IR Compressor

IR Compressor

Uploaded by

Tariq AmirCopyright:

Available Formats

IR Compressor

IR Compressor

Uploaded by

Tariq AmirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

IR Compressor

IR Compressor

Uploaded by

Tariq AmirCopyright:

Available Formats

4/30/2009

NHP-1500WCU Portable Oil-Free Compressor

Service Training

DANNY POELMANS Product Service Manager Portable Compressors & Tools

NHP-1500WCU Portable Oil-Free Compressor

4/30/2009

Training Contents

Basic Component Layout Main Components Intellisys Controller Safety Labels Operation Components Electronic Control Sys. Troubleshooting using special tools Displays & Menus Unit Shutdowns and Alarms Warranty

MACHINE LAYOUT

4/30/2009

Machine Layout

Air In

Air In

Air In

Exhaust Through Ro oof

RAD

Fuel Top Hyd. Middle A/E Oil Bottom

Compressor

Diesel Engine

I/C Top A/C Bottom

CAC

Air In Air In

Machine Layout

Sealed Base 2270 Liters

4/30/2009

Machine Layout

Airflow Airflow

AIREND

ENGINE

Airflow

Airflow

Airflow

AIRFLOW~ 820m/min, ~29,000 cfm

MAIN COMPONENTS

4/30/2009

Main Components Cummins QSX15

600 HP @ 1800 RPM Full Load Speed 1200 RPM No Load Speed EPA Tier 3 and EEC Stage 3 emissions certified EFC and 15% hp margin for continuous duty operation

Main Components Cummins QSX15

4/30/2009

Main Components Cummins QSX15

Main Components Cummins QSX15

4/30/2009

Main Components Cummins QSX15

Main Components Cummins QSX15

4/30/2009

Main Components Cummins QSX15

Main Components Oil-Free Compressor

Working pressure range between 4.1 and 10.7 bar. Outlet air temp is A+11C

4/30/2009

Main Components Oil-Free Compressor

HELICAL ROTARY SCREW SPECIAL MICRO COATING FOR PROTECTION FROM CORROSION AGMA 12 DRIVEN AND TIMING GEARS FOUR ROLLER BEARINGS AND TWO 4 POINT AIRCRAFT TYPE THRUST BEARINGS STAINLESS STEEL AIR SEALS VENTED TO ATMOSPHERE BRASS SPIRAL TYPE LABYRINTH SEALS FOR BEARING LUBRICATING OIL METRIC FASTENERS

Main Components Oil-Free Compressor

Two-Stage A/E Highly efficient shaft sealing UltraCoat rotor and housing protection Stainless Steel high-pressure rotors

4/30/2009

Main Components Oil-Free Compressor

Synchro gears

Labyrinth bearing seals

Main Components INTELLISYS Controller

Total Control at Your Fingertips Easy Operation Adjustable Operating Parameters Time-Saving Diagnostics Comprehensive Data Display

10

4/30/2009

Main Components INTELLISYS Controller

INTELLISYS Controller is the heart of the NHP 1500 machine monitor and control system. It provides data collection, alarming and control functions for compressor operations operations. It is an Intel micro-controller based unit with analog and digital inputs and outputs.

Main Components INTELLISYS Controller - Functions

First function of INTELLISYS is to scan all analog and digital inputs at a given time interval. The inputs are scanned every 100 milliseconds. The values are then compared against min. and max. values and an ALERT or SHUTDOWN is issued. d l d i i d Second function to monitor discharge press., and varies engine speed to maintain air press. at desired setpoint. Third function to retrieve diagnostic info from the engine.

11

4/30/2009

SAFETY

SAFETY This machine should not be used:

For direct or indirect human consumption of the compressed air. Outside the ambient temperature range -20F to 115F. (-20F ( 20F will need cold weather options) options). When an actual or foreseeable risk of hazardous levels of flammable gases or vapors exists. With guards, or controls or switches missing or disabled. For storage or transportation of materials inside or on the enclosure.

12

4/30/2009

SAFETY- Labels

COMPRESSOR OPERATION

13

4/30/2009

Compressor Operation

ATMOSPHERIC AIR IS DRAWN IN FROM THE RIGHT END OF THE CABINET VIA INTERNAL SOUND ATTENUATING DUCTING. WHEN THE INLET CONTROL BUTTERFLY VALVE IS OPEN THE AIR ENTERS THE 1st STAGE AIREND WHERE IT IS COMPRESSED TO 26 TO 31 PSIG. THE AIR DISCHARGES THE AIREND VIA A VENTURI USED TO DISSIPATE PRESSURE PULSATION. FROM THE VENTURI THE AIR MOVES THROUGH A STAINLESS STEEL FLEXIBLE SECTION AND ENTERS THE INTERCOOLER WHERE THE AIR IS COOLED TO 20 ABOVE AMBIENT TEMPERATURE. THE AIR EXITS THE INTERCOOLER AND PROCEEDS THROUGH STAINLESS STEEL PIPING TO A MOISTURE SEPARATOR ( WHICH INTERNALS ARE EPOXY COATED) WHERE CONDENSATE IS REMOVED BEFORE PROCEEDING TO THE 2nd STAGE AIREND. THE AIR EXITS THE 2nd STAGE AIREND DIRECTLY INTO A SILENCER BOTTLE AFTER WHICH BOTTLE, IT FLOWS INTO THE AFTERCOOLER. THE AIR TEMPERATURE IS LOWERED TO WITHIN 20F OF THE AMBIENT AIR TEMPERATURE BEFORE EXITING THROUGH A STAINLESS STEEL PIPE, INTO A CHECK VALVE AND THEN INTO A MOISTURE SEPARATOR . ANY MOISTURE THAT HAS CONDENSED DUE TO THE LOWERING OF THE TEMPERATURE IS REMOVED IN THE SEPARATOR AND THEN THE AIR FLOWS TO THE CUSTOMER SYSTEMS.

