DF172POH

DF172POH

Uploaded by

Brian SuhCopyright:

Available Formats

DF172POH

DF172POH

Uploaded by

Brian SuhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

DF172POH

DF172POH

Uploaded by

Brian SuhCopyright:

Available Formats

P O H

THIS MANUAL IS INTENDED FOR FLIGHT SIMULATION USE ONLY. NO RESPONSIBILITY FOR TYPOGRAPHIC OR OTHER ERRORS IS TAKEN.

CESSNA MODEL 172 P

FOREWORD

FOREWORD

I would like to extend my compliments and thanks to Alex Franzen, who expended a great deal of time and talent to produce this manual, based on the actual C-172P POH, for the DF2000 / FSD Cessna 172P. It is an outstanding effort! This manual is intended for use along with the detailed documentation originally provided with our C-172P panel, and also makes reference to certain features of our panel. It is people such as Alex who make this hobby the great one that it is, and we all hope you enjoy many happy hours flying the 172, with this manual as your guide. Happy Flying!

Louis J Betti

Executive Director - DreamFleet 2000

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

GENERAL INFORMATION TOC

SECTION 1

TABLE OF CONTENTS

Introduction Performance-Specifications Dimensions Descriptive Data -Engine -Propeller -Fuel -Oil -Maximum Certificated Weight -Standard Airplane Weight 1 1 2 3 3 3 3 3 4 4

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

GENERAL INFORMATION PAGE 1

INTRODUCTION

This handbook includes the material required to be furnished to the pilot by CAR Part 3. Section 1 provides basic data and information of general interest.

PERFORMANCE-SPECIFICATIONS

SPEED: Maximum at sea level Cruise, 75% power at 8000 ft CRUISE: Recommended lean mixture with fuel allowance for engine start, takeoff, climb and 45 minutes reserve 75% power at 8000 ft 40 gallons usable fuel 75% power at 8000 ft 50 gallons usable fuel 75% power at 8000 ft 62 gallons usable fuel Maximum Range at 10000 ft 40 gallons usable fuel Maximum Range at 10000 ft 50 gallons usable fuel Maximum Range at 10000 ft 62 gallons usable fuel RATE OF CLIMB AT SEA LEVEL SERVICE CEILING TAKEOFF PERFORMANCE Ground Roll Total Distance Over 50-ft Obstacle LANDING PERFORMANCE (KCAS) Ground Roll Total Distance Over 50-ft Obstacle STALL SPEESDS (KCAS) Flaps Up, Power Off Flaps Down, Power Off MAXIMUM WEIGHT Ramp Takeoff or Landing STANDARD EMPTY WEIGHT Skyhawk Skyhawk II MAXIMUM USEFUL LOAD Skyhawk Skyhawk II BAGGAGE ALLOWANCE WING LOADING: Pounds/Sq Ft POWER LOADING: Pounds/HP FUEL CAPACITY Standard Tanks Long Range Tanks Integral Tanks PROPELLER: Fixed Pitch, Diameter 123 Knots 120 Knots NOTE: The performance figures are based on the indicated weights, standard atmospheric conditions, level, hard-surface, dry runways and no wind. They are calculated values derived from flight tests conducted by the Cessna Aircraft Company under carefully documented conditions and will vary with individual airplanes and numerous factors affecting flight performance.

440 NM 3.8 HRS 585 NM 5.0 HRS 755 NM 6.4 HRS 520 NM 5.6 HRS 680 NM 7.4 HRS 875 NM 9.4 HRS 700 FPM 13000 FT 890 FT 1625 FT 540 FT 1280 FT 51 Knots 46 Knots 2407 LBS 2400 LBS 1414 LBS 1440 LBS 993 LBS 967 LBS 120 LBS 13.8 15.0 43 54 68 75 GAL GAL GAL IN

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

GENERAL INFORMATION PAGE 2

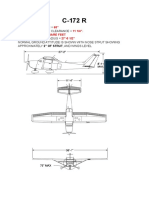

DIMENSIONS

5-4.15 26-11 NOTES: 1. Wing span shown with strobe lights installed. 2. Maximum height shown with nose gear depressed, all tires and nose strut properly inflated and flashing beacon installed 3. Proper ground clearance is 11 3/4 4. Wing area is 174 square feet 5. Minimum turning radius is 25-5 1/2

11-4

FLIGHT SIMULATION USE ONLY

36-0

75 max

8-4 1/2

8-9 1/2

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

GENERAL INFORMATION PAGE 3

DESCRIPTIVE DATA

ENGINE

- Number of engines: 1 - Engine Manufacturer: Avco Lycoming - Engine Model Number: O-320D2J - Engine Type: Normally aspirated, direct-drive, air-cooled, horizontally opposed, carburetor equipped, four-cylinder engine with 319.8 cu.in. displacement - Horsepower Rating and Engine Speed: 160 rated HP at 2700 RPM

PROPELLER

- Propeller Manufacturer: McCauley Accessory Division. - Propeller Model Number: 1C160/DTM7557 - Number of Blades: 2 - Propeller Diameter, Maximum: 75 inches, Minimum: 74 inches. - Propeller Type: Fixed Pitch

FUEL

Approved Fuel Grades: 100LL Grade Aviation Fuel (Blue) 100 (Formerly 100/130) Grade Aviation Fuel (Green) Fuel Capacity: Standard Tanks: Total Capacity: 43 gallons Total Capacity Each Tank: 21.5 gallons Tatoal Usable: 40 gallons. Long Range Tanks: Total Capacity: 54 gallons Total Capacity Each Tank: 27 gallons Tatoal Usable: 50 gallons. Integral Tanks: Total Capacity: 68 gallons Total Capacity Each Tank: 34 gallons Tatoal Usable: 62 gallons. NOTE: Isopropyl alcohol or ethylene glycol monomethyl ether may be added to the fuel supply. NOTE: To ensure maximum fuel capacity when refueling and minimize cross-feeding when parked on a sloping durface, place the fuel selector valve in either LEFT or RIGHT position.

FLIGHT SIMULATION USE ONLY

OIL

Oil Grade (Specififications): MIL-L-6082 Aviation Grade Straight Mineral Oil: Use to replenish supply during first 25 hours and at the forst 25-hour oil change. Continue to use until a total of 50 hours has accumulated or oil consumption has stabilized. MIL-L-22851 Ashless Dispersant Oil: This oil must be used after first 50 hours or oil consumption has stabilized.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

GENERAL INFORMATION PAGE 4

MAXIMUM CERTIFICATED WEIGHT

-Ramp Normal Category: 2407 lbs Utility Category: 2107 lbs -Takeoff Normal Category: 2400 lbs Utility Category: 2100 lbs -Landing Normal Category: 2400 lbs Utility Category: 2100 lbs NOTE: The maximum combined weight capacity for baggage areas 1 and 2 is 120 lbs

STANDARD AIRPLANE WEIGHT

-Standard empty weight: Skyhawk: 1414 lbs Skyhawk II: 1440 lbs -Maximum useful load: Skyhawk Normal Category: 993 lbs Utility Category: 693 lbs Skyhawk II Normal Category: 967 lbs Utility Category: 667 lbs

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

LIMITATIONS TOC

SECTION 2

TABLE OF CONTENTS

Airspeed Limitations Airspeed Indicator Markings Power Plant Limitations Power Plant Instrument Markings Weight Limits -Normal Category -Utility Category Center Of Gravity Limits -Normal Category -Utility category Maneuver Limits -Normal Category -Utility Category Flight Load Factor Limits -Normal Category -Utility Category Kinds of Operational Limits Fuel Limitations 1 1 2 2 3 3 3 3 3 4 4 4 5 5

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

LIMITATIONS PAGE 1

AIRSPEED LIMITATIONS

Airspeed Limitations and their operational significance are shown in figure 2-1. Maneuvering speed shown apply to normal category operations. The utility category maneuvering speed is 102 KIAS at 2100 pounds.

SPEED VNE Never Exceed Speed

KCAS KIAS 152 158

REMARKS Do not exceed this speed in any operation Do not exceed this speed except in smooth air, and then only with caution

VNO

Maximum Structural Cruising Speed

123

127

VA

Maneuvering 2400 2000 1600

Speed: Pounds Pounds Pounds

97 91 81

99 92 82

Do not make full or abrupt control movements above this speed

VFE

Maximum Flaps Extended Speed: 10 Flaps 10 - 30 Flaps Maximum Window Open Speed

108 84 152

110 85 158

Do not exceed this speed with flaps down Do not exceed this speed with windows open Figure 2-1. Airspeed Limitations

FLIGHT SIMULATION USE ONLY

AIRSPEED INDICATOR MARKINGS

Airspeed Indicator markings and their color code significance areshown in figure 2-2.

MARKING

KIAS VALUE OR RANGE 33 - 85

SIGNIFICANCE

White Arc

Green Arc

44 - 127

Yellow Arc Red Line

127 - 158 158

Full Flap Operating Range. Lower limit is maximum weight VS0 in landing configuration. Upper limit is maximum speed permissible with flaps extended. Normal Operating Range. Lower limit is maximum weight VS at most forward C.G. with flaps retracted. Upper limit is maximum structural cruising speed. Operating must be conducted with aution and only in smooth air. Maximum speed for all operations. Figure 2-2. Airspeed Indicator Makings

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

LIMITATIONS PAGE 2

PO WE R PL AN T L I M I TATI O N S

-Engine Manufacturer: Avco Lycoming. -Engine Model Number: O-320-D2J. -Maximum Power: 160 BHP rating. -Engine Operating Limits or Takeoff and continous Operations: Maximum Engine Speed: 2700 RPM. Maximum Oil Temperature: 245F (118C). -Oil Pressure Minimum: 25 psi. Maximum: 115 psi. -Fuel Grade: See Fuel Limitations. -Oil Grade (Specification): MIL-L-6082 Aviation Grade Streight Mineral Oil or MILL-22851 Ashless Dispersant Oil. -Propeller Manufacturer: McCauley Accessory Division. Propeller Model Number: 1C160/DTM7557. -Propeller Diameter, Maximum: 75 inches. Minimum: 74 inches. NOTE: The static RPM range at full throttle (carburetor heat off and mixrure leaned to maximize RPM) is 2300 tp 2420 RPM.

