3212fb-RGB LED Driver

3212fb-RGB LED Driver

Uploaded by

nevdullCopyright:

Available Formats

3212fb-RGB LED Driver

3212fb-RGB LED Driver

Uploaded by

nevdullOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

3212fb-RGB LED Driver

3212fb-RGB LED Driver

Uploaded by

nevdullCopyright:

Available Formats

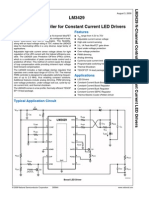

LTC3212

1

3212fb

Typical applicaTion

FeaTures

applicaTions

DescripTion

RGB LED Driver and

Charge Pump

The LTC

3212 is a low noise charge pump RGB LED

driver capable of driving three LEDs up to 25mA each

from a 2.7V to 5.5V input. Low external part count (one

fying capacitor, two bypass capacitors and one to three

programming resistors) makes the LTC3212 ideally suited

for small, battery-powered applications.

Built-in soft-start circuitry prevents excessive inrush cur-

rent during start-up and mode switching. High switching

frequency enables the use of small external capacitors.

The charge pump shuts down to a high impedance mode

to prevent LED leakage while the LTC3212 is off.

Each LED may be individually turned on or off via a single

pin interface. The current through the LEDs may be indi-

vidually programmed with resistors or may share a single

programming resistor. White mode adjusts the red, green

and blue LED current ratios for a white light when all three

LEDs are programmed to be on.

LED currents are regulated using internal low dropout

current sources. Automatic mode switching optimizes

effciency by monitoring the LED current drivers and

switches mode only when dropout is detected. The part

is available in a 3mm 2mm 12-lead DFN package.

RGB Power Supply and Current Control

Power and Current Control for Driving RGB LEDs

Individually Programmable Current Sources

1x or 2x Mode, Low Noise, Constant Frequency

Charge Pump

Single Wire Enable Control for All LEDs

White Mode Adjusts R, G, B Currents for White Light

25mA Maximum LED Current

V

IN

Range: 2.7V to 5.5V

Automatic Soft-Start, Mode Switching and Output

Disconnect in Shutdown Mode

Available in 12-Lead (3mm 2mm) DFN Package

Cellular Phones

Media Players

RGB Back Lights

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

Protected by U.S. Patents, including 6411531.

LEDR

CPO

CM CP

V

IN

LEDEN

1F

1F

LTC3212 1F

R G B

3212 TA01a

11.8k

V

IN

2.7V TO 5.5V

I

SETB

I

SETR

I

SETG

LEDG

LEDB

INDIVIDUAL

SETTINGS

15mA

15mA

15mA

LEDR

LEDG

LEDB

WHITE

MODE

13.5mA

15mA

11.2mA

LTC3212

2

3212fb

pin conFiGuraTion absoluTe MaxiMuM raTinGs

V

IN

to GND ................................................... 0.3V to 6V

CPO to GND ................................................. 0.3V to 6V

LEDEN ............................................. 0.3V to V

IN

+ 0.3V

I

CPO

(Note 2) ..........................................................75mA

I

LED(R,G,B)

(Note 2) .................................................30mA

CPO Short-Circuit Duration .............................. Indefnite

Operating Temperature Range

(Notes 3, 4) .......................................... 40C to 85C

Storage Temperature Range ................... 65C to 125C

(Note 1)

TOP VIEW

13

DDB PACKAGE

12-LEAD (3mm 2mm) PLASTIC DFN

CP

CPO

LEDEN

I

SETB

I

SETR

I

SETG

VIN

CM

GND

LEDB

LEDR

LEDG

8

7

10

9

11

12

5

6

4

2

3

1

T

JMAX

= 125C,

JA

= 76C/W

EXPOSED PAD (PIN 13) IS GND, MUST BE SOLDERED TO PCB

orDer inForMaTion

elecTrical characTerisTics

PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

Operating Voltage 2.7 5.5 V

I

VIN

Operating Current I

CPO

= 0mA, 1x Mode

I

CPO

= 0mA, 2x Mode

0.4

2.0

mA

mA

V

IN

Shutdown Current LEDEN = Low 3 8 A

LED Current

Current Ratio (I

LEDG

/I

SETG

) I

SETG

= 78A 173 192 210 A/A

Current Ratio (I

LEDB

/I

SETB

) I

SETB

= 78A 173 192 210 A/A

Current Ratio (I

LEDB

/I

SETG

) White Mode, I

SETG

= 78A 128 144 160 A/A

Current Ratio (I

LEDR

/I

SETR

) I

SETR

= 78A 173 192 210 A/A

Current Ratio (I

LEDR

/I

SETG

) White Mode, I

SETG

= 78A 154 171 186 A/A

I

LED

Dropout Voltage (V

ILED

) Mode Switching Theshold, I

LED

= 15mA 150 mV

t

EN

Current Source Enable Time (LEDEN = High) (Note 5) 400 s

Mode Switching Delay 50 120 250 s

Charge Pump (CPO)

Charge Pump Output Voltage Clamp 5.1 V

1x Mode Output Impedance (Notes 6, 7) 5

The denotes the specifcations which apply over the full operating

temperature range, otherwise specifcations are at T

A

= 25C. V

IN

= 3.6V.

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC3212EDDB#PBF LTC3212EDDB#TR LCWM 12-Lead (3mm 2mm) Plastic DFN 40C to 85C

Consult LTC Marketing for parts specifed with wider operating temperature ranges.

Consult LTC Marketing for information on non-standard lead based fnish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifcations, go to: http://www.linear.com/tapeandreel/

LTC3212

3

3212fb

elecTrical characTerisTics

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: Based on long-term current density limitations.

