Timber Growth

Timber Growth

Uploaded by

Abdul Sukur KamsirCopyright:

Available Formats

Timber Growth

Timber Growth

Uploaded by

Abdul Sukur KamsirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Timber Growth

Timber Growth

Uploaded by

Abdul Sukur KamsirCopyright:

Available Formats

Timber growth

Geoff' s Woodwork

for Students of Woodwork

Timber growth

Cross section of a tree truck

Annual or growth rings ~ in temperate climates there are two

distinctive growth seasons, spring and summer ~ the spring growth is

rapid and is shown as a broad band whereas the hotter, dryer summer

growth shows up narrow. In tropical countries the growth rings are

more even and difficult to distinguish.

http://www.geoffswoodwork.co.uk/timber%20growth.htm (1 of 5)7/28/2004 7:56:46 AM

Timber growth

Bark ~ the outer layer, corklike and provides protection to the tree

from knocks and other damage.

Bast ~ the inner bark, carries enriched sap from the leaves to the cells

where growth takes place.

Cambium ~ layer of living cells between the bast and the sapwood.

Crown ~ the branches and leaves that provides its typical summer

shape.

Heartwood ~ mature timber, no longer carries sap, the heart of the tree,

provides the strength of the tree. Usually a distinctive darker colour

than the sapwood.

Medulla ray ~ (rays) food storage cells radiating from the medulla ~

provides a decorative feature found in quarter cut timber.

Pith or medulla ~ the centre of the tree, soft and pithy especially in the

branches.

Sapwood ~ new growth, carries the raw sap up to the leaves. Usually

lighter in colour than the heartwood, especially in softwoods.

Trunk ~ main structure of the tree, produces the commercial timber.

Root structure ~ Absorbs water and minerals from the soil. It is the

anchor of the treee.

http://www.geoffswoodwork.co.uk/timber%20growth.htm (2 of 5)7/28/2004 7:56:46 AM

Timber growth

Hardwoods and Softwoods.

There are two main groups of timber producing trees used

commercially; softwoods and hardwoods. These terms immediately

create contention because they do not accurately describe the timber

correctly.

Softwoods. Softwoods are coniferous trees and the timber is not

necessarily 'soft'. They are 'evergreen'. (The larch is an exception)

Their general characteristics are:

Straight, round but slender, tapering trunk.

The crown is narrow and rises to a point.

It has needle like or scale-like shaped leaves and it's fruit, i.e. it's seeds

are carried in cones.

The bark is course and thick and softwoods are evergreen and as such

do not shed their leaves in autumn.

Hardwoods. Hardwood trees are broadleaf and generally deciduous.

Their timber is not necessarily hard. For instance, balsa (the timber

used for making model planes) is a hardwood. The general

characteristics are:

Stout base that scarcely tapers but divides into branches to form a

wide, round crown.

The leaves are broad and may have single or multi lobes.

The bark may be smooth or course and varies in thickness and colours.

Its fruit may be: nuts, winged fruits, pods, berries, or fleshy fruits.

http://www.geoffswoodwork.co.uk/timber%20growth.htm (3 of 5)7/28/2004 7:56:46 AM

Timber growth

Other terms

( ** I am afraid there are often contradictory explanations in some terms. UK readers especially be aware of the n.american

term of 'burl' in examinations)

Branch ~ main bough from trunk

Bole ~ The greater part of the trunk under the first branch.

Boulle (log) ~ french term for through and through cutting of the trunk and retained complete in the seasoning process

especially for matching grain. (included for interest only)

Bur(r) (burl n.americ.) ~ produced by the tree to form over early growth of twigs known as epicormic shoots. Also formed to

protect damaged timber. Provides beautiful figure prized by cabinet makers and for making veneers.

Burl ** ~ (buttress) Briar pipes are made from this material nearer the root structure. I believe North American usage

includes the description similar to burr.

Butt (butt-swell) ~ The wider part of the trunk especially close to the ground. Veneers have some 'burry' circles but is

characterised by a wild freakish pattern.

