Quality Management System For Concrete Construction: ACI 121R-04

Quality Management System For Concrete Construction: ACI 121R-04

Uploaded by

askarahCopyright:

Available Formats

Quality Management System For Concrete Construction: ACI 121R-04

Quality Management System For Concrete Construction: ACI 121R-04

Uploaded by

askarahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Quality Management System For Concrete Construction: ACI 121R-04

Quality Management System For Concrete Construction: ACI 121R-04

Uploaded by

askarahCopyright:

Available Formats

ACI 121R-04

Quality Management System for

Concrete Construction

Reported by ACI Committee 121

Paul Zoltanetzky, Jr.

Chair

Jon B. Ardahl

Vice Chair

Paul Hedli

Secretary

Anthony R. Ameruso

Robert S. Jenkins

Gajanan M. Sabnis

Casimir Bognacki

H. P. Errol Lim

Johan C. Schor

Martin Brugger

Stephen Marchese

Roger D. Tate

Martin J. Fradua

Anand S. Mehta

Thomas G. Tyler

Alejandro Graf

Larry G. Mrazek

Woodward L. Vogt

Thomas M. Greene

Oon-Soo Ooi

Roger E. Wilson

C. Raymond

Hays*

*Led the task group that developed the 2003 revisions.

Note: Associate and Consulting Members who contributed to the development of this report: Morris V. Huffman, Godwin

Amekuedi, Paul D. Brooks, and Jack Holley.

This document provides guidance for the development and implementation

of quality systems for concrete construction projects. This document is

meant to be used by the architects/engineer and consultant communities

and specifically by owners, designers, and constructors of concrete construction

projects. A quality system involves the identification of quality objectives and

their incorporation into the quality plan, which is implemented by project

participants. A quality system allows user judgment with respect to

owners needs; defined quality objectives; project size, importance, and

complexity; and project organization skills.

This document follows the ANSI/ISO/ASQ Q9000 Series of Quality

Management Standards, which are similar to the auto industry QS 9000

Standards. The ANSI/ISO/ASQ Q9000 series is the American English

version of the ISO 9000 series. The ISO 9000 series is a standard for the

development of quality systems, published by the International Organization

ACI Committee Reports, Guides, Standard Practices, and

Commentaries are intended for guidance in planning,

designing, executing, and inspecting construction. This

document is intended for the use of individuals who are

competent to evaluate the significance and limitations of its

content and recommendations and who will accept

responsibility for the application of the material it contains.

The American Concrete Institute disclaims any and all

responsibility for the stated principles. The Institute shall not

be liable for any loss or damage arising therefrom.

Reference to this document shall not be made in contract

documents. If items found in this document are desired by the

Architect/Engineer to be a part of the contract documents, they

shall be restated in mandatory language for incorporation by

the Architect/Engineer.

It is the responsibility of the user of this document to

establish health and safety practices appropriate to the specific

circumstances involved with its use. ACI does not make any

representations with regard to health and safety issues and the

use of this document. The user must determine the

applicability of all regulatory limitations before applying the

document and must comply with all applicable laws and

regulations, including but not limited to, United States

Occupational Safety and Health Administration (OSHA)

health and safety standards.

for Standardization (ISO), established in Geneva, Switzerland. This agency

has representatives from more than 90 countries. The ISO 9000 series is

meant to be used by any organization anywhere in the world for the

development and implementation of quality systems for the manufacturing

and supply of products, the development and supply of services, or both.

Keywords: procedure; quality assurance; quality control.

CONTENTS

Chapter 1Introduction, p. 121R-2

1.1Scope and purpose

1.2Definitions

Chapter 2 Administrative aspects of a quality

system, p. 121R-3

2.1Responsibilities of the owner

2.2Characteristics of a quality system

2.3Initial project and preconstruction meetings

Chapter 3Quality plan, p. 121R-4

Chapter 4Quality manual, p. 121R-4

4.1Elements

4.2Responsibilities of the project team

4.3Quality policy

4.4Organization responsibilities

4.5Management representative

Chapter 5Quality manual elements, p. 121R-5

5.1Quality system procedures

ACI 121R-04 supersedes ACI 121R-98 and became effective September 19, 2004.

Copyright 2004, American Concrete Institute.

All rights reserved including rights of reproduction and use in any form or by any

means, including the making of copies by any photo process, or by electronic or

mechanical device, printed, written, or oral, or recording for sound or visual reproduction or for use in any knowledge or retrieval system or device, unless permission in

writing is obtained from the copyright proprietors.

121R-1

121R-2

ACI COMMITTEE REPORT

5.2Contract review

5.3Design control

5.4Document and data control

5.5Purchasing

5.6Control of owner-supplied product

5.7Product identification and traceability

5.8Process control

5.9Inspection and testing

5.10Control of measuring and test equipment

5.11Inspection and test status

5.12Control of nonconforming product

5.13Corrective and preventative action

5.14Handling and storage

5.15Control of quality records

5.16Audits

5.17Training

5.18Statistical techniques

Chapter 6References, p. 121R-7

6.1Referenced standards and reports

6.2Cited references

Appendix AQuality manual example, p. 121R-11

CHAPTER 1INTRODUCTION

1.1Scope and purpose

This document provides guidance for the development and

implementation of a quality system for concrete construction

projects. It is based on the ISO 9000-1994 Quality Systems

Standards requirements. With the exception of management

responsibility and servicing, all elements of ISO 9001 are

mentioned briefly. Where this document uses the word

should, the ISO standard uses shall, making these

requirements mandatory. This document does not establish

project work relationships. The project contract documents

define the owner/project team relationship and govern the

performance of these parties through the duration of the

project. This document is a management tool intended to

facilitate successful interaction among project team members.

This guide will accommodate projects that vary in size,

complexity, and number of organizations involved. On a

large project, all major organizations involved should

develop a quality plan with appropriate elements. On a small

project, a single overall quality plan and the contract documents can suffice.

Since the publication of ACI 121R-98, the ANSI/ISO/ASQ

Q9000-1994, which was the basis of the document, has been

revised. The latest revision is ANSI/ISO/ASQ Q9001-2000.

The 20 paragraphs have been restructured into five paragraphs.

The ANSI/ISO/ASQ Q9001-2000 standard now follows a

process approach. The process approach is a system methodology that recognizes that processes and their interactions are

the keys to establishing a quality management system.

The new standard (ANSI/ISO/ASQ ISO Q9001-2000)

consists of five interrelated elements that emphasize the

process approach. The new standard is driven by continual

improvement. They are: 4.0, Quality Management System; 5.0,

Management Responsibility; 6.0, Resource Management; 7.0,

Product Realization; and 8.0, Measurement, Analysis, and

Improvement. Exclusions are still permitted, for example, if you

do not do design, it can be excluded. More emphasis is placed

on the measurement, analysis, and improvement process.

The need to establish documented procedures has been

reduced to six specific references that are: 4.2.3, Control of

Documents; 4.2.4, Control of Records; 8.2.2, Internal Audit;

8.3, Control of Nonconforming Product; 8.5.2, Corrective

Action; and 8.5.3, Preventative Action. The organization can

rely on quality records to demonstrate that some action has

been completed.