Note 3: The LTC3212E is guaranteed to meet performance specifcations

from 0C to 85C. Specifcations over the 40C to 85C ambient

operating temperature range are assured by design, characterization and

correlation with statistical process controls

The denotes the specifcations which apply over the full operating

temperature range, otherwise specifcations are at T

A

= 25C. V

IN

= 3.6V.

PARAMETER CONDITIONS MIN TYP MAX UNITS

2x Mode Output Impedance (Notes 6, 7) 25

CLK Frequency 650 900 1275 kHz

LEDEN

High Level Input Voltage (V

IH

) 1.4 V

Low Level Input Voltage (V

IL

) 0.4 V

Input Current (I

IH

) LEDEN = 3.6V 3 10 A

Input Current (I

IL

) 1 1 A

t

PWH

High Pulse Width 0.08 s

t

PWL

Low Pulse Width 0.08 20 s

t

SD

Low Time to Shutdown (LEDEN = Low) 350 s

I

SET(R,G,B)

V

ISET

864 925 985 mV

I

ISET

140 A

Note 4: This IC includes overtemperature protection that is intended

to protect the device during momentary overload conditions. Junction

temperature will exceed 125C when overtemperature protection is active.

Continuous operation above the specifed maximum operating junction

temperature may impair device reliability.

Note 5: If the LTC3212 has been shut down, then the initial enable time

is longer due to the bandgap settling time and the CPO output capacitor

soft-start time.

Note 6: 1x mode output impedance is defned as (V

IN

V

CPO

)/I

OUT

.

2x mode output impedance is defned as (2V

IN

V

CPO

)/I

OUT

.

Note 7: Guaranteed by design.

Typical perForMance characTerisTics

Dropout Time 2x Mode CPO Ripple

LED Pin Dropout Voltage

vs LED Pin Current

CPO

1V/DIV

LED

500mV/DIV

50s/DIV

3212 G01

2x MODE

1x MODE

3.6V 5.1V

0V

1V

DROPOUT

DROPOUT

DELAY

LED CURRENT (mA)

0

L

E

D

D

R

O

P

O

U

T

V

O

L

T

A

G

E

(

m

V

)

100

150

20

3212 G03

50

0

5 10 15

250

200

500ns/DIV V

IN

= 3.6V

I

CPO

= 75mA

C

CPO

= 1F

3212 G02

V

CPO

20mV/DIV

AC COUPLED

LTC3212

4

3212fb

Typical perForMance characTerisTics

1x Mode Charge Pump

Resistance vs Temperature

2x Mode CPO Open-Loop Output

Resistance

2x Mode CPO Voltage

vs CPO Current

Oscillator Frequency

vs V

IN

Voltage

V

IN

Shutdown Current

vs V

IN

Voltage

1x Mode No-Load V

IN

Current

vs V

IN

Voltage

2x Mode V

IN

Current

vs V

IN

Voltage

V

IN

(V)

2.7

O

P

E

N

-

L

O

O

P

O

U

T

P

U

T

R

E

S

I

S

T

A

N

C

E

(

)

27

31

3.6

3212 G05

23

19

25

29

33

35

21

17

15

3.0 3.3 4.0

85C

C1, C2, C3 = 1F

V

CPO

= 4.8V

25C

40C

CPO CURRENT (mA)

0

4.0

C

P

O

V

O

L

T

A

G

E

(

V

)

4.2

4.4

4.6

4.8

5.2

20 30 40 50

3212 G06

60 10 25 35 45 55 65 70

5.0

3.6V

3.1V

3.2V

3.3V 3.4V

V

IN

= 3.0V

C1, C2, C3 = 1F

3.5V

V

IN

(V)

2.7

F

R

E

Q

U

E

N

C

Y

(

k

H

z

)

888

890

892

3.9 4.7

3212 G07

886

884

3.1 3.5 4.3 5.1 5.5

882

880

V

IN

(V)

2.7

0

I

V

I

N

(

A

)

1

2

3

4

6

3.5 3.1 3.9 4.3 4.7 5.1

3212 G08

5.5

5

V

IN

(V)

2.7

290

V

I

N

C

U

R

R

E

N

T

(

A

)

300

310

320

330

350

3.1 3.5 3.9 4.3

3212 G09

5.1 4.7 5.5

340

Start-Up and Mode Switch

V

IN

(V)

2.7

V

I

N

C

U

R

R

E

N

T

(

m

A

)

3.5

3.9

3212 G10

2.0

1.0

3.1 3.5 4.3

0.5

0

4.0

3.0

2.5

1.5

4.7 5.1 5.5

CPO

1V/DIV

LEDEN

2V/DIV

200s/DIV V

IN

= 3.6V

3212 G11

SOFT-START

DROPOUT

DELAY

1x

MODE

2x

MODE

0V

0V

3.6V

3.6V

5V

TEMPERATURE (C)

40

5.0

5.5

6.5

20 60

3212 G04

4.5

4.0

20 0 40 80

3.5

3.0

6.0

R

E

S

I

S

T

A

N

C

E

(

)

V

IN

= 3V

I

CPO

= 50mA

V

IN

= 3.6V

V

IN

= 4.2V

LTC3212

5

3212fb

pin FuncTions

CP, CM (Pins 1, 11): Charge Pump Flying Capacitor Pins.

A 1F X5R or X7R ceramic capacitor should be connected

from CP to CM.