Buttress ~ On some trees the widening of the bole providing interesting grain especially for veneers. The part of the trunk or

bole as it enters the ground. Large tropical trees have 'butresses' reaching well over a metre from the ground.

Crotch ~ the forked meeting of the trunk with a branch forming interesting growth ring formation.

Trunk ~ stem ~ main part of tree ~ see bole

text and graphics © G.Malthouse ~ all rights reserved 17th April 2004

search my site:

GO

sitemap

http://www.geoffswoodwork.co.uk/timber%20growth.htm (4 of 5)7/28/2004 7:56:46 AM

Conversion of timber

Geoff's Woodwork

for Students of Woodwork

Conversion of timber (updated Apr 2004)

As soon as possible after felling the tree should be converted into usable timber.

There are two main methods of converting timber:

● Through and through (or Plain or Crown sawn) which produces tangential boards and

● Quarter Sawn which produces radial boards.

The Quarter sawn is far more expensive because of the need to double (or more) handle the log. There is also more

wastage. It is however more decorative and less prone to cup or distort. Note also there are two ways of sawing the

quarter.

Through and through produces mostly tangentially sawn timber and some quarter sawn stuff. (see diagram)

Tangential timber is the most economical to produce because of the relatively less repetitive production methods. It

is used extensively in the building industry.

There are other ways but they are all variations of tangential and radial cuts to obtain the best or most economical

boards for the use it is to be put. These basic cuts are not always able or need to be, on the exact tangent or radius of

the trunk. The cuts, that fall between, crown and quarter are called 'rift' and between 'rift' and 'quarter' are identified

as 'figured' - see below for explanation. Boxing the heart refers to eliminating the heartwood from the boards that

would otherwise produce shakes, juvenile wood or may even be rotten.

http://www.geoffswoodwork.co.uk/conversion.htm (1 of 3)7/28/2004 8:00:38 AM

Conversion of timber

Tangential boards (crown, plain or flat sawn) are

used extensively for beams and joists. They are

stronger when placed correctly edge up with the

load in the tangential axis. These type of boards

suffer from 'cupping' if not carefully converted,

seasoned, and stored properly. Annual growth

rings form an angle less than 45 degrees.

Radial boards (radial, figured or quarter sawn) are

typically cut on 'the quarter' and produce a pattern

of the medullary rays especially in quartered oak.

Such timber is expensive due to the multiple cuts

required to convert this board. The radial face of

the board is slightly stronger and stiffer than the

tangentially face but the cross section and

condition of the timber has more effect on

strength. Annual growth rings form an angle

greater than 45 degrees.

Crown sawn is obtained by sawing tangentially to

the annual rings. It is also referred to as 'Plain

Sawn' or 'through and through'.

Rift sawn is the cut which falls between crown and

true quarter sawn. It is straight grained and in oak,

does not reveal any 'silver ribbon' grain features.

Quality floor boards are prepared from rift sawn

timber because it wears well and shrinks less.

Annual growth rings form an angle between 30 and

60 degrees.

Quarter sawn boards are radial cut from the centre

http://www.geoffswoodwork.co.uk/conversion.htm (2 of 3)7/28/2004 8:00:38 AM

Conversion of timber

of the tree. It produces the distinctive silver ribbon

effect (in oak) across the whole board. Annual

growth rings form an angle greater than 45

degrees. True quartered boards producing the best

features will have the angle on or very much closer

to 90 degrees.

'Figured' - is the cut between 'rift' and 'true

quartered'. It has varying degrees of 'silver

ribbon' (in oak) showing through but not the full

figured effect found in true quarter sawn boards.

Different species have their best features enhanced

by choosing the best cut appropriate to their

species.

text and graphics © G.Malthouse ~ all rights reserved ~ 18th April 2004

search my site:

GO

sitemap

home foundation basics resources safety

key skills trade needs technology photos links

Last updated 24th April 2004

http://www.geoffswoodwork.co.uk/conversion.htm (3 of 3)7/28/2004 8:00:38 AM

seasoning

Geoff's Woodwork

for Students of Woodwork

Seasoning Timber

Seasoning is the controlled process of reducing the moisture content (MC) of the timber so that it

is suitable for the environment and intended use. We need to reduce the MC of timber for the

following reasons:

● Every time the MC reduces the timber shrinks especially tangentially.