A key terminology change from supplier to organization

when speaking of the firm seeking certification has been

implemented in ANSI/ISO/ASQ Q9001-2000. The term

suppliers is still used in ANSI/ISO/ASQ Q9001-2000. Its

meaning is now subcontractors to the organization. The

terminology used in ANSI/ISO/ASQ Q9001-2000 should

not be confused with the terminology used in ACI 121R-04.

The terminology used in ACI 121R-04 is different. Some

terms used in ANSI/ISO/ASQ Q9001-2000 have a meaning

different from that of terms used in ACI 121R-04. The terminology is defined in Section 1.2.

Whereas ANSI/ISO/ASQ Q9001-2000 has been reformatted,

the basic requirements of ANSI/ISO/ASQ Q9001-1994 are

now contained in Section 7.0 of the new standard.

The guidance contained in ACI 121R-04 provides the

owner with steps necessary to ensure development and

implementation of a successful quality system.

1.2Definitions

The definitions given in this section are taken from

American National Standards Institute/International

Organization for Standardization/American Society for

Quality (ANSI/ISO/ASQ) A8402.

contractora supplier in a contractual situation.

ownerthe organization that is responsible for the project

and the recipient of the product. The term encompasses the

agents of the owner, such as project/construction manager,

engineer, architect, quality consultant, and others, who have

been delegated some responsibility.

procedureA specified way of doing an activity.

Note:

In many cases, procedures are documented.

When a procedure is documented, the term written procedure or documented procedure is frequently used.

A written procedure usually contains the purpose and scope

of an activity; what shall be done and by whom; when,

where, and how it shall be done.

producta product is the result of activities or processes.

It may include service, hardware, processed materials,

software, or a combination thereof.

qualitythe totality of characteristics of an entity that

bear on its ability to satisfy stated and implied needs.

quality assurance (QA)actions taken by an organization

to provide and document assurance that what is being done

and what is being provided are in accordance with applicable

standards of good practice and follow the contract documents

for the work.

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

Table 2.1Elements of a quality system

Document

Contents

Owners policy statement

Quality objectives

Quality plan, Scope of work

Chapter 3 Organizational relationships

Authority/responsibilities of

various organizations

Quality

manual with

Elements,

Chapters

4 and 5

Elements applicable to that

organizations scope of work

Program

Implementing procedures

Organization responsible for

development of documents

Table 2.2Development of a quality system by

project phase and responsibilities

Project phase

Owner or designated

project manager

All organizations required

by the owner to develop a

quality manual

quality control (QC)actions taken by an organization

producing a product to provide control and documentation

over what is being done and what is being provided so that

the applicable standard of good practice and the contract

documents for the work are followed.

quality manuala document that states company policy

and describes the quality system of an organization.

quality planactivities that establish the objectives and

requirements for quality. It usually is project specific and

makes reference to the quality manual.

quality policyA statement of an organizations objectives

and commitment to quality.

quality systemthe organizational structure, responsibilities, procedures, processes, and resources needed to

ensure that an organizations quality objectives are met. As

used in this document, the quality system is spearheaded by

the owner and consists of the owners internal policies and

procedures for contracting, the (project) quality plan, and the

quality manuals implemented by the project team.

subcontractororganization that provides a product and

or service to a supplier.

supplierorganization that provides a product to the owner.

CHAPTER 2ADMINISTRATIVE ASPECTS

OF A QUALITY SYSTEM

2.1Responsibilities of the owner

The owner should be responsible for establishing the project

requirements before a project starts. Project requirements are

influenced by factors including available budget, function or

purpose, and desired service life. The owner should be

responsible for establishing a quality system, which includes

selecting competent organizations and individuals. If the owner

does not have the skills, personnel, or both, required to fulfill

these responsibilities, the owner should designate an organization or individual to perform these functions. Table 2.1

describes the elements of a quality system.

2.2Characteristics of a quality system

Table 2.2 indicates the various phases of a project and how

the quality system is developed. These phases represent the life

cycle of the project. The table also indicates responsibilities of

the organizations involved. It should be modified to fit the

specific organizational arrangements and quality objectives for

the project.

The quality system provides a framework for the information

flow between project organizations and interaction among

121R-3

Quality

system phase

Source of quality Responsible review

requirements or

organization and

reference guidance

action

Owner review and

Owner, project

approval is required

Owner*

Planning and

manager, consultant, if project quality

develops

definition of

engineer, and this plan was developed

requirements project quality

document

by another

plan

organization

Design

Designer

Owners project

develops

quality plan and this

quality manual

document

Owner, project

manager, or

Procurement both, develops

procurement

procedures

Owner, project

manager, designer,

contractor, and this

document

Owner or project

manager reviews

and approves

designer quality

manual

Owner, project

manager, designer,

and contractor

jointly review

procurement

procedures

Construction

Any combination or

Owner, project

contractors

owners project

manager, and

develop

and

Construction

quality plan, contract designer review

submit

documents, and this contractors quality

contractor

document

manual

quality manual

Material

testing

Testing

Owner, project

Any combination or

laboratory

manager, designer,

owners

project

develops and

or contractor

quality plan, contract

submits a

review material

documents,

and

this

material testing

testing laboratorys

document

quality manual

quality manual

*Indicates

owner or owners project manager who may be the architect, engineer,

construction manager, general contractor, or quality consultant.

individuals on the project team. Information flow and

management of information is essential for achieving effective

interaction among project personnel. The quality system

developed in accordance with Table 2.2 ensures that project

information flow is relevant, accurate, consistent, and

timely. The project benefits because:

Standards of performance are established;

Areas of responsibility are specified;

Decision points are identified;

Appropriate follow-up, actions, and decisions are

delineated; and

Criteria for project performance and assessment are

provided.

The arrangement of a quality plan into discrete project

phases is not to imply that project phases do not overlap.

Activities at a given phase may require that an activity be

initiated that relates to an earlier phase. Therefore, the boundaries between project phases are not always sharply defined.

Each construction activity is unique because of the

different conditions and requirements associated with each

project. Additionally, an individual activity should comply

with cost, safety procedures, and code and regulatory

requirements. Efficiency is improved when a construction

project is conducted with well-defined, well-documented,

and well-implemented plans and detailed procedures.

The recommendations in each phase, contained in the

last column of Table 2.2, provide an overview of the quality

principles and necessary elements to ensure that a coordinated quality plan is implemented for the project.

121R-4

ACI COMMITTEE REPORT

2.3Initial project and preconstruction meetings

A project team may consist of the owner, constructor,

designer, and subcontractors to the designer, constructor,

or both. On a project with a design/build project delivery

system, the team may consist of the owner and supplier.

The supplier in this case provides both the design of the

product and the product to the owner. To facilitate

communication among project organizations, the identification, responsibility, and authority for interaction and

exchange of information among the project teams should

be established. Good communication is the hallmark of a

quality project. All members of the project team should

frequently communicate their expectations and anticipated

problems. Open and frank discussions are essential. The

project team should plan to meet frequently.

Once the project team has been assembled, a project

meeting chaired by the owner is recommended. The meeting

should include the owner or the owners representative,

design professionals, contractors, principal subcontractors,

testing agencies, and representatives from regulatory agencies.

