D1VW Uk

D1VW Uk

Uploaded by

sureshllsCopyright:

Available Formats

D1VW Uk

D1VW Uk

Uploaded by

sureshllsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

D1VW Uk

D1VW Uk

Uploaded by

sureshllsCopyright:

Available Formats

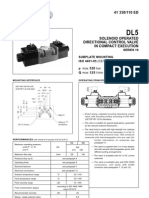

Catalogue HY11-3500/UK

Characteristics

The NG06 directional control valve series D1VW provides high functional limits up to 80 l/min in combination with a very low, energy-saving pressure drop. A wide variety of spool options allows to design an unlimited number of hydraulic circuits. Versions with 8 watt coils, position control, Atex approval, surface protection and connector variants are shown in the following chapters.

Directional Control Valve Series D1VW

Technical data

General Design Actuation Nominal size Mounting interface Mounting position Ambient temperature MTTFD value Weight Hydraulic Max. operating pressure Fluid Fluid temperature Viscosity permitted Viscosity recommended Filtration Flow max. Leakage at 50 bar Static / Dynamic Step response Electrical characteristics Duty ratio Max. switching frequency Protection class Supply voltage Tolerance supply voltage Current consumption hold Current consumption in rush Power consumption hold Power consumption in rush Solenoid connection Wiring min. Wiring length max. Directional spool valve Solenoid DIN NG06 / CETOP 03 / NFPA D03 DIN 24340 A6 / ISO 4401 / CETOP RP 121-H / NFPA D03 unrestricted, preferably horizontal [C] -25...+50 [years] 150 [kg] 1.5 (1 solenoid), 2.1 (2 solenoids) [bar] P, A, B: 350; T: 210 (DC), T: 140 (AC) Hydraulic oil in accordance with DIN 51524 / 51525 [C] -25 ... +70 [cSt] / [mm/s] 2.8...400 [cSt] / [mm/s] 30...80 ISO 4406 (1999); 18/16/13 (meet NAS 1638: 7) [l/min] 80 (see shift limits) [ml/min] Up to 10 per flow path, depending on spool, up to 15 per flow path for spool type 008 + 009 see table response time 100% ED; CAUTION: coil temperature up to 150 C possible [1/h] 15000 (not for soft shift) IP 65 in accordance with EN 60529 (with correctly mounted plug-in connector) Code K J U G Y T 110V at 50Hz/ 230V at 50Hz/ [V] 12 V = 24 V = 98 V = 205 V = 120V at 60Hz 240V at 60Hz [%] 10 10 10 10 5 5 [A] 2.72 1.29 0.33 0.15 0.6 / 0.55 0.3 / 0.27 [A] 2.72 1.29 0.33 0.15 2.5 / 2.4 1.25 / 1.2 32.7 W 31 W 31.9 W 30.2 W 70 / 70 VA 70 / 70 VA 32.7 W 31 W 31.9 W 30.2 W 280 / 290 VA 280 / 290 VA Connector as per EN 175301-803, solenoid identification as per ISO 9461 (code W). [mm] 3 x 1.5 recommended [m] 50 recommended

With electrical connections the protective conductor (PE W) must be connected according to the relevant regulations.

D1VW UK.INDD RH 05.08.2011

2-7

Parker Hannifin Corporation Hydraulics Group

Catalogue HY11-3500/UK

Ordering Code

Directional Control Valve Series D1VW

W

Wet pin armature solenoid, threaded in tube Spool type Spool position

2

3 position spools Code Spool type a 0 b 001 002 003 004 005 006 007 008

1)

Directional Size 3-chamber control DIN NG06 valve valve CETOP 03 NFPA D03

Code C Standard

3 position spools Spool position 3 positions. Spring offset in position 0. Operated in position a or b. Spool type 008,009, 204, 205 2 positions. Spring offset in position 0.

009 1) 010 011 014 015 016 021 022 031 032 034 035 061 081 082 102 204 205

1) 1)

Operated in position a.

