C43

Uploaded by

rudramansingh123Copyright:

Available Formats

C43

Uploaded by

rudramansingh123Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

C43

Uploaded by

rudramansingh123Copyright:

Available Formats

Quality

According to standards Number

C43

UNI 7847: 1979 -Si% Mn% P% max 0,030 + 0.005 S% max 0,030 + 0.005

Lucefin Group

Chemical composition

C% 0,40-0,46 0,15-0,40 0,50-0,80 0.02 0.03 0.04 By agreement this steel can be supplied with Cr, Mo, Ni, Cu the max Permissible deviations on the product

Temperature C

Hot forming 1100-850 Soft annealing 690 air (HB max 220) Normalizing 870 air Isothermal annealing 820 furnace cooling to 660 after, air (HB 155-205) Quenching 840 water Natural -(HB max 231) Quenching -End quench hardenability test -Tempering 550-650 air Preheating welding AC1 730 Stress relieving 180 Stress relieving after welding not recommended AC3 MS Mf 780 360 150

Mechanical properties

Hot rolled mechanical properties obtained from test blanks after normalizing UNI 7847: 1979 diameter Testing at room temperature (longitudinal) test blanks mm R Rp 0.2 A% C% Kcu over to N/mm2 N/mm2 min. min. min. J min. 16 100 570-720 300 18 --HB for information 169-223

Hot rolled Mechanical properties on test blank after quenching and tempering (valid for products with no heat treatment) For execution 5 (quenched and tempered materials), values must be guaranteed on the product UNI 7847:1979 Only reference. diameter Testing at room temperature (longitudinal) test blanks mm R Rp 0.2 A% C% Kcu HB over to N/mm2 N/mm2 min min. min. J min for information 16 690-840 470 15 -25 210-250 16 40 640-790 400 16 -20 198-237 40 100 570-720 360 17 -20 169-223 For size over 100 mm mechanical properties can be agreed upon before order placement Cold drawn diameter over to Testing at room temperature (longitudinal) R N/mm2 Rp 0.2 N/mm2 min

A% min

HB

No indications are shown in the reference standards please refer to the same values of quality C40E C45E Jominy test HRC distance in mm from quenched end 1.5 3 5 7 9 11 13 15 20 min No indications are shown in the reference standards max please refer to the same values of quality C 45E

EUROPE EN -ITALY UNI C43 CHINA -GERMANY DIN --

Min surface hardness after hardening and stress relieving 25 30 35 40 45 50 HRC

FRANCE AFNOR -U.K. B.S. -RUSSIA --

54

USA AISI/SAE --

You might also like

- Chemical Composition of ASME SA 36 Steel and IS 2062 Steel: %No ratings yetChemical Composition of ASME SA 36 Steel and IS 2062 Steel: %2 pages

- EN 10 204 - 3.1 Quality Inspection PO.011.2022 10396282-30 21547528 2023-07-21No ratings yetEN 10 204 - 3.1 Quality Inspection PO.011.2022 10396282-30 21547528 2023-07-211 page

- EN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 OnwardsNo ratings yetEN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 Onwards1 page

- Phoenix Steel Processing Co., LTD: Mill'S Test CertificateNo ratings yetPhoenix Steel Processing Co., LTD: Mill'S Test Certificate1 page

- Declaration of Performance: Construction Product: System 2+No ratings yetDeclaration of Performance: Construction Product: System 2+1 page

- Material Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical PropertiesNo ratings yetMaterial Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical Properties4 pages

- Ssab Emea Ab, Se-613 80 Oxelösund, Sweden: Carbon Equivalent Etc C93-C99No ratings yetSsab Emea Ab, Se-613 80 Oxelösund, Sweden: Carbon Equivalent Etc C93-C991 page

- Din 76 - 2024 - Undercuts para ParafusosNo ratings yetDin 76 - 2024 - Undercuts para Parafusos5 pages

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204-3.1No ratings yetRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204-3.11 page

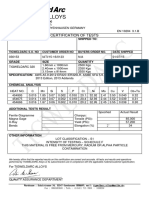

- Tigweldarc Alloys: Certification of TestsNo ratings yetTigweldarc Alloys: Certification of Tests1 page

- V Viraj Profiles Limited (Fastener Division) : CustomerNo ratings yetV Viraj Profiles Limited (Fastener Division) : Customer1 page

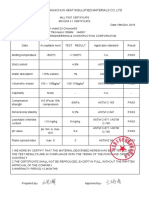

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATENo ratings yetHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATE1 page

- 0.25 IN SHEET 316 SS HN 118T CERT. 215721 North American Stainless Canada IncNo ratings yet0.25 IN SHEET 316 SS HN 118T CERT. 215721 North American Stainless Canada Inc1 page

- TATA STEEL LTD., Wire Division Technical Delivery Conditions (TDC)No ratings yetTATA STEEL LTD., Wire Division Technical Delivery Conditions (TDC)2 pages

- STAINLESS STEEL 431 / S43100/ 1.4057 SS 431: AvailabilityNo ratings yetSTAINLESS STEEL 431 / S43100/ 1.4057 SS 431: Availability3 pages

- Quality C43: Flame and Induction Hardening SteelNo ratings yetQuality C43: Flame and Induction Hardening Steel2 pages