The meeting agenda should be distributed before the meeting

to allow the participants to prepare.

After the project meeting, the contractor should chair a

similar preconstruction meeting attended by subcontractors,

materials suppliers, vendors, and other suppliers that support

the contractor. The design professional may be invited to

attend, but generally only as an observer or a source of information for the contractor. The purpose of this meeting is to

communicate the project requirements to the contractors

subcontractors. The meeting procedure and agenda items are

similar to the initial project meeting, but particular emphasis is

placed on performance of the contractors team and commitment to the project. This is the phase where a review of such

items as plans, specifications, unique requirements, and

submittals is made and all parties commit to the same qualityassurance goals.

Both meetings should develop common goals and lines of

communication for the participants involved in the project.

Minutes of both meetings should be kept and distributed in a

timely manner to all attendees.

Critical interface and authority issues, such as who can

authorize the addition of water to concrete, should be decided.

Contingency authority delegation should be established in the

event that the person or group with primary authority is not

available.

CHAPTER 3QUALITY PLAN

The project quality plan should be developed early in the

project to document the owners quality objectives. The plan

should include at least the following elements:

Owners policy statement;

Quality objectives and expectations;

Scope of the plan;

Organizational relationships and interfaces;

Authority and responsibilities of organizations and

contractors; and

A description of the required quality manual for each

organization assigned the responsibility to develop one.

As a project goes through the phases outlined in Table 2.2, the

plan can change. The project team should review periodically

and, if necessary, update the plan during the life of the project.

Updated copies of the plan should be provided in a controlled

fashion to all affected organizations. The audit party that is

responsible for verifying compliance with the project quality

plan should verify the implementation of changes.

CHAPTER 4QUALITY MANUAL

4.1Elements

Each organization assigned responsibility in the quality plan

should detail, in a quality manual, the methods used to meet

the owners stated quality objectives. The quality manual

should include those elements described in Chapter 5 as

appropriate to their scope of work. A quality manual should

normally contain or refer to, as a minimum:

Quality policy;

The responsibilities, authorities, and interrelationships

of the personnel who manage, perform, verify, or

review work that affects quality;

The procedures, such as quality system procedures,

design procedures, and construction procedures; and

Statements about reviewing, updating, and controlling

the manual. (See Section 5.4 Document and data control).

A quality manual can vary in depth and format to suit the

needs of the organization.

4.2Responsibilities of the project team

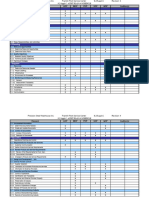

Table 4.1 shows a list of quality manual elements that

should be addressed by each project organization. A similar

table should be developed by the owner or the owners

designate in the project quality plan. Each organization

shown in the table should develop its own manual. Once developed, these manuals can typically serve more than one project.

4.3Quality policy

Management with executive responsibility of each of the

project team members should define a policy for quality,

including objectives for quality and its commitment to

quality. The quality policy should be relevant to the owners

goals and expectations. Project team member management

should ensure that this policy is understood at all levels of the

project team members organization.

4.4Organization responsibilities

The quality manual should define the organizational

structure, responsibility, and authority of personnel and

organizations that manage, perform, verify, or review work

affecting quality. This should include designation of the

person or organization responsible for the management and

direction of quality assurance.

4.5Management representative

The design professional, contractors management, or

both, with the highest level of responsibility for operations,

should appoint a member of their own organization who,

irrespective of other responsibilities, should have defined

authority for ensuring that a quality manual is established,

implemented, and maintained in accordance with the contract.

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

121R-5

Table 4.1Elements of a quality manual

Element

Supplier, architect,

engineer

Supplier, contractor

Subcontractor

Subcontractor, material

supplier

Inspection agency,

testing laboratory

Quality policy

Organization

responsibilities

Contract review,

Section 5.2

Design control,

Section 5.3

Document and data

control, Section 5.4

Purchasing, Section 5.5

Control of ownersupplied product,

Section 5.6

Product identification

and traceability,

Section 5.7

Process control,

Section 5.8

Inspection and testing,

Section 5.9

Control or measuring and

test equipment,

Section 5.10

Inspection and test status,

Section 5.11

Control on

nonconforming product,

Section 5.12

Corrective and preventive

action, Section 5.13

Handling and storage,

Section 5.14

Control of quality

records, Section 5.15

Internal quality audits,

Section 5.16

Training, Section 5.17

Statistical techniques,

Section 5.18

Note: An X indicates that the organization should have a section in their quality manual addressing the scope or responsibility (such as review, approve, comment, reject) for that element.

CHAPTER 5QUALITY MANUAL ELEMENTS

5.1Quality system procedures

The project team members should:

Prepare, document, and maintain procedures consistent

with the requirements of the contract and the owners

stated quality policy; and

Implement the quality system and its procedures.

5.2Contract review

The supplier and any subcontractor should have a documented

procedure for reviewing bids or accepting a contract. The

purpose of this procedure is to ensure that the scope of work is

clearly defined, and the supplier and any subcontractor has the

capability to meet the contract.

5.3Design control

The design professional should establish and maintain

procedures to control and verify the design of the product to

ensure that the specified requirements are met.

5.4Document and data control

The project team members should establish and maintain

procedures to control all documents and data that relate to

the requirements of the contract including, to the extent

applicable, documents of external origin such as standards

and owners drawings.

Document control is critical to ensure that the latest revisions

of drawings and specifications are used in the execution of

the work. All documents essential to the quality of the delivered

product should be controlled. Controlled documents should

at least include contracts, drawings, specifications, master

drawing list, critical procedures and work instructions,

quality manual, project quality plan, and critical data.

Controlling documents should include the registration of the

document recipients, ensuring that the document recipients

only have the latest version of a document and removing

superseded documents from the work area.

121R-6

ACI COMMITTEE REPORT

5.5Purchasing

The project team members should establish and maintain

procedures to ensure that purchased products conform to

specified requirements. This recommendation should only

apply to those responsible for purchasing permanent

building materials, equipment, or design services.

The selection of a supplier should include an evaluation of

the suppliers capability to process materials in accordance

with the requirements of contract documents and to deliver

the materials at a rate consistent with the project schedule.

The evaluation should review the suppliers history of

performance and appropriate documentation for objective

evaluation and determine the suppliers technical capability.

For concrete production facilities, certification by National

Ready-Mix Concrete Association (NRMCA) procedure is

recommended. For precast concrete production facilities,

certification by the Precast/Prestressed Concrete Institute

(PCI) is recommended.

5.6Control of owner-supplied product

The supplier should have documented procedures to

verify, store, and maintain owner-supplied product.

5.7Product identification and traceability

Where appropriate, the supplier should establish and

maintain procedures for identifying the product by suitable

means upon receipt and during all stages of production,

delivery, and installation.

Where and to the extent that traceability is a specified requirement, the subcontractor or supplier should establish and maintain procedures for unique identification of individual products

or batches. This identification should be recorded.

