M001 e

M001 e

Uploaded by

Adolfo BurgosCopyright:

Available Formats

M001 e

M001 e

Uploaded by

Adolfo BurgosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

M001 e

M001 e

Uploaded by

Adolfo BurgosCopyright:

Available Formats

THE OPTIMUM SOLUTION

Complete range of products

www.chris-marine.com

CHRIS-MARINE and IOP Marine the optimum solution

Top quality maintenance equipment

For almost five decades we have designed, manufactured and sold maintenance machines for diesel engines. Today these machines are world-renowned for being operator friendly and of high quality. Now and since the 1960's, quality, reliability and usability remain to be our key trademarks. We are constantly growing and have sales offices in Sweden, Singapore, China, India, Japan and Greece. In Singapore there is also a well-equipped workshop, and in Denmark there is IOP Marine, a market leader in fuel injector test equipment. A close cooperation with local agents also helps us to serve our customers independent of their location.

Well Educated and Dedicated Staff

130 well educated men and women worldwide are working to improve our products and services. They are constantly increasing the quality, the hallmarks of Chris-Marine and IOP Marine.

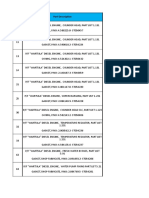

VALVE SPINDLE AND SEAT MAINTENANCE

CYLINDER LINER MAINTENANCE

SEALING SURFACE MAINTENANCE

FUEL INJECTOR TEST AND MAINTENANCE

HYDRAULIC POWER UNITS

INDUCTION HEATING MAINTENANCE

SPECIAL EQUIPMENT

VALVE SPINDLE AND SEAT MAINTENANCE

BSP Valve spindle grinding machine For grinding of valve spindles on high and medium speed diesel engines. Electrically driven. The touch panel offers an improved user interface with several operator languages available. For stem diameter 6 50 mm.

HVG Valve grinding machine For 4-stroke valves and smaller 2-stroke valves and seats. Air- and electrically driven. Stem diameters smaller than 50 mm. Cooling water system included.

150S Valve spindle grinding machine

Air driven support grinder to be used in lathe. Recommended for valve disc diameters larger than 130 mm and 2-stroke valve seats. Template for accurate angle setting included.

75H Valve spindle grinding machine Air driven support grinder to be used in lathe. Recommended for valve disc diameters smaller than 180 mm, and smaller 2-stroke valve seats. Template for accurate angle setting included.

VGT Valve spindle and seat grinding machine For 2-stroke valve spindles and seats up to 96 mm stem diameter. Electrically driven. Unique self-centering system. Approved and recommended by major engine designers.

LBD Valve spindle and seat grinding machine

For all type of 2-stroke valve spindles and seats. Air- or electrically driven. Unique self-centering system for valves and seats. Approved and recommended by major engine designers.

MSD Valve seat grinding machine

For 4-stroke valve seats from 40 270 mm diameter. Air driven with air-cooled grinding surface. User-friendly with possibility for several preset grinding angles.

VSL Valve seat lathe For 4-stroke valve seats. Electrically driven with stepless speed control. Unique portable lathe for efficient and user-friendly machining of valve seats from 50 230 mm diameter. Seat finish produced to highest requirements.

VRL Seat recess and valve seat lathe Electrically driven for machining of seat recesses in cylinder heads for overdimensioned valve seats. Working range 60 200 mm diameter. Capable of machining vertically, horizontally and chamfering. Automatic centering with unique two-part spindle for excellent accessibility. An extra accessory is used for machining of valve seats. ACCESSORIES

CBN-grinding stones Consumables

CYLINDER LINER MAINTENANCE

HONING MACHINES

Removes ovality, restore surfaces and generates a crosspattern. For in-situ use or together with honing rig type HR.

HON S For 4-stroke and smaller 2-stroke engines Used for engines, cylinder diameter 150 600 mm. Air- or electrically driven. Available with 4- or 8-armed honing head. Hoist with variable speed. Interchangeable gear boxes for correct honing speed.