PO WE R PL AN T I N S TRUM E N T M ARKI N GS

Power plant instrument markings and their color code significance are shown in figure 2-3

RED LINE INSTRUMENT MINIMUM LIMIT

GREEN ARC NORMAL OPERATING

RED LINE MAXIMUM LIMIT

FLIGHT SIMULATION USE ONLY

Tachometer: Sea Level 5000 Feet 10000 Feet Oil Temperature Oil Pressure Fuel Quantity (Standard Tanks) Fuel Quantity (Long Range Tanks) Fuel Quantity (Integral Tanks) Suction

---

2100-2450 RPM 2100-2575 RPM 2100-2700 RPM 100-245F 60-90 psi ---

2700 RPM

--25 psi E (1.5 gal. Unusable Each Tank) E (2.0 gal. Unusable Each Tank R (3.0 gal. Unusable Each Tank) ---

245F 115 psi ---

---

---

---

---

4.5 - 5.5 in. Hg

---

Figure 2-3 Power Plant Instrument Markings

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

LIMITATIONS PAGE 3

WE I GHT L I M I TS

NORMAL CATEGORY

-Maximum Ramp Weight: 2407 lbs. -Maximum Takeoff Weight: 2400 lbs. -Maximum Landing Weight: 2400 lbs. -Maximum Weight in Baggage Compartment: Baggage Area 1 (or passenger on childs seat) - Station 82 tp 108: 120lbs. See following note. Baggage Area 2 - Station 108 to 142: 50 lbs. See following note.

UTILITY CATEGORY

-Maximum Ramp Weight: 2107 lbs. -Maximum Takeoff Weight: 2100 lbs. -Maximum Landing Weight: 2100 lbs. -Maximum Weight in Baggage Compartment: In the utility category, the baggage compartement and rear seat must not be occupied. NOTE: The maximum combined weight capacity for baggage areas 1 and 2 is 120 lbs.

CE N TE R O F GRAV I TY L I M I TS

NORMAL CATEGORY

-Center of Gravity Range: Forward: 35.0 inches aft of datum at 1950 lbs or less, with straight line variation to 39.5 inches aft of datum at 2400 lbs. Aft: 47.3 inches aft of datum at all weights. Reference datum: Lower portion of front face of firewall.

UTILITY CATEGORY

-Center of Gravity Range: Forward: 35.0 inches aft of datum at 1950 lbs or less, with straight line variation to 36.5 inches aft of datum at 2100 lbs. Aft: 40.5 inches aft of datum at all weights. Reference datum: Lower portion of front face of firewall.

FLIGHT SIMULATION USE ONLY

M AN E UV E R L I M I TS

NORMAL CATEGORY

This airplane is certificated in both the normal and utility category. The normal category is applicable to aircraft intended for non-aerobatic operations. These include any maneuvers incidental to normal flying, stalls (except whip stalls), lazy eights, chandelles, and turns in which the angle of bank is not more than 60. Aerobatic maneuvers, including spins, are not approved.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

LIMITATIONS PAGE 4

UTILITY CATEGORY

This airplane is not designed for purely aerobatic flight. However, in the aquisition of various certificates such a commercial pilot and flight instructor, certain maneuvers are required by the FAA. All of these maneuvers are

permitted in this airplane when operated in the utility category. In the utility category, the baggage compartment and rear seat must not be occupied. No aerobatic maneuvers are approved except those listed below:

MANEUVER Chandelles Lazy Eights Steep Turns Spins Stalls (except Whip Stalls)

RECOMMENDED ENTRY SPEED* 105 knots 105 knots 95 knots Slow Deceleration Slow Deceleration

*Abrupt use of the controls is prohibited above 99 knots

Aerobatics that may impose high loads should not be attempted. The important thing to bear in mind in flight maneuveres is that the airplane is clean in aerodynamic design and will buils up speed quickly with the nose down. Proper speed control is an essential requirement for execution of any maneuver, and care should always be exercised

to avoid excessive speed which in turn can impose excessive loads. In the execution of all maneuvers, avoid abrupt use of the controls. Intentional spins with flaps extended are prohibited.

FLIGHT SIMULATION USE ONLY

F L I GHT L O AD F ACTO R L I M I TS

NORMAL CATEGORY

Flight Load Factors (maximum Takeoff Weight - 2400 lbs): *Flaps Up +3.8g, -1.52g *Flaps Down +3.0g *The design load factors are 150% of the above, and in all cases, the structure meets or exceeds design loads.

UTILITY CATEGORY

Flight Load Factors (maximum Takeoff Weight - 2100 lbs): *Flaps Up +4.4g, -1.76g *Flaps Down +3.0g *The design load factors are 150% of the above, and in all cases, the structure meets or exceeds design loads.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

LIMITATIONS PAGE 5

KI N DS O F O PE RATI O N AL L I M I TS

The airplane is equipped for day VFR and may be equipped for night VFR and/or IFR operations. FAR Part 91 establishes the minimum required instrumentation and equipment for these operations. The reference to types of flight operations on the operating limitations placard reflects equipment installed at the time of Airworthiness Certificate issuance. Flights into known icing conditions is prohibited.

F UE L L I M I TATI O N S

Fuel Capacity: Standard Tanks: Total Capacity: 43 gallons Total Capacity Each Tank: 21.5 gallons Tatal Usable: 40 gallons Long Range Tanks: Total Capacity: 54 gallons Total Capacity Each Tank: 27 gallons Tatal Usable: 50 gallons Integral Tanks: Total Capacity: 68 gallons Total Capacity Each Tank: 34 gallons Tatal Usable: 62 gallons NOTE: To ensure maximum fuel capacity when refueling and minimize cross-feeding when parked on a sloping surface, place the fuel selector valve either LEFT or RIGHT position.

Takeoff and land with the fuel selector valve handle in the BOTH position Maximum slip or skid duration with one tank dry: 30 seconds. With 1/4 tank or less, prolonged

imcoordinated flight is prohibited when operating on either left or right tank in level flight. Fuel remaining in the tank after the fuel quantity indicator reads empty (red line) cannot be safely used in flight.

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

EMERGENCY PROCEDURES TOC

SECTION 3

TABLE OF CONTENTS

Introduction Airspeeds for Emergency Procedures Engine Failures -Engine Failure during Takeoff Run -Engine Failure immediately after T/O -Engine Failure during Flight Forced Landings -Emergency Landing without Engine Power -Precautionary Landing with Engine Power -Ditching Fires -During Start on Ground -Engine Fire in Flight -Electrical Fire in Flight -Cabin Fire -Wing Fire Landing with a Flat Main Tire Electrical Power Supply System Malfunctions -Ecxessive rate of Discharge -Low-Voltage Light illuminates Icing -Inadverted Icing Encounter -Static Source Blockage 1 1 1 1 2 2 2 3 3 4 4 4 4 5 5 5 6 6

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

EMERGENCY PROCEDURES PAGE 1

I N TRO DUCTI O N

This Section provides checklists and amplified procedures for coping with emergencies that might occur. Emergencies caused by airplane or engine malfunctions are extremely rare if proper preflight inspections and maintainance are practiced. Enroute weather emergencies can be minimized or eliminated by careful flight planning and good judgement when unexpected weather is encountered. However, should an emergency arise, the basic guidelines described in this section should be considered and applied as necessary to correct the problem.

AI RS PE E DS F O R E M E RGE N CY O PE RATI O N

Engine Failure After Takeoff: Wing Flaps Up Wing Flaps Down Maneuvering Speed: 2400 Lbs 2000 Lbs 1600 Lbs Maximum Glide Precautionary Landing With Engine Power Landing Without Engine Power: Wing Flaps Up Wing Flaps Down 65 KIAS 60 KIAS 99 92 82 65 60 KIAS KIAS KIAS KIAS KIAS

65 KIAS 60 KIAS

E N GI N E F AI L URE S

FLIGHT SIMULATION USE ONLY

ENGINE FAILURE DURING TAKEOFF RUN

[1] [2] [3] [4] [5] [6] Th rot t l e B ra k e s Wi n g F l a ps Mi x t ure I gn i t i on S w i t c h Ma s t e r S w i t c h ------------I DLE AP P LY R E TR ACT I DLE CUT- O F F OFF OFF

ENGINE FAILURE IMMEDIATELY AFTER TAKEOFF

[1] [2] [3] [4] [5] [6] Ai rs pe e d Mi x t ure F ue l S e l e c t or Va l v e I gn i t i on S w i t c h Wi n g F l a ps Ma s t e r S w i t c h ------------6 5 K I AS ( fl a ps up) 6 0 K I AS ( fl a ps d ow n ) I DLE CUT- O F F OFF OF AS R E Q UI R E D OFF

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

EMERGENCY PROCEDURES PAGE 2

ENGINE FAILURE DURING FLIGHT

[1] [2] [3] [4] [5] [6] Airspeed Carburetor Heat Fuel Selevtor Valve Mixture Ignition Switch Primer ------------65 KIAS ON BOTH RICH BOTH IN and LOCKED

F O RCE D L AN DI N GS

EMERGENCY LANDING WITHOUT ENGINE POWER

[1] [2] [3] [4] [5] [6] [7] [8] [9] Airspeed Mixture Fuel Selector Valve Igition Switch Wing Flaps Master Switch Doors Touchdown Brakes --- 65 KIAS (flaps up) 60 KIAS (flaps down) --- IDLE CUT-OFF --- OFF --- OFF --- AS REQUIRED (30 recommended) --- OFF --- UNLATCH PRIOR TO TOUCHDOWN --- SLIGHTLY TAIL LOW --- APPLY HEAVILY

FLIGHT SIMULATION USE ONLY

PRECAUTIONARY LANDING WITH ENGINE POWER

[1] [2] [3] Wing Flaps Airspeed Selected Field --- 20 --- 60 KIAS --- FLY OVER, noting terrain and obstruction then retract flaps upon reaching a safe altitude and airspeed ----------OFF 30 (on final approach) 60 KIAS OFF UNLATCH PRIOR TO TOUCHDOWN --- SLIGHTLY TAIL LOW --- OFF --- APPLY HEAVILY

[4] [5] [6] [7] [8] [9] [10] [11]

Avionics Power Switch and Electrical Switches Wing Flaps Airspeed Master Switch Doors Touchdown Ignition Switch Brakes

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

EMERGENCY PROCEDURES PAGE 3

DITCHING

[1] Radio --- TRANSMIT MAYDAY on 121.5 MHz, giving location and intentions and SQUAWK 7700 --- SECURE OR JETTISON ------------------INTO THE WIND PARALLEL TO SWELLS 20 - 30 ESTABLISH 300 FT/MIN DESCENT AT 55 KIAS UNLATCH LEVEL ATTITUDE AT EST. RATE OF DESCENT CUSHION at touchdown with folded coat EVACUATE through cabin doors. INFLATE REMEMBER: Mayday 121.5 MHz Squawk 7700

[2] [3]

[4] [5] [6] [7] [8] [9] [10]

Heavy Objects) Approach High Winds, Heavy Seas Lgt. Winds, Heavy Swells Wing Flaps Power Cabin Doors Touchdown Face Airplane Life Vests and Raft

If necessary, open window and flood the cabin to equalize pressure so doors can be opened.