5.8Process control

The supplier should identify and plan the production and

installation processes that directly affect quality. Suppliers

should ensure that these processes are carried out under

controlled conditions. Controlled conditions should include

the following:

Procedures defining the manner of production and

installation where the absence of such procedures could

adversely affect quality;

Use of suitable production and installation equipment

and suitable working environment;

Compliance with reference standards/codes, quality

plans, or documented procedures, or all three;

Monitoring and control of suitable process parameters

and product characteristics;

Approval of processes and equipment, as appropriate;

Criteria for workmanship, which should be stipulated in

the clearest practical manner (that is, written standards,

representative samples, or illustrations);

Suitable maintenance of equipment to ensure continuing

process capability; and

Qualifications of personnel assigned to the project.

5.9Inspection and testing

The supplier should establish and maintain procedures for

inspection and testing activities to verify that the specified

requirements of the product are met. The required inspection

and testing, and the records to be established, should be

detailed in the quality plan or procedures. Testing should be

performed by an agency accredited according to the

requirements of ASTM C 1077 and E 329 or ISO/IEC

17025. Test technicians should have ACI certification

appropriate to the work performed.

Minimum requirements for inspection of all construction

operations should be defined, and inspection should follow

the guidance of ACI 311.4R and ACI SP-2. Inspectors

should have appropriate ACI certification. Minimum

requirements may include inspection of the formwork

system, installation of reinforcement within tolerance,

concrete quality as evidenced by required tests, verification

of operations and facilities of production, concrete placements,

and curing. Other considerations that could be included are

reshore and form removal requirements, repair work, core

drilling, sampling and testing, weather conditions, bonding

and jointing, leveling and alignment operations, finishing

operations, grouting operations, and protective coating

operations. Periodic photographs and video records documenting construction sequence, job progress, and construction

details are recommended.

5.10Control of measuring and test equipment

The supplier and subcontractor should establish and maintain procedures to control, calibrate, and maintain inspection, measuring, and test equipment (including test software)

used by the supplier to demonstrate conformance of a

product to the specified requirements. The accuracy of test

equipment and measuring should be established and should

be consistent with the measurement capability.

5.11Inspection and test status

The inspection and test status of the product should be

identified by suitable means. The status should indicate the

conformance or nonconformance of the product with regard

to inspection and tests performed. The identification of

inspection and test status should be maintained, as defined in

the quality plan, procedures, or both, throughout production

and installation of the product to ensure that only products

that have passed the required inspections and tests (or

released under an authorized concession) are dispatched,

used, or installed. ACI 311.4R, 311.5R, and ASTM E 329

contain detailed recommendations for the inspection of

concrete construction.

5.12Control of nonconforming product

The supplier should establish and maintain procedures to

ensure that products that do not conform to specified requirements are prevented from unintended use or installation. This

control should provide for identification, documentation,

evaluation, disposition of nonconforming products, and

notification, as required in the project quality plan.

Categories of dispositions are as follows:

Rework: the process of restoring an item to the original

requirement;

Repair: the process of restoring an item to an acceptable

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

condition even though the repaired item may not comply

with the original requirements;

Accepted as is: a nonconforming condition that, after

evaluation, is determined to satisfy requirements,

including those of performance, maintainability, fitness

for use, and safety or to satisfy requirements associated

with a purpose different from the original one; and

Reject: a disposition that indicates an item is unsuitable

for its intended purposes and cannot be economically

reworked or repaired. The item should be segregated or

removed and replaced.

Repaired or reworked items should be reinspected. Because

repaired items may not comply with the original requirements,

criteria for the acceptability of the repair should be furnished

to the individual or team performing the inspection. Reworked

items should be inspected in accordance with the original

requirements.

5.13Corrective and preventive action

Significant nonconformance of a recurring nature indicates a system problem that should be addressed in a corrective action request. Determining the root cause of such

conditions as well as the appropriate corrective actions

should preclude future similar nonconforming conditions.

The organization should establish and maintain procedures

for implementing corrective and preventive action. Any

corrective or preventive action taken to eliminate the causes

of actual or potential nonconformities should be, to a degree,

appropriate to the magnitude of problems and commensurate

with the risks encountered. Changes to the procedures

resulting from corrective and preventive action should be

implemented and recorded.

5.14Handling and storage

Procedures for handling and storage should be established

as required by the contract.

5.15Control of quality records

Procedures for identification, collection, indexing, access,

filing, storage, maintenance, and disposition of quality records

should be established. Quality records should be maintained to

demonstrate conformance to specified requirements and the

effective operation of the quality system. The following is a list

of some of the records and documents that may be applicable:

Contract documents;

Procedures;

Personnel qualification records;

Design drawings and calculations;

Specifications;

Procurement documents;

Material qualification records including reinforcement

and structural steel test reports;

Field sketches and working drawings;

Change orders;

Technical reports and photos;

Inspection and test records;

Nonconformance reports;

Concrete mixture proportions and delivery tickets;

121R-7

Placing drawings;

Record or as-built drawings;

Contractors log books; and

Minutes of meetings during construction.

Generally, the storage requirement should be a minimum

of 3 years after the project has received final acceptance. If

the owner, prevailing law, or insurance provisions require a

longer period, it should be specified.

5.16Audits

Quality audits should be scheduled as appropriate for the

status and importance of the activity to be audited and be

conducted by personnel independent of those having direct

responsibility for the activity being audited. The design

professional, contractor, and other project team members

may have a procedure for internal quality audits. Such a

procedure is a requirement of ISO 9001.

Companies certified by ANSI/ISO/ASQ 9001, QS9001,

NRMCA, PCI, and national accrediting authorities are subject

to external audits on an annual basis, if not more frequently.

The owner should establish and maintain procedures for

planning and implementing external quality audits to verify

whether quality activities and related results comply with

planned arrangements and to determine the effectiveness of

the quality system. The use of companies subject to independent external audits, such as ANSI/ISO, should reduce the

frequency and extent of external audits by the owner.

5.17Training

The supplier should establish and maintain procedures for

identifying training needs and provide for training of all

personnel performing activities affecting quality. Personnel

performing specific assigned tasks should be qualified on the

basis of appropriate education, training, experience, certification or all four, as required. Appropriate records of

training should be maintained.

The American Concrete Institute certification programs

should be used to establish qualifications for concrete

construction inspectors, concrete craftsmen, field technicians,

and laboratory technicians.

5.18Statistical techniques

The supplier should identify the need for statistical techniques to establish, control, and verify process capability and

product characteristics.

ACI 318 requires the use of statistics to establish mixture

proportions or conservative assumptions are required. ACI

214R provides the method of evaluation of strength testing.

The owner should ensure that the concrete supplier is

furnished copies of all concrete test reports.

CHAPTER 6REFERENCES

6.1Referenced standards and reports

The standards and reports listed below were the latest

editions at the time this document was prepared. Because

these documents are revised frequently, the reader is advised

to contact the proper sponsoring group if it is desired to refer

to the latest version.