Compressor Operation

Hypothetical compression cycle 32oC, 65% Relative Humidity, 1 bar Dirt Water Air

14

4/30/2009

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters Butterfly unloader - Hydraulic control

15

4/30/2009

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters Butterfly unloader Compression (STAGE 1)

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters Butterfly unloader Compression (STAGE 1) 1st stage discharge : 185oC, 100% RH, 3.5 bar

16

4/30/2009

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters y Butterfly unloader Compression (STAGE 1) 1st stage discharge : 185oC, 100% RH, 3.5 bar Venturi

v1 v2

u1

u2

v1

v2

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters y Butterfly unloader Compression (STAGE 1) 1st stage discharge : 185oC, 100% RH, 3.5 bar Venturi Intercooler

17

4/30/2009

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters y Butterfly unloader Compression (STAGE 1) 1st stage discharge : 185oC, 100% RH, 3.5 bar Venturi Intercooler Water separator

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters y Butterfly unloader Compression (STAGE 1) 1st stage discharge : 185oC, 100% RH, 3.5 bar Venturi Intercooler Water separator 2nd stage inlet : 44oC, 100% RH,3.5 bar

18

4/30/2009

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar Filters Butterfly unloader Compression (STAGE 1) 1st stage discharge : 185oC, 100% RH, 3.5 bar Venturi Intercooler 2nd stage inlet : 44oC, 100% RH,3.5 bar Compression (STAGE 2) 2nd stage discharge 185oC, 100% RH, 10.3 bar

Compressor Operation

Ambient air / Inlet air : 32C, 65% RH, 1 bar 2nd stage discharge : , , 185oC, 100% RH, 10.3 bar Venturi

19

4/30/2009

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar (abs vol = 42.5m/min) 2nd stage discharge : 185oC 100% RH 10 3 bar C, RH, 10.3 Venturi Aftercooler

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar (abs vol = 42.5m/min) 2nd stage discharge : 185oC 100% RH 10 3 bar C, RH, 10.3 Venturi Aftercooler Water separator

20

4/30/2009

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar (abs vol = 42.5m/min) 2nd stage discharge : 185oC 100% RH 10 3 bar C, RH, 10.3 Venturi Aftercooler Water separator Discharge

Compressor Operation

Ambient air / Inlet air : 32oC, 65% RH, 1 bar (abs vol = 42.5m/min) 2nd stage discharge : 185oC 100% RH 10 3 bar C, RH, 10.3 Venturi Aftercooler Water separator Discharge air : 43oC, 100% RH, 10.3 bar, (abs vol ~7.3m/min) CTD = C ld T Cold Temperature Diff t Difference or temperature above t t b ambient = 43oC - 32oC = 11oC

21

4/30/2009

Compressor Operation

Condensate burn-off, not

Mass of water precipitated @ 42.5m/min = 44.6 kg / hour = 1080 kg / day

GENERAL OPERATION

22

4/30/2009

General Operation - Transport

Compact design & 3 handling methods

Beaver tail

Flat bed

Hoisted by crane Towed Fork lifted

Long distance: 20ft Container

General Operation - Installation

Installation Example:

Manifold for multiple units or pressure sensor

Compressed air

Check valve

Dryer

Installation

23

4/30/2009

General Operation - Installation

This will limit turbulence and restriction in the airline thereby improving airflow.

Check and isolation valves in vital locations can help when the need arises to move part of the installation.

General Operation

Place unit in an open, well ventilated area. Position as level as possible, max. 5 degree out-of-level operation.

24

4/30/2009

General Operation - Fork Tubes

Place Drawbar in vertical stowing position. Size Fork Truck lifting capacity per gross weight of machine.

General Operation - Wheel Chocks

Located inside of front door. Secure unit with chocks before disconnecting drawbar from tow vehicle.

25

4/30/2009

General Operation - Fuel Tanks

Unit has on-board fuel tanks with a capacity of 300 gallons which provides 10-11 hours of full load operation. To minimize condensation re-fill the tank at the end of each day

General Operation - Compressor Oil Level

The proper oil level is labeled on the sump dipstick. The oil level is most consistent when checked NOT running.

26

4/30/2009

General Operation - Hydraulic Oil Level

The proper oil level is mid-way on the sight gauge. Check the oil level when the unit is warm and not running. Use IR Hydraulic Oil P/N 54758321- 5 gal. 54758339- 55 gal. 54758347- 275 gal.

General Operation - Controls & Instruments

Message Display Menu Selection Start Button U o d u o Unload Button Power On-Off Switch

Lamp & Switch Scroll Buttons Load Button Stop Button Either Inject Hour Meter

27

4/30/2009

General Operation - Controls & Instruments 4. Start 5. Load

1. ON

3. Etherstart

General Operation - Controls & Instruments

Manual operation: Starting the machine

Ingersoll -Rand

INTELLISYS

1) Switch Power to On

28

4/30/2009

General Operation - Controls & Instruments

2) Press the Start button

General Operation - Controls & Instruments

..10 seconds.