F I RE S

DURING START ON GROUND

FLIGHT SIMULATION USE ONLY

[1]

Cranking

--- CONTINUE to get a start...

A. If engine starts [2] Power [3] Engine

--- 1700 RPM for a few minutes --- SHUTDOWN and inspect for damage

...which would suck the flames and accumulated fuel through the carburetor and into the engine

B. If engine fails to start [4] Throttle [5] Mixture [6] Cranking [7] Fire Extinguisher

[8]

Engine

[9]

Fire

[10]

Fire Damage

FULL OPEN IDLE CUT-OFF CONTINUE OBTAIN (have ground attendants obtain if not installed) --- SECURE a. Master Switch --- OFF b. Ignition Switch --- OFF c. Fuel Selector Valve --- OFF --- EXTINGUISH using fire extinguisher, wool blanket or dirt --- INSPECT

---------

repair damage or replace damaged components or wiring before conducting another flight

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

EMERGENCY PROCEDURES PAGE 4

ENGINE FIRE IN FLIGHT

[1] [2] [3] [4] [5] [6] Mixture Fuel Selector Valve Master Switch Cabin Heat and Air Airspeed Forced Landing ------------IDLE CUT-OFF OFF OFF OFF (except overhead vents) 100 KIAS EXECUTE

If fire is not extinguished, increase glide speed to find an airspeed which will provide an incombustible mixture

ELECTRICAL FIRE IN FLIGHT

[1] [2] [3] [4] [5] Master Switch Avionics Power Switch All other switches (except ignition switch) Vents/Cabin Air/Heat Fire Extinguisher --- OFF --- OFF --- OFF --- CLOSED --- ACTIVATE (if available)

If fire appears out and electrical power is necessary for continuance of flight: [6] [7] [8] [9] [10] Master Switch Circuit Breakers --- ON --- CHECK for faulty circuit Do not reset Radio Switches --- OFF Avionics Power Switch --- ON Radio/Electrical Switches --- ON one at a time, with delay after each until short circuit is localized Vents/Cabin Air/Heat --- OPEN when it is ascertained that fire completely extinguished

WARNING: After discharging an extinguisher within closed cabin, ventilate the cabin!

FLIGHT SIMULATION USE ONLY

[11]

CABIN FIRE

[1] [2] [3] [4] Master Switch --Vents/Cabin Air/Heat --Fire Extinguisher --Land the airplane as soon as inspect for damage OFF CLOSED (to avoid drafts) ACTIVATE (if available) possible to WARNING: After discharging an extinguisher within closed cabin, ventilate the cabin!

WING FIRE

[1] [2] [3] Navigation Light Switch --- OFF Pitot Heat Switch (if installed) --- OFF Strobe Light Switch (if installed) --- OFF

NOTE: Perform a sideslip to keep the flames away from the fuel tank and cabin, and land as soon as possible using wing flaps only as required for final approach.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

EMERGENCY PROCEDURES PAGE 5

L AN DI N G WI TH A F L AT M AI N TI RE

LANDING WITH A FLAT MAIN TIRE

[1] [2] Approach Touchdown --- NORMAL --- GOOD TIRE FIRST NOTE: Try to hold airplane off flat tire as long as possible.

E L E CTRI CAL PO WE R S UPPL Y S YS TE M M AL F UN CTI O N S

AMMETER SHOWS EXCESSIVE RATE OF DISCHARGE

[1] [2] [3] [4] Alternator Alternator Circuit Breaker Nonessential Electrical Equipment Flight --- OFF --- PULL --- OFF --- TERMINATE as soon as practical

FLIGHT SIMULATION USE ONLY

LOW-VOLTAGE LIGHT ILLUMINATES DURING FLIGHT (Ammeter Indicates Discharge)

[1] [2] [3] [4] [5] [6] Avionics Power Switch Alternator Circuit Breaker Master Switch Master Switch Low-Voltage Light Avionics Power Switch --- OFF ----------CHECK IN OFF ON CHECK OFF ON

If low-voltage Light illuminates again: [7] Alternator --- OFF [8] Nonessential Radio and Electrical Equipment --- OFF [9] Flight --- TERMINATE as soon as practical

NOTE: Illumination of the lowvoltage light may occur during low RPM conditions with an electrical load on the system such as during low RPM taxi. Under these conditions, the light will go out at higher RPM. The master switch need not be recycled since an overvoltage condition has not occured to de-activate the alternator system.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

EMERGENCY PROCEDURES PAGE 6

ICIN G

INADVERTED ICING ENCOUNTER

[1] [2] [3] Turn pitot heat switch ON (if installed) Turn back or change altitude to obtain an outside air temperature that is less conductive to icing. Pull cabin heat control full out and open defroster outlets to obtain maximum windshield defroster airflow. Adjust cabin air control to get maximum defroster heat and airflow. Open the throttle to increase engine speed and minimize ice build up on propeller blades. Watch for signs of carburetor air filter ice and apply carburetor heat as required. An unexplained loss in engine speed could be caused by carburetor ice or air intake filter ice. Lean the mixture for maximum RPM, if carburetor heat is used continously. Plan a landing at the nearest airport. With an extremely rapid ice build-up, select a suitable off airport landing site. With an ice accumulation of 1/4 inch or more on the wing leading edges, be prepared for significantly higher stall speed. Leave wing flaps retracted. With a severe ice build-up on the horizontal tail, the change in wing wake airflow direction caused by wing flap extension could result in a loss of elevator effectiveness. Open left window and, if practical, scrape ice from a portion of the windshield for visibility in the landing approach. Perform a landing approach using a forward slip, if necessary, for improved visibility. Approach at 65 to 75 KIAS depending upon the amount of the accumulation. Perform a landing in level attitude.

[4] [5]

[6] [7] [8]

[9] [10] [11] [12]

FLIGHT SIMULATION USE ONLY

STATIC SOURCE BLOCKAGE (Erroneous Instrument Reading Suspected)

[1] [2] Alternate Static Source Valve Airspeed

--- PULL ON --- Consult appropriate calibration tables in Section 5

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

NORMAL PROCEDURES TOC

SECTION 4

TABLE OF CONTENTS

Introduction Speeds fo r No rma l O pera t i o n Befo re St a rt i ng Eng i ne St a rt i ng Eng i ne Befo re Ta keo ff Ta keo ff -No rma l Ta keo ff -Sho rt F i eld Ta keo ff Enro ut e Cli mb Crui se D esc ent s Befo re L a ndi ng L a ndi ng -No rma l L a ndi ng -Sho rt F i eld L a ndi ng -Ba lked L a ndi ng A ft er L a ndi ng Sec uri ng A i rpla ne 1 1 1 2 2 3 3 3 3 4 4 4 5 5 5 5

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

NORMAL PROCEDURES PAGE 1

I N TRO DUCTI O N

Section 4 provides checklists and amplified procedures for the conduct operation. of normal

S PE E DS F O R N O RM AL O PE RATI O N

Unless otherwise noted, the following speeds are based on a maximum weight of 2400 pounds and may be used for lesser weight. However, to achieve the performance specified in Section 5 for takeoff distance, the speed appropriate to the particular weight must be used.

FLIGHT SIMULATION USE ONLY

Takeoff, Flaps Up: Normal Climb Out Short Field Takeoff, Flaps 10, Speed at 50 Feet Enroute Climb, Flaps Up: Normal, Sea Level Normal, 10000 Feet Best Rate of Climb, Sea Level Best Rate of Climb, 10000 Feet Best Angle Of Climb, Sea Level Best Angle Of Climb, 10000 Feet Landing Approach: Normal Approach, Flaps Up Normal Approach, Flaps 30 Short Fiel Approach, Flaps 30 Balked Landing: Maximum Power, Flaps 20 Maximum Recommended Turbulent Air Penetration Speed: 2400 lbs 2000 lbs 1600 lbs Maximum Demonstrated Crosswind Velocity: Takeoff or Landing

70 - 80 KIAS 56 KIAS 75 - 85 70 - 80 76 71 60 65 KIAS KIAS KIAS KIAS KIAS KIAS

65 - 75 KIAS 60 - 70 KIAS 61 KIAS 55 KIAS

99 KIAS 92 KIAS 82 KIAS 15 KNOTS

BE F O RE S TARTI N G E N GI N E

BEFORE STARTING ENGINE

[1] [2] [3] [4] Preflight Inspection Seats, Seat Belts, Shoulder Harnesses Fuel Selector Valve Avionics Power Switch, Autopilot, Electrical Equipment Brake Circuit Breakers --- COMPLETE --- ADJUST and LOCK. --- BOTH CAUTION: The Avionics Power Switch must be OFF during engine start to prevent possible damage to avionics.