HON X/P For large 4-stroke and all 2-stroke engines

Used for engines, cylinder diameter 320 1000 mm. For large-bore liners in workshops when an extremely powerful honing machine is required. Driving unit with stepless adjustable speed. Available with 8-armed honing head, used together with diamond stones. Electrically driven with or without automatic stroke control. Driving unit speed, hoisting speed and stone pressure can be controlled from operator position.

SRM Surface roughness measuring device

for standard-compliant roughness measurements With the SRM, the cylinder liner roughness can be measured and documented before, during and after honing. It is easy to use; switch on and measure.

DGL Deglazing machine For restoring the surface in glazed liners. For in-situ use right on the engine stud bolts. Electrically driven. Operating range 320 500 mm bore. Also available in multi-engine version for use in-situ.

WGM Wavecut grinding machine

For overhauling MAN B&W 2-stroke engines. Operating range 500 980 mm bore. Easy alignment on top of the liner. Wavecut pattern is created during the normal time for piston overhaul (a few hours). Controlled from operator position.

VKS Wear edge milling machine Air driven machine for liner diameters 280 980 mm. Safe and quick removal of wear edges before piston pulling and honing.

LDM Liner diameter measuring instrument

With the LDM measuring instrument, the cylinder liner diameter can be measured on large 2-stroke engines without removing the cylinder cover. The instrument is entered into the cylinder through the scavenging air ports and placed on the piston crown.

ACCESSORIES

Super cutting diamond stones Automatic stroke control Consumables

SEALING SURFACE MAINTENANCE

Machines for horizontal and vertical maintenance on cylinder cover, liner and frames.

CPL Surface grinding machine

Air driven. Versatile and flexible for surfaces that require the highest precision. Working range 200 650 mm diameter.

CPM Surface grinding machine Air driven semi-automatic machine with working range 350 700 mm diameter. Versatile and robust for highest demand on precision grinding.

CPS Surface grinding machine Air- or electrically driven semi-automatic machine with working range 600 1400 mm diameter. For multiple applications on all large-bore 2-stroke engines.

CPT Portable lathe Electrically driven general purpose lathe. Working range 300 1100 mm diameter. Robust design providing high accuracy to match tough tolerance requirements. Stepless feed both horizontally and vertically.

PTL Portable lathe Electrically driven lathe for precision work in engine frames. Hole sizes 300 900 mm diameter and 900 mm depth. Stepless feed both horizontally and vertically.

ACCESSORIES

CBN Grinding stones Consumables

FUEL INJECTOR TEST AND MAINTENANCE

FPT Fuel pump test equipment Determine wear condition of 4-stroke engine fuel pumps and compare with existing performance data. The FPT test method does not require large setups. VPU Fuel injector

test equipment for 4-stroke engines Air-powered test rigs for optimal test of mechanical and electronic fuel injectors.

VPUD Fuel injector

test equipment for 2- and 4-stroke engines Air-powered test rigs with analog or digital readout for optimal test of 2-stroke fuel injectors from MAN Diesel and Wrtsil as well as all types of 4-stroke engine injectors.

FPG Grinding machine for fuel pump components

Air- and electrically driven machine for grinding of sealing surfaces in fuel pumps. Designed to meet the high requirements when restoring fuel pump components.

VPA Fuel injector test equipment, workshop version Air-driven, PLC-controlled test device for testing of all 2- and 4-stroke fuel injection valves including slide valves.

ACCESSORIES

PPMI Slide valves tester, retrofit for existing installations The PPMI 1000 is the only solution available for testing of slide fuel valves with a traditional Obel-P or 3:rd party test rig.

HYDRAULIC POWER UNITS

HPU Hydraulic power pack series, 2- and 4-stroke engines A series of PowerPacks from small hand powered pumps to large air powered units supplying hydraulic pressure to all types of hydraulic tools. Can loosen the biggest cylinder cover in less than 5 minutes.

HPU Hydraulic power unit A compact airpowered PowerPack controlled with a foot pedal for optimum flexibility during 4-stroke engine maintenance.

MPU Two-Speed hydraulic power unit

The long handle and automatic flow switch ensures continuous easy pumping. Sturdy construction with a special gauge protection system.

ACCESSORIES

Digital Reference Gauge For exact verification of pressure. Compatible with handpumps and HPU units, 0-2500 bar.