Operated in position b.

Spring offset in position b.

Spring offset in position a.

2 positions. Operated in position 0.

Operated in position b.

Operated in position a.

2 positions. Spring offset in position 0.

Spring offset in position a.

Spring offset in position b.

2 positions. Operated in position 0.

Code Standard

A B

a

P

b

T

2 position spools Code Spool type a b 020 026 030 083 1) 101 208

1)

2 position spools Spool position Spool type 083 2 positions. Spring offset in position b. Operated in position a. 2 positions. Operated in position a or b. No center or offset position. A B 2 positions. a b Spring offset in position a. P T Operated in position b.

Consider specific spool position.

D1VW UK.INDD RH 05.08.2011

2-8

Parker Hannifin Corporation Hydraulics Group

Catalogue HY11-3500/UK

Ordering Code

Directional Control Valve Series D1VW

W

Seals Solenoid voltage Solenoid connector as per EN 175301-803, without plug

(other connectors are available for D1MW Series)

Solenoid option

Design series

(not required for ordering)

2

Code omit T S2 3) S3 3) 4N

3)

Solenoid option Standard solenoid with manual override without manual override Soft shift orifice size 0.5 mm. Soft shift orifice size 0.75 mm. with lockable manual override

3)

DC only

Code K J U G

2) 2)

Voltage 12V = 24V = 98V = 205V = 110V 50Hz / 120V 60Hz 230V 50Hz / 240V 60Hz

Y T

2)

To be used in combination with rectifier plugs at 120VAC / 230VAC power supply.

Code N V

Seals NBR FPM

Further spool types, solenoid voltages and connectors on request.

D1VW UK.INDD RH 05.08.2011

2-9

Parker Hannifin Corporation Hydraulics Group

Catalogue HY11-3500/UK

Flow Curve Diagram

Flow curve

24 14 13

Directional Control Valve Series D1VW

10 9 8 7 20 6 5 16 11 12 12 4 3 2 1

Pressure drop [bar]

20

40

60

80 Flow [l/min]

All characteristic curves measured with HLP46 at 50C. Position b B-T 2 4 4 3 2 4 2 2 2 6 2 4 3 8 3 13 13 10 4 3 2 A-T 5 5 2 3 3 Position b P-B 4 B-T 2 2 A-B Position a A-T 2 4 6 3 2 4 2 2 2 4 2 3 2 3 8 13 13 9 4 3 2 5 B-T 5 7 2 3 3 Position a A-T 2 P-B 2 2 Position 0 A-T 5 7 7

Spool 001 002 003 004 005 006 007 010 011 014 015 016 020B 026B 030B 034 035 081 082 101B 102 61 83H 104 208 008 009 83B 204 205 Spool 021 022

P-A 2 1 3 2 2 1 3 3 2 3 3 2 4 4 2 4 3 13 13 11 1 1 5 1 3 P-B 4 5 5 1 4 P-A 2 P-A 6 2

P-B

P-B 2 1 3 2 2 1 2 3 2 2 3 2 2 4 1 3 4 13 13 10 1 1 5 2 2 P-A 4 6 5 4 1 P-B 4 P-A 5 2

P-A

P-A 1 12 7

P-B 1

B-T 5 7 2

P-T 2

7 3 14 2 12

7 7

14 7

5 7

1)

7 5

1)

5 3 3 P-A

5 2

8 14

6 14

P-B

A-T

B-T

P-T 9 7 7 5

7 7

4 4

A-B Only for pressure compensation, no high flow possible.

1)

D1VW UK.INDD RH 05.08.2011

2-10

Parker Hannifin Corporation Hydraulics Group

Catalogue HY11-3500/UK

Shift Limits

The diagram below specifies the shift limits for valves with DC solenoids. Valves with spool position F or M can only be operated up to 70% of the limits. The specifications apply to a viscosity of 40mm2/s and balanced flow Valve with standard DC solenoid

350 300 250 200

081 082

Directional Control Valve Series D1VW

conditions. The shift limits can be considerably lower at unbalanced flow conditions. To avoid flow rates beyond the shift limits, a plug-in orifice can be inserted in the P-port.