29

4/30/2009

General Operation - Controls & Instruments

3) Engine cranks and starts 4) Engine reaches idle speed

1200 rpm

General Operation - Controls & Instruments

5) Engine warms up. (Machine can go on load only once engine jacket temperature reaches 40oC)

1200 rpm pressure

6) Pressure adjustment / setting through scroll bar and menus

O O

30

4/30/2009

General Operation - Controls & Instruments

5) Machine up to temperature. Press load button

1200 rpm 40oC

General Operation - Controls & Instruments

6) Machine goes on load, revs climb

1800 rpm Pressure

O O

31

4/30/2009

General Operation - Controls & Instruments

7) Machine is operational. Settings can be changed if required.

1800 rpm Pressure

General Operation - Controls & Instruments

8) Take the machine off-load

O O

32

4/30/2009

General Operation - Controls & Instruments

9) Switch off the machine. Wait 3 minutes

119 s

General Operation - Controls & Instruments

Shut down

Ingersoll -Rand

INTELLISYS

10) Switch Power to Off

33

4/30/2009

General Operation Start Sequence

1. 2. 3. 4. Flip the Power button to the ON position. Display will alluminate. Check E stops and open the air outlet valve. In cold weather conditions press the Etherstart button twice. Press the Start button if a condition exists which would prevent a normal start sequence then the engine will not run and the failure will be displayed on the controller. Audible alarm will sound for 10 seconds. Unit will go through the warmup fase. After warmup fase Load button can be pushed.

5. 6.

General Operation - Emergency Stop Button

Press this button to immediately stop unit. Use this button ONLY during emergency conditions. The g y Stop button should be used for normal stops. Engine damage could occur Another Emergency Stop is located on the drawbar end of unit.

34

4/30/2009

General Operation - Service Valve

Open Service Valve before starting.

General Operation - Stopping The Unit

Press STOP button. The compressor will unload and engine speed will go to idle. A three minute cool down will begin. When the cool down is complete the engine will stop complete, stop. Switch the POWER switch to OFF.

35

4/30/2009

COMPONENTS

COMPONENTS - Cummins QSX-15

Engine speed varies between 1200 and 1800 RPM while compressor is loaded to match the required volume flow. Full flow at set point press. @ 1200 RPM is approx. 1000 CFM. Full flow at set point press. @ 1800 RPM is 1500 CFM

36

4/30/2009

COMPONENTS Heat Exchangers

Condensate burn-off

Stage 2

QSX - 15

Stage 1

Unloader

Air - Air : Air Intercooler Air - Air : Aftercooler Wtr - Air : Engine radiator

Oil - Air : Airend oil cooler Air - Air : Engine charge air cooler Oil - Air : Hydraulic oil Fuel - Air : Diesel return cooler

COMPONENTS Coolant System

Engine Charge Air Cooler

Clogged cooler will lead to engine high temp shutdown Clean from roof side

Exhaust

37

4/30/2009

COMPONENTS Coolant System Conditioner

Engine Coolant Conditioner Filter

Replace every coolant interval Switch valve to OFF position Replace filter Switch valve to ON position

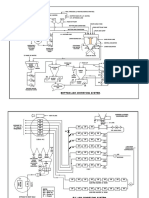

COMPONENTS Air System

2nd MS

1st MS Safety Valve

After Cooler

Inter Cooler Inlet Valve

Air End

Engine

Check Valve

38

4/30/2009

COMPONENTS - Air System Unloaded

COMPONENTS Air System Loaded

39

4/30/2009

COMPONENTS - Inlet Butterfly - Blowdown Valve

Adjustable unit Can be rebuilt

COMPONENTS - Inlet Butterfly - Blowdown Valve

Compressor inlet butterfly valve and blowdown valve are controlled by a solenoid which directs oil to a cylinder by the y y Intellisys Controller. The compressor is either loaded (inlet valve fully open/BDV fully closed) or unloaded ( inlet valve fully closed/BDV fully open.)

40

4/30/2009

COMPONENTS Pulsation Dampers

On first and second stage outlet dampers have been placed to even out the p pulsations after air compression.

COMPONENTS - Inter-Cooler

Cools to Ambient Temp. plus 12 degrees C

41

4/30/2009

COMPONENTS - After-Cooler

Ambient Temp. plus 11degrees C Stainless Steel to protect the quality of air

COMPONENTS - Moisture Separator

First Stage Moisture Separator Solenoid drain valve located on bottom of the separator Moisture bleed-off to engine exhaust

42

4/30/2009

COMPONENTS - Moisture Separator

Second Stage Moisture Separator

Valve &Condensate Solenoid Orifice

Solenoid is normally open Only closes on machine start up

COMPONENTS - Check Valve

This valve will prevent backflow of plant air into the airend when the machine is idling or shutdown g