CPO (Pin 2): CPO is the output of the charge pump. A 1F

X5R or X7R ceramic capacitor is required from CPO to

GND. While operating, this pin will supply current to the

LEDs and while in shutdown mode this pin will be high

impedance.

LEDEN (Pin 3): The LEDEN pin is used to program, enable

and shut down the part. A 3A internal current source

pulls this pin to ground.

I

SETB

, I

SETR

, I

SETG

(Pins 4, 5, 6): LED current program-

ming resistor pins. A resistor connected between a pin

and GND is used to set the LED current. A resistor from

I

SETG

to GND is required. Resistors on I

SETR

and I

SETB

are optional. If I

SETR

and/or I

SETB

is not connected to a

resistor I

SETR

s and/or I

SETB

s respective output(s) will be

automatically programmed by the resistor connected to

I

SETG

. If I

SETR

or I

SETB

is unused the pin should be con-

nected to V

IN

.

LEDG, LEDR, LEDB (Pins 7, 8, 9): These pins are

the LED current output pins. The LEDs are connected

from either the charge pump or V

IN

(anode) to LED

(R, G, B) (cathode).

GND (Pin 10): This pin should be connected directly to a

low impedance ground plane.

V

IN

(Pin 12): Supply voltage for the LTC3212. V

IN

should

be bypassed with a low impedance ceramic capacitor to

GND of at least 1F of capacitance.

Exposed Pad (Pin 13): GND. The Exposed Pad must be

soldered to a low impedance ground plane for optimum

performance.

LTC3212

6

3212fb

block DiaGraM

4

+

LED

CURRENT

SOURCE

ENB

LEDB

LEDR

LEDG

3212 BD

I

SETB

ENR ENG ENB

3

LEDEN

3A

12

V

IN

5

+

LED

CURRENT

SOURCE

ENR

I

SETR

6

+

LED

CURRENT

SOURCE

OPEN

DETECTION/

AUTOSET

ENG

I

SETG

10

GND

CONTROL LOGIC

DROPOUT

DETECTION

V

REF

CP

TSD

9

8

7

10k

SHUT

DOWN

CPO

2

1

CM

11

+

900kHz

OSCILLATOR

The LTC3212 uses a switched capacitor charge pump to

power three LEDs with a programmable regulated cur-

rent. The part powers up into 1x mode. In this mode V

IN

is directly connected to CPO. When powering up into 1x

mode, the LTC3212 charges the CPO capacitor to near

V

IN

before directly connecting V

IN

to CPO. This prevents

a large in-rush current. 1x mode provides maximum ef-

fciency and minimum noise. The LTC3212 will remain

in this mode until one of the LED current source drivers

operaTion

begins to drop out of regulation. When this drop out oc-

curs the LTC3212 will switch to 2x mode after a soft-start

period. The part will return to 1x mode when the part is

shut down and reprogrammed.

The current delivered through the LED load is controlled

by an internal programmable low dropout current source.

The current is programmed by resistors connected between

the I

SET(R,G,B)

pins and GND.

LTC3212

7

3212fb

operaTion

An overcurrent shutdown mode on the I

SET

pins will pre-

vent damage to the part and the LED by shutting down

the LED drivers. Choosing an R

SET

value of 5.9k or greater

will ensure that the part stays out of this mode. When in

normal operating mode current, regulation is achieved by

controlling an active current source.

In shutdown mode all internal circuitry is turned off and

the LTC3212 draws very little current from the V

IN

supply.

The LTC3212 enters shutdown mode after the LEDEN pin

is brought low for 350s.

Short-Circuit Protection

When LEDEN is brought high, the part will connect V

IN

to CPO through a weak pull-up until CPO has charged to

near V

IN

. After the LTC3212 detects that the CPO voltage

is near the V

IN

voltage, it then enables 1x mode. If the

CPO is shorted or falls below approximately 1V, then the

LTC3212 is disabled. After falling below 1V the LTC3212

will use the weak pull-up to charge CPO to near V

IN

before

re-enabling the chip.

Soft-Start

To prevent excessive inrush during start-up and mode

switching, the LTC3212 employs built-in soft-start circuitry.

Soft-start is achieved by increasing the current available

to the CPO capacitor over a period of approximately

100s.

Charge Pump Strength

When the LTC3212 operates in 2x mode, the charge

pump can be modeled as a Thevenin equivalent circuit

to determine the amount of current available from the

effective input voltage and the effective open-loop output

resistance, R

OL

.

+

R

OL

CPO 2V

IN

3212 F01

Figure 1. CPO Equivalent Open-Loop

R

OL

is dependent on a number of factors including the

oscillator frequency, fying capacitor values and switch

resistances. From Figure 1 we can see that the maximum

output current in 2x mode is proportional to:

2V CPO

R

IN

OL

LED Current Programming

The LTC3212 includes three accurate, programmable cur-

rent sources that are capable of driving LED currents up

to 25mA continuously. The current is programmed using

an external resistor for each channel. The equation for

each external resistance is:

R

I

R

I

R

SETG

LEDG

SETB

LEDB

SETR

=

=

=

177 6

177 6

177 6

.

.

.

II

LEDR

Alternatively, if either the I

SETR

or I

SETB

pins are connected

to V

IN

, the respective LEDR and/or LEDB current will au-

tomatically use the R

SETG

resistor and be set to:

I

R

I

R

LEDR

SETG

LEDB

SETG

=

=

177 6

177 6

.

.