011 003, 004, 015 021, 022 020, 030

Pressure [bar]

150 100 50 0 350 300 250 200

026 005, 016 010 007, 008, 009, 014, 083

10

20

30

40

50

60

70

80

90

Flow [l/min]

001,002, 006

Pressure [bar]

150 100 50 0 0 10 20 30 40 50 60 70 80 90

Measured with HLP46 at 50C, 90% Unom and warm solenoids

Flow [l/min]

Valve with standard AC solenoid

Pressure [bar]

350 300 250 200 150 100 50 0 350 300 250 200 150 100 50 0 0 10 20 30 40 50 60 70 80 90

082 101 007, 014, 081 026 005, 008, 016, 020 004 002 004 006, 030 005, 008, 016, 020

002

001

10

20

30

40

50

60

70

80

90

Flow [l/min]

Pressure [bar]

009, 011, 102 003, 015, 204, 205

010,021, 022

Measured with HLP46 at 50C, 95% Unom and warm solenoids

D1VW UK.INDD RH 05.08.2011

Flow [l/min]

2-11

Parker Hannifin Corporation Hydraulics Group

Catalogue HY11-3500/UK

Response Times

Shift limit diagram - Soft shift with 1 DC solenoid

350 300

101

Directional Control Valve Series D1VW

Supply pressure [bar]

002, 020

030

009, 102

001, 004, 081

250 200 150 100 50

0 10 20 30 40 50 60 70 80 Flow [l/min]

Shift limit diagram - Soft shift with 2 DC solenoid

350 300

020D 002 009 081, 082 001, 004

Supply pressure [bar]

250 200 150 100 50

0 10 20 30 40 50 60 70 80 Flow [l/min]

Measured with HLP46 at 50C, 90% Unom and warm solenoids

Response times D1VW Standard and Soft Shift

Standard solenoid Standard DC Standard AC Standard DC with rectifier plug Response times Soft Shift Code S2 S3 0.50mm 0.75mm Orifice w/o w/o w/o 2 solenoid valve 3 positions Center position: Closed Energize De-energize 200 - 750 310 - 650 180 - 300 300 - 400 Energize 45 - 60 13 60 -70 2 solenoid valve 3 positions Center position: Open Energize De-energize 220 - 400 350 - 750 200 - 350 300 - 500 De-energize 20 - 30 20 70- 90 1 solenoid valve 2 positions Energize 90 - 350 90 - 350 De-energize 160 - 500 130 - 350

Orifice size

The lower value applies to small flow rates and low pressure, the upper value to high flow rates and high pressure Step response times were obtained under the following conditions: HLP46 at 50C with the valve operating at nominal pressure and flow. Published response times are nominal and may vary with spool, flow, pressure and temperature.

Acceleration for orifice size 0.75, code S3 (measured against a standard valve)

build-in orifice

For even softer shifting, the proportional spools 081, 082, 101 and 102 can be used.

D1VW UK.INDD RH 05.08.2011

2-12

Parker Hannifin Corporation Hydraulics Group

Catalogue HY11-3500/UK

Dimensions

Interface EN 175301-803, DC solenoid B, E, F -style

9.5

Directional Control Valve Series D1VW

H, K, M -style

9.5

93

93

22

A B 5.5

22

69

A B 5.5

91.4

162

46

134.6 162

46

C, D -style

9.5

Option 4N, with lockable manual override (available for all styles, DC only)

9.5

69

93

93

22

22

A B 5.5

A B 5.5

91.4

226

46

119.4

190

Interface EN 175301-803, AC solenoid B, E, F -style

9.5

H, K, M -style

9.5

69.5 93.5

69

22

A B 5.5 127 152 46 46

22

B 5.5 46

84 152

C, D -style

9.5

22

B 5.5

84 211

Surface finish BK375 4x M5x30 DIN 912 12.9 7.6 Nm 15% NBR: SK-D1VW-N-91 FPM: SK-D1VW-V-91

The space necessary to remove the plug per EN 175301-803, design type AF is at least 15 mm. The torque for the screw M3 of the plug has to be 0.5 to 0.6 Nm.

