMSHAFTS L-TWINS 1979 TO 2017No ratings yet

- How to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackFrom EverandHow to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Vi: the Ironhead Sportster: 1957 to 1985From EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Vi: the Ironhead Sportster: 1957 to 1985No ratings yet