[5] [6]

--- OFF --- TEST and SET --- CHECK IN

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

NORMAL PROCEDURES PAGE 2

S TARTI N G E N GI N E

STARTING ENGINE

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] Mixture Carburetor Heat Master Switch Prime Throttle Propeller Area Ignition Switch Oil Pressure Flashing Beacon and Navigation Lights Avionics Power Switch Radios ----------------RICH COLD ON AS REQUIRED OPEN 1/8 INCH CLEAR START CHECK

Prime 2 to 6 strokes; none if engine is warm

--- ON as required --- ON --- ON

BE F O RE TAKE O F F

BEFORE TAKEOFF

[1] [2] [3] [4] [5] [6] [7] [8] Parking Brake --- SET Cabin Doors and Windows --- CLOSED and LOCKED Flight Controls --- FREE and CORRECT Flight Instruments --- SET Fuel Selector Valve --- BOTH Mixture --- RICH (below 3000 feet) Elevator Trim and Rudder Trim --- TAKEOFF Throttle --- 1700 RPM a. Magnetos --- CHECK b. Carburetor Heat --- CHECK (for RPM drop) c. Engine Instruments and Ammeter --- CHECK d. Suction Gauge --- CHECK Throttle --- 1000 RPM or LESS Radios --- SET Autopilot (if installed) --- OFF Air Conditioner (if installed) --- OFF Strobe Lights --- AS DESIRED Brakes --- RELEASE

FLIGHT SIMULATION USE ONLY

RPM drop should not exceed 125 RPM on either magneto or 50 RPM difference between magnetos

[9] [10] [11] [12] [13] [14]

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

NORMAL PROCEDURES PAGE 3

TAKE O F F

NORMAL TAKEOFF

[1] [2] [3] [4] [5] Wing Flaps Carburetor Heat Throttle Elevator Control Climb Speed --------0 - 10 COLD FULL OPEN LIFT NOSE WHEEL (at 55 KIAS) --- 70 - 80 KIAS

SHORT FIELD TAKEOFF

[1] [2] [3] [4] [5] [6] [7] [8] Wing Flaps Carburetor Heat Brakes Throttle Mixture Brakes Elevator Control Climb Speed ----------10 COLD APPLY FULL OPEN RICH (above 3000 feet LEAN for max RPM) --- RELEASE --- SLIGHTLY TAIL DOWN --- 56 KIAS (until obstacles are cleared)

E N RO UTE CL I M B

FLIGHT SIMULATION USE ONLY

ENROUTE CLIMB

[1] [2] [3] Airspeed Throttle Mixture --- 70 - 80 KIAS --- FULL OPEN --- RICH (above 3000 feet LEAN to obtain max RPM)

If a maximum performance climb is necessary, use speeds shown in the Rate of Climb chart in Section 5.

CRUI S E

CRUISE

[1] [2] [3] Power Elevator and Rudder Trim (if installed) Mixture --- 2100 - 2700 RPM --- ADJUST --- LEAN (no more than 75% recommended)

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

NORMAL PROCEDURES PAGE 4

DE S CE N T

DESCENT

[1] [2] [3] [4] Fuel Selector Valve Mixture Power Carburetor Heat --- BOTH --- ADJUST for smooth operation --- AS DESIRED --- FULL HEAT AS REQUIRED

BE F O RE L AN DI N G

BEFORE LANDING

[1] [2] [3] [4] [5] [6] Seats, Seat Belts, Shoulder Harnesses Fuel Selector Valve Mixture Carburetor Heat Autopilot Air Conditioner (if installed)

-----------

SECURE BOTH RICH ON OF

--- OFF

FLIGHT SIMULATION USE ONLY

L AN DI N G

NORMAL LANDING

[1] [2] Airspeed Wing Flaps --- 65 - 75 KIAS (flaps up) --- AS DESIRED (0 - 10 below 110 KIAS, 10 - 30 below 85 KIAS) --- 60 - 70 KIAS (flaps DOWN) --- MAIN WHEELS FIRST --- LOWER NOSE WHEEL GENTLY --- MINIMUM REQUIRED

[3] [4] [5] [6]

Airspeed Touchdown Landing Roll Braking

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

NORMAL PROCEDURES PAGE 5

SHORT FIELD LANDING

[1] [2] [3] [4] [5] [6] [7] Airspeed Wing Flaps Airspeed Power Touchdown Brakes Wing Flaps --------65 - 75 KIAS (flaps UP) FULL DOWN 61 KIAS (until flare) REDUCE to idle after clearing obstacles --- MAIN WHEELS FIRST --- APPLY HEAVILY --- RETRACT

BALKED LANDING

[1] [2] [3] [4] [5] Throttle Carburetor Heat Wing Flaps Climb Speed Wing Flaps ----------FULL OPEN COLD 20 (immediately) 55 KIAS 10 (until obstacles are cleared) RETRACT (after reaching a safe altitude and 60 KIAS)

AF TE R L AN DI N G

FLIGHT SIMULATION USE ONLY

AFTER LANDING

[1] [2] Wing Flaps Carburetor Heat --- UP --- COLD

S E CURI N G AI RPL AN E

SECURING AIRPLANE

[1] [2] Parking Brake Avionics Power Switch, Electrical Equipment, Autopilot Mixture Ignition Switch Master Switch Control Locks --- SET

[3] [4] [5] [6]

-----------

OFF IDLE CUT-OFF OFF OFF INSTALL

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE TOC

SECTION 5

TABLE OF CONTENTS

Example Takeoff Cruise Fuel Required Landing Airspeed Calibration Stall Speeds Takeoff Distance Maximum Rate of Climb Time, Fuel & Distance to Climb Cruise Performance Range Profiles Endurance Profiles Landing Distance 1 1 2 2 3 4 5 6 7 7 8 9, 10 10, 11 12

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 1

E XAM PL E

Throughout this Section we will consider the following specifications an example to demonstrate usage of the performance charts. TAKEOFF CONDITIONS Field length Field pressure altitude Temperature CRUISE CONDITIONS Total distance Pressure Altitude Temperature Expected wind enroute LANDING CONDITIONS Field length Field pressure altitude Temperature 3200 feet 2000 feet 30C 320 nm 5500 feet 20C 10 knot headwind 3000 feet 2000 feet 25C

TAKE O F F

The takeoff distance chart, figure 5-4 should be consultet, keeping in mind that that the distances shown are based on the short field technique. Conservative distances can be established by reading the chart at the next higher value of weight, altitude and temperature. For example, a weight of 2400 pounds, pressure altitude of 2000 feet and a temperature of 30C should result in the following:

Ground roll Total distance to clear a 50-foot obstacle A correction for the effect of wind may be based on Note 3 of the

1200 Feet 2220 Feet

FLIGHT SIMULATION USE ONLY

takeoff chart. The correction for a 12 knot headwind is:

12 Knots 9 Knots

10% = 13% Decrease

This results in the following distances, corrected for wind: Ground roll, zero wind Decrease in ground roll (1200 Feet 13%) Corrected Ground Roll 1200 156 1044

Total distance to clear a 50-foot obstacle, zero wind Decrease in total distance (2220 Feet 13%) Corrected total distance to clear 50-foot obstacle

2220 289 1931

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 2

CRUI S E

The cruising altitude should be selected based on a consideration of trip length, winds aloft, and the airplanes performance. A typical cruising altitude and the expected wind enroute have been given for the sample problem. However, the power setting selection for cruise must be determined based on several considerations. These include the cruise performance characteristics presented in figure 5-7, the range profile chart presented in figure 5-8, and the endurance profile chart presented in figure 5-9. The relationship between power and range is illustrated by the range profile chart. Considerable fuel savings and longer range result when lower power settings are used. For thze sample problem, a cruise power of approximately 65% will be used. The cruise performance chart, figure 5-7, is centered at 6000 feet altitude and 20C above standard temperature. These values most nearly correspond to the planned altitude and expected temperature conditions. The engine speed chosen is 2500 RPM, which results in the following:

Power True airspeed Cruise fuel flow

66% 112 knots 7.4 GPH

F UE L RE Q UI RE D

The total fuel requirement for the flight may be estimated using the performance information in figzres 5-6 and 5-7. For the sample problem, figure 5-6 shows that a climb from 2000 feet to 6000 feet requires 1.6 gallons of fuel. The corresponding distance during the climb is 10 nautical miles. These values are for a standard temperature and are sufficiently accurate for most flight planning purposes. However, a further correction for the effect of temperature may be made as noted on the climb chart. The approximate effect of a nonstandard temperature is to increase the time, fuel, and distance by 10% for each 10C above standard temperature, due to the lower rate of climb. In this case, assuming a temperature 16C above standard, the correction would be:

FLIGHT SIMULATION USE ONLY

16C 10C

10% = 16% Increase

With this factor included, the fuel estimate would be calculated as follows:

Fuel to climb, standard temperature Increase due to non-standard temperature (1.6 16%) Corrected fuel to climb

1.6 0.3 1.9 gal.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 3

Using a similar procedure for the distance to climb results in 12 nautical miles. The resultant cruise distance is:

Total distance Climb distance Cruise distance

320 -12 308

nm

With an expected 10 knot headwind, the ground speed for cruise is predicted to be:

112 -10 102 knots

Therefor, the time required for the cruise portion of the trip is:

308 nm 102 knots

= 3.0 hours

The fuel required for cruise is:

3.0 hours

7.4 gallons/hour = 22.2 gallons

A 45-minute reserve requires:

45 60

7.4 gallons/hour = 5.6 gallons

The total estimated fuel required is as follows:

Engine start, taxi, takeoff Climb Cruise Reserve Total fuel required

1.1 1.9 22.2 5.6 30.8

gallons

FLIGHT SIMULATION USE ONLY

Once the flight is underway, ground speed checks will provide a more accurate basis

for estimating the time enroute and the corresponding fuel required to complete the trip

with ample reserve.