121R-8

ACI COMMITTEE REPORT

American Concrete Institute

214R

Evaluation of Strength Test Results of

Concrete

311.1R

ACI Manual of Concrete Inspection (SP-2)

311.4R

Guide for Concrete Inspection

311.5R

Guide for Concrete Plant Inspection and

Testing of Ready-Mixed Concrete

318

Building Code Requirements for Structural

Concrete and Commentary

ASTM International

ASTM C 1077

Practice for Laboratories Testing Concrete

and Concrete Aggregates for use in

Construction and Evaluation Criteria for

Laboratory

ASTM E 329

Specification for Agencies Engaged in the

Testing and/or Inspection of Materials

Used in Construction

American National Standards Institute (ANSI), International

Organization for Standardization (ISO), American Society for

Quality (ASQ), International Electrotechnical Commission

(IEC)

ISO 8402

Quality Management and Quality

Assurance Vocabulary

ANSI/ISO/ASQ

Q9000-1 or ISO 9000-1 Quality Management and Quality

Assurance StandardsPart 1: Guidelines for Selection and Use (Guidelines for the selection of the Quality

Systems Model appropriate to the

Supplier and on how to use this model)

ANSI/ISO/ASQ

Q9001 or ISO 9001 Quality Systems Model for Quality

Assurance in Design/Development,

Production,

Installation,

and

Servicing (This Quality Systems

Model applies to suppliers, which

provide products and design services,

which may include the design of the

products they provide. This model is

most appropriate for design/builders

and designers)

ANSI/ISO/ASQ

Q9002 or ISO 9002 Quality Systems Model for Quality

Assurance in Production, Installation,

and Servicing (This Quality Systems

Model applies to suppliers, which

provide products. This model is most

appropriate for constructors who do

not provide design services)

ANSI/ISO/ASQ

Q9003 or ISO 9003 Quality Systems Model for Quality

Assurance in Final Inspection and

Test (This Quality Systems Model

applies to suppliers, which provide

only inspection and testing. This model

ISO 9004-1

ISO/IEC 17025

is most appropriate for owners and

testing laboratories)

Quality Management and Quality

Systems ElementsGuidelines

General Requirements for the Competence of Testing and Calibration

Laboratories

ACI Certification Programs

ACI Shotcrete Nozzleman (Dry-Mix Process)

ACI Shotcrete Nozzleman (Wet-Mix Process)

Concrete Construction Inspector

Concrete Field Testing Technician Grade I

Concrete Flatwork Finisher and Technician

Concrete Laboratory Technician Grades I & II

Concrete Strength Testing Technician

Concrete Transportation Construction Inspector

CSA-Based Concrete Field Testing Technician

Field Aggregate Testing Technician

Laboratory Aggregate Testing Technician

Tilt-Up Supervisor and Technician

The above references may be obtained from the following

organizations:

American Society for Quality (ASQ)

611 East Wisconsin Ave.

P.O. Box 3005

Milwaukee, WI 53201-3005

Phone: (414) 272-8575 or (800) 248-1946

Fax: (414) 272-1734

www.asq.org

International Organization for Standardization (ISO)

1, rue de Varemb

Case postale 56

CH-1211 Geneva 20

Switzerland

Phone: 41 22 749 01 11

Fax: 41 22 733 34 30

E-mail: central@iso.org

Web: http://www.iso.org

ASTM International

100 Barr Harbor Dr.

West Conshohocken, PA 19428-2959

Phone: (610) 832-9693

Fax: (610) 832-9555

www.astm.org

American Concrete Institute

P.O. Box 9094

Farmington Hills, MI 48333-9094

Phone: (248) 848-3700

Fax: (248) 848-3701

www.concrete.org

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

6.2Cited references

ACI Committee 121, 1998, Quality Management System

for Concrete Construction (ACI 121R-98), American

Concrete Institute, Farmington Hills, Mich., 9 pp.

ANSI/ISO/ASQ, 1994, Quality Systems Model for

Quality Assurance in Design, Development, Production,

Installation and Servicing (ANSI/ISO/ASQ Q9001-1994),

American National Standards Institute, Washington, D.C.,

121R-9

International Organization for Standardization, Geneva, Switzerland, and American Society for Quality, Milwaukee, Wisc.

ANSI/ISO/ASQ, 2000, Quality Systems Model for

Quality Assurance in Design, Development, Production, Installation and Servicing (ANSI/ISO/ASQ Q9001-2000), American National Standards Institute, Washington, D.C.,

International Organization for Standardization, Geneva, Switzerland, and American Society for Quality, Milwaukee, Wisc.

APPENDIX A QUALITY MANUAL EXAMPLE

XYZ CORP

QUALITY POLICY MANUAL

EXAMPLE LEVEL: 1

ISSUE DATE: XX/XX/XX

ACI COMMITTEE REPORT

121R-12

FOREWORD

This Quality Policy Manual is based on the requirements of ANSI/ISO/ASQC Q9001:

1994 (ISO 9001-1994) as issued by the International Organization for Standardization

(ISO) and published by The American Society for Quality (ASQ).

This Quality Policy Manual is a controlled document and consists of this foreword, the

company's quality policy and mission statement, supporting company policies regarding

the twenty elements of the ISO 9001standard, and a record of revisions.

XYZ Corp

123 Concrete Blvd.

New York, NY

99999

Attn: Quality Assurance Coordinator

X-XXX-XXX-XXXX

SECTION 1

MANAGEMENT RESPONSIBILITY

This section of the Quality Policy Manual establishes XYZ CORPs policy regarding its quality policy,

goals and objectives, and describes the organization and responsibilities of management with

respect to a company-wide Job Management Process (JMP) system.

QUALITY POLICY

In order to meet XYZ CORPs business objectives of providing the highest quality concrete

construction services, XYZ CORP has implemented the following quality objectives:

A Quality Assurance system based on ISO 9001 in use and will be further developed.

Standard measures of performance are being employed to monitor productivity, (Job Cost

Reports) and client satisfaction in order for XYZ CORP to be the preeminent concrete

construction company.

Customer feedback from a Client Satisfaction measurement system will be optimally utilized to

monitor their view of XYZ CORPs services and to define further improvement.

Optimum use will be made of co-worker training initiatives to improve XYZ CORP as an

organization.

XYZ CORP has published our mission statement, which includes the companys quality objectives

and strives to ensure that the importance of this statement is discussed during routine training

sessions and/or during new co-worker orientations. All permanent co-workers are required to be

aware of the mission statement and to understand how the mission statement affects both customer

and company operations.

XYZ MISSION STATEMENT

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

121R-13

The XYZ CORP mission is to be the preeminent concrete construction company through commitment

to the following:

Safety:

Maintaining the safest working conditions and work force in the industry.

People:

Employing the best people in the industry and creating cohesive, collaborative work teams by

perpetuating the no gap philosophy.

Quality:

Delivering unparalleled, high-quality workmanship and service.

Customer:

Building lifelong, professional customer relationships based on trust, integrity, and competency.

Continuous Improvement:

Producing more with less through marathon effort and constant vigilance of cost and productivity.

We will move forward with balance and make lasting contributions to our people, our communities

and the construction industry. Our quality motto is:

XYZ QUALITY MOTTO"

Objectives for quality improvement are measurable and include improving client satisfaction through

minimizing construction errors on each construction project. Customer satisfaction is monitored as

detailed in the Job Management Process (JMP) manual.