● Consequently it will show fewer tendencies to warp, split or shake.

● Seasoned timber although lighter will be stronger and more reliable.

● The sap in timber is a food for fungi and wood parasites. Remove the sap and the wood

will be less attractive to these dangers.

● For construction grade timber the timber must be below 20% MC to reduce the chances of

Dry Rot and other fungi infestations.

● Dry well seasoned timber is stronger.

http://www.geoffswoodwork.co.uk/seasoning.htm (1 of 5)7/28/2004 8:02:56 AM

seasoning

● Dry well seasoned timber is easier to work with and consequently safer especially machine

working.

● Timber with higher moisture content is difficult to finish i.e. paint, varnish, etc.

There are two main ways of seasoning timber, Natural (Air) and Artificial (Kiln) drying. Both

methods require the timber be stacked and separated to allow the full circulation flow of air, etc.

around the stack.

Air Seasoning.

Air seasoning is the method used with the timber stacked in the open air. It requires the

following:

● Stacked stable and safely with horizontal spacing of at least 25 mm.

● Vertical spacing achieved by using timber battens (piling sticks) of the same or neutral

species. Today some timber yards are using plastics. The piling sticks should be

vertically aligned and spaced close enough to prevent bowing say 600 to 1200 mm max

centres.

● Ends of boards sealed by using a suitable sealer or cover to prevent too rapid drying out

via the end grain.

● The stack raised well clear of the ground, vegetation, etc to provide good air circulation

and free from rising damp, frost, etc.

● Over head cover from effects of direct sunlight and driving weather.

The details depend on the size, quantity and species of the timber. You cannot however expect

to obtain less than 16 - 17% mc in the UK. Further seasoning needs to be done inside, in heated

and ventilated buildings.

Kiln Seasoning.

There are two main methods used in artificial seasoning, compartmental, and progressive. Both

methods rely on the controlled environment to dry out the timber and require the following

factors:

● Forced air circulation by using large fans, blowers, etc.

● Heat of some form provided by piped steam.

● Humidity control provided by steam jets.

http://www.geoffswoodwork.co.uk/seasoning.htm (2 of 5)7/28/2004 8:02:56 AM

seasoning

The amount and duration of air, heat and humidity again depends on species, size, quantity, etc.

Schedules are published for the various species to enable operators to select an appropriate

drying environment. In the UK they are usually provided by the Kiln Manufacturers and also

published in the Handbook of Hardwoods and Handbook of Softwoods (BRE).

Compartmental.

A compartment kiln is a single enclosed container or building, etc. The timber is stacked as

described above and the whole stack is seasoned using a programme of settings until the whole

stack is reduced to the MC required.

Progressive.

A progressive kiln has the stack on trolleys that ‘progressively’ travel through chambers that

change the conditions as it travels through the varying atmospheres.

The advantage of this system, although much larger, has a continuous flow of seasoned timber

coming off line.

How to Season your own timber.

This process is for small batches and is based on a one inch thick board, for other thicknesses

and varying species you should adjust this time according to your experience and judgement. I

have made notes in italics below to help you along the way.

In the UK - generally ~ for a one-inch thick board such as oak will take about 12 months.

Beech is much faster. Further rough guides for Air drying times for fresh felled timber in

temperate areas similar to the UK:

Softwoods ~ 25 mm thick, stacked in spring reduces to about 20 % in 1 1/2 to 3 months.

Softwoods ~ 50 mm thick, stacked in spring reduces to about 20 % in 3 to 4 months.

Hardwoods ~ 25 mm thick, stacked in autumn reduces to about 20 % the following summer.

Hardwoods ~ 50 mm thick, stacked in autumn reduces to about 20 % the following autumn.