LTC3212

8

3212fb

White Mode

The LTC3212 has a white mode that automatically scales

the current in the red, green and blue LEDs to a preset mix

when selected. This allows the currents programmed with

the external resistors to be set independently of the ratio

needed for white light, increasing the fexibility of program-

ming other colors. The intensity of the white is set by the

resistor on I

SETG

. The ratio used for white mode is:

I

R

I

R

I

LEDG

SETG

LEDR

SETG

LEDB

=

=

=

177 6

159 8

133 2

.

.

.

RR

SETG

Enable

Each LED driver output may be programmed on or off

by pulsing the LEDEN pin while enabling the LTC3212.

An internal counter and decoder selects the output con-

fguration from the number of pulses. This counter is

operaTion

clocked by the rising edges of the LEDEN signal. Refer to

Figure 2 for timing details. The outputs are programmed

using Table 1.

Table 1. LED Programming

PULSES R G B

1 0 0 1

2 0 1 0

3 0 1 1

4 1 0 0

5 1 0 1

6 1 1 0

7+ White Mode

Mode Switching

The LTC3212 will automatically switch from 1x to 2x mode

whenever it detects a LED driver is entering dropout. The

part will wait approximately 140s before switching to 2x

mode. This delay will act as fltering to prevent the part

from incorrectly switching to 2x mode due to a momen-

tary glitch on the V

IN

supply. The mode may be reset by

entering shutdown mode and reprogramming.

LEDEN

SHUTDOWN

LED

CURRENT

t

PWH

80ns

t

PWL

80ns

t

EN

400s

t

SD

350s

PROGRAMMED

CURRENT

3212 F02

Figure 2. LED Selection and Shutdown Timing Diagram

LTC3212

9

3212fb

applicaTions inForMaTion

V

IN

, CPO Capacitor Selection

The style and value of the capacitors used with the LTC3212

determine several important parameters such as regulator

control loop stability, output ripple, charge pump strength

and minimum start-up time.

To reduce noise and ripple, it is recommended that low

equivalent series resistance (ESR) ceramic capacitors are

used for both C

VIN

and C

CPO

. Tantalum and aluminum

capacitors are not recommended due to high ESR.

The value of C

CPO

directly controls the amount of output

ripple for a given load current. Increasing the size of C

CPO

will reduce output ripple at the expense of longer start-up

time. The peak-to-peak output ripple of the 2x mode is

approximately given by the expression:

V

RIPPLEP-P

=

I

f C

OUT

OSC CPO

2

where f

OSC

is the LTC3212 oscillator frequency or typically

900kHz and C

CPO

is the output storage capacitor.

Flying Capacitor Selection

Warning: Polarized capacitors such as tantalum or

aluminum should never be used for the fying capaci-

tors since their voltage can reverse upon start-up of the

LTC3212. Ceramic capacitors should always be used for

the fying capacitors.

The fying capacitors control the strength of the charge

pump. In order to achieve the rated output current it is

necessary to have at least 0.6F of capacitance for fying

capacitor. Capacitors of different materials lose their ca-

pacitance with higher temperature and voltage at different

rates. For example, a ceramic capacitor made of X7R mate-

rial will retain most of its capacitance from 40C to 85C

whereas a Z5U or Y5V style capacitor will lose considerable

capacitance over that range. Z5U and Y5V capacitors may

also have a very poor voltage coeffcient causing them

to lose 60% or more of their capacitance when the rated

voltage is applied. Therefore, when comparing different

capacitors, it is often more appropriate to compare the

amount of achievable capacitance for a given case size

rather than comparing the specifed capacitance value. For

example, over rated voltage and temperature conditions,

a 1F, 10V, Y5V ceramic capacitor in a 0603 case may not

provide any more capacitance than a 0.22F, 10V, X7R

available in the same case. The capacitor manufacturers

data sheet should be consulted to determine what value

of capacitor is needed to ensure minimum capacitances

at all temperatures and voltages.

Table 2 shows a list of ceramic capacitor manufacturers

and how to contact them:

Table 2. Recommended Capacitor Vendors

AVX www.avxcorp.com

Kemet www.kemet.com

Murata www.murata.com

Taiyo Yuden www.t-yuden.com

Vishay www.vishay.com

Layout Considerations and Switching Noise

The LTC3212 has been designed to minimize EMI. How-

ever due to its high switching frequency and the transient

currents produced by the LTC3212, careful board layout

is necessary. A true ground plane and short connections

to all capacitors will improve performance and ensure

proper regulation under all conditions.

The fying capacitor pins CP and CM will have 5ns to 10ns

edge rate waveforms. The large dv/dt on these pins can

couple energy capacitively to adjacent PCB runs. Magnetic

felds can also be generated if the fying capacitors are

not close to the LTC3212 (i.e., the loop area is large).

To decouple capacitive energy transfer, a Faraday shield

may be used. This is a grounded PCB trace between the

sensitive node and the LTC3212 pins. For a high quality

AC ground, it should be returned to a solid ground plane

that extends all the way to the LTC3212.

LTC3212

10

3212fb

Power Effciency

To calculate the power effciency () of an LED driver chip,

the LED power should be compared to the input power.

The difference between these two numbers represents

lost power whether it is in the charge pump or the cur-

rent sources. Stated mathematically, the power effciency

is given by:

=

P

P

LED

IN

The effciency of the LTC3212 depends upon the mode in

which it is operating. Recall that the LTC3212 operates

as a pass switch, connecting V

IN

to CPO, until dropout

is detected at an I

LED

pin. This feature provides the op-

timum effciency available for a given input voltage and

LED forward voltage. When it is operating as a switch, the

effciency is approximated by:

= = =

P

P

V I

V I

V

V

LED

IN

LED LED

BAT BAT

LED

BAT

since the input current will be very close to the sum of

the LED currents.