High-pressure Hoses and CEJN couplings High-pressure hoses 1 6 m with protection cover and 120 sealing surface, compatible with CEJN 116 resp 125 series couplings.

INDUCTION HEATING MAINTENANCE

MPI Multi purpose induction heating tool

The MPI unit generates heat directly to metal objects. It is very precise and there is no open flame with noxiuos gasses, soot or heat loss to the surroundings. Use the MPI for valve seat removal, shrink fitting, brazing and soldering or for spot heating.

Ultrasonic - Workshop A complete solution to the cleaning requirements of both power generation and marine industries. The surrounding transducer set-up ensures unique and highly effective cleaning of engine parts such as pistons, valve spindles, fuel injectors, cylinder heads etc. Features environmentally friendly cleaning compared to conventional cleaning liquids.

SPECIAL EQUIPMENT

WR Working rig Manual or electric turning gear. Useful tool when overhauling exhaust valve cages and cylinder heads. The range of rigs suits all 2-stroke valve cages and 4-stroke cylinder heads.

TGM Tube grinding machine

Air driven handheld universal machine for tube sizes 27 76 mm diameter with sphere radius 100 mm.

HR Honing rig

Honing rig for work shop application, shown here with air driven hoist.

THE OPTIMUM SOLUTION

SWEDEN

Chris-Marine AB Stenyxegatan 3 PO Box 9025 SE-200 39 Malm Tel: +46 - 40 671 2600 Fax: +46 - 40 671 2699 info@chris-marine.com

DENMARK

IOP Marine A/S Engager 7 DK-2605 Brndby Tel: +45 - 4498 3833 Fax: +45- 4498 1125 contact@iopmarine.dk

SINGAPORE

Chris-Marine (S) Pte. Ltd. 46 Lokyang Way, Jurong Singapore 628646 Tel: +65 - 6268 8611 Fax: +65 - 6264 3932 chrism@chris-marine.com.sg

GREECE

CM Hellas Ltd. 16, Dodekanisou Str. (1st floor) GR-18541 Piraeus Tel: +30 - 210 482 6060 Fax: +30 - 210 483 9323 info.gr@chris-marine.com

P.R. OF CHINA

Chris-Marine Trading (Shanghai) Co,. Ltd. Room 311, No.1 Building, No.288 Wu Hua Road, Shanghai 200086 Tel: +86 - 21 6575 9331 Fax: +86 - 21 6575 9552 info.cn@chris-marine.com

INDIA

Chris-Marine Rep Office India Plot No. 1/1, Vikas Apartment Trimurty Nagar, Ring Road Nagpur-440022, Maharashtra Tel: +91 - 712 224 6902 info.in@chris-marine.com IOP & Chris-Marine Japan Office Kobe Kokusai Kaikan 22 Fl., 8-1-6 Goko-dori Chuo-ku, Kobe, 651-0087 Tel: +81 - 78 570 5642 Fax: +81 - 78 570 5601 info.jp@chris-marine.com

BKM Reklam AB

JAPAN

M001-1207/E

You might also like

- Wartsila W28SG 1Document5 pagesWartsila W28SG 1hadNo ratings yet

- Product Manual Wooward 03035Document10 pagesProduct Manual Wooward 03035nabila100% (1)

- Catálogo de Peças W32Document588 pagesCatálogo de Peças W32Rafael Schneweiss100% (1)

- Deutz 444 Main and Big End Bearing SetsDocument2 pagesDeutz 444 Main and Big End Bearing SetsD.Poljachihin100% (1)

- B-62444e-1!04!050120 Series 16 18 TB TC 16i 18i Ta Super Cap T and Super Cap II TDocument606 pagesB-62444e-1!04!050120 Series 16 18 TB TC 16i 18i Ta Super Cap T and Super Cap II TSam eagle goodNo ratings yet

- User Manual For Software Product 1K62 Lathe Simulator Brief Description of The Software ProductDocument11 pagesUser Manual For Software Product 1K62 Lathe Simulator Brief Description of The Software ProductAlix BoubanNo ratings yet

- Manual WartsilaDocument330 pagesManual WartsilaAndres RamirezNo ratings yet

- Wartsila Spare PartDocument6 pagesWartsila Spare Partbalakn marineNo ratings yet