However, note that these times show reduction to only 20 %. Further outdoor exposure may

bring it down to 16 or 17 % but usually will require indoor drying to get to 12 % or less.

Extreme care and good judgement is needed to get timber down to these levels without tension

and stresses developing. Low heat, correct humidity and ventilation is what you must get right

and certainly do not try to force the pace. Read R.B. Hoadley's book, Understanding Wood for

a better guide to home seasoning.

http://www.geoffswoodwork.co.uk/seasoning.htm (3 of 5)7/28/2004 8:02:56 AM

seasoning

These are rule of thumb for temperate climates and you must make checks, record conditions and

use your judgement and make adjustments where necessary.

Take samples from centre of stack, identify, weigh and record. Note the season of the year that

you start the process and carefully note weather extremities to help you predict the duration and

effects.

After approximately 3 months for softwoods and 12 months for hardwoods – start weighing

samples (note times above) and record together with notes on the weather in the immediate past

cycle. You may well want to start weighing and recording before these times to get a better

understanding of the different species you may have in the stack.

Weigh and record every week thereafter and after three consecutive weighs showing no

difference consider the stack Air Dry for external use.

Test using the oven method to determine the %MC and whether it is fit for your use.

Re-stack the timber in-doors. Take care that the environment is not too hot and there is sufficient

ventilation. You need to control this environment and thus you need to take regular readings of

temperature and humidity of the air and % mc of timber samples.

Take samples from centre of stack, identify, weigh and record temperatures and humidity if you

have access to an hydrometer.

Continue to weigh and record every week and after three consecutive weighs showing no

difference consider the stack Air Dry for internal use.

Test using the oven method.

Continue the process until you reach the % MC you require for your particular use.

Keep your notes and they will help you to predict the seasoning process of future batches.

Test using the oven method.

Remove sample from centre of stack. Cut off a member 300 mm long. Cut off a small cube

sample approx. 25 mm long. Weigh and record. Place in a warm oven (experience must judge

- dangers of over heating is obvious) for 15 to twenty minutes or so and re-weigh and record.

Continue until there are no discernible differences between readings. You will now have a wet

weight and a dry weight. The %MC is obtained by the formulae –

Wet weight – dry weight / dry weight X 100 = %MC (this is a standard scientific formulae for

determining wood %MC - not mine !)

http://www.geoffswoodwork.co.uk/seasoning.htm (4 of 5)7/28/2004 8:02:56 AM

seasoning

A moisture meter is very handy but not quite so accurate as the oven method. Why not test your

sample using the oven method and then see how much you can trust your meter?

Top

more information at 'Conversation on seasoning' - (timber, boards, sticks and PEG)

text and graphics © G.Malthouse ~ all rights reserved

search my site:

GO

sitemap

home foundation basics resources safety

key skills trade needs technology photos links

Last uploaded 12th December 2003

http://www.geoffswoodwork.co.uk/seasoning.htm (5 of 5)7/28/2004 8:02:56 AM

Shrinkage

Geoffs Woodwork

for Students of Woodwork

Timber defects

Shrinkage

When timber is seasoning and it's moisture content (MC) is reduced below the Fibre Saturated Point (FSP)

continued drying will cause dramatic change such as increase in strength but also distortion and shrinkage.

Shrinkage is the greatest tangentially over the radial direction with little loss along the length of the board, etc.

Cupping

Because of this varying

shrinkage rates tangential

boards tend to cup because

of the geometry of the

annual rings shown on the

end grain. It can be seen

that some rings are much

longer than the others close

to the heart. Therefore they

will be more shrinkage at

these parts than the others ~

cupping is the result.

In square section timber cut

from the same place,

diamonding is the result.

http://www.geoffswoodwork.co.uk/shrinkage.htm (1 of 5)7/28/2004 8:05:12 AM

Shrinkage

Knots

Knots are the result of the

trees attempt to make

branches in the early growth

of the tree. They are the

residue of a small twig,

shoot, etc. that died or was

broken off by man or an

animal in the wood or

forest. The tree

subsequently continued its

growth over this wood.