At moderate to high output power, the quiescent current

of the LTC3212 is negligible and the expression above is

valid.

Once dropout is detected at any LED pin, the LTC3212

enables the charge pump in 2x mode.

In 2x boost mode, the effciency is similar to that of a

linear regulator with an effective input voltage of 2 times

the actual input voltage. In an ideal 2x charge pump, the

power effciency would be given by:

IDEAL

LED

IN

LED LED

BAT LED

LED

P

P

V I

V I

V

V

= = =

2 2

BBAT

In some applications it may be possible to increase the

effciency of the LTC3212. If any of the LEDs maximum

forward voltage is less than the minimum V

IN

supply volt-

age minus I

LED

dropout voltage then the charge pump is

not needed to drive that LED. This is often the case with

the red LED due to its lower forward voltage. Its anode

may be connected directly to V

IN

, bypassing the charge

pumps losses in 2x mode.

Thermal Management

If the junction temperature increases above approximately

140C the thermal shutdown circuitry will automatically

deactivate the output current sources and charge pump.

To reduce maximum junction temperature, a good thermal

connection to the PC board is recommended. Connecting

the Exposed Pad to a ground plane and maintaining a solid

ground plane under the device will reduce the thermal

resistance of the package and PC board considerably.

applicaTions inForMaTion

LTC3212

11

3212fb

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representa-

tion that the interconnection of its circuits as described herein will not infringe on existing patent rights.

packaGe DescripTion

DDB Package

12-Lead Plastic DFN (3mm 2mm)

(Reference LTC DWG # 05-08-1723 Rev )

2.00 0.10

(2 SIDES)

NOTE:

1. DRAWING IS NOT A JEDEC PACKAGE OUTLINE

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE TOP AND BOTTOM OF PACKAGE

0.40 0.10

BOTTOM VIEWEXPOSED PAD

0.64 0.10

(2 SIDES)

0.75 0.05

R = 0.115

TYP

R = 0.05

TYP

2.39 0.10

(2 SIDES)

3.00 0.10

(2 SIDES)

1 6

12 7

PIN 1 BAR

TOP MARK

(SEE NOTE 6)

0.200 REF

0 0.05

(DDB12) DFN 0106 REV

0.23 0.05

0.45 BSC

PIN 1

R = 0.20 OR

0.25 45

CHAMFER

0.25 0.05

2.39 0.05

(2 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

APPLY SOLDER MASK TO AREAS THAT ARE NOT SOLDERED

0.64 0.05

(2 SIDES)

1.15 0.05

0.70 0.05

2.55 0.05

PACKAGE

OUTLINE

0.45 BSC

LTC3212

12

3212fb

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

FAX: (408) 434-0507

www.linear.com LINEAR TECHNOLOGY CORPORATION 2007

LT 0707 REV B PRINTED IN USA

relaTeD parTs

Typical applicaTion

Three Independent Programming Resistors (10mA, 15mA, 20mA)

LEDB

CPO

CM CP

CPO

V

IN

LEDEN

1F

1F

LTC3212 1F

LEDR = 10mA

LEDB = 15mA

LEDG = 20mA

3212 TA02

8.87k 17.8k 11.8k

V

IN

2.7V TO 5.5V

I

SETB

I

SETR

I

SETG

LEDR

LEDG

PART

NUMBER

DESCRIPTION

COMMENTS

LTC3200-5 Low Noise, 2MHz Regulated Charge Pump White

LED Driver

Up to 6 White LEDs, V

IN

: 2.7V to 4.5V, V

OUT(MAX)

= 5V, I

Q

= 8mA, I

SD

1A,

ThinSOT Package

LTC3201 Low Noise, 1.7MHz Regulated Charge Pump

White LED Driver

Up to 6 White LEDs, V

IN

: 2.7V to 4.5V, V

OUT(MAX)

= 5V, I

Q

= 6.5mA, I

SD

1A,

10-Lead MS Package

LTC3202 Low Noise, 1.5MHz Regulated Charge Pump

White LED Driver

Up to 8 White LEDs, V

IN

: 2.7V to 4.5V, V

OUT(MAX)

= 5V, I

Q

= 5mA, I

SD

1A,

10-Lead MS Package

LTC3205 Multidisplay LED Controller 92% Effciency, V

IN

: 2.8V to 4.5V, I

Q

= 50A, I

SD

1A, 4mm 4mm QFN Package

LTC3206 I

2

C Multidisplay LED Controller 92% Effciency, 400mA Continuous Output Current; Up to 11 White LEDs in 4mm

