Drill Pipe Performance Data Sheet

Drill Pipe Performance Data Sheet

Uploaded by

Hamdi SaidCopyright:

Available Formats

Drill Pipe Performance Data Sheet

Drill Pipe Performance Data Sheet

Uploaded by

Hamdi SaidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Drill Pipe Performance Data Sheet

Drill Pipe Performance Data Sheet

Uploaded by

Hamdi SaidCopyright:

Available Formats

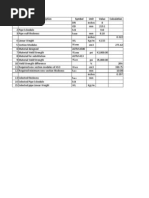

Pipe Size & Weight:

Pipe Grade:

Range:

Tool Joint:

DRILL PIPE PERFORMANCE DATA SHEET

IMPERIAL UNIT

DRILL PIPE DIMENSIONS & MATERIALS

3-1/2 15.50 lb/ft EU

S135

2

4.75 X 2.5625 NC38

DRILL PIPE WEAR & MECHANICAL PERFORMANCES

NEW

PIPE

NEW

PREMIUM

3.500

0.449

4.304

2.923

5.847

580,995

37,954

30,363

30,308

30,194

3.320

0.359

3.342

2.239

4.477

451,115

29,063

23,250

27,710

26,049

0.506

0.661

4.750

2.563

634,795

19,186

13,400

11,500

9,600

4.781

BOX WEAK

4.781

2.563

634,795

19,215

13,500

11,500

9,600

4.781

BOX WEAK

PIPE

Pipe size

Pipe Grade

Pipe Body Material Yield Strength

Pipe Length Range 2 or 3

ID

Calculated Plain End Weight

Cross Sectional Area OD

Cross Sectional Area ID

in

in

lbs/ft

in Sq

in Sq

3-1/2_15.50_lb/ft_EU

S135

135,000

2

2.602

14.631

9.621

5.317

ksi

in

in

in

in

deg

NC38

120

4.750

2.563

10.500

12.000

35

ft

lbs/ft

gal/ft

gal/ft

gal/ft

in

31.00

16.60

0.529

0.254

0.275

2.438

psi

OD

Wall Thickness

Cross Sectional Area Pipe Body

Section Modulus

Polar Section Modulus

Tensile Strength

Torsional Strength

80% Torsional Strength

Internal Pressure Capacity

Collapse Capacity

TOOL JOINT

Connection Type

Material Yield Strength

OD

ID

Pin Tong Length

Box Tong Length

Pin shoulder Angle

DRILL PIPE ASSEMBLY

Shoulder-Shoulder Length

Adjusted Weight

Closed End Dsplacement

Open End Displacement

Fluid Capacity

Drift Size

Tool Joint / Pipe Body Torsional Ratio

TOOL JOINT

OD

ID

Tensile Strength

Torsional Strength

Max Recommended Make-up Torque

Recommended Make-up Torque

Min Recommended Make-up Torque

Balanced OD

Weak Connection

in

in

lbs

ft-lbs

ft-lbs

ft-lbs

ft-lbs

in

Premium Class OD Calculated for Balanced Connection

Datasheet for Reference Only

All new and premium properties are calculated based on nominal in accordance to API.

Torque performances calculated with coefficient of friction 0.08.

API recommends a torsional ratio of 0.8 or greater.

The use of the information is at reader's discretion and no warranty is implied or expressed by DP-Master with the use of information contained herein.

The information in this publication is subjected to change without notice, please contact DP-Master for the latest publication.

DP-MASTER MANUFACTURING

in

in

in Sq

in Cu

in Cu

lbs

ft-lbs

ft-lbs

psi

psi

PUBLIC RELEASE 13/5/2012

You might also like

- Xt39 Spec SheetDocument3 pagesXt39 Spec SheetjdcomptonNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Jis G3444Document12 pagesJis G3444yapsguanNo ratings yet

- HandBook Stuctural SteelDocument267 pagesHandBook Stuctural SteelOnn Lajer100% (9)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- 200 KG Sib (W.o.no-005)Document13 pages200 KG Sib (W.o.no-005)ManikandanNo ratings yet

- Pipe Chart InterpipeDocument2 pagesPipe Chart InterpipeintheesNo ratings yet

- Calc SheetsDocument12 pagesCalc SheetsMohamed AliouaNo ratings yet

- AEGNEP Compressed AirDocument42 pagesAEGNEP Compressed AirDavid HayesNo ratings yet

- Hamerlug Unions (Anson)Document15 pagesHamerlug Unions (Anson)Leonardo ViannaNo ratings yet

- BlackhawkDocument12 pagesBlackhawkandy131078No ratings yet

- Rectangular Ducts and FittingsDocument31 pagesRectangular Ducts and FittingsSreejith MpNo ratings yet