The knot may be live,

sound, or tight or if it has

become separated and is

contained in residue of bark,

dead.

Dead knots become loose

and downgrade the

appearance and stability of

the board. Most grading

systems uses the amount of

knot area as an indication of

its quality. The more knots

the less the quality.

Dead loose knots are

extremely dangerous to

machinists. The cutters may

pick these up and eject them

rapidly towards the operator.

Splits

A separation of the wood

fibres along the grain

forming a fissure that

extends through the board

from one side to the other.

It is usual in end grain and is

remedied by cutting away

the defected area. All

boards should have an

allowance so that some end

grain may be cut away

because of possible shakes

or splits.

http://www.geoffswoodwork.co.uk/shrinkage.htm (2 of 5)7/28/2004 8:05:12 AM

Shrinkage

Checks and end

checking

A separation of the fibres

along the grain forming a

fissure which shows up on

one face or at the end grain

but does not continue

through to the other side.

Wind or twisting

Spiral or corkscrew

distortion in a longitudal

direction of the board.

Due to the board being cut

close to the centre of the tree

which has spiral grain.

The board is of not much use

but small cuttings may be

obtained from it with careful

selection.

Bow

Bowing is concave/convex

distortion along the length of

the board.

It is a seasoning and or

storage defect caused by the

failure to support the board

with stickers at sufficient

intervals. The boards own

weight and probably those

above it bears down and the

resultant bow is inevitable.

This defect can and should

be avoided by careful use of

stickers supporting the board

at the correct width.

http://www.geoffswoodwork.co.uk/shrinkage.htm (3 of 5)7/28/2004 8:05:12 AM

Shrinkage

Spring

Spring is concave/convex

distortion along the length of

the board again but this time

the distortion is in the flat

plane of the board.

Boards with this defect may

have been cut from near the

heart of the board and is the

result of growth stresses

being released on conversion.

Useable timber may be

recovered from these boards

by cutting a straight edge

and re sawing. The grain

direction however may not

be satisfactory for aesthetics

and care should be taken for

placing the possible short

grain figure where stability

is required.

Shakes

Shakes are separation of the

fibres along the grain

developed in the standing

tree, in felling or in

seasoning. They are caused

by the development of high

internal stresses probably

caused by the maturity of

the tree.

The shake is the result of

stress relief and in the first

place results in a single

longitudal crack from the

heart and through the

diameter of the tree.

As the stress increases a

second relief crack takes

form at right angles to the

first and is shown as a

double heart shake.

Further cracks are known as

star shakes and show the

familiar pattern shown.

Ring or partial cup shakes in

the form of longitudal

tangential cracks occur as a

result of high radial

tension. It is often said that

http://www.geoffswoodwork.co.uk/shrinkage.htm (4 of 5)7/28/2004 8:05:12 AM

Shrinkage

it is caused by an early frost

freezing the rising sap or

perhaps a heavy felling on

hard ground.

External radial cracks are

caused by the tree laying too

long before it is converted

and seasoned.

top

reference sources: H.E. Desch & J.M. Dinwoodie ~ Timber text and graphics © G.Malthouse ~ all rights reserved

search my site:

GO

sitemap

home foundation basics resources safety

key skills trade needs technology photos links

Last uploaded 21st April 2003

http://www.geoffswoodwork.co.uk/shrinkage.htm (5 of 5)7/28/2004 8:05:12 AM

You might also like

- Key - Friends Global 11Document73 pagesKey - Friends Global 11linhbttNo ratings yet

- (Barash) Clinical Anesthesia (6th Ed.)Document3,968 pages(Barash) Clinical Anesthesia (6th Ed.)menocide_ss67% (3)

- A Treatise On Stairbuilding and HandrailDocument431 pagesA Treatise On Stairbuilding and HandrailChris ReddersenNo ratings yet

- Glossary of Woodworking Hand ToolsDocument25 pagesGlossary of Woodworking Hand ToolsBojanNo ratings yet