L AN DI N G

A procedure similar to takeoff should be used for estimating the landing distance at the destination airport. Figure 5-10 presents landing distance information for the short field technique. The distance corresponding to 2000 feet and 30C are as follows:

Ground roll Total distance to clear a 50-foot obstacle

610 1390

feet feet

A correction for the effect of wind may be made based on

Note 2 of the landing chart using the same procedure as

outlined for takeoff.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 4

AI RS PE E D CAL I BRATI O N

CONDITION: Power required for level flight or maximum rated RPM dive.

FLAPS UP KIAS KCAS FLAPS 10 KIAS KCAS FLAPS 30 KIAS KCAS 40 47 50 53 60 61 70 70 80 80 85 84 ------------------------40 49 50 55 60 62 70 70 80 79 90 100 110 89 98 108 ----------------50 56 60 62 70 70 80 79 90 100 110 120 130 140 150 160 89 98 107 117 126 135 145 154

HEATER/VENTS AND WINDOWS CLOSED

NORMAL KIAS ALTERNATE KIAS FLAPS 10 NORMAL KIAS ALTERNATE KIAS FLAPS 30 NORMAL KIAS ALTERNATE KIAS

50 51

60 61

70 71

80 82

90 100 110 120 130 140 91 101 111 121 131 141

-----

40 40

50 51

60 61

70 71

80 81

90 100 110 90 99 108

-----

-----

-----

40 48

50 50

60 60

70 70

80 79

85 83

-----

-----

-----

-----

-----

HEATER/VENTS OPEN AND WINDOWS CLOSED FLAPS UP

FLIGHT SIMULATION USE ONLY

NORMAL KIAS ALTERNATE KIAS FLAPS 10 NORMAL KIAS ALTERNATE KIAS FLAPS 30 NORMAL KIAS ALTERNATE KIAS WINDOWS OPEN FLAPS UP NORMAL KIAS ALTERNATE KIAS FLAPS 10 NORMAL KIAS ALTERNATE KIAS FLAPS 30 NORMAL KIAS ALTERNATE KIAS

40 36

50 48

60 59

70 70

80 80

90 100 110 120 130 140 89 99 108 118 128 139

40 38

50 49

60 59

70 69

80 79

90 100 110 88 97 106

-----

-----

-----

40 34

50 47

60 57

70 67

80 77

85 81

-----

-----

-----

-----

-----

40 26

50 43

60 57

70 70

80 82

90 100 110 120 130 140 93 103 113 123 133 143

40 25

50 43

60 57

70 69

80 80

90 100 110 91 101 111

-----

-----

-----

40 25

50 41

60 54

70 67

80 78

85 84

-----

-----

-----

-----

-----

Figure 5-1 Airspeed Calibration (Sheet 2 of 2)

ALTERNATE STATIC SOURCE

FLAPS UP

NORMAL STATIC SOURCE

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 5

S T A LL S P E E DS

CONDITIONS: Power Off NOTES: 1. Altitude loss during a stall recovery may be as much as 230 feet. 2. KIAS values are appoximate.

MOST REARWARD CENTER OF GRAVITY ANGLE OF BANK WEIGHT LBS FLAP DEFLECTION KIAS UP 2400 10 30 44 35 33 0 KCAS 51 48 46 47 38 35 30 KIAS KCAS 55 52 49 52 42 39 45 KIAS KCAS 61 57 55 62 49 47 60 KIAS KCAS 72 68 65

MOST FORWARD CENTER OF GRAVITY ANGLE OF BANK WEIGHT LBS FLAP DEFLECTION KIAS UP 2400 10 30 44 37 33 0 KCAS 52 49 46 47 40 35 30 KIAS KCAS 56 53 49 52 44 39 45 KIAS KCAS 62 58 55 62 52 47 60 KIAS KCAS 74 69 65

FLIGHT SIMULATION USE ONLY

Figure 5-3 Stall Speeds

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 6

TA K EOFF DIS TA N CE

CONDITIONS: FLAPS 10 Full Throttle Prior to Brake Release Pavel, Level, Dry Runway Zero Wind Maximum Weight 2400 lbs mixture should be leaned to give maximum RPM in a full throttle, static runup. 3. Decrease distances 10% for each 9 knots headwind. For operation with tailwinds up to 10 knots, increase distances by 10% for each 2 knots. 4. For operation on a dry, grass runway, increase distances by 15% of the ground roll figure.

NOTES: 1. Short field technique as specified in Section 4. 2. Prior to takeoff from fields above 3000 feet elevation, the

TAKEOFF SPEED KIAS WEIGHT PRESS LBS ALT LIFT AT FT GRND OFF 50 FT ROLL

0C

10C

20C

30C

40C

TOTAL TO CLR 50 FT OBS

GRND ROLL

TOTAL TO CLR 50 FT OBS

GRND ROLL

TOTAL TO CLR 50 FT OBS

GRND ROLL

TOTAL TO CLR 50 FT OBS

GRND ROLL

TOTAL TO CLR 50 FT OBS

2400

51

56

S.L 1000 2000 3000 4000 5000 6000 7000 8000 S.L 1000 2000 3000 4000 5000 6000 7000 8000

795 875 960 1055 1165 1285 1425 1580 1755 650 710 780 855 945 1040 1150 1270 1410

1460 1605 1770 1960 2185 2445 1755 3140 3615 1195 1310 1440 1585 1750 1945 2170 2440 2760 970 1080 1160 1270 1400 1545 1710 1900 2125

860 940 1035 1140 1260 1390 1540 1710 1905 700 765 840 925 1020 1125 1240 1375 1525 565 615 675 740 815 900 990 1095 1215

1570 1725 1910 2120 2365 2660 3015 3450 4015 1280 1405 1545 1705 1890 2105 2355 1655 3016 1035 1135 1240 1365 1500 1660 1845 2055 2305

925 1015 1115 1230 1355 1500 1665 1850 2060 750 825 905 995 1100 1210 1340 1485 1650 605 665 725 800 880 970 1070 1180 1310

1685 1860 2030 2295 2570 2895 3300 3805 4480 1375 1510 1660 1835 2040 2275 2555 2890 3305 1110 1215 1330 1465 1615 1790 1990 2225 2500

995 1090 1200 1325 1465 1620 1800 2000 ---805 885 975 1070 1180 1305 1445 1605 1785 650 710 780 860 945 1040 1150 1275 1410

1810 2000 2220 2480 2790 3160 3620 4220 ---1470 1615 1785 1975 2200 2465 2775 3155 3630 1185 1295 1425 1570 1735 1925 2145 2405 2715

1065 1170 1290 1425 1575 1745 1940 ------865 950 1045 1150 1270 1405 1555 1730 1925 695 765 840 920 1015 1120 1235 1370 1520

1945 2155 2395 2685 3030 3455 3990 ------1575 1735 1915 2130 2375 2665 3020 3450 4005 1265 1385 1525 1685 1865 2070 2315 2605 2950

FLIGHT SIMULATION USE ONLY

2200

49

54

2000

46

51

S.L 525 1000 570 2000 625 3000 690 4000 755 5000 830 6000 920 7000 1015 8000 1125

Figure 5-4. Takeoff Distance

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 7

M A XIM U M RA TE OF CL IM B

WEIGHT LBS 2400 PRESS ALT FT S.L. 2000 4000 6000 8000 10000 12000 CLIMB SPEED KIAS 76 75 74 73 72 71 70 RATE OF CLIMB - FPM -20 805 695 590 485 380 275 175 0 745 640 535 430 330 225 125 20 685 580 480 375 275 175 --40 625 525 420 320 220 ----CONDITIONS: Flaps Up Full Throttle NOTE: Mixture leaned above 3000 feet for maximum RPM:

Figure 5-5. Maximum Rate of Climb

TIM E, FU EL A N D DIA TN CE TO CL IM B

MAXIMUM RATE OF CLIMB

FLIGHT SIMULATION USE ONLY

WEIGHT LBS

PRESSURE ALTITUDE FT

TEMP CLIMB SPEED C KIAS

RATE OF CLIMB FPM

FROM SEA LEVEL TIME MIN FUEL USED GALLONS DISTANCE NM

CONDITIONS: Flaps Up Full Throttle Standard Temperature NOTES: 1. Add 1.1 gallons of fuel for engine start, taxi and takeoff allowance. 2. Mixture leaned above 3000 feet for maximum RPM. 3. Increase time, fuel and distance by 10% for each 10C above standard temp. 4. Distances shown are based on zero wind.

2400

S.L. 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000

15 13 11 9 7 5 3 1 -1 -3 -5 -7 -9

76 76 75 75 74 74 73 72 72 71 71 70 70

700 655 610 560 515 470 425 375 330 285 240 190 145

0 1 3 5 7 9 11 14 17 20 24 29 35

0.0 0.3 0.6 1.0 1.4 1.7 2.2 2.6 3.1 3.6 4.2 4.9 5.8

0 2 4 6 9 11 14 18 22 26 32 38 47

Figure 5-6. Time, Fuel, and Distance to Climb

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 8

CRU IS E PERFORM A N CE

PRESS ALT FT 2000

RPM

20C BELOW STANDARD TEMP % BHP --72 65 58 52 --72 69 62 56 51 --73 66 60 54 49 --77 70 63 57 52 74 67 61 55 50 67 64 59 53 KTAS --110 104 99 92 --115 109 104 98 91 --114 108 103 96 90 --119 113 106 101 95 118 112 106 100 93 114 111 105 98 GPH --8.1 7.3 6.6 6.0 --8.6 7.8 7.0 6.3 5.8 --8.2 7.4 6.7 6.1 5.7 --8.7 7.8 7.1 6.4 6.0 8.3 7.5 6.8 6.3 5.8 7.5 7.2 6.6 6.1