4mm QFN Package

LTC3208 High Current Software Confgurable Multidisplay

LED Controller

95% Effciency, V

IN

: 2.9V to 4.5V, 1A Output Current; Up to 17 LEDs for 5 Displays,

5mm 5mm QFN Package

LTC3209 600mA MAIN/Camera LED Controller Up to 8 LEDs, 94% Effciency, V

IN

: 2.9V to 4.5V, 1x/1.5x/2x Boost Modes, 4mm

4mm QFN Package

LTC3210/

LTC3210-1

500mA MAIN/Camera LED Controller Up to 5 LEDs, 95% Effciency, V

IN

: 2.9V to 4.5V, 1x/1.5x/2x Boost Modes, Exponential

Brightness Control, -1 Version Has 64-Step Linear Brightness Control, 3mm 3mm

QFN Package

LTC3210-2 MAIN/CAM LED Controller with 32-Step

Brightness Control

Drives 4 MAIN LEDs, 3mm 3mm QFN Package

LTC3210-3 MAIN/CAM LED Controller with 32-Step

Brightness Control

Drives 3 MAIN LEDs, 3mm 3mm QFN Package

LTC3214 500mA Camera LED Charge Pump 93% Effciency, V

IN

: 2.9V to 4.4V, 1x/1.5x/2x Boost Modes, 3mm 3mm DFN Package

LTC3215 700mA High Current, Low Noise, White LED

Driver

93% Effciency, V

IN

: 2.9V to 4.4V, 1x/1.5x/2x Boost Modes, 3mm 3mm DFN Package

LTC3216 1A High Current, Low Noise, White LED Driver 93% Effciency, V

IN

: 2.9V to 4.4V, 1x/1.5x/2x Boost Modes, Independent Low/High

Current Programming

LTC3217 600mA Low Noise Multi-LED Camera Light

Charge Pump

Up to 4 LEDs, 92% Effciency, V

IN

: 2.9V to 4.5V, 1x/1.5x/2x Boost Modes, Independent

Torch and Flash I

SET

and Enable Pins, 3mm 3mm QFN Package

LT3465/

LT3465A

1.2MHz/2.4MHz White LED Boost Converters with

Internal Schottky

Up to 6 White LEDs, V

IN

: 12.7V to 16V, V

OUT(MAX)

= 34V, I

Q

= 1.9mA, I

SD

<1A,

ThinSOT Package

ThinSOT is a trademark of Linear Technology Corporation.

You might also like

- LP3944Document14 pagesLP3944alephzeroNo ratings yet

- LMD18201 3A, 55V H-Bridge: Literature Number: SNVS092CDocument14 pagesLMD18201 3A, 55V H-Bridge: Literature Number: SNVS092CIrfan AbbasiNo ratings yet

- LM3530 High Efficiency White LED Driver With Programmable Ambient Light Sensing Capability and I C-Compatible InterfaceDocument45 pagesLM3530 High Efficiency White LED Driver With Programmable Ambient Light Sensing Capability and I C-Compatible Interfacethoth2487No ratings yet

- LM3414/LM3414HV 1A 60W Common Anode Capable Constant Current Buck LED Driver Requires No External Current Sensing ResistorDocument20 pagesLM3414/LM3414HV 1A 60W Common Anode Capable Constant Current Buck LED Driver Requires No External Current Sensing ResistorAyala KarlNo ratings yet

- MP3389 r1.04Document16 pagesMP3389 r1.04Andres Alegria100% (1)

- LCD221SD Service ManualDocument41 pagesLCD221SD Service Manual1cvbnmNo ratings yet

- Green Mode PWM Controller Ap384XgDocument13 pagesGreen Mode PWM Controller Ap384XgbaphometabaddonNo ratings yet

- Am7946 Slic DatasheetDocument15 pagesAm7946 Slic DatasheetJohnny WalkerNo ratings yet

- Octal Configurable Low/High Side Driver: DescriptionDocument18 pagesOctal Configurable Low/High Side Driver: DescriptionDan Esenther100% (1)

- LMD 18200Document14 pagesLMD 18200Itzamary Romero SosaNo ratings yet

- L6565Document18 pagesL6565Sergio Daniel BarretoNo ratings yet

- LM3914 Dot/Bar Display Driver: Literature Number: SNVS761ADocument24 pagesLM3914 Dot/Bar Display Driver: Literature Number: SNVS761AJhonny RodriguezNo ratings yet

- R1218x SERIES: Step-Up DC/DC Converter For White LED BacklightDocument21 pagesR1218x SERIES: Step-Up DC/DC Converter For White LED Backlight666667No ratings yet

- Diodes Ap1538sg-13Document14 pagesDiodes Ap1538sg-13sonytechoNo ratings yet

- Dual Half Bridge Driver: Multipower BCD TechnologyDocument9 pagesDual Half Bridge Driver: Multipower BCD TechnologyDan EsentherNo ratings yet

- SG 6841 TDocument14 pagesSG 6841 TBayron Salazar SaborioNo ratings yet

- Icl 7673Document7 pagesIcl 7673Luis AlfredoNo ratings yet

- GM7230-V1 01Document10 pagesGM7230-V1 01Alfredo Valencia RodriguezNo ratings yet

- 3226fa-2cell Supercap Charter With Backup ControllerDocument16 pages3226fa-2cell Supercap Charter With Backup ControllernevdullNo ratings yet

- EN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated InductorDocument16 pagesEN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated Inductorcatsoithahuong84No ratings yet

- LM3914Document19 pagesLM3914Brzata PticaNo ratings yet

- High Efficiency, Main Power Supply Controller For Notebook ComputerDocument26 pagesHigh Efficiency, Main Power Supply Controller For Notebook Computerpiron123No ratings yet

- Snva 397 ADocument15 pagesSnva 397 AAriel NavarreteNo ratings yet

- LD7552 DS 00Document10 pagesLD7552 DS 00BRIGHT_SPARKNo ratings yet

- Mach Cong Suat Cau H - Lmd18200Document14 pagesMach Cong Suat Cau H - Lmd18200hieuhuech1No ratings yet

- Datasheet LM3429Document34 pagesDatasheet LM3429Bagus KrisviandikNo ratings yet

- Fan 7316Document21 pagesFan 7316sontuyet82No ratings yet

- Ltc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching RegulatorsDocument28 pagesLtc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching Regulatorscatsoithahuong84No ratings yet