- Component ServiceDocument7 pagesComponent ServiceFahmi AliNo ratings yet

- Wartsila OemDocument2 pagesWartsila OemAbid LakhaniNo ratings yet

- Damper Offer WartsilaDocument2 pagesDamper Offer WartsilaapsNo ratings yet

- Zav40s 9Document8 pagesZav40s 9Alain Jimenea0% (1)

- WärtsiläDocument28 pagesWärtsiläUsama Mughal100% (1)

- Pci 344Document2 pagesPci 344Андрей АндреевNo ratings yet

- Services by Wartsila BangladeshDocument2 pagesServices by Wartsila Bangladeshakhi5000No ratings yet

- 97537xuerfkdujhuv &rpsuhvvruvlghehdulqjv: NjurxqgDocument1 page97537xuerfkdujhuv &rpsuhvvruvlghehdulqjv: NjurxqgAlexanderNo ratings yet

- Goltens Inservice2013 WebDocument11 pagesGoltens Inservice2013 WebGiovanniJaraNo ratings yet

- Geislinger DamperDocument45 pagesGeislinger Damperandreyeng0% (1)

- Service Bulletin A - 3.1: Technical Information To All The Owners of Sulzer A Type Diesel Engines 22.03.96Document8 pagesService Bulletin A - 3.1: Technical Information To All The Owners of Sulzer A Type Diesel Engines 22.03.96zbkt07No ratings yet

- Manifold Pressure Fuel Limiter For UG-8L Governors: Product Manual 03507 (Revision NEW)Document12 pagesManifold Pressure Fuel Limiter For UG-8L Governors: Product Manual 03507 (Revision NEW)wjzlj100% (1)

- Wartsila O E W 38 TRDocument12 pagesWartsila O E W 38 TRbunguiaoNo ratings yet

- SKF Thap 030Document102 pagesSKF Thap 030seansotoNo ratings yet

- Nohab Polar Connecting RodsDocument2 pagesNohab Polar Connecting Rodsswiatekpiotrwp.pl0% (1)

- XAAB145597 SpcenDocument600 pagesXAAB145597 Spcenufficio.tecnicoNo ratings yet

- Ser Ser Ser Ser Service Vice Vice Vice Vice Manual Manual Manual Manual ManualDocument86 pagesSer Ser Ser Ser Service Vice Vice Vice Vice Manual Manual Manual Manual ManualsukauriNo ratings yet

- SogavDocument39 pagesSogavGalih YugaNo ratings yet

- Service Info No. 0016 - ComDocument1 pageService Info No. 0016 - Comcupid75No ratings yet

- V222TI Operation & Maintenance ManualDocument294 pagesV222TI Operation & Maintenance ManualLisandroNo ratings yet

- Wartsila O E X35 MIMDocument582 pagesWartsila O E X35 MIMMarian Czeszkiewicz100% (1)

- Mak Engine Maintenance ManualDocument5 pagesMak Engine Maintenance ManualBadla full movie ,amitabh bacchan 2018 in hdNo ratings yet

- LUB OILS NOHAB W25 W25SG W25DF 9193911800eDocument2 pagesLUB OILS NOHAB W25 W25SG W25DF 9193911800eLIVIA100% (2)

- Operation Manual: Issue 001 2019-10Document486 pagesOperation Manual: Issue 001 2019-10Hải Nguyễn VănNo ratings yet

- 1D - DVS - B&W - Man - 6S60MC-C - Vol4 - Final - 354Document354 pages1D - DVS - B&W - Man - 6S60MC-C - Vol4 - Final - 354tomo1973100% (1)

- BULLETIN Gudgeon Pin With A 40 MM 3211P286 - 02Document3 pagesBULLETIN Gudgeon Pin With A 40 MM 3211P286 - 02enzobvNo ratings yet

- Turbocharger Division: Specification: Hs 5800 A1F 91 Ms 156 Serial N°: 527 000Document17 pagesTurbocharger Division: Specification: Hs 5800 A1F 91 Ms 156 Serial N°: 527 000ronny ArdiansyahNo ratings yet