STANDARD TEMPERATURE % BHP 76 69 62 55 50 76 73 65 59 54 48 77 69 63 57 52 47 77 73 66 60 55 50 70 64 58 53 49 64 61 56 51 KTAS 114 109 103 97 91 117 114 108 102 96 89 119 113 107 101 95 88 121 118 112 106 100 93 117 111 105 98 91 112 109 103 96 GPH 8.5 7.7 6.9 6.3 5.8 8.5 8.1 7.3 6.6 6.1 5.7 8.6 7.8 7.0 6.4 5.9 5.5 8.6 8.2 7.4 6.7 6.2 5.8 7.8 7.1 6.5 6.0 5.7 7.1 6.8 6.3 5.9

20C ABOVE STANDARD TEMP % BHP 72 65 59 53 48 72 69 62 57 51 47 72 66 60 55 50 46 73 69 63 58 53 49 66 61 56 51 47 61 59 54 50 KTAS 114 108 102 96 89 116 113 107 101 94 88 118 112 106 99 92 86 120 117 111 104 97 91 115 109 102 96 89 111 107 100 94 GPH 8.1 7.3 6.6 6.1 5.7 8.1 7.7 7.0 6.4 5.9 5.5 8.1 7.4 6.7 6.2 5.8 5.5 8.1 7.8 7.1 6.5 6.0 5.7 7.4 6.8 6.3 5.9 5.6 6.9 6.6 6.1 5.8

CONDITIONS: 2400 Pounds

2500 2400 2300 2200 2100 2550 2500 2400 2300 2200 2100 2600 2500 2400 2300 2200 2100 2650 2600 2500 2400 2300 2200 2600 2500 2400 2300 2200 2550 250 2400 2300

4000

6000

8000

FLIGHT SIMULATION USE ONLY

10000

12000

Figure 5-7. Cruise Performance

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 9

RA N GE PROFIL E

12000

10000

ALTITUDE - FEET

8000

FU LL T

HR OT T

114 KIAS

101 KIAS

45 MINUTE RESERVE 40 GALLONS USABLE FUEL

LE

120 KIAS

6000

118 KIAS

109 KIAS

99 KIAS

75% POWER

65% POWER

4000

55% POWER

CONDITIONS: 2400 Pounds Recommended Lean Mixture for Cruise Standard Temperature Zero Wind Note: This chart allows for the fuel used for engine start, taxi, takeoff and climb, and the distance during climb 600

2000

112 KIAS

105 KIAS

96 KIAS

S.L. 400

450

500

550

RANGE - NAUTICAL MILES

RA N GE PROFIL E

FLIGHT SIMULATION USE ONLY

12000

10000

ALTITUDE - FEET

8000

FU LL

TH RO T

114 KIAS

TL

101 KIAS

45 MINUTE RESERVE 50 GALLONS USABLE FUEL

120 KIAS

6000

118 KIAS

109 KIAS

99 KIAS

75% PO WER

65% POWER

4000

55% POWER

CONDITIONS: 2400 Pounds Recommended Lean Mixture for Cruise Standard Temperature Zero Wind Note: This chart allows for the fuel used for engine start, taxi, takeoff and climb, and the distance during climb 750

2000

112 KIAS

105 KIAS

96 KIAS

S.L. 550

600

650

700

RANGE - NAUTICAL MILES

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 10

RA N GE PROFIL E

12000

ALTITUDE - FEET

8000

FU LL

TH

10000

RO

TT LE

114 KIAS

101 KIAS

45 MINUTE RESERVE 62 GALLONS USABLE FUEL

120 KIAS

6000

118 KIAS

109 KIAS

99 KIAS

75% POW ER

ER

65% POW

4000

55% POWER

CONDITIONS: 2400 Pounds Recommended Lean Mixture for Cruise Standard Temperature Zero Wind Note: This chart allows for the fuel used for engine start, taxi, takeoff and climb, and the distance during climb

2000

112 KIAS

105 KIAS

96 KIAS

S.L. 700

750

800

850

900

950

RANGE - NAUTICAL MILES

EN DU RA N CE PROFIL E

FLIGHT SIMULATION USE ONLY

12000

10000

ALTITUDE - FEET

8000

FU

LL TH RO

TT

45 MINUTE RESERVE 40 GALLONS USABLE FUEL

LE

6000

75% POWER

65% POWER

4000

55% POWER

CONDITIONS: 2400 Pounds Recommended Lean Mixture for Cruise Standard Temperature Note: This chart allows for the fuel used for engine start, taxi, takeoff and climb, and the distance during climb 6 7

2000

S.L.

ENDURANCE - HOURS

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 11

EN DU RA N CE PROFIL E

12000

10000

ALTITUDE - FEET

8000

FU

LL T

HR O

TT

45 MINUTE RESERVE 50 GALLONS USABLE FUEL

LE

6000

75% POWER

65% POWER

4000

55% POWER

CONDITIONS: 2400 Pounds Recommended Lean Mixture for Cruise Standard Temperature Note: This chart allows for the fuel used for engine start, taxi, takeoff and climb, and the distance during climb 8

2000

S.L.

ENDURANCE - HOURS

EN DU RA N CE PROFIL E

FLIGHT SIMULATION USE ONLY

12000

ALTITUDE - FEET

8000

FU

LL

TH

10000

RO

TT

45 MINUTE RESERVE 62 GALLONS USABLE FUEL

LE

6000

CONDITIONS: 2400 Pounds Recommended Lean Mixture for Cruise Standard Temperature

75% POWER

65% POWER

55% POWER

4000

2000

Note: This chart allows for the fuel used for engine start, taxi, takeoff and climb, and the distance during climb

S.L.

10

ENDURANCE - HOURS

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

PERFORMANCE PAGE 12

LA N DI N G DI S T A N C E

CONDITIONS: Flaps 30 Power Off Maximum Braking Paved, Level, Dry Runway Zero Wind NOTES: 1. Short field technique as specified in Section 4. 2. Decrease distances 10% for each 9 knots headwind. For operation with tailwinds up to 10 knots, increase distances by 10% for each 2 knots. 4. For operation on a dry, grass runway, increase distances by 15% of the ground roll figure.

WEIGHT LBS

SPEED AT 50 FT KIAS

0C PRESS ALT FT GRND

ROLL

10C

20C

30C

40C

TOTAL TO CLR 50 FT OBS

GRND ROLL

TOTAL TO CLR 50 FT OBS

GRND ROLL

TOTAL TO CLR 50 FT OBS

GRND ROLL

TOTAL TO CLR 50 FT OBS

GRND ROLL

TOTAL TO CLR 50 FT OBS

2400

61

FLIGHT SIMULATION USE ONLY

S.L 1000 2000 3000 4000 5000 6000 7000 8000

510 530 550 570 595 615 640 665 690

1235 1265 1295 1330 1365 1400 1435 1475 1515

530 550 570 590 615 640 660 690 715

1265 1295 1330 1360 1400 1435 1470 1515 1555

550 570 590 615 635 660 685 710 740

1295 1325 1360 1395 1430 1470 1510 1550 1595

570 590 610 635 660 685 710 735 765

1325 1360 1390 1430 1470 1510 1550 1590 1635

585 610 630 655 680 705 730 760 790

1350 1390 1425 1460 1500 1540 1580 1630 1675

Figure 5-10. Landing Distance

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

AIRPLANE & SYSTEMS DESCRIPTION TOC

SECTION 6

TABLE OF CONTENTS

Instrument Panel Engine Oil System Inition-Starter System Air Induction System Carburetor and Priming System Cooling System Propeller Fuel System Brake System Electrical System Lighting Stall Warning System Avionivs Support Equipment Static Dischargers Pitot Static System and Instruments Vacuum System and Instruments 1 2 2 2 2 3 3 3 4 4 6 6 6 6 7 7

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

AIRPLANE & SYSTEMS DESCRIPTION PAGE 1

I N S TRUM E N T PAN E L

3 9 11

10

12

13

14

15

17

19

21

23

25

27

28

FLIGHT SIMULATION USE ONLY

16

18

20

22

24

26

1. Oil Temperature/Oil Pressure 2. Fuel Quantity Indicators 3. Suction gage 4. Clock/Timer 5. Air Spee Indicator 6. Attitude Indicator 7. Altimeter 8. Course Deviation Indicator 9. Magnetic Compass 10. COM/NAV Radios

11. 12. 13. 14. 15. 16. 17. 18. 19. 20.

Autopilot Ammeter Master Switch Primer Ignition Switch Thermometer Tachometer Turn Coordinator RGT / CHT Heading Indicator

21. Circuit Breakers/Light Switches 22. Vertical Speed Indicator 23. Instrument Lighting Dimmer 24. Carburetor Heat 25. Throttle Control 26. Course Deviation Indicator 27. Mixture Control 28. Wing Flap Switch

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

AIRPLANE & SYSTEMS DESCRIPTION PAGE 2

E N GI N E O I L S YS TE M

Oil for the engine lubrication is supplied from a sump at the bottom of the engine. The capacity of the enfine sump is seven quarts (one additional quart is contained in the full flow oil filter. Oil is drawn from the sump through an oil suction strainer screen into the enginedriven oil pump. From the pump oil is routed to a bypass valve. If the oil is cold, the bypass valve allows the oil to bypass the oil cooler and go directly from the pump to the full flow oil filter. If the oil is hot, the bypass valve routes the oil out of the accessory housing and into a flexible hose leading to the oil cooler on the right rear engine baffle. Pressure oil from the cooler returns to the accessory housing where it passes through the full flow oil filter. The filter oil then enters a pressure relief valve which regulates engine oil pressure by allowing excessive oil to return to the sump while the balance of the oil is circulated to various engine parts for lubrication. Residual oil is returned to sump by gravity flow. An oil filter cap/oil dipstick is located at the right rear of the engine. The filler cap/dipstick is accesible through an access door on the top right side of the engine cownling. The engine should not be operated on less that five quarts of oil. For extended flight fill to seven quarts (dipstick indication only).

I GN I TI O N -S TARTE R S YS TE M

Engine ignition is provided by two engine-driven magnetos, and two spark plugs in each cylinder. The right magneto fires the lower right and upper right spark-plugs. Normal operation is conducted with both magnetos due to the more complete burning of the fuel-air mixture with dual ignition. Ignition and starter operation is controlled by a rotary type switch located on the left switch and control panel. The switch is labelled clockwise: OFF, R, L, BOTH and START. The engine should be operated on BOTH magnetos except for magnetochecks. The R and L position are for checking purposes and emergency use only. When the switch is rotated to the spring-loaded STARTposition, the starter contactor is energized and the starter will crank the engine. When the switch is released, it will automatically return to the BOTHposition.