43

4/30/2009

COMPONENTS - Safety Valve

Valve setting 165 PSI Located on 2nd stage Inlet

COMPONENTS Lube Oil System

OIL FLOW SYSTEM THE PURPOSE OF THE OIL SYSTEM IS TO SUPPLY LUBRICATION TO THE BEARINGS IN THE AIREND AND FOR HOUSING COOLING ON THE 2nd STAGE AIREND. THE OIL IS DRAWN THROUGH A STRAINER, USED TO FILTER OUT LARGE CONTAMINANTS AND THEN THROUGH A SUCTION TUBE WHICH CONNECTS TO THE OIL PUMP. THE OIL PROCEEDS TO THE SUCTION PORT ON THE OIL PUMP AND IS THEN ELEVATED IN PRESSURE TO APPROXIMATELY 40 - 45PSIG. THERE IS A PRESSURE RELIEF VALVE ON THE PUMP DISCHARGE PIPING WHICH IS USED TO ADJUST SYSTEM OIL PRESSURE THE OIL IS DISCHARGED TO THE OIL COOLER WHERE THE OIL IS COOLED TO APPROXIMATELY 130 - 140F. A THERMALLY CONTROLLED MIXING VALVE IS LOCATED ON THE COOLER OUTLET. THIS VALVE MIXES HOT OIL, (WHICH BYPASSES THE COOLER) AND COOL OIL FROM THE OIL COOLER TO MAINTAIN THE OPTIMUM OIL TEMPERATURE. (APPROX. 130 - 140F). THE OIL LEAVES THE THERMAL MIXING VALVE AND PROCEEDS THROUGH A 10 MICRON OIL FILTER AND THEN IS DIVERTED TO MULTIPLE OIL FEED POINTS ON THE TWO AIRENDS. THE OIL PRESSURE IS CONTROLLED BY THE USE OF AN ORIFICE, SIZED BY THE FACTORY, LOCATED IN THE OIL OUT PIPING ON THE 2nd STAGE AIREND HOUSING. THE OIL THAT HAS BEEN FEED TO THE BEARINGS IS DRAINED FROM THE AIRENDS VIA OVERSIZED DRAIN PORTS LOCATED ON THE BOTTOM SIDE OF THE AIRENDS. PRESSURIZED OIL IS ALSO SUPPLIED TO THE 1SV SOLENOID FOR OPERATING THE CONTROL VALVE HYDRAULIC CYLINDER USED TO LOAD AND UNLOAD THE UNIT.

44

4/30/2009

COMPONENTS Lube Oil System

COMPONENTS Lube Oil System

45

4/30/2009

COMPONENTS Compressor Oil Sump

Compressor Lubricate 25 gallons capacity Must be changed at 6 months or 1000 hrs of operation hrs. Use IR Hydraulic Oil P/N 54758321- 5 gal. 54758339- 55 gal. 54758347- 275 gal.

COMPONENTS Gear Case Breather

Clean breather every 2000 hours or 12 months of operation

46

4/30/2009

COMPONENTS Air End Oil Pump

PUMPS OIL UNDER PRESSURE TO ALL BEARINGS AND OIL FOR COOLING TO 2nd STAGE JACKET POSITIVE DISPLACEMENT GEAR TYPE. DRIVEN BY OLDHAM COUPLING ON BULL GEAR SHAFT

COMPONENTS Pressure Relief Valve

Valve Setting is 42-44 PSI at 1800 RPM Loaded

PREVENTS OIL SYSTEM FROM BEING OVER PRESSURIZED FACTORY SET AT 42 PSIG NORMAL OIL PRESSURE 40 - 45 PSIG (oil temp > 120 F - 49C) 120F 49 C)

47

4/30/2009

COMPONENTS Compressor Oil Filter

Spin-on filter element Has a internal bypass valve (opens @ 25psi) Filter must be changed at 6 months or 1000 hrs. of operation

COMPONENTS Oil Temp Control Valve

By-Pass Cooler to reach operating temp. at start-up Thermostat opens @ 135F 57 C 57C

48

4/30/2009

COMPONENTS Compressor Oil Cooler

LAT= 115 Degrees

COMPONENTS Engine Oil Replenishment

Eliminates the need for daily shutdown to check engine oil level. Tank holds 10 gal of engine gal. oil and the level should be visible in sight tube. This does not extend the engine oil change interval.

49

4/30/2009

COMPONENTS Hydraulic Fan System

COMPONENTS Hydraulic Oil Filter

Filter must be changed at 6 months or 1000 hrs. of operation Spin-on filter element Spin on Has a internal bypass valve (opens @ 25psi 1.7bar)

50

4/30/2009

COMPONENTS Hydraulic Sump Tank

Hydraulic oil capacity 27 gallons Must be changed at 6 months or 1000 hrs of operation hrs. Use IR Hydraulic Oil P/N 54758321- 5 gal. 54758339- 55 gal. 54758347- 275 gal.

COMPONENTS Hydraulic Oil Manifold

Hydraulic Press. Gauge (2250 PSI @ 1800 RPM Loaded 1150-1250 PSI @ 1200 RPM 1150 1250 Unloaded

51

4/30/2009

COMPONENTS Hydraulic Pump

Pump is driven off the engine flywheel

COMPONENTS Fan Motor

Fan Speed @ 1200 RPM Unloaded=1050-1150 RPM Fan Speed @ 1800 RPM Loaded 1630 1644 Loaded=1630-1644 RPM Grease fitting on top should be serviced each oil change

52

4/30/2009

COMPONENTS Hydraulic Cooler

LAT= 130 F 54C

COMPONENTS Fuel System

53

4/30/2009

COMPONENTS Fuel/Water Separator Filter

Drain the water from filters daily. These filter elements should be changed every 500 hrs or hrs. 3 months service.

Check for water

Change over valve one filter can be isolated to service with machine running

COMPONENTS Fuel Pump

Primary machine fuel feed pump

54

4/30/2009

COMPONENTS Fuel Cooler

Cools the fuel before return to fueltank

COMPONENTS Remote Fueling Connection

One 3/4 Female Connector(Supply) One 3/4 Male Connector (Return)

55

4/30/2009

COMPONENTS 3 Way Valve

Lever Handle in the horizontal(down) position allows for Remote Fueling

COMPONENTS Condensate System

56

4/30/2009

COMPONENTS Condensate Burn-Off System

Collects all the water from the after-cooler water separator and injects it into the engine exhaust where it is FLASH EVAPORATED.