- Alarko Fcu İngDocument16 pagesAlarko Fcu İngcalavera83No ratings yet

- PIPE SpecificationDocument6 pagesPIPE SpecificationNamta GeorgeNo ratings yet

- BS3974 Pipe SupportsDocument20 pagesBS3974 Pipe SupportsTony100% (1)

- Walkway GratingDocument2 pagesWalkway Gratingbijukoottala100% (1)

- 40LM040-100 PDDocument16 pages40LM040-100 PDMohamad AsrulNo ratings yet

- Duct FittingsDocument31 pagesDuct FittingsSam Jose100% (8)

- Papeo Asme b30Document22 pagesPapeo Asme b30greelmindNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetAnonymous DDqgH1Y2MKNo ratings yet

- Section 4 - BS3974Document21 pagesSection 4 - BS3974vsubhramaniyun100% (1)

- Alloy Chain Sling Working Load LimitsDocument14 pagesAlloy Chain Sling Working Load LimitsjillianixNo ratings yet

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Document12 pagesInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ibmsherNo ratings yet

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNo ratings yet

- Jis G3464 PDFDocument14 pagesJis G3464 PDFhbookNo ratings yet

- Casing DesignDocument49 pagesCasing DesignAmar BenAmar100% (1)

- Copper Tube For HVACR ApplicationsDocument4 pagesCopper Tube For HVACR ApplicationskabeerdossNo ratings yet

- Zeta Tray Icms 3Document13 pagesZeta Tray Icms 3Sebin KvNo ratings yet

- Down The Hole Drill Strings, Secoroc - tcm892 2899264Document16 pagesDown The Hole Drill Strings, Secoroc - tcm892 2899264Dennis TedeschiNo ratings yet

- ASTM A53 Vs A500 EquivalenceDocument6 pagesASTM A53 Vs A500 Equivalenceemmanuilmoulos6339No ratings yet

- Inter PipeDocument7 pagesInter Pipehesham3bbasNo ratings yet

- Original PipedataDocument1 pageOriginal PipedataKirana SbNo ratings yet

- Heavy WeightDocument1 pageHeavy Weightمحمد سعيدNo ratings yet

- Heavy Weight - Data TableDocument1 pageHeavy Weight - Data TableMachx MasterNo ratings yet

- 2010walkway Expanded MetalDocument2 pages2010walkway Expanded MetalthorenNo ratings yet

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonNo ratings yet

- API Drill Pipe Specs-1Document26 pagesAPI Drill Pipe Specs-1SACHIN H. DHAMAPURKARNo ratings yet

- Fire Piping Astm A795Document3 pagesFire Piping Astm A795sinahimsNo ratings yet

- CanalizacionesDocument32 pagesCanalizacionesJulissa SalinasNo ratings yet

- Alcoa Aluminium Drill PipeDocument2 pagesAlcoa Aluminium Drill Pipeamir_hayfaNo ratings yet

- Pipe Schedule-Thickness Chart PDFDocument3 pagesPipe Schedule-Thickness Chart PDFSozhanSureshkumar86% (7)

- Casing DesignDocument48 pagesCasing Designdrillinganaco60% (5)

- Teddington Catalogue 2013Document76 pagesTeddington Catalogue 2013Joanna NewtonNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenFrom EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenRating: 5 out of 5 stars5/5 (1)

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- 1150ADocument28 pages1150AHamdi SaidNo ratings yet

- 4200Document44 pages4200Hamdi Said100% (1)

- Make-Up Torque Ft/Lbs Size WT/FT Wall GradeDocument7 pagesMake-Up Torque Ft/Lbs Size WT/FT Wall GradeYudha Satria0% (1)

- Full Circle Releasing Spears: Instruction Manual 2100Document16 pagesFull Circle Releasing Spears: Instruction Manual 2100Hamdi SaidNo ratings yet

- 08 AIM - Best Drilling Practices PlanFINAL 2-26-2014-cDocument8 pages08 AIM - Best Drilling Practices PlanFINAL 2-26-2014-cHamdi Said100% (1)

- A120 Series 70 150 Overshot ManualDocument48 pagesA120 Series 70 150 Overshot ManualHamdi SaidNo ratings yet

- T-Seals: Product DescriptionDocument5 pagesT-Seals: Product DescriptionHamdi SaidNo ratings yet

- 8.5 MM65DH 895978Document1 page8.5 MM65DH 895978Hamdi SaidNo ratings yet

- Long BHA Stif BHA Circ No ROT Rot (No) Mov (No) : Near BTMDocument1 pageLong BHA Stif BHA Circ No ROT Rot (No) Mov (No) : Near BTMHamdi SaidNo ratings yet

- Ballooning EffectDocument11 pagesBallooning EffectHamdi SaidNo ratings yet

- Maggie N 1X Bha-4Document1 pageMaggie N 1X Bha-4Hamdi SaidNo ratings yet