AI R I N DUCTI O N S YS TE M

FLIGHT SIMULATION USE ONLY

The engine air induction system receives ram air through an intake in the lower front portion of the engine cowling. The intake is covered by an air-filter which removes dust and other foreign matter from the induction air. Airflow passing through the filter enters an airbox. After passing through the airbox, induction air

enters the inlet in the carburetor which is under the engine, and is then ducted to the engine cylinders through intake manifold tubes. In the event carburetor ice is encountered or the intake filter becomes blocked, alternate heated air can beobtained from a shroud around an exhaust riser through a duct to a valve in the

airbox operated by the carburetor heat control on the instrument panel. Heated air from the shroud is obtained from an unfiltered outside source. Use of full carburetor heat at full throttle will result in a loss of approximately 75 to 150 RPM.

CARBURE TO R AN D PRI M I N G S YS TE M

The engine is equipped with an up-draft, float-type, jetcarburetor mounted on the bottom of the engine. The carburetor is equipped with an enclosed accelerator pump, an idle cut-off mechanism and a manual mixture control. Fuel is delivered to the carburetor by gravity flow from the fuel system. In the carburetor, fuel is atomized, properly mixed with intake air and delivered to the cylinders through intake manifold tubes. The proportion of atomized fuel to air may be controlled, within limits, by the mixture control on the instrument panel. For easy starting in cool weather, the engine is equipped with a manual primer. The primer is actually a small pump which draws fuel from the fuel strainer when the plunger is pulled out, and injects it into the cylinder intake ports when the plunger is pushed back in.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

AIRPLANE & SYSTEMS DESCRIPTION PAGE 3

CO O L I N G S YS TE M

Ram air for engine cooling enters through two intake openings in the front of the engine cowling. The cooling air is directed around the cylinders and other areas of the engine by baffling, and is then exhausted through an opening at the bottom aft edge of the cowling. No manual cooling system control is provided.

PRO PE L L E R

The airplane is equipped with a two-bladed, fixed-pitch, one-piece forged aluminium alloy propeller wich is anodized to retard corrosion. The propeller is 75 inches in diameter.

F UE L S YS TE M

The airplane may be equipped with a standard fuel system or either of two long range systems. Each system consists of two vented fuel tanks (one tank each wing), a four-position selector valve, fuel strainer, manual primer, and carburetor. The 68gallon long-range system utilizes integral tanks and the other two systems employ removable aluminium tanks. Fuel flows by gravity from the two wing tanks to a four-position selector valve labelled BOTH, LEFT, RIGHT and FUEL TANKS FUEL LEVEL FULL FULL FULL TOTAL FUEL TOTAL UNUSABLE 3 4 6 TOTAL USABLE 40 50 62

STANDARD LONG RANGE LONG RANGE (INTEGRAL)

43 54 68

OFF. With the selector valve in either the BOTH, LEFT or RIGHT position, fuel flows through a strainer to the carburetor. From the carburetor, mixed fuel and air flows to the cylinders through

fuel quantity tansmitter

FLIGHT SIMULATION USE ONLY

fuel quantity filler cap tansmitter left fuel tank selector valve vent with check valve drain valve

vented filler cap

right fuel tank

drain valve selector valve drain plug fuel strainer

to engine engine primer

fuel strainer crain control throttle control

carburetor mixture control

to engine

intake manifold tubes. The manual primer draws its fue from the fuel strainer and injects it into the cylinder intake ports. Fuel system venting is essential to system operation. Blockage of the system will result in decreasing fuel flow and eventual engine stoppage. Venting is accomlished by an interconnecting line from the right fuel tank to the left fuel tank. The left fuel tank is vented overboard through a vent line, equipped with a check valve, which protrudes from the bottom surface of the left wing near the wing strut. The right fuel tank filler cap is also vented. When long range integral tanks are installed, the airplane may be serviced to a reduced capacity to permit heavier cabin loadings. This is accomplished by filling each tank to the bottom edge of the fuel filler collar, thus giving a reduced fuelload of 24 gallons in each tank. Fuel Quantity is measured by two float-type fuel quantity transmitters and indicated by two elictrically-operated fuel quantity

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

AIRPLANE & SYSTEMS DESCRIPTION PAGE 4

indicators on the left side of the instrument panel. An empty tank is indicated by a red line and the letter E. When an indicator shows an empty tank, approximately 1.5 gallons remain in a standard tank, and 2 gallons remain in a long range tank (3 gallons when long range integral tanks are installes) as unusable fuel. The indicators cannot be relied upon for accurate readings during skids, slips, or unusual attitudes. The fuel selector valve should be in BOTH position for takeoff, climb, landing and maneuvers that involve prolonged slips or skids. Operation from either LEFT or RIGHT tank is reserved for cruising flight. NOTE1: When the fuel selector valve handle is in the BOTH position in cruising flight, unequal fuel flow from each tank may occur if the

wings are not maintained exactly level. Resulting wing heaviness can be alleviated gradually by turning the selector valve handle to the tank in the heavy wing. NOTE2: When the fuel tanks are 1/4 full or less, prolonged uncoordinated flight such as slips or skids can cover the fuel tank outlets. Therefor, if operating with one fuel tank dry or if operating on LEFT or RIGHT tank when 1/4 full or less, do not allow the airplane to remain in uncoordinated flight for periods in excess of 30 seconds. NOTE3: It is not practical to measure the time required to consume all of the fuel in one tank, and, after switching to the opposite tank, expect an equal duration from the remaining fuel. The airspace

in both fuel tanks is interconnected by a vent line and, therefor, some sloshing of fuel between tanks can be expected when the tanks are nearly full and the wings are not level. The fuel system is equipped with drain valves to provide a means for the examination of fuel in the system foe contamination and grade. The system should be examined before the first flight of every day and after each refueling, by using the sampler cup provided to drain fuel from the wing tank sumps, and by utilizing the fuel strainer drain under an access door on the aft right side of the top engine cowling. If takeoff weight limitations for the next flight permit, the fuel tanks shoul be filled after each flight to prevent condensation.

BRA K E S YS TEM

The airplane has a singe -disc, hydraulically-actuated brake on ech main landing gear wheel. Each brake is connected, by a hydraulic line, to a master cylinder attached to each of the pilots rudder pedals. The brakes are operated by applying pressure to the top of either the left (pilots) or right (copilots) set of rudder pedals, which are interconnected. When the airplane is parked, both main wheel brakes may be set by utilizing the parking brake which is operated by a handle under the left side of the instrument panel. To apply the parking brake, set the brakes with the rudder pedals, pull the handle aft, and rotate it 90 down. For maximum brake life, keep the brake system properly maintained, and minimize brake usage during taxi operations and landings. Some of the symtoms of impending brake failure are: gradual decrease in braking action after brake application, noisy or dragging brakes, soft or spongy pedals, and excessive travel and weak braking action. If any of these symptoms appear, the brake system is in need of immediate attention. If, during taxi or landing roll, braking action decreases, let up on the pedals and then re-apply the brakes with heavy pressure. If the brakes become spongy or pedal travel increases, pumping the pedals should build braking pressure. If one brake becomes weak or fails, use the other brake sparingly while using opposite rudder, as required, to offset the good brake.

FLIGHT SIMULATION USE ONLY

EL ECTRICA L S YS TEM

The airplane is equipped with a 28-volt, direct-current, electrical system. The system is powered by a belt-driven, 60-amp alternator and a 24-volt battery, located on the left forward side of the firewall. Power is supplied to most general electrical and all avionics circuits through the primary bus bar and the avionics bus bar, which is interconnected by an avionics power switch. The primary bus is on anytime the master switch is turned on, and is not affected by starter or external power usage. Both bus bars are on anytime the master and avionics power switches are turned on. CAUTION: Prior to turning the master switch on or off, starting the engine or applying an external power

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

AIRPLANE & SYSTEMS DESCRIPTION PAGE 5

source, the avionics power switch, labeled AVIONICS POWER, should be turned off to prevent any harmful transient voltage from damaging the avionics equipment.

MASTER SWITCH

FLIGHT SIMULATION USE ONLY

The master switch is a split rocker-type switch labeled MASTER, and is ON in the up position. The right half of the switch labeled BAT controls all the electrical power to the airplane. The left half, labeled ALT controls the alternator. Normally, both sides of the master switch should be used simultaneously; however, the BAT side of the switch could be turned on seperately to check equipment while on the ground. To check or use avionics equipment or radios while on the ground, the avionics power switch must also be turned on. The ALT side of the switch, when placed in the OFF position, removes the alternator from the electrical system. While this switch in the OFF position, the entire electrical load is placed on the battery. Continued operation with the alternator switch in the OFF position will reduce battery power low enough to open the battery contactor, remove power from the alternator field, and prevent alternator restart.

move to OFF position. If this occurs, allow the circuit breaker to cool for about two minutes before placing the switch in the ON position again. If the circuit breaker opens again, do not reset it. The avionics power switch should be placed in the OFF position prior to turning the master switch ON or OFF, starting the engine, or applying an external power sourve, and may be utilized in place of the individual avionics equipment switches.

off and back on again. If the warning light does not illuminate again, a malfunction has occured, and the flight should be terminated as soon as practical.

CIRCUIT BREAKERS AND FUSES

AMMETER

The ammeter, located on the lower left side of the instrument panel, indicates the amount of current in amperes, from the alternator to the battery or from the battery to the airplane electrical system. When the engine is operating and the master switch is turned on, the ammeter indicates the charging rate applied to the battery. In the event the alternator is not functioning or the elctrical load exceeds the output of the alternator, the ammeter indicates the battery discharge rate.