COMPONENTS 24 Volt DC Heating

57

4/30/2009

COMPONENTS Fuel Heaters

COMPONENTS Stage One Moisture Separator

58

4/30/2009

COMPONENTS Stage Two Moisture Separator

COMPONENTS 115 Volts AC Heating Compressor Side

Hydraulic Oil Sump Tank Heater A/E Oil Sump Tank Heater Heat Trace Lines AC Pl I Plug-Ins

59

4/30/2009

COMPONENTS Hydraulic Oil Sump

COMPONENTS A/E Oil Sump Heater

60

4/30/2009

COMPONENTS Heat Trace Lines

COMPONENTS AC Plug-Ins

61

4/30/2009

COMPONENTS 115 Volts AC Heating Engine Side

Engine Coolant Heater Engine Oil Pan Heater Battery Pads

COMPONENTS Coolant System

Engine Charge Air Cooler

Clogged cooler will lead to engine high temp shutdown Clean from roof side

62

4/30/2009

COMPONENTS Coolant System

Engine Coolant Conditioner Filter

Replace every coolant interval Switch valve to OFF position Replace filter Switch valve to ON position

COMPONENTS Engine Coolant Heater 1500 W

63

4/30/2009

COMPONENTS Engine Oil Pan Heater 350 W

COMPONENTS Battery Pads

64

4/30/2009

COMPONENTS Pressure Transducers

The Electronics System contains Pressure Transducers to measure pressure changes. These devices have an output signal of .45 VDC, to 4.5 VDC, corresponding to 0 PSI and the maximum PSI for a selected transducer which will be 100,225, or 30 PSI. The 0-30 PSI transducer is a vacuum transducer and the 100-225 PSI units are gauge press.devices. A 5 VDC excitation signal is provided to power the transducers.

COMPONENTS Pressure Transducers

P7

L5 P4 P8

T4 T2 T3 V2 P3 P2

L4

Stage 2

T5

QSX - 15

Stage 1

T7

T1 P5 P6 T8 P1 IV T6 BDV MUF

FL V

Exhaust

V1

65

4/30/2009

COMPONENTS Pressure Transducers HYD Tank Located

PT1= Stg1 Inlet Vac PT2= Stg2 Inlet Press PT3= Stg2 Disch Press PT4 PT4= Package Disch Press

PT 1 PT 2 PT 3 PT 4

COMPONENTS Pressure Transducer 1

Stage 1 Inlet Vacuum 0-30 IN. Vacuum Transducer 0.3-0.6 Loaded 10.8-11.3 Unloaded 10 8 11 3 U l d d

66

4/30/2009

COMPONENTS Pressure Transducer 2

2nd Stage Inlet Press. 0-100 PSI Pressure Transducer 28 32 PSI Loaded 28-32 0 PSI Unloaded

COMPONENTS Pressure Transducer 3

2nd Stage Discharge Press. 0-225 PSI Pressure Transducer 152 PSI Loaded 0-4 PSI Unloaded

67

4/30/2009

COMPONENTS Pressure Transducer 4

Package Discharge Pressure 0-225 Pressure Transducer 150 PSI Loaded 0-2 0 2 PSI Unloaded U l d d

COMPONENTS Pressure Transducers

PT5= Oil Filter In Press PT6= Oil Filter Out Press PT7= Remote Press

PT PT 7 5/6

68

4/30/2009

COMPONENTS Pressure Transducer 5 & 6

PT5= Oil Pressure In PT6= Oil Pressure Out Both are 0-100 PSI Pressure Transducers 42-44 PSI For Oil Press. Out Loaded

COMPONENTS Pressure Transducer 7

Remote Pressure Signal 0-225 Pressure Transducer

69

4/30/2009

COMPONENTS Temperature Sensors

There are two types of temperature sensors, RTDS and Thermistors. Both of these devices exhibit a change in resistance as the temperature changes. g p g g This resistance change causes an input voltage change to the INTELLISYS Controller Input and is interpreted as a temperature change.

COMPONENTS RTD Locations

RT 1- 1st Stage Temperature Out RT 2- 2nd Stage Temperature IN RT 3- 2nd Stage Temperature Out RT 4- P k 4 Package Discharge Ai T Di h Air Temperature t RT 5- A/E Oil Injection Temperature RT 6- 1st Stage Inlet Temperature RT 7- Engine Coolant Temperature RT 8- Inter-cooler Temperature Out

70

4/30/2009

COMPONENTS RT 1

100 OHM RTD 1st Stage Temperature Out 350-370F /167-188C Loaded 180F / 82C Unloaded

COMPONENTS RT 2

100 OHM RTD 2nd Stage Temp. In Ambient Plus 25 Degree Loaded Ambient Plus 10 Degree Unloaded

71

4/30/2009

COMPONENTS RT 3

100 OHM RTD 2nd Stage Temp. Out 360-380 F / 182-193C Loaded 173F / 78C Unloaded

COMPONENTS RT 4

100 OHM RTD Package Discharge Air Temperature Ambient Plus 25 FLoaded 25FLoaded

72

4/30/2009

COMPONENTS RT 5

10K OHM Thermister A/E Oil Injection Temperature 136F / 58C Loaded 132F / 55.5C U l d d 55 5C Unloaded