RESPONSIBILITY AND AUTHORITY

The responsibility, authority and interrelation of co-workers who manage, perform, and verify work

affecting quality is defined in individual sections of this Quality Policy Manual. The company ensures

that these individuals have the organizational freedom and responsibility to:

Initiate action to prevent the occurrence of nonconformities relating to the company's design and

construction services

Identify and record any issues relating to XYZ CORPs services

Initiate, recommend, or provide solutions through designated channels

Verify the implementation of corrective actions

Control further activities until the deficiency or unsatisfactory condition has been corrected

Listed on the following page are quality system activities and the individual assigned the

responsibility and authority for the activity. A designate has been established to ensure that these

activities are addressed and/or completed when the individual assigned is not available.

ACI COMMITTEE REPORT

121R-14

Clause

Activity

Primary

Responsibility & Authority

Designate

(In Absence Of Primary)

4.01

Management Review

President

Executive Management Team

4.02

Quality System Implementation

Management Representative

Executive Management Team

Quality Planning

Administration Managers

Operations Managers

Contract Review Estimating

Estimating Managers

Administration Managers

Contract Review Contracts

Contracts Manager

Contracts Administrator

4.04

Design Control

Estimating Managers

Administration Managers

4.05

Document & Data Control

Quality Assurance Coordinator

Contracts Manager

4.06

Purchasing

Operations Managers

Estimating Managers

Subcontractor Assessment

Operations Managers

Estimating Managers

4.07

Customer-Supplied Product

Project Managers

Operations Managers

4.08

Identification & Traceability

Project Managers

Operations Managers

4.09

Process Control

Project Managers

Operations Managers

4.10

Inspection & Testing

Project Managers

Operations Managers

4.11

Calibration

Project Managers

Operations Managers

4.12

Inspection & Test Status

Project Managers

Operations Managers

4.13

Control of Nonconforming Product

Project Managers

Operations Managers

4.14

Corrective Action

Project Managers

Operations Managers

Preventive Action

Operations Managers

Project Managers

Project Managers

Operations Managers

4.16

Handling, Storage, Packaging...

Delivery

Control of Quality Records

Project Managers

Operations Managers

4.17

Internal Quality Audits

Quality Assurance Coordinator

Executive Management Team

4.18

Training

Director of Craft Training

4.19

Servicing

Operations Managers

Director of Leadership &

Management Training

Project Managers

4.20

Statistical Techniques

Quality Assurance Coordinator

Executive Management Team

4.03

4.15

RESOURCES

The President, in conjunction with the Executive Management Team (EMT), identifies and allocates

adequate resources for project management to specific co-workers, based on experience, work

history, knowledge, and communication skills. Training needs for all co-workers, including

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

121R-15

management and supervisory positions, are addressed as detailed in the training section of this

policy manual.

MANAGEMENT REPRESENTATIVE

The Contracts Administrator has been assigned the responsibility of Management Representative

and represents the company on quality matters. The Management Representative has direct access

to the President and is responsible for ensuring that the requirements of ISO 9001 are established,

implemented, and maintained. This responsibility includes:

Assisting the President and EMT members in establishing quality policies, operating procedures

and work instructions.

Monitoring quality system activities to verify implementation.

Reporting on the performance of the quality system to the EMT as a basis for improvement.

Coordinating the development and review of quality system documentation.

Coordinating and managing the company's internal quality audit system.

MANAGEMENT REVIEW

Scheduled reviews of XYZ CORPs quality system are conducted to ensure its continued

effectiveness. At least once a quarter, these reviews are carried out by the Executive Management

Team (EMT) under the direction of the Management Representative. Management reviews include

an assessment of the suitability and effectiveness of the quality system along with a review of:

Compliance with ISO 9001 requirements and XYZ CORPs stated quality objectives.

Internal and external nonconforming issues.

Customer complaints.

Training initiatives.

Internal audit findings and associated corrective and preventive actions.

Management review meetings are recorded and any findings, recommendations, and corrective

actions are submitted to the responsible manager(s) for review and implementation.

The Executive Management Team reviews this manual at least annually to ensure adequacy and

conformance to XYZ CORPs policies and assesses the effectiveness and suitability of the quality

system in relation to the companys quality objectives.

ACI COMMITTEE REPORT

121R-16

ATTACHMENT

Functional Chart

Quality Assurance Manager

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

121R-17

SECTION 2

QUALITY SYSTEM & QUALITY PLANNING

This section of the Quality Policy Manual establishes XYZ CORPS policy regarding how it will

establish, document, and maintain a quality system that supports the requirements of ISO 9001 and

provides assurance that services meet company and customer-specific requirements.

QUALITY SYSTEM

XYZ CORP has implemented a three-tier quality system consisting of:

Quality Policy Manual

Job Management Process (JMP) Work Instructions

Records supporting the effective implementation of XYZ CORP's quality system

QUALITY POLICY MANUAL

The Quality Policy Manual defines quality policies and addresses the specific requirements of ISO

9001.

JMP WORK INSTRUCTIONS

Operations Managers, in conjunction with Administration Managers, are responsible to identify the

need for and implementation of JMP work instructions that define how quality-critical activities are

performed.

RECORDS AND DOCUMENTATION

Operations and Administration Managers are responsible to ensure that Job Management Process

(JMP) records and supporting documentation (checklists, forms, etc.) are completed in order to

monitor and improve processes. JMP documents (instructions, forms, checklist, etc.) are readily

available for review by our customers, regulatory agencies, and registration bodies.

QUALITY PLANNING

XYZ CORP anticipates the necessity for quality planning and, where deemed appropriate, conducts

quality planning activities as outlined in the Job Management Process (JMP) manual.

Quality planning activities may not require the creation of additional policies, procedures and/or

work instructions. Where appropriate, quality planning activities utilize existing XYZ CORP

quality system documentation.

As a part of XYZ CORP's quality planning activities, the Regional Vice Presidents, in conjunction

with Operations and Administration Managers, identify and acquire, where appropriate, any

additional controls, processes, equipment, resources, and/or skills that may be required to

achieve the level of quality needed.

XYZ CORP's quality planning activities ensure that co-workers and subcontractors achieve the

required and/or specified quality requirements. Quality planning activities include the updating,

as necessary, of inspection and test activities and the identification and acquisition of additional

resources to ensure that quality requirements can be achieved.

Project requirements are reviewed to determine XYZ CORP's ability to complete the designated

requirements. Where requirements may exceed existing capabilities, XYZ CORP will develop

and/or acquire the additional resources necessary to ensure that these requirements are

addressed.

121R-18

ACI COMMITTEE REPORT

Construction documents and specified project requirements are reviewed to ensure that

standards for acceptability are identified and documented. These standards for acceptability are

communicated to ensure that co-workers are aware of the requirements.

Records of quality planning activities are retained.

SECTION 3

CONTRACT REVIEW

This section of the Quality Policy Manual establishes XYZ CORPS policy regarding contract review

activities completed by XYZ CORP co-workers.

The Contracts Manager is responsible to coordinate and monitor the implementation of XYZ CORPs

customer order (contract review) process and to ensure that the established system for review of

customer orders meets both XYZ CORPs and customer requirements.