- The Solution at Hand - Excerpt - Robert Wearing's Best Carpentry DevicesDocument36 pagesThe Solution at Hand - Excerpt - Robert Wearing's Best Carpentry DevicesChris SpragueNo ratings yet

- Weaving Loom Parts Catalogue Somet Rapier SpareDocument106 pagesWeaving Loom Parts Catalogue Somet Rapier Sparealper güzel100% (1)

- Burns and NutritionDocument30 pagesBurns and NutritionKAUSHAL ARYA100% (4)

- Preparation No 1Document9 pagesPreparation No 1Jessa Mae Jamito EncinasNo ratings yet

- Air Drying of Lumber: Forest ServiceDocument66 pagesAir Drying of Lumber: Forest Servicejing ledesmaNo ratings yet

- Wood Veneer: Log Selection, Cutting, and DryingDocument148 pagesWood Veneer: Log Selection, Cutting, and DryingStan MacapiliNo ratings yet

- Basic Wood JointsDocument2 pagesBasic Wood JointsJonathan Delos SantosNo ratings yet

- Wood Book SampleDocument31 pagesWood Book SampleStefan Neagu100% (1)

- Book Data Fats That Heal Fats That KillDocument5 pagesBook Data Fats That Heal Fats That Killnandoperu33% (3)

- 100 Quotes From The Movie "The Secret"Document17 pages100 Quotes From The Movie "The Secret"Elmer GatchalianNo ratings yet

- Medicinal Uses of Mushroom: Amit PrasadDocument11 pagesMedicinal Uses of Mushroom: Amit PrasadAmit PrasadNo ratings yet

- Wooden (Disambiguation) Heartwood (Disambiguation) Woodland Commodity Lumber Wood (Disambiguation)Document19 pagesWooden (Disambiguation) Heartwood (Disambiguation) Woodland Commodity Lumber Wood (Disambiguation)Ashutosh OjhaNo ratings yet

- Natural DefectsDocument8 pagesNatural Defectswan8789100% (1)

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.From EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.No ratings yet

- A Beginner's Guide to the Art of Woodcarving - Follow the Step by Step Instructions and Images to Produce Your First Piece of WoodcarvingFrom EverandA Beginner's Guide to the Art of Woodcarving - Follow the Step by Step Instructions and Images to Produce Your First Piece of WoodcarvingNo ratings yet

- Salt Damage To Wood: "Fuzzy Wood" Often Confused With Fungal DecayDocument2 pagesSalt Damage To Wood: "Fuzzy Wood" Often Confused With Fungal DecayGunner92No ratings yet

- Wood AnatomyDocument16 pagesWood AnatomyDennis GilberoNo ratings yet

- Wood AnatomyDocument73 pagesWood AnatomyJay_ntNo ratings yet

- The Wood-Mizer Way: Issue 89Document32 pagesThe Wood-Mizer Way: Issue 89jmooney3381100% (3)

- Woodwork Joints PDFDocument173 pagesWoodwork Joints PDFRobert Guerra RiveraNo ratings yet

- Timber 01Document16 pagesTimber 01Kasun DulanjanaNo ratings yet

- Wood Defects' Knots, Spiral Grain, Juvenile Wood and Reaction WoodDocument24 pagesWood Defects' Knots, Spiral Grain, Juvenile Wood and Reaction WoodssamisNo ratings yet

- Table of Wood DensityDocument9 pagesTable of Wood DensityAri WahyuNo ratings yet

- 6 Conversion of TimberDocument8 pages6 Conversion of TimberKara Brown100% (1)

- Wood DefectsDocument7 pagesWood DefectsSonalika PatiNo ratings yet

- Topic 2 - TimberDocument72 pagesTopic 2 - TimberDuke100% (1)

- Moisture Relations and Physical Properties of Wood - US - DoEDocument20 pagesMoisture Relations and Physical Properties of Wood - US - DoEPeter KimbelNo ratings yet

- Wood Cells and The Meaning of Grain: Differences in Structure in The Cross-Section of The TreeDocument9 pagesWood Cells and The Meaning of Grain: Differences in Structure in The Cross-Section of The TreeJuan RiveraNo ratings yet