COMPONENTS RT 6

10K OHM Thermister 1st Stage Inlet Temp Ambient Plus 10 Degree Loaded & Unloaded

73

4/30/2009

COMPONENTS RT 7

100 OHM RTD Engine Coolant Temp 179F / 81.5C Loaded

COMPONENTS RT 8

100 OHM RTD Inter-Cooler Temperature Out Ambient Plus 25 Degree Loaded

74

4/30/2009

Electronic Sys.Troubleshooting Procedures and Techniques Basic troubleshooting steps: Collect all facts concerning the problem Analyze the problem thoroughly C Consider any recent repairs th t could relate t th problem id t i that ld l t to the bl Double check before replacing components Determine the cause of the problem and make a thorough repair

MAINTENANCE - Engine

75

4/30/2009

MAINTENANCE - Compressor

MAINTENANCE Compressor Inlet valve

THREE MAJOR COMPONENTS INLET VALVE NOTHING SERVICEABLE ADJUST TO .012 / 3.05mm UNLOADED HYDRAULIC CYLINDER REBUILD KIT AVAILABLE BLOWDOWN VALVE REBUILD KIT AVAILABLE

76

4/30/2009

MAINTENANCE Compressor Inlet valve

To atmosphere

Unloaded

2nd stage air

0.12 gap

Spring loaded closed

MAINTENANCE Compressor Inlet valve

To atmosphere

Start to load

2nd stage air

77

4/30/2009

MAINTENANCE Compressor Inlet valve Fully Loaded

2nd stage air

MAINTENANCE Compressor Inlet valve

To atmosphere

Start to unload

2nd stage air

78

4/30/2009

MAINTENANCE Compressor Inlet valve

To atmosphere

Unloaded

2nd stage air

MAINTENANCE Diesel Fuel

79

4/30/2009

MAINTENANCE Oil Recommendation

OPTIONS

80

4/30/2009

OPTIONS

Options Without running gear Remote start, auto start systems & trickle charger S Special colour i l l Interior lights Spark arrestor Engine oil top-up system

OPTIONS Autostart on sensor input

Primary

Dryer

Installation

Pressure transducer on customer installation will trigger start and stop

81

4/30/2009

OPTIONS Autostart on switch

Electrical relay contact

Primary

Dryer

Installation

Customer control room switch will start /stop compressor

OPTIONS Special Colour

82

4/30/2009

OPTIONS Internal Lights

OPTIONS Auto Oil Top-up Tank

83

4/30/2009

WARRANTY

WARRANTY

84

4/30/2009

WARRANTY

WARRANTY

85

4/30/2009

WARRANTY

86

You might also like

- CD Plus 25-260 Instruction Book EN Antwerp 2920711112Document96 pagesCD Plus 25-260 Instruction Book EN Antwerp 2920711112Miguel CastañedaNo ratings yet

- EK175 NG NK Airend DL071AA 20210208144344 20220524080843Document58 pagesEK175 NG NK Airend DL071AA 20210208144344 20220524080843abdur rohmanNo ratings yet

- WS4500 7500英文操作维护说明书88290021 328Document53 pagesWS4500 7500英文操作维护说明书88290021 328Isidro Onez100% (1)

- Enduro Tempest CTDocument6 pagesEnduro Tempest CTleandrod28100% (2)

- Xrvs 1000 Service PDFDocument10 pagesXrvs 1000 Service PDFpowermanagerNo ratings yet

- 99 AX Booster Assembly ManualDocument34 pages99 AX Booster Assembly ManualFernando Nunez100% (1)

- Ingersoll Rand X-IRI Communications Gateway Operators ManualDocument81 pagesIngersoll Rand X-IRI Communications Gateway Operators ManualWilliam PachecoNo ratings yet

- BOM 10214 B4-41-1000 - Lowres - tcm261 - 900685Document92 pagesBOM 10214 B4-41-1000 - Lowres - tcm261 - 900685Nuno PaivaNo ratings yet

- Fuelmiser A4 Brochure 2019 Update LowresDocument12 pagesFuelmiser A4 Brochure 2019 Update LowresSideth ChivNo ratings yet

- Kaeser BoosterDocument5 pagesKaeser Boostercasv9100% (1)

- SSR 250-450 Horsepower: Parts List Recommended SparesDocument96 pagesSSR 250-450 Horsepower: Parts List Recommended SparesarmandoNo ratings yet

- Student Practice Questions For Chemical Engineering Calculations For CombustionDocument6 pagesStudent Practice Questions For Chemical Engineering Calculations For CombustionDonPedrew60% (5)

- Doosan Compressor HP375WJD, XP375WJD and P425WJDDocument126 pagesDoosan Compressor HP375WJD, XP375WJD and P425WJDJonh Dayrus Ventura AlvarezNo ratings yet

- LGCY10-10 Instruction ManualDocument57 pagesLGCY10-10 Instruction ManualVinod SekharNo ratings yet

- Oil Free Reciprocating Compressors - IRDocument2 pagesOil Free Reciprocating Compressors - IRvmohan01No ratings yet

- Electra-Saver Electra-Saver Ii Stationary Base-Mounted CompressorDocument105 pagesElectra-Saver Electra-Saver Ii Stationary Base-Mounted CompressorJesus Enriquw Osuna RamosNo ratings yet

- Chicago Pneumatic QRS 3-15 Instruction Book EN 2200780021 02Document41 pagesChicago Pneumatic QRS 3-15 Instruction Book EN 2200780021 02Giovanny MosqueraNo ratings yet