Upon receipt of a request for quote (RFQ), request for bid proposal or contract, the contract

documents are reviewed to ensure that the requirements are understood and that needed

information (scope of work, terms and conditions, specifications, etc.) is available. Contract

documents are reviewed prior to submitting a proposal and/or prior to accepting an individual

customer contract.

The principle contract documents for XYZ CORPs operations are the initial request for quote

(RFQ) or request for bid proposal package and the subsequent customer contract.

Contract review activities are conducted by co-workers as defined in XYZ CORPs Job

Management Process (JMP) manual.

Verbal requests for construction services are documented by XYZ CORP co-workers to ensure

that client requirements are adequately recorded and communicated.

The contract review process ensures that the contract documents clearly define, as appropriate:

Scope of Work

Customer's requirements, including standard terms and conditions and exclusions

Identification of any customer-supplied materials

Job-site requirements and/or specifications

Construction schedule

Regulatory requirements (OSHA, state, and local codes)

Insurance/bond requirements

The contract review process includes a review of XYZ CORPs ability to meet the stated design and

construction build requirements, including the availability of adequate subcontractor resources and

appropriately trained or skilled co-workers. Should any requirements of the contract be unclear or

ambiguous and require clarification, the customer is contacted for clarification.

Where required by contract, a project schedule is established prior to initiating any design and/or

construction build activities. The project schedule is agreed upon by both XYZ CORPs management

and the customer before beginning design and/or construction build activities.

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

121R-19

AMENDMENTS TO CONTRACTS

When amendments are required on accepted contracts, XYZ CORP co-workers will control further

construction activities and ensure that the proper co-worker(s) are made aware of the changes

pending and/or required.

Change Orders to accepted contracts are reviewed and approved by the appropriate Project

Manager.

CONTRACT REVIEW RECORDS

Records of contract review are indicated by either a verbal verification (as noted in the file) or by the

signatures and/or initials of designated XYZ CORP co-worker(s), and are maintained by the

Contracts Manager in designated project files. These records, where required by contract, are made

available for review by the customer.

SECTION 4

DESIGN CONTROL

This section of the Quality Policy Manual establishes XYZ CORPS policy regarding the activities

associated with design control activities.

DESIGN AND DEVELOPMENT PLANNING

Estimating Managers, in conjunction with Operations Managers, are responsible for coordinating design

control activities associated with the design and development of concrete forms used at construction

sites. Project Managers are responsible for ensuring that all design-related requirements, as required for

the specific forms applications, are addressed.

The responsibilities for form design projects are identified during the bid/proposal stage and included in

the completed project timeline schedule. Additional details regarding specific form requirements are

detailed in a Form Design Checklist. The project schedule, along with the Form Design Checklist, is

updated as the design evolves. Design control activities ensure that:

Only qualified personnel with adequate resources are assigned to design and design verification

activities.

Design and design verification activities are planned and recorded when completed.

ORGANIZATIONAL AND TECHNICAL INTERFACES

Organizational and technical interfaces between XYZ CORP and supporting organizations (departments

and/or subcontractors/vendors) that provide input to the design process are identified during the initial

design and development phase to ensure that responsibilities for both internal and external design

activities are established, documented, and reviewed.

DESIGN INPUT

Inputs for design include specifications and/or contract requirements from the customer, and previous

designs. Responsibilities for identifying and documenting design input requirements are defined during

the form design planning phase. This responsibility includes the resolution of unclear, ambiguous, or

conflicting requirements with those responsible for the specification.

DESIGN OUTPUT

The primary output of the form design process is form drawings and a form equipment list. These

outputs are reviewed to ensure that the outputs (completed forms) meet the specified input requirements.

121R-20

ACI COMMITTEE REPORT

Additional requirements include the review of details to ensure that completed documentation and

subsequent forms:

Contains or references acceptance criteria.

Conforms to appropriate regulatory requirements.

Identifies those characteristics of the design that relate to safety or performance.

The outputs of the design process are documented (e.g., drawings, lists, etc.) and are detailed in terms

that allow the outputs to be checked against the input requirements.

Form design drawings, lists, etc., are reviewed and approved by designated personnel before

release.

DESIGN REVIEW

Design reviews are planned and conducted at various stages of the design. These design reviews are

documented and records maintained. Attendees at each design review include key co-workers from

affected and/or concerned functions, as well as representatives from subcontractors/vendors, as

required.

DESIGN VERIFICATION

Design verification activities are performed and recorded. Design verification activities are completed at

the time of review and approval of the form design drawings. The Estimating Manager and/or the

designated Project Manager, is responsible for reviewing and approving the form design drawings.

DESIGN VALIDATION

Design validation occurs at the construction site, and includes the set-up and use of the completed forms.

Issues associated with the set-up and use of the forms are recorded in order to document and provide

assurance that the completed forms meet the specified requirements.

DESIGN CHANGES

Design changes are reviewed, authorized, and recorded by the Estimating Manager and/or the

designated Project Manager.

SECTION 5

DOCUMENT & DATA CONTROL

This section of the Quality Policy Manual establishes XYZ CORPS policy regarding document and

data control. Document and data control applies to project documents, i.e., data, drawings,

specifications, etc., and quality system documents (quality manual, procedures, work instructions,

forms, etc.), that are used to monitor and control the company's processes.

Customer-supplied documents, data, and specifications are included in the document control

system.

External documents used by XYZ CORP, including the ISO 9001 Standards, are included in the

company's document and data control system. These documents are included in the company's

master list of documents.

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

121R-21

DOCUMENT & DATA APPROVAL AND ISSUE

The Quality Assurance Coordinator, in conjunction with the Executive Management Team, is

responsible to coordinate XYZ CORPs document and data control activities for corporate

documents and data. Corporate control of documents and data is completed as specified in the Job

Management Process (JMP) manual.

The Management Representative is responsible to ensure that policies, procedures, work

instructions, forms, etc., are implemented and maintained.

Quality system documents are approved by authorized personnel prior to distribution.

The document control system ensures that only current issues of relevant quality system

documents are available. Obsolete documents are identified as "obsolete" and/or "void" and,

where deemed appropriate, removed from points of issue or use.

A master list, identifying individual quality system documents, along with the current revision level

and/or approval date, and supporting distribution list(s), are maintained.

DOCUMENT & DATA CHANGES

Document control procedures apply to revisions, amendments, or other changes to XYZ CORPs

quality system documentation. Records of document changes and/or modifications are maintained.

Changes and/or revisions to quality system documents are approved by the originating function

or authority responsible for the original document approval, as appropriate.

SECTION 6

PURCHASING & EVALUATION OF SUBCONTRACTORS

This section of the Quality Policy Manual establishes XYZ CORPS policy regarding purchasing and

operating practices.

EVALUATION OF SUBCONTRACTORS

Operations and Estimating Managers are responsible to:

Coordinate regional purchasing activities and to ensure that purchasing policies and procedures

are followed.

Coordinate the evaluation and approval of subcontractors used to supply materials and services

to construction locations.

Subcontractors are assessed and approved before being placed on the Approved Subcontractor List.

Subcontractor approval is based on industry reference, bid review information, past performance

and/or verification of an ISO 9001-registered quality system.

Records of subcontractor approvals are maintained. A current listing of Approved Subcontractors

for use by all regional offices is maintained at XYZ CORP corporate offices.