- Ss-đã Chuyển ĐổiDocument10 pagesSs-đã Chuyển ĐổiTrần Hoài VinhNo ratings yet

- Holeby GenSetsDocument71 pagesHoleby GenSetsStanislav RekyvchakNo ratings yet

- L32-40CD B3-SparePartsCatalogueDocument254 pagesL32-40CD B3-SparePartsCataloguejamukanak pad100% (1)

- DBAF396689Document562 pagesDBAF396689mahumedes jameahNo ratings yet

- 3210Q011 04gb PDFDocument2 pages3210Q011 04gb PDFDenim102100% (1)

- Daaf006099 000Document2 pagesDaaf006099 000apsNo ratings yet

- Overall Data: Engine Power (ISO 3046 - I) Nominal Power of Gensets KW HP P (KW) P (kVA) P (KW) P (kVA)Document1 pageOverall Data: Engine Power (ISO 3046 - I) Nominal Power of Gensets KW HP P (KW) P (kVA) P (KW) P (kVA)ghostt123No ratings yet

- Injection Nozzle Opening Pressure: Lmbo QFKD Fkpqor'qflkDocument1 pageInjection Nozzle Opening Pressure: Lmbo QFKD Fkpqor'qflkAlexander100% (1)

- DPG 2223Document56 pagesDPG 2223rogerioNo ratings yet

- Spare Parts Notice: RT-156 Wärtsilä 2-StrokeDocument8 pagesSpare Parts Notice: RT-156 Wärtsilä 2-StrokeRaul DiazNo ratings yet

- Datasheet For ABC Diesel Engine Type: DZCDocument1 pageDatasheet For ABC Diesel Engine Type: DZCEditya Angga Wijaya100% (1)

- Wartsila O E W 20 PG M.Document148 pagesWartsila O E W 20 PG M.Uhrin ImreNo ratings yet

- ABB Turbocharging TPS - . - D / E - The PerformerDocument4 pagesABB Turbocharging TPS - . - D / E - The PerformerTibor AngeloNo ratings yet

- Installation and Operation Manual: Pressure Shutdown Device For The 3161 GovernorDocument22 pagesInstallation and Operation Manual: Pressure Shutdown Device For The 3161 Governorarvatti100% (1)

- Final Drawing HX020 HX026 - Sperre Control CircuitDocument60 pagesFinal Drawing HX020 HX026 - Sperre Control CircuitMohamedNo ratings yet

- UG-5.7, 8, and 10 Lever Governor: Product Manual 03036 (Revision J)Document56 pagesUG-5.7, 8, and 10 Lever Governor: Product Manual 03036 (Revision J)sunchit1986No ratings yet

- HOUTTUIN Catalog GeneralDocument12 pagesHOUTTUIN Catalog GeneralRelu123No ratings yet

- Safety Spare Parts For Wärtsilä Vasa 22, 22 - 26 EnginesDocument4 pagesSafety Spare Parts For Wärtsilä Vasa 22, 22 - 26 EnginesigorNo ratings yet

- 3211 T035 GBDocument2 pages3211 T035 GBAlexanderNo ratings yet

- Deutz: ETL No.: 0506 6258 Big End Bearing Constr. Group: 06Document1 pageDeutz: ETL No.: 0506 6258 Big End Bearing Constr. Group: 06Mohsen MoghadamNo ratings yet

- Air Driven Hoist Type 125 & 250Document19 pagesAir Driven Hoist Type 125 & 250Samer SalibaNo ratings yet

- SW280 SW28 Cylinder Head OverviewDocument2 pagesSW280 SW28 Cylinder Head OverviewD.Poljachihin100% (1)

- Bulletin #D15EDocument4 pagesBulletin #D15EPanos PanosNo ratings yet

- Rta 54 PDFDocument8 pagesRta 54 PDFAnonymous d00A9zetNo ratings yet

- Mira 2012Document18 pagesMira 2012Michael Kubler100% (1)

- Hydraulic Equipment & Machinery: Hydropower Engineering SystemsDocument4 pagesHydraulic Equipment & Machinery: Hydropower Engineering Systemsbukit_guestNo ratings yet

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Ready To Export MachineDocument5 pagesReady To Export Machinesanthosh.smtsNo ratings yet