- Richtek RT7247ADocument15 pagesRichtek RT7247Ajhg-crackmeNo ratings yet

- Datasheet PDFDocument32 pagesDatasheet PDFMochamad AlbiNo ratings yet

- AP358 DatasheetDocument13 pagesAP358 DatasheetRafael OliveiraNo ratings yet

- White LED Driver With Wide PWM Dimming Range Features: FN6264.3 Data Sheet March 7, 2008Document10 pagesWhite LED Driver With Wide PWM Dimming Range Features: FN6264.3 Data Sheet March 7, 2008ram12krishnaNo ratings yet

- Fully Integrated H-Bridge Motor Driver: VNH3SP30Document26 pagesFully Integrated H-Bridge Motor Driver: VNH3SP30Dan EsentherNo ratings yet

- L6208D To L6208PDDocument16 pagesL6208D To L6208PDwtn2013No ratings yet

- LMD18201 3A, 55V H-Bridge: General DescriptionDocument8 pagesLMD18201 3A, 55V H-Bridge: General DescriptionNairo FilhoNo ratings yet

- Quad Power Amplifier With Built-In Voltage Converter: DescriptionDocument10 pagesQuad Power Amplifier With Built-In Voltage Converter: DescriptionbakaninhaNo ratings yet

- Features General Description: Stereo 2.6W Audio Power Amplifier (With DC - Volume Control)Document28 pagesFeatures General Description: Stereo 2.6W Audio Power Amplifier (With DC - Volume Control)Díaz Rivero Cesar EnriqueNo ratings yet

- LCT B85TDU22H Service ManualDocument59 pagesLCT B85TDU22H Service ManualCristina NistorNo ratings yet

- RT9202Document16 pagesRT9202bachet56No ratings yet

- Features Description: Ltc3536 1A Low Noise, Buck-Boost DC/DC ConverterDocument28 pagesFeatures Description: Ltc3536 1A Low Noise, Buck-Boost DC/DC ConverternevdullNo ratings yet

- Al8860 1019719Document18 pagesAl8860 1019719hansNo ratings yet

- MPM01 MPM04 Application NoteDocument16 pagesMPM01 MPM04 Application Noteprotek506No ratings yet

- LT1618 DatasheetDocument16 pagesLT1618 DatasheetkurabyqldNo ratings yet

- A3979 DatasheetDocument15 pagesA3979 DatasheetИван КосмонавтNo ratings yet

- MC3479 Stepper Motor Driver: FeaturesDocument10 pagesMC3479 Stepper Motor Driver: FeaturesHenry CastandNo ratings yet

- Feature General Description: HT7A6005 Low Power, Wide Temperature Range General Purpose Current Mode PWM ControllerDocument11 pagesFeature General Description: HT7A6005 Low Power, Wide Temperature Range General Purpose Current Mode PWM ControllerEnéas BaroneNo ratings yet

- LIN Transceiver: Automotive and IndustrialDocument19 pagesLIN Transceiver: Automotive and IndustrialRayan88No ratings yet

- Vestel 17mb24h Service ManualDocument46 pagesVestel 17mb24h Service Manualchris_crtv3753No ratings yet

- lm3914 PDFDocument25 pageslm3914 PDFRogers Ferreras BenitezNo ratings yet

- LTC3421 - 3A Micropower Synchronous Boost ConverterDocument16 pagesLTC3421 - 3A Micropower Synchronous Boost ConverterRata DanielNo ratings yet

- HP 23 (22) Xi Backlight Driver EUP2589 PDFDocument12 pagesHP 23 (22) Xi Backlight Driver EUP2589 PDFmariusvNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Design of Electrical Circuits using Engineering Software ToolsFrom EverandDesign of Electrical Circuits using Engineering Software ToolsNo ratings yet

- Features Description: Ltc3536 1A Low Noise, Buck-Boost DC/DC ConverterDocument28 pagesFeatures Description: Ltc3536 1A Low Noise, Buck-Boost DC/DC ConverternevdullNo ratings yet

- AD7814Document8 pagesAD7814nevdullNo ratings yet

- Ad 22105Document8 pagesAd 22105nevdullNo ratings yet

- 43AR104 Antenna: Dimensions (In.)Document1 page43AR104 Antenna: Dimensions (In.)nevdullNo ratings yet

- 4071fc-Li-Ion-Poly Battery Charger System With Low Batt DiscoDocument18 pages4071fc-Li-Ion-Poly Battery Charger System With Low Batt DisconevdullNo ratings yet

- Adt 7310Document24 pagesAdt 7310nevdullNo ratings yet

- Cd4013 One-Shot and Latch Circuits: Size Document Number RevDocument1 pageCd4013 One-Shot and Latch Circuits: Size Document Number RevnevdullNo ratings yet

- 4011 BDocument7 pages4011 BGayanDissanayakeNo ratings yet

- 3625f-High Efficiency 2-Cell Supercap ChargerDocument16 pages3625f-High Efficiency 2-Cell Supercap ChargernevdullNo ratings yet

- Hcf4017 Data Sheet 2Document8 pagesHcf4017 Data Sheet 2Filipe CoimbraNo ratings yet

- Cmos Asynchronous Fifo 256 X 9, 512 X 9 and 1,024 X 9 IDT7200L IDT7201LA IDT7202LADocument14 pagesCmos Asynchronous Fifo 256 X 9, 512 X 9 and 1,024 X 9 IDT7200L IDT7201LA IDT7202LAnevdullNo ratings yet

- Thru Hole (THM) & Surface Mount (SMT) Coin Cell RetainersDocument2 pagesThru Hole (THM) & Surface Mount (SMT) Coin Cell RetainersnevdullNo ratings yet

- 3226fa-2cell Supercap Charter With Backup ControllerDocument16 pages3226fa-2cell Supercap Charter With Backup ControllernevdullNo ratings yet