A current listing of Approved Subcontractors is maintained by the Estimating Manager(s).

ACI COMMITTEE REPORT

121R-22

Records of Approved Subcontractors who fail to deliver satisfactory performance are maintained,

reviewed, and addressed by the Operations Manager. The type and extent of control required for

specific subcontractor is dependent on the impact of the supplied product and/or service on the

quality of the services provided by XYZ CORP.

PURCHASING DATA

Purchasing documents are reviewed by the Project Manager prior to release to ensure that the

following, as appropriate, are complete and accurate:

Description of the material, equipment, labor and/or service being purchased is adequately

defined in the Scope of Work.

That the purchasing documents designate a specified dollar amount for the item(s) or service(s)

specified.

Project start and duration date(s)

Applicable specifications and/or requirements are identified

Customer and Site requirements, including completion date(s) are defined

Title, number, and issue of applicable quality standard(s) are specified

Changes to purchasing documents are processed in the same manner as the original and, where

applicable, the original purchasing document(s) are referenced.

VERIFICATION OF PURCHASED PRODUCT

Where XYZ CORP inspects items at the subcontractor's facilities, the requirements for release of the

product or service are specified in the purchasing documents.

Where specified by contract, the customer is afforded the right to inspect items at XYZ CORP's

subcontractors to verify that materials or services conform to specified requirements.

Inspection by the customer does not absolve XYZ CORP of providing acceptable product and/or

services nor does it eliminate possible rejection by the customer.

SECTION 7

CUSTOMER-SUPPLIED PRODUCT

This section of the Quality Policy Manual establishes XYZ CORPS policy regarding customersupplied product. Customer-supplied product includes drawings, specifications, materials,

equipment, and other items provided by the customer and used in the completion of a construction

project.

CUSTOMER-SUPPLIED PRODUCT

The assigned Project Manager is responsible to coordinate customer-supplied product and to ensure

that these items are not lost, damaged, or inappropriately used.

Job site Project Managers and Superintendents are responsible to identify and communicate the

receipt of customer-supplied product. Product supplied by the customer is received per XYZ CORPs

receiving inspection procedures.

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

121R-23

Customer-supplied product is identified and controlled to ensure that it is not lost and/or

damaged. Such product that is lost, damaged, or otherwise unsuitable for use is recorded and

reported to the customer.

Customer-supplied nonconforming or unacceptable product is identified and reported to the

customer. These materials are withheld from use until the disposition and/or disposal

requirements have been agreed to between the customer and XYZ CORP.

SECTION 8

IDENTIFICATION & TRACEABILITY

This section of the Quality Policy Manual establishes XYZ CORPS policy regarding construction

project identification and traceability requirements, and defines the authority and responsibilities for

these activities.

Project Managers are responsible for communicating policies regarding the identification of projectspecific materials, including drawings, specifications, material, and inspection results along with

labeling/tagging of materials and/or equipment as required.

All construction-related items are identified, as appropriate, by suitable means from receipt

through all phases of construction.

Where traceability is a specified requirement, the assigned Project Manager is responsible for

ensuring that traceability efforts are coordinated and completed.

Traceability requirements include drawings, inspections, concrete logs, re-steel logs, etc.

associated with specific construction projects and provide for a system of positive control

throughout the construction phases.

Where applicable, identification and traceability details are recorded on construction documents, i.e.,

inspection reports, logs, drawings, specifications, etc.

SECTION 9

PROCESS CONTROL

This section of the Quality Policy Manual establishes XYZ CORPs policy regarding the control of

processes used in construction projects. The requirements of this section apply to estimating,

design, and construction processes and/or any company or customer-specific special process having

a direct effect on the quality of XYZ CORPs construction services.

PROCESS CONTROL

Operation and Estimating Managers, in conjunction with the Project Managers, are responsible for

coordinating XYZ CORPs construction activities and for ensuring that the completion of these

activities is controlled and in compliance with the company's quality system requirements. Controlled

conditions include:

The availability of documented work instructions defining how processes are completed (where

the absence of these instructions would adversely affect quality).

The use of suitable equipment and a suitable working environment.

121R-24

ACI COMMITTEE REPORT

Compliance with reference codes, standards, documented procedures, and/or quality plans.

The monitoring and control of construction parameters.

The approval of processes and equipment, as appropriate.

A clear description of criteria for workmanship (concrete finish, concrete flatness, etc.).

Suitable maintenance of XYZ CORPs equipment.

Where the results of completed work cannot be verified by subsequent inspection and testing, the

work is completed by qualified co-workers.

SECTION 10

INSPECTION & TESTING

This section of the Quality Policy Manual establishes XYZ CORPs policy regarding inspection and

testing and defines the authority and responsibility for ensuring that the company's receiving, inprocess and final inspection activities are controlled. The requirements of this section apply to XYZ

CORP materials received at job sites and to in-process and final inspection job site activities.

RECEIVING INSPECTION AND TESTING

Project Managers are responsible for coordinating inspection and testing activities and for ensuring

that these activities comply with XYZ CORP and customer requirements.

XYZ CORP Purchased Materials:

Product and/or material arriving at job sites is not used until inspected or otherwise verified as

conforming to specified requirements. Inspection requirements include:

Review and verification of the shipping documents

Inspection for transit damage

Compliance with established identification and traceability requirements

Compliance with special handling, storage, or packaging requirements

Compliance with specified quality certification requirements

Subcontractor/Vendor-Purchased Materials:

Receiving inspection of subcontractor-purchased materials is the responsibility of the subcontractor.

XYZ CORP co-workers are available to provide site-specific requirements for handling, storage, etc.

Material released for urgent use is positively identified and documented for traceability to the job,

pour location, subcontractor, etc. against which the material was released.

IN-PROCESS INSPECTION & TESTING

In-process inspections of construction activities and subcontracted services used at XYZ CORP job

sites are performed to ensure that the results of these activities and services meet specified

requirements.

FINAL INSPECTION & TESTING

Final project inspection is performed, in conjunction with the appropriate external parties (General

Contractor, Construction Manager, etc.), according to what is specified in the contract documents to

verify that the final construction conforms to the specified requirements. Final inspection includes

verification that all required receiving and/or in-process inspections have been performed and the results

are acceptable.

QUALITY MANAGEMENT SYSTEM FOR CONCRETE CONSTRUCTION

121R-25

INSPECTION & TEST RECORDS

Records of all inspections performed by XYZ CORP or external parties are maintained. Nonconforming

products found during inspections and tests are handled according to the control of nonconforming

product procedure. Inspection and test records, where required by customer contract, are made available

for review by the customer. These records identify the inspection authority and/or individual responsible

for the final release of project.

SECTION 11

CONTROL OF INSPECTION, MEASURING & TEST EQUIPMENT

This section of the Quality Policy Manual establishes XYZ CORPS policy regarding the control of

inspection, measuring, and test equipment, and establishes the authority and responsibilities

associated with calibration activities.

INSPECTION, MEASURING, & TEST EQUIPMENT

Designated Project Managers are responsible to coordinate and administer XYZ CORPs calibration

program. Calibration activities ensure that inspection, measuring and test equipment is calibrated at