D1VW UK.INDD RH 05.08.2011

69.5 93.5

2-13

Parker Hannifin Corporation Hydraulics Group

69.5 93.5

Catalogue HY11-3500/UK

Notes

2-14

Parker Hannifin Corporation Hydraulics Group

You might also like

- Worksheets Pneumatics Basic LevelDocument144 pagesWorksheets Pneumatics Basic Levelvrjr0% (1)

- Denison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01Document12 pagesDenison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01abuzer1981No ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument9 pagesSeries D1VW Characteristics: Directional Control ValvejuanNo ratings yet

- SD 11 eDocument12 pagesSD 11 eseaqu3stNo ratings yet

- Series D3MW Characteristics: FeaturesDocument6 pagesSeries D3MW Characteristics: FeaturesPdroGsus Abregú TerronesNo ratings yet

- SD 16 eDocument20 pagesSD 16 eseaqu3stNo ratings yet

- SD 6 eDocument16 pagesSD 6 eseaqu3stNo ratings yet

- SD 25 eDocument20 pagesSD 25 eseaqu3stNo ratings yet

- SD 5 eDocument12 pagesSD 5 eseaqu3stNo ratings yet

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDocument10 pagesHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111No ratings yet

- Sds 150 eDocument16 pagesSds 150 ejbsb1No ratings yet

- ATOSs Valves DHI-0711Document4 pagesATOSs Valves DHI-0711Cardoso MalacaoNo ratings yet

- ALISON HIDRAULIC - Catalogue PDFDocument250 pagesALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- D 631 Series ValvesDocument12 pagesD 631 Series ValvesJosé Olave100% (1)

- SD 14 eDocument12 pagesSD 14 eseaqu3stNo ratings yet

- Rexroth FDDocument116 pagesRexroth FDIvan GudeljNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Elettrovalvole Denison HydraulicsDocument62 pagesElettrovalvole Denison HydraulicsZMCONTROLNo ratings yet

- Re29061 4WREEDocument18 pagesRe29061 4WREEManuel VizcarraNo ratings yet

- SD 25 eDocument20 pagesSD 25 ejbsb1100% (1)

- Proportional Control Valves D631 Series ISO 4401 Size 05Document8 pagesProportional Control Valves D631 Series ISO 4401 Size 05Devendra BangarNo ratings yet

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDocument8 pages4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNo ratings yet

- 3-4WE Re23327 - 2008-08Document16 pages3-4WE Re23327 - 2008-08Ramón Fernández PérezNo ratings yet

- Ev DG05Document14 pagesEv DG05mtbecerrapNo ratings yet

- SD25Document20 pagesSD25Mauricio Ariel H. OrellanaNo ratings yet

- Welding Consumables-Stainless SteelDocument27 pagesWelding Consumables-Stainless SteelibicengNo ratings yet

- DPC 38 eDocument12 pagesDPC 38 ejbsb1No ratings yet

- Duplo MaticDocument8 pagesDuplo MaticHENRYGALLEGOSNo ratings yet

- Atos HidraulicaDocument8 pagesAtos HidraulicaFabinhoTowerNo ratings yet

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (2)

- Series 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)Document4 pagesSeries 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)chekit9No ratings yet

- Ec 1305 PDFDocument23 pagesEc 1305 PDFNguyen Van ChungNo ratings yet

- Solenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06Document4 pagesSolenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06RFIGUEROACNo ratings yet

- Functional Description: HA 5115 8/2005 Proportional Directional Control ValvesDocument19 pagesFunctional Description: HA 5115 8/2005 Proportional Directional Control ValvesgatodeftoneNo ratings yet