- Atlas Copco Electronic Condensate Drains: EWD SeriesDocument1 pageAtlas Copco Electronic Condensate Drains: EWD SeriestariqNo ratings yet

- LLS S-220000S S 220000S S V VC CC C-220000S S: Industrial Air CompressorDocument148 pagesLLS S-220000S S 220000S S V VC CC C-220000S S: Industrial Air Compressormoh hardiusNo ratings yet

- Xa (VHT) S Atlas Copco 486Document76 pagesXa (VHT) S Atlas Copco 486Suharyanto EdyNo ratings yet

- Air Compressor Parts-Catalog 2Document125 pagesAir Compressor Parts-Catalog 2José Antonio Nicolás Alarcón VNo ratings yet

- Ebe99q Parts 2016Document80 pagesEbe99q Parts 2016Ekemini StephenNo ratings yet

- 1CV Overhaul PDFDocument15 pages1CV Overhaul PDFsteve@air-innovations.co.zaNo ratings yet

- 2935 0751 31 - Large Compressors Product Grouping ChartDocument1 page2935 0751 31 - Large Compressors Product Grouping ChartNicholas MurondaNo ratings yet

- Osp 150v5adDocument11 pagesOsp 150v5adQuy HoangNo ratings yet

- SA220-280AW Serial Operator Manual-FS (62英文版)Document52 pagesSA220-280AW Serial Operator Manual-FS (62英文版)Shihab AlakhallyNo ratings yet

- 88290022-798 (r03) EC 2000 User ManualDocument22 pages88290022-798 (r03) EC 2000 User ManualBilal Ijaz Sheikh100% (3)

- Guide To EPA Tier 4 Emissions Limits LEXE0152 01Document4 pagesGuide To EPA Tier 4 Emissions Limits LEXE0152 01Sixto Guarniz AnticonaNo ratings yet

- Air Treatment SolutionsDocument7 pagesAir Treatment SolutionsPrince NeroNo ratings yet

- 2954 0012 03 - XAHS 306 - MD - ASLDocument198 pages2954 0012 03 - XAHS 306 - MD - ASLcarlos andres salazar sanchez50% (2)

- QMB 10-25 - Mar 91 - Version A - 50033-100Document19 pagesQMB 10-25 - Mar 91 - Version A - 50033-100Nelia ShkutNo ratings yet

- I R Xhp1170fcat C18 WFT Manual PDFDocument78 pagesI R Xhp1170fcat C18 WFT Manual PDFnafta ecopetrol100% (1)

- Qsi750 #4Document82 pagesQsi750 #4Christian M. PaucarNo ratings yet

- FD CatalogueDocument16 pagesFD Cataloguevirtech1No ratings yet

- A56 Sullair 02250167-328 (XH-XHH Tier III Open Frame - Rev3)Document124 pagesA56 Sullair 02250167-328 (XH-XHH Tier III Open Frame - Rev3)Francisco Renteria100% (1)

- Part Book v900 Wux CompressedDocument145 pagesPart Book v900 Wux CompressedAd GautamaNo ratings yet

- UP5-4 UP5-5.5 UP5-7.5 UP5-15c Parts 80445265 Oct 2008Document108 pagesUP5-4 UP5-5.5 UP5-7.5 UP5-15c Parts 80445265 Oct 2008JoeNo ratings yet

- 1070 WcatDocument59 pages1070 Wcatvictoros27No ratings yet

- Emotron FDU 2.0 AC DriveDocument226 pagesEmotron FDU 2.0 AC DriveIonescu LucianNo ratings yet

- Xamthvs 900 1150 CD7 PDFDocument6 pagesXamthvs 900 1150 CD7 PDFpowermanagerNo ratings yet

- Compresor 100 HP KOBELCODocument34 pagesCompresor 100 HP KOBELCOJULIO FOXNo ratings yet

- Gen Auto XMDocument47 pagesGen Auto XMCameron Ledingham100% (1)

- Atlas Copco Worldwide WarrantyDocument1 pageAtlas Copco Worldwide WarrantyAdeel Sajjad AwanNo ratings yet

- Work Instructions For Air End Overhauling of CompressorsDocument1 pageWork Instructions For Air End Overhauling of CompressorsDushanthaNo ratings yet

- Mam 6090Document64 pagesMam 6090AmatorNikNo ratings yet

- QuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFDocument6 pagesQuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFmds9185No ratings yet

- User'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerDocument67 pagesUser'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerValentin Bogdan100% (1)

- SCR 100GV - 7 Oil Free Compressor Manual English (B) - 2011-9-9 EnglishDocument49 pagesSCR 100GV - 7 Oil Free Compressor Manual English (B) - 2011-9-9 EnglishlucasNo ratings yet

- Atlas Copco Compressor Technique General Product Catalogue - tcm157-3586607 PDFDocument220 pagesAtlas Copco Compressor Technique General Product Catalogue - tcm157-3586607 PDFIonutNo ratings yet

- Atlas Copco 100 HP ACDocument66 pagesAtlas Copco 100 HP ACwhalenon100% (1)

- GHS 350-900 VSD+ (Qingdao)Document116 pagesGHS 350-900 VSD+ (Qingdao)Leonardo Augusto Ramirez SaenzNo ratings yet

- ZH 6000-10000 MK 4 İnst BookDocument90 pagesZH 6000-10000 MK 4 İnst BookESRANo ratings yet

- Chicao Pneumatic Compressors Brochure (US)Document16 pagesChicao Pneumatic Compressors Brochure (US)Sumit Bhasin100% (1)