ALTERNATOR CONTROL UNIT AND LOW-VOLTAGE WARNING LIGHT

The airplane is equipped with a combination alternator regular high-low voltage control unit mounted on the engine side of the firewall and a red warning light , labeled LOW VOLTAGE, on the left side of the instrument panel below the ammeter. In the event an over-voltage condition occurs, the alternator control unit automatically removes alternator field current which shuts down the alternator. The battery will then supply system current as shown by a discharge rate on the ammeter. Under these conditions, depending on electrical system load, the low-voltage warning light will illuminate when system voltage drops below normal. The alternator control unit may be reset by turning the master switch

Most of the elecrical circuits in the airplane are protected by push-to-reset type circuit breakers mounted on the left side of the switch and control panel. However, circuit breakers protecting the alternator output and the strobe light/avionics cooling fan circuits are the pulloff type. In addition to the individual circuit breakers, a toggle switch/circuit breaker, labeled AVIONICS POWER, on the left side of the switch and control panel, also protects the avionics system. The control wheel map light (if installed) is protected by the NAV LT circuit breaker and a fuse behind the instrument panel. Electrical circuits which are not protected by circuit breakers are the battery contactor closing (external power) circuit, clock circuit, and flight hour recorder circuit. These circuits are protected by fuses mounted adjacent to the battery.

AVIONICS POWER SWITCH

Electrical power from the airplane primary bus to the avionics bus is controlled by a toggle switch/circuit braker labeled AVIONICS POWER. The switch is located on the left side of the switch and control panel and is ON in the up position. With the switch in the OFF position, no electrical power will be applied to the avionics equipment, regardless of the position of the master switch or the individual equipment switches. The avionics power switch also functions as a circuit breaker. If an electrical malfunction should occur and cause the circuit braker to open, electrical power to the avionics equipment will be interrupted and the switch will automatically

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

AIRPLANE & SYSTEMS DESCRIPTION PAGE 6

L IGHTIN G

Conventional navigation lights are located on the wing tips and top of the rudder. A single landing light is located in the cowl nose cap. Dual landing/taxi lights are available and also located in the cowl nose cap. Additional lighting is available and includes a flashing beacon mounted on top of the vertical fin, a strobe light on each wing tip, and a courtesy light recessed into the lower surface of each wing slightly outboard of the cabin doors. The flashing beacon should not be used when flying through clouds or overcast; the flashing light reflected from the water droplets or particles in the atmosphere, particularly at night can produce vertigo and loss of orientation.

S TA L L W A RN IN G S YS TEM

The airplane is equipped with a pneumatic-type stall warning system consisting of an inlet in the leading edge of the left wing and an air-operated horn near the upper left corner of the windshield. As the airplane approaches a stall, the low pressure on the upper surface of the wings moves forward around the leading edge of the wings. This low pressure creates a differential pressure in the stall warning system which draws air through the warning horn, resultig in an audible warning at 5 to 10 knots above stall.

FLIGHT SIMULATION USE ONLY

A VION ICS S U PPORT EQU IPM EN T

If the airplane is equipped with avionics, various avionics support equipment may also be installed. Equipment available includes an avionics cooling fan, microphoneheadset installations and control surface dischargers.

S TA TIC DIS CHA RGERS

If frequent IFR flights are planned, installation of wick-type static dischargers is recommended to improve radio communications during flight through dust or various forms of precepitation. Under these conditions, the buildup and discharge of static electricity from the trailing edges of the wings, rudder, elevator, propeller tips and radio antennas can result in loss of usable radio signals on all communications and navigation equipment. Usually the ADF is first to be affected and VHF communication equipment is the last to be affected.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

AIRPLANE & SYSTEMS DESCRIPTION PAGE 7

PITOT S TA TIC S YS TEM A N D IN S TRU M EN TS

The pitot-static system supplies ram air pressure to the airspeed indicator and static pressure to the air speed indicator, vertical speed indicator and altimeter. The system is composed of either an unheated or heated pitot tube mounted on the lower surface of the left wing, an external static port on the lower left side of the forward fuselage, and the associated plumbing necessary to connect the instruments to the sources. The heated pitot system (if installed) consists of a heating element in the pitot tube, a rocker switch labeld PITOT HT, a 5-amp circuit breaker, and associated wiring. A static pressure alternate source valve may be installed on the switch and control panel below the throttle, and can be used if the external static pressure source is malfunctioning. as supplied by static source.

ALTIMETER

AIRSPEED INDICATOR

The airspeed indicator is calibrated in knots. Limitation and range markings include the white arc, green arc, yellow arc and a red line.

Airplane altitude is depicted by a barometric type altimeter. A knob near the lower left portion of the indicator provides adjustment of the instruments barometric scale to the current altimeter setting.

VERTICAL SPEED INDICATOR

The vertical speed indicator depicts airplane rate of climb and descent in feet per minute. The pointer is actuated by atmospheric pressure changes resulting from changes of altitude

VA CU U M S YS TEM A N D IN S TRU M EN TS

An engine-driven vacuum system provides the suction necessary to operate the attitude indicator and directional indicator. The system consistes of a vacuum pump mounted on the engine, a vacuum relief valve and vacuum system airfilter on the left side of the firewall below the instrument panel, and instruments on the left side of the instrument panel. The attitude indicator gives a visual indication of flight attitude. Bank attitude is presented by a pointer at the top of the indicator relative to the bank scale which has index marks at 10, 20, 30, 60 and 90 either side of the center mark. Pitch and roll attitudes are presented by a miniature airplane superimposed over a symbolic horizon area divided into two sections by a white horizon bar.

ATTITUDE INDICATOR

FLIGHT SIMULATION USE ONLY

vacuum system air filter

vacuum pump

overboard vent line vacuum relief valve

DIRECTIONAL INDICATOR

attitude indicator

suction gage directional indicator inlet air vacuum discharge air

A directional indicator displays airplane heading on a compass card in relation to a fixed simulated airplane image and index. The indicator will precess slightly over a period of time. Therefor the compass card should be set in accordance with the magnetic compass just prior to takeoff, and occasionally readjusted on extended flights.

SUCTION GAGE

The suction gage is calibrated in inches mercury and indicates suction available for operation of the attitude and directional indicators.

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

SUPLEMENTS TOC

SUPPLEMENT

TABLE OF CONTENTS

Digital Clock/Timer Cessna 400 Glide Slope Autopilot Autopilot Procedures -Before Takeoff and Landing -Inflight Wings Leveling -NAV Intercept (VOR/LOC) -NAV Tracking (VOR/LOC) -Heading Select 1 1 2 2 2 2 3 3 3

FLIGHT SIMULATION USE ONLY

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

SUPPLEMENTS PAGE 1

DIGITAL CLOCK/TIMER

The Astro Tech LC-2 Quartz Chronometer is a precision, solid state time keeping device which will display to the pilot the timeof-day, the calendar date, and the elapsed time interval between a series of selected events, such as in-flight check points or legs of a cross-country flight, etc. These three modes of operation fuction independently and can be alternately selected for viewing in the liquid crystal display (LCD) on the front face of the instrument. Four push button type switches directly below the display control all time keeping functions. The digital display features an internal light to ensure good visibility under low cabin lighting conditions or at night. Buttons: ST/SP Starts and Stops the Stopwatch RST Resets the Stopwatch Lower MODE Toggles between Stopwatch / Simulation Speed / Zoom Factor Upper Mode Switches between Local Time and Zulu Time (indicated by a yellow spot)

CESSNA 400 GLIDE SLOPE

The Cessna 400 Glide Slope is an airborne navigation receiver which receives and interprets glide slope signals from a groundbased Instrument Landing System (ILS). It is used with the localizer function of a VHF navigation system when making instrument approaches to an airport. The glide slope provides vertical path guidance while the localizer provides horizontal track guidance. The Cessna 400 Glide Slope system consists of a remotemounted receiver coupled to an existing navigation system, a panel-mounted indicator and an externally mounted antenna. Operation of the Cessna 400 Glide Slope system is controlled by the associated navigation system.

FLIGHT SIMULATION USE ONLY

TO RECEIVE GLIDE SLOPE SIGNALS

[1] N AV F re q ue n c y S e l e c t K n ob - - - S e l e c t d e s i re d l oc a l i ze r

SECTION: | 1 | 2 | 3 | 4 | 5 | 6 | SUPP |

SUPPLEMENTS PAGE 2

AUTOPILOT

GENERAL INFORMATION

The installed autopilot is a singleaxis (aileron control) autopilot with an additional altitude hold and glide slope hold function. Roll and yaw motions of the airplane are sensed by the turn coordinator gyro. Deviation from the selected heading are sensed by the directional gyro. The computer-amplifier electronically computes the necessary correction and signals the actuator to move the ailerons to maintain the airplane in the commanded lateral attitude or heading. the heading selected via the bug on the directional indicator. NAV TRK By engaging this button the airplane will hold a radial selected on NAV1. It is possible to engage both HDG SEL and NAV TRK simultanously. HDG SEL is given priority until a VOR radial is intercepted, at which point the HDG SEL button will disengage and the aircraft will turn to and track the radial. This mode is generally unavailable if an active frequency is not selected. HI SENS By depressing this button the aircraft will track a localizer frontcourse and also the glide slope. BCK CRS This mode permits tracking of the back course localizer. generally unavailable if an active

frequency is not selected. CENTER BANK KNOB The center knob provides variable aileron control to execute a standard rate turn. In the default state, the knob is off (pushed in). Clicking on the center of the knob will pull it in the on position, engaging the wing leveler. With the knob pulled out moving it into the right position the aircraft will enter a standard rate turn to the right. Moving it into the left position the aircraft will enter a standard rate turn to the left. Re-centering the knob from either the left or right position will re-engage the wing leveler.

BUTTONS

ON/OFF The autopilot can be activated via the on/off switch located to the left of the large center knob. The switch will turn to the offposition when the battery is switched off. HDG SEL By engaging this button the airplane will turn to and maintain

FLIGHT SIMULATION USE ONLY

AUTOPILOT PROCEDURES

BEFORE TAKE-OFF AND LANDING