- 3459-10v Micropower Synchronous Boost ConverterDocument12 pages3459-10v Micropower Synchronous Boost ConverternevdullNo ratings yet

- 2990fc-Quad I2c Voltage, Current and Temp MonitorDocument24 pages2990fc-Quad I2c Voltage, Current and Temp MonitornevdullNo ratings yet

- 3490fa-Single Cell 350ma LED DriverDocument12 pages3490fa-Single Cell 350ma LED DrivernevdullNo ratings yet

- 1316f Micropower DC DC ConverterDocument16 pages1316f Micropower DC DC ConverternevdullNo ratings yet

- Top View of Assembly Rear View of Assembly: Maximum P.C. Board SizeDocument1 pageTop View of Assembly Rear View of Assembly: Maximum P.C. Board SizenevdullNo ratings yet

- Section A-A End View of Assembly Top View of Assembly: Maximum P.C. Board SizeDocument1 pageSection A-A End View of Assembly Top View of Assembly: Maximum P.C. Board SizenevdullNo ratings yet

- 1595C Enclosure: Part NumbersDocument1 page1595C Enclosure: Part NumbersnevdullNo ratings yet

- USB 2.0 Common Mode Choke - 0805: US UK Taiwan China SingaporeDocument2 pagesUSB 2.0 Common Mode Choke - 0805: US UK Taiwan China SingaporenevdullNo ratings yet

- Chapter 7Document26 pagesChapter 7bekinatheroNo ratings yet

- Hinusdtan College of Science & Technology: ECE-064 Earthquake Resistant Design UNIT-5Document29 pagesHinusdtan College of Science & Technology: ECE-064 Earthquake Resistant Design UNIT-5Faraan KhanNo ratings yet

- Network Detection and Response in The SOC SecuronixDocument7 pagesNetwork Detection and Response in The SOC SecuronixAvo AndrinantenainaNo ratings yet

- Essay Examples: Narrative EssaysDocument6 pagesEssay Examples: Narrative EssaysAngelito MamersonalNo ratings yet

- 8051&C IDocument142 pages8051&C IphapdnNo ratings yet

- V3F16L 5009Document1 pageV3F16L 5009Simone menottiNo ratings yet

- RRL YoungfaithcatholicsDocument7 pagesRRL YoungfaithcatholicsJhea Cabos GaradoNo ratings yet

- The Islamia University of Bahawalpur: TopicDocument5 pagesThe Islamia University of Bahawalpur: TopicJam ShahzaibNo ratings yet

- Module 2 - Melc Activity AnswerDocument18 pagesModule 2 - Melc Activity AnswerAlma AgnasNo ratings yet

- How To ... Teach Vocabulary: Teacher's Book. Pearson Longman Extra Words Feature Which Allows Students ToDocument1 pageHow To ... Teach Vocabulary: Teacher's Book. Pearson Longman Extra Words Feature Which Allows Students ToPaula UrbaniNo ratings yet

- Exploring Financial Capability of Smes and Improving Financial Management Performance Using Financial ApplicationDocument5 pagesExploring Financial Capability of Smes and Improving Financial Management Performance Using Financial ApplicationJEROME ORILLOSANo ratings yet

- WEEK 2 - Level 0 - Jar TestDocument2 pagesWEEK 2 - Level 0 - Jar TestWHfamilyNo ratings yet

- Why Are Filipino Consumers Strong Adoptersof Mobile ApplicationsDocument13 pagesWhy Are Filipino Consumers Strong Adoptersof Mobile ApplicationselenaorNo ratings yet

- WHO Global Programme To Eliminate Lymphatic FilariasisDocument107 pagesWHO Global Programme To Eliminate Lymphatic FilariasisVergaaBellanyNo ratings yet

- Farming Dissertation IdeasDocument6 pagesFarming Dissertation IdeasWriteMyPaperOnlineNewark100% (1)

- Royal HaskoningDHV Shipyards Brochure PDFDocument16 pagesRoyal HaskoningDHV Shipyards Brochure PDFSUBIN MATHEWNo ratings yet

- En 81-44Document120 pagesEn 81-44ricardoalconNo ratings yet

- 2 Hour Lesson Plan 2Document4 pages2 Hour Lesson Plan 2api-241659479No ratings yet

- FRSTDocument183 pagesFRSTJavier NavarreteNo ratings yet

- What Is SMARTDocument6 pagesWhat Is SMARTannhat141No ratings yet

- C4 Strategic ManagementDocument5 pagesC4 Strategic ManagementAdnan ZiaNo ratings yet

- Why An Electronic Choke Circuit Diagram Is ImportantDocument10 pagesWhy An Electronic Choke Circuit Diagram Is ImportantjackNo ratings yet

- Resume - Rhafael LachicaDocument5 pagesResume - Rhafael Lachicamarg lachicaNo ratings yet

- 11 Hwarang Do en InglesDocument3 pages11 Hwarang Do en Inglesjanali69100% (1)

- Psychology - LearningDocument36 pagesPsychology - LearningHannah Song100% (1)

- NCP 3 in ER Module (Bernales, JLE)Document3 pagesNCP 3 in ER Module (Bernales, JLE)Jan Lianne BernalesNo ratings yet

- Marketing ResearchDocument20 pagesMarketing ResearchDeryl GalveNo ratings yet

- Control Lab1Document59 pagesControl Lab1Marlon Boucaud0% (1)

- Brochure Evolve DatasheetDocument3 pagesBrochure Evolve DatasheetAhmed GhufranNo ratings yet