- SL-E Air End Service Manual Compressor ScrollDocument35 pagesSL-E Air End Service Manual Compressor ScrollLucky Karunia Setyawan PratamaNo ratings yet

- DXR75 1000 June 1996Document2 pagesDXR75 1000 June 1996SergiSerranoNo ratings yet

- Intermech Bbrfbrvip CNG Compressors 55 450 KW 75 600 HP Tcm1143-3540245Document13 pagesIntermech Bbrfbrvip CNG Compressors 55 450 KW 75 600 HP Tcm1143-3540245Chakravarthy BharathNo ratings yet

- IA Compressor & SystemDocument51 pagesIA Compressor & SystemKazi Irfan100% (2)

- BOGE IA Screw CompressorDocument51 pagesBOGE IA Screw CompressorTaifurNo ratings yet

- M/S. Airro Engineering Co.: Operation & Instructions Manual FOR Oxygen PlantDocument16 pagesM/S. Airro Engineering Co.: Operation & Instructions Manual FOR Oxygen PlantDr Gajanan ShirkeNo ratings yet

- Prepared By: Hassan Alqarni Abdullah AlsubahiDocument50 pagesPrepared By: Hassan Alqarni Abdullah Alsubahiاشرينكيل مسونكيل100% (1)

- Compressedairsystem 230612032028 778a4694Document21 pagesCompressedairsystem 230612032028 778a4694mohammedsaad qureshiNo ratings yet

- Dimethyl Ether ProductionDocument12 pagesDimethyl Ether Productionragilpriyanto100% (1)

- A D C B: Bottom Ash Conveying SystemDocument16 pagesA D C B: Bottom Ash Conveying SystemRohit BaruaNo ratings yet

- PP Aaa PP1 107Document18 pagesPP Aaa PP1 107Rabah AmidiNo ratings yet

- Test SciDocument7 pagesTest SciMary Ann MariquitNo ratings yet

- Flow in Pipes-Sample Problems and TutorialsDocument15 pagesFlow in Pipes-Sample Problems and TutorialsNickson Koms100% (2)

- Fas 20 PDFDocument4 pagesFas 20 PDFMohammad HusainNo ratings yet

- 3-1 R15 MechDocument64 pages3-1 R15 Mechowusuansahphilip17No ratings yet

- HKS EVC V Boost Controller Setup InstructionsDocument7 pagesHKS EVC V Boost Controller Setup InstructionsDave_B100% (2)

- Casing Design1Document9 pagesCasing Design1wissam hashimiNo ratings yet

- Axens AdsorbentsDocument19 pagesAxens AdsorbentsfloretotesoroNo ratings yet

- Vapour Pressure of Water at High TemperatureDocument3 pagesVapour Pressure of Water at High TemperatureJose GalvanNo ratings yet

- Compressor Stage Pressure - Design & OptimizationDocument4 pagesCompressor Stage Pressure - Design & OptimizationAshwin ChandaranaNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity CalculationSampathkumar AttuluriNo ratings yet

- Intake and Exhaust: Group 15Document14 pagesIntake and Exhaust: Group 15Noob StalkerNo ratings yet

- EGR365 Lab8 - Drag Coefficient of A SphereDocument4 pagesEGR365 Lab8 - Drag Coefficient of A Spherejoeblow4224No ratings yet

- Air Conditioning in A CarDocument11 pagesAir Conditioning in A CarKareem Mohammed Faried HassanNo ratings yet

- N Gasdehydrationboosterstationutilitiesdubai 130315160039 Phpapp01Document171 pagesN Gasdehydrationboosterstationutilitiesdubai 130315160039 Phpapp01Said Ahmed SalemNo ratings yet

- Zhang2006 PDFDocument9 pagesZhang2006 PDFLuiz EliasNo ratings yet

- Design Standard: DIN EN ISO 4126-1: Design of Safety ValvesDocument21 pagesDesign Standard: DIN EN ISO 4126-1: Design of Safety ValvesMoe MozhganNo ratings yet

- Roots B Centrifugal BrochureDocument24 pagesRoots B Centrifugal BrochureStephenson ViegasNo ratings yet

- Forced Draft FansDocument29 pagesForced Draft FansFour AyesNo ratings yet

- Parker Autoclave-Valvula-De-PurgaDocument2 pagesParker Autoclave-Valvula-De-PurgaJorge OportoNo ratings yet

- D02601880 - Instruction Manual PDFDocument2 pagesD02601880 - Instruction Manual PDFОлег ОрловскийNo ratings yet

- What Changes Take Place When Water Is Heated or CooledDocument3 pagesWhat Changes Take Place When Water Is Heated or CooledCrystaelechanNo ratings yet

- Chapter 5 Rotating EquipmentDocument32 pagesChapter 5 Rotating EquipmentAeffandii SamawiNo ratings yet

- Success: Instrumentation Engineers LTDDocument4 pagesSuccess: Instrumentation Engineers LTDKazi AlimNo ratings yet

- CBSE Class 11 Physics Thermal Properties of FluidsDocument2 pagesCBSE Class 11 Physics Thermal Properties of FluidsDr.Varsha DangeNo ratings yet

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- Ventis Mx4 Personal Gas Monitor: Reliable, Portable, and Adaptable Gas DetectionDocument6 pagesVentis Mx4 Personal Gas Monitor: Reliable, Portable, and Adaptable Gas DetectionJulinho Inza CarhuachinNo ratings yet