- II-Mid PAPER-BMP Autumn 2012Document2 pagesII-Mid PAPER-BMP Autumn 2012Atul GaurNo ratings yet

- Clarke CL430 - CL500M ManualDocument28 pagesClarke CL430 - CL500M Manual69x4No ratings yet

- 9179Document8 pages9179Ranjith CLNo ratings yet

- Lathe PDFDocument130 pagesLathe PDFNitin B maskeNo ratings yet

- 2020 DMT Production Facilities. CNC Park Online UseDocument35 pages2020 DMT Production Facilities. CNC Park Online Usemoisii teodoraNo ratings yet

- Vishnu Internship Report 1Document27 pagesVishnu Internship Report 1Vishnu ChitragarNo ratings yet

- 2 B.TECH EXPERIMENT'S SEM IV - Wire DrawingDocument3 pages2 B.TECH EXPERIMENT'S SEM IV - Wire DrawingNeelNo ratings yet

- Manualplus 620: User'S ManualDocument525 pagesManualplus 620: User'S ManualcioparNo ratings yet

- Pengaruh Kecepatan Potong, Gerak Makan Dan Ketebalan Pemotongan Terhadap Getaran Benda Kerja Pada Proses SekrapDocument8 pagesPengaruh Kecepatan Potong, Gerak Makan Dan Ketebalan Pemotongan Terhadap Getaran Benda Kerja Pada Proses SekrapAndi SetiawanNo ratings yet

- Perform Lathe Manual PDFDocument12 pagesPerform Lathe Manual PDFsimon pNo ratings yet

- FMP-302 Lecture 3 4 Lathe, Types, OperationsDocument57 pagesFMP-302 Lecture 3 4 Lathe, Types, OperationsJahangir AliNo ratings yet

- Solution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minDocument11 pagesSolution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minwoihoNo ratings yet

- Equipment Earmould Lab: Silicone Materials Silicone Lacquers Earmould Manufacturing ToolsDocument22 pagesEquipment Earmould Lab: Silicone Materials Silicone Lacquers Earmould Manufacturing ToolsLuisita AlzateNo ratings yet

- Hot & Cold WorkingDocument23 pagesHot & Cold WorkingzackaiedaNo ratings yet

- Ise Module 4 KtuDocument40 pagesIse Module 4 Ktuvcb57xbtd5No ratings yet

- OAL Profile 2013Document21 pagesOAL Profile 2013tawatesNo ratings yet

- Company Profile Pt. SSJDocument25 pagesCompany Profile Pt. SSJoganuluNo ratings yet

- Boring Machine: M. Murali Mohan, Asst. Professor, Dept. of Mechanical Engineering, GPREC, KurnoolDocument48 pagesBoring Machine: M. Murali Mohan, Asst. Professor, Dept. of Mechanical Engineering, GPREC, KurnoolMuraliMohan50% (2)

- Presentation On Heavy Engineering Corporation LimitedDocument20 pagesPresentation On Heavy Engineering Corporation LimitedSandeepRajNo ratings yet

- Machine Shop Lab Manual 2018Document16 pagesMachine Shop Lab Manual 2018S B MALLURNo ratings yet

- SherlineDocument48 pagesSherlineheliocoelhojr100% (1)

- VRTurningDocument2 pagesVRTurningJunior GamerNo ratings yet

- Files Documents GENOS L2000 L3000-e-OAC-E 2b 200 Feb2022Document13 pagesFiles Documents GENOS L2000 L3000-e-OAC-E 2b 200 Feb2022S'làh S'égnìNo ratings yet

- MCQ On IMEDocument3 pagesMCQ On IMERafiya KaziNo ratings yet

- Fomrhi Q135Document42 pagesFomrhi Q135Gaetano PreviteraNo ratings yet

- NANO 160 NANO 200: CNC AutomationDocument2 pagesNANO 160 NANO 200: CNC AutomationRajesh S Pande - AURA AutomationsNo ratings yet

- 658 Mr. Dinesh Kumar Saini Jaipur (LD-1)Document2 pages658 Mr. Dinesh Kumar Saini Jaipur (LD-1)DInesh KumarNo ratings yet