- Hand PlanesDocument3 pagesHand PlanesDavid DonaldsonNo ratings yet

- Wood Drying PDFDocument13 pagesWood Drying PDFJahangir MiltonNo ratings yet

- Wood TypesDocument20 pagesWood TypesjaironoeNo ratings yet

- Week 2 - Making A Lap Joint and Dovetail Lap JointDocument6 pagesWeek 2 - Making A Lap Joint and Dovetail Lap JointAndy Joseph StotenNo ratings yet

- Wood AdhesivesDocument238 pagesWood Adhesiveslcfong88No ratings yet

- Carpentry ShopDocument12 pagesCarpentry ShopNikhil Patel100% (1)

- Wood DecayDocument5 pagesWood DecayArchanna Vyass100% (1)

- Wood Joints PDFDocument9 pagesWood Joints PDFGlennNo ratings yet

- TIMBER DEFECT SiapDocument18 pagesTIMBER DEFECT Siapndali_2No ratings yet

- (Woodworking Plans) Woodsmith Magazine Oak BookcaseDocument8 pages(Woodworking Plans) Woodsmith Magazine Oak Bookcasejaime100% (1)

- Dry Kiln Operator's Manual: Forest Service Forest Products Laboratory Madison, Wisconsin Agriculture Handbook No. 188Document273 pagesDry Kiln Operator's Manual: Forest Service Forest Products Laboratory Madison, Wisconsin Agriculture Handbook No. 188Diego Calero100% (1)

- Basics of Furniture and Hardware 1Document19 pagesBasics of Furniture and Hardware 1Mansi ShawNo ratings yet

- Carpentry Joints (Woodwork)Document16 pagesCarpentry Joints (Woodwork)KadambiniNo ratings yet

- Wood Joint Strength TestingDocument11 pagesWood Joint Strength TestingNelson TacyNo ratings yet

- Fifty Lessons in Wood Working - 1892Document120 pagesFifty Lessons in Wood Working - 1892workshopcarpintaria100% (3)

- Workshop I Lab ManualDocument26 pagesWorkshop I Lab ManualdibyenindusNo ratings yet

- Woodworking Crafts April 2018Document92 pagesWoodworking Crafts April 2018a silva100% (1)

- Buying Wood: All AboutDocument4 pagesBuying Wood: All AboutsossieNo ratings yet

- Properties of TimberDocument44 pagesProperties of TimberMary Joy RuilesNo ratings yet

- Wood Joint Work Part 4Document2 pagesWood Joint Work Part 4Lo M'hNo ratings yet

- Cutting A Bridle JointDocument6 pagesCutting A Bridle JointMario BerronesNo ratings yet

- Carpentry Final OutputDocument15 pagesCarpentry Final OutputGabriel RamosNo ratings yet

- WoodTypes PDFDocument20 pagesWoodTypes PDFCarolFerrão100% (1)

- CARP02 Building Materials and Hand ToolsDocument88 pagesCARP02 Building Materials and Hand ToolsMark Lloyd-JonesNo ratings yet

- How Wood DriesDocument51 pagesHow Wood DriesnamkvalNo ratings yet

- Forest Ecology and Management: Contents Lists Available atDocument10 pagesForest Ecology and Management: Contents Lists Available atAlex OliveiraNo ratings yet

- Woodwork JointsDocument5 pagesWoodwork JointsAbdul Sukur Kamsir100% (3)

- WoodworkDocument10 pagesWoodworkMr DamphaNo ratings yet

- Cost Sheet HardDocument14 pagesCost Sheet HardkrishasweetyNo ratings yet

- Workshop Assignment: By: Sneha Motghare Div: B Roll No:26 Batch:2 Taught By: Vilas SirDocument15 pagesWorkshop Assignment: By: Sneha Motghare Div: B Roll No:26 Batch:2 Taught By: Vilas SirVinay MotghareNo ratings yet