- SDM 102 eDocument24 pagesSDM 102 eseaqu3stNo ratings yet

- Atos Industrial ValvesDocument22 pagesAtos Industrial ValvesM S GokulNo ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument8 pagesSeries D1VW Characteristics: Directional Control ValveJas SumNo ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- JCI Cataloge 2014Document60 pagesJCI Cataloge 2014KAZIMALI25No ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- Data JohnsonControlDocument233 pagesData JohnsonControlQuyết Nguyễn MạnhNo ratings yet

- SDM140EDocument36 pagesSDM140Eseaqu3stNo ratings yet

- 62 SeriesDocument8 pages62 SeriesDevendra BangarNo ratings yet

- Trokraki On - Off VentilDocument12 pagesTrokraki On - Off VentilAdvokat HadziTonicNo ratings yet

- H Electro Hydraulic Controls YukenDocument142 pagesH Electro Hydraulic Controls Yukenchidambaram kasi100% (1)

- Butterfly ValvesDocument6 pagesButterfly ValvesMustapha_Kamel_6389No ratings yet

- DCV 03 hk66t102Document15 pagesDCV 03 hk66t102seaqu3stNo ratings yet

- Series R5U Characteristics: Pilot Operated Pressure Unloading ValveDocument5 pagesSeries R5U Characteristics: Pilot Operated Pressure Unloading ValveHarinderNo ratings yet

- 977205PDocument49 pages977205PChu QuynhNo ratings yet

- PARKER Valvula Direccional D3W UKDocument7 pagesPARKER Valvula Direccional D3W UKComassur SA de CVNo ratings yet

- Servovalve Andritz HydroDocument4 pagesServovalve Andritz HydroYhony Gamarra VargasNo ratings yet

- Catalogo Electrovalvulas ATOS SPADocument4 pagesCatalogo Electrovalvulas ATOS SPACapces FrostmooreNo ratings yet

- Vickers DG4V-3 DG4V-3S 6xDocument32 pagesVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroNo ratings yet

- HOV1BDocument4 pagesHOV1Behab8320014413No ratings yet

- Rexroth 4we10 Data SheetDocument10 pagesRexroth 4we10 Data SheetOrlando Arias100% (1)

- HVAC+Valves+and+Actuators+Catalogue+07 2011Document64 pagesHVAC+Valves+and+Actuators+Catalogue+07 2011Jafar JalladNo ratings yet

- Vsd03m SelDocument12 pagesVsd03m SelBrayan AguileraNo ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument8 pagesSeries D1VW Characteristics: Directional Control ValveFkrmcofmfmNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Parker Valve Industrial Electrohydraulic ElectronicsDocument54 pagesParker Valve Industrial Electrohydraulic Electronicssureshlls100% (1)

- AWEX e PDFDocument4 pagesAWEX e PDFsureshllsNo ratings yet

- Network Design Manual v7.7Document194 pagesNetwork Design Manual v7.7somchak2000100% (3)

- Apar Industries Limited: (Unit: Uniflex Cables)Document45 pagesApar Industries Limited: (Unit: Uniflex Cables)jack jNo ratings yet

- Electro Magnetic Brakes: Instantly! Silently! As Frequently As You Like!Document5 pagesElectro Magnetic Brakes: Instantly! Silently! As Frequently As You Like!sureshllsNo ratings yet

- C70SS-C90SDR PLC Complete Manual PDFDocument290 pagesC70SS-C90SDR PLC Complete Manual PDFthuanNo ratings yet

- Irjet V9i1195Document5 pagesIrjet V9i1195BensonNo ratings yet

- Class 6 Hydraulic ValvesDocument103 pagesClass 6 Hydraulic ValvesSoheilDarvishMotavalli100% (2)

- BSeries Maintenance Operation PDFDocument61 pagesBSeries Maintenance Operation PDFEdwing GRNo ratings yet