- Specification & Construction of Custom Stile & Rail Doors: A Division of Amherst Woodworking & Supply, IncDocument31 pagesSpecification & Construction of Custom Stile & Rail Doors: A Division of Amherst Woodworking & Supply, Incrcmmaz100% (1)

- Unit 3Document58 pagesUnit 3Yoghi KalamNo ratings yet

- How To Make A Trestle PonyDocument4 pagesHow To Make A Trestle Ponymondomondo100% (1)

- Elementary WoodworkingDocument152 pagesElementary WoodworkingArtisan Ideas100% (6)

- Carpentry & Joinery by Frederick C. WebberDocument376 pagesCarpentry & Joinery by Frederick C. WebberBlakdawg15100% (1)

- Catalogo PD05A RDocument2 pagesCatalogo PD05A RJorge FerreiraNo ratings yet

- Antimalarial DrugsDocument49 pagesAntimalarial DrugsMalueth Angui50% (2)

- SomewhereinBangkokThaiRestaurantofAvon256 Payee'sDocument4 pagesSomewhereinBangkokThaiRestaurantofAvon256 Payee'sChanya SiboribounNo ratings yet

- Pump Test BrochureDocument12 pagesPump Test BrochureRiki MandolNo ratings yet

- 5 Viscosity PDFDocument8 pages5 Viscosity PDFDENY MOL BENNYNo ratings yet

- Epas 10 Lecture Maintain and Repair Flat IronDocument2 pagesEpas 10 Lecture Maintain and Repair Flat IronRap PerezNo ratings yet

- 2-7 - May 25 - McIver - Phase Shifter Principles PDFDocument38 pages2-7 - May 25 - McIver - Phase Shifter Principles PDFCriselvine S Dela CruzNo ratings yet

- Proceedings FinalDocument31 pagesProceedings FinalPalaniVelRajanNo ratings yet

- Classism Reflective Essay 22.editedDocument4 pagesClassism Reflective Essay 22.editedjohn wanjiruNo ratings yet

- Information AgeDocument11 pagesInformation AgeTrisha FontanillaNo ratings yet

- User Manual NapoliDocument44 pagesUser Manual NapoliAhmed saNo ratings yet

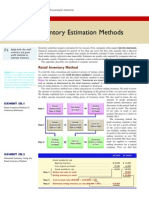

- Inventory EstimationDocument4 pagesInventory EstimationShy Ng0% (1)

- Oraciones para El PictionaryDocument1 pageOraciones para El PictionaryElvisBryanHerreraMartinezNo ratings yet

- Opd - Scan Ii PDFDocument6 pagesOpd - Scan Ii PDFDfhos Oftalmo ServiceNo ratings yet

- Fischer Connectors Core SeriesDocument206 pagesFischer Connectors Core SeriesAbhijeet KibeNo ratings yet

- DM No. 176 S. 2020 Alignment To Child Protection Policy To The New Normal Et. AlDocument6 pagesDM No. 176 S. 2020 Alignment To Child Protection Policy To The New Normal Et. AlAnj De GuzmanNo ratings yet

- 3 ActivitiesDocument42 pages3 ActivitiesM usmanNo ratings yet

- U5 Word List'Document6 pagesU5 Word List'Đào Trần Nhật AnhNo ratings yet

- Rosen 48V 200AH LiFePo4 Battery-PowerwallDocument5 pagesRosen 48V 200AH LiFePo4 Battery-Powerwallgihan_maNo ratings yet

- Module 1 Understanding Culture Society and PoliticsDocument41 pagesModule 1 Understanding Culture Society and Politicsbldryn lnNo ratings yet

- Power Devices: Selection Guide 2009Document80 pagesPower Devices: Selection Guide 2009DoDuyBacNo ratings yet

- LNG 3 3 e 11 150dpi NB19 15617Document24 pagesLNG 3 3 e 11 150dpi NB19 15617Pawan ChaturvediNo ratings yet

- Soya Bean FiberDocument12 pagesSoya Bean FiberAnonymous wA6NGuyklDNo ratings yet