- Manual Proportional Directional Control Valve (With Pressure Compensation, Multiple Valve Series)Document6 pagesManual Proportional Directional Control Valve (With Pressure Compensation, Multiple Valve Series)Fawzi AlzubairyNo ratings yet

- Rapid Transverse and Feed Control Hydraulic CircuitDocument10 pagesRapid Transverse and Feed Control Hydraulic CircuitAditya GosiNo ratings yet

- GD - FFD-19Document43 pagesGD - FFD-19Baha SevinçNo ratings yet

- HAWE Proportional Directional Spool VALVEDocument28 pagesHAWE Proportional Directional Spool VALVECosma Petru-Raul100% (1)

- Hydraulics & Pneumatics: Introduction To Electro-PneumaticsDocument67 pagesHydraulics & Pneumatics: Introduction To Electro-PneumaticsSAMUEL MAKATANENo ratings yet

- Isuzu N-Series Elf Workshop Manual - Power Take Off With Oil Pump - LGPTO-WE-0091 PDFDocument63 pagesIsuzu N-Series Elf Workshop Manual - Power Take Off With Oil Pump - LGPTO-WE-0091 PDFRicardo Cornejo LafuenteNo ratings yet

- Automatic Control For Mechanical Engineers, M Galal RabieDocument176 pagesAutomatic Control For Mechanical Engineers, M Galal RabieGalal RabieNo ratings yet

- D77005 enDocument46 pagesD77005 enzliangNo ratings yet

- VCB22 Series - Data Sheet (En)Document11 pagesVCB22 Series - Data Sheet (En)marklaforest0% (1)

- Wandfluh - 4-2 Way-Solenoid Spool Valve SpecsDocument5 pagesWandfluh - 4-2 Way-Solenoid Spool Valve SpecsHanzoNo ratings yet

- 4-2 Directional Spool Valve 4WE6DDocument2 pages4-2 Directional Spool Valve 4WE6DRaphael SasdelliNo ratings yet

- Cat HY14 3000 Republic, Manatrol - 07 06Document166 pagesCat HY14 3000 Republic, Manatrol - 07 06James PhamNo ratings yet

- Hydraulics and Pneumatics SystemsDocument4 pagesHydraulics and Pneumatics SystemsKrista JacksonNo ratings yet

- Chapter 5Document36 pagesChapter 5muhammad irfan hakimi bin nor yazidNo ratings yet

- Electro Pneumatic Technology 2Document29 pagesElectro Pneumatic Technology 2Victor Al100% (1)

- D288THK006 6202 0Document21 pagesD288THK006 6202 0Luis Cardenas LopezNo ratings yet

- Lab 9Document5 pagesLab 9Fazail BangashNo ratings yet

- HY14-2500 12-11 Directional Control Valves PDFDocument250 pagesHY14-2500 12-11 Directional Control Valves PDFPartsGopher.comNo ratings yet

- Industrial Pneumatics Basics - by CEREBRO SWITCH-desbloqueadoDocument80 pagesIndustrial Pneumatics Basics - by CEREBRO SWITCH-desbloqueadoFernando MatiasNo ratings yet

- Parker Pneumatic CatalogueDocument809 pagesParker Pneumatic CatalogueEdo NurkanovicNo ratings yet

- Center Drive Units (Cdu) Se-876-03-1110 - R1Document32 pagesCenter Drive Units (Cdu) Se-876-03-1110 - R1amir ghaznaviNo ratings yet

- Barksdale Controls Valves RegulatorsDocument42 pagesBarksdale Controls Valves Regulatorsuldarico lozanoNo ratings yet

- Lab Manual Oil Hydraulics & Pneumatics (2171912)Document70 pagesLab Manual Oil Hydraulics & Pneumatics (2171912)pnjohn2822No ratings yet

- CV - Bifold Group CatalogDocument576 pagesCV - Bifold Group Catalogking4life50% (2)

- Hyadraulic SymbolsDocument8 pagesHyadraulic SymbolsDhiraj ShindeNo ratings yet