Part-Vi Materials

Part-Vi Materials

Uploaded by

joydeep_d3232Copyright:

Available Formats

Part-Vi Materials

Part-Vi Materials

Uploaded by

joydeep_d3232Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Part-Vi Materials

Part-Vi Materials

Uploaded by

joydeep_d3232Copyright:

Available Formats

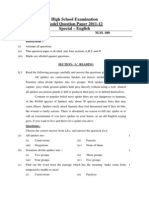

TECHNICAL SPECIFICATION for CIVIL WORKS

PART VI MATERIALS

CONTENTS

Clause No. Title Page No.

1.0 1.1 1.2 1.3 1.4 1.5 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7

GENERAL Scope Standard Approval of Tests Codes Rejection of Materials MATERIALS FOR CONCRETE Aggregates Coarse Aggregates Fine Aggregates Lime Surkhi Cement Water Admixture for Concrete STEEL For Reinforcement For Binding Wire For Structural work and Insert Steel Tubes Testing Conduits Foundation Bolts

M 5 of 39

M - 6 of 39

M - 15 of 39

RAPDRP/Part B

PART-VI (FINAL)

M-1 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Clause No. Title Page No.

4.0 4.1 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7 6.0 6.1 6.2 6.3 6.4 6.5 7.0 7.1 7.2 7.3 7.4 7.5 7.6

ASBESTOS CEMENT PRODUCTS General BRICKS Brick Handling Samples and Inspection Brick Bats Cement, Lime and Water Sand for Masonry Mortar Sand for Plastering FLOORING & PAVING Cement & Binders Aggregates Tiles Pigments Dividing Strips TIMBER General Country Wood Teak Wood Storage & Inspection Moisture Content Flush door Shutters, Shelves

M - 16 of 39

M - 17 of 39

M - 18 of 39

M - 19 of 39

8.0 FITTINGS FOR DOORS, WINDOWS ETC. 8.1 General 8.2 Hinges 8.3 Sliding Door Bolts 8.4 Door Latch 8.5 Tower Bolts 8.6 Door Handles 8.7 Mortice Lock

M - 20 of 39

RAPDRP/Part B

PART-VI (FINAL)

M-2 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Clause No. Title Page No.

8.8 Floor Door Stopper 8.9 Hooks & Eyes 8.10 Fan Light Pivots 8.11 Fan Light Catch 8.12 Chain with Hook for Fan Light 8.13 Hasp and Staple 8.14 Hydraulic Door Closer 8.15 Steel Frames 8.16 Casement Window Fasteners 8.17 Casement Brass Stays 8.18 Quadrant Stays 9.0 9.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8 9.9 10.0 10.1 10.2 10.3 10.4 10.5 11.0 11.1 11.2 11.3 11.4 11.5 11.6 11.7 11.8 11.9 11.10 WINDOWS, VENTILATORS & ROLLING SHUTTERS, COLLAPSIBLE GATE General Steel Doors, Windows, Ventilators M.S. Bolts etc. Hardware Mastic Steel Rolling Shutter Collapsible Gate Aluminium Doors, Windows & Ventilators Materials GLASS General Plain Transparent Glass Ground or Frosted Glass Thickness Inspection PAINT General Sampling & Testing Storage Paints for Priming Paints for Finishing White Wash, Colour Wash Cement Paint Distemper Varnish Polish

PART-VI (FINAL)

M - 24 of 39

M - 25 of 39

M - 26 of 39

RAPDRP/Part B

M-3 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Clause No. Title Page No.

12.0 12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8 13.0 13.1 13.2 13.3 13.4 13.5 13.6 13.7 13.8 13.9 13.10 13.11 13.12 14.0 14.1 14.2 14.3 14.4 14.5 14.6 15.0 15.1 16.0 17.0

WATERPROOFING MATERIALS Integral Cement Water proofing compounds Bitumen Bitumen Primer Bitumen Felt Bitumen Mastic Bitumen Compounds Surface Application Materials Polymer based Paints DRAINAGE AND SANITATION (INTERNAL) General HDPE Pipes for Rainwater Indian Pattern Orissa Type W.C. Wash Hand Basin Mirror and Frame Glass Shelf Towel Rail Soap Container / Soap Disc Floor Trap Gully Trap C.I. Manhole Cover / PFRC Cover / FRC Cover Toilet Paper Holder WATER SUPPLY & PLUMBING (INTERNAL) General M.S. Galvanised Pipes and Fittings Bib Tap and Stop Valve Valves Shower Rose Storage Tank ROADS General SCHEDULE OF TESTS ON MATERIALS LIST OF MATERIALS

M - 28 of 39

M - 29 of 39

M - 31 of 39

M - 33 of 39 M - 34 of 39 M - 35 of 39

RAPDRP/Part B

PART-VI (FINAL)

M-4 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

PART VI MATERIALS

1.0 1.1 GENERAL Scope This part deals with the requirements of materials for use in permanent work with regard to quality, testing, approval and storage, before they are used on work. This part is supplementary to Part-V : Workmanship and Other Parts of the Technical Specifications for Civil Works. 1.2 Standard Approved quality of materials shall be used in permanent work and shall be procured from approved manufacturers in order to ensure uniformity of quality and assurance of timely supply. 1.3 1.3.1 Approval of Tests All material to be used in permanent construction shall be subject to approval of the WBSEDCL. The TENDERER shall apply sufficiently in advance with samples of the materials including the supporting test results free of cost if asked for from the approved laboratory and other documentary evidences from the manufacturer wherever applicable and indicating the type of materials and their respective sources. The delivery of materials at site shall commence only after the approval of the quality, grading and sources of the materials. The quality of all materials once approved shall be maintained throughout the period of construction and periodical approved tests shall be carried out to ensure that it is maintained, if necessary. The brands/makes of materials specified in the Technical Specifications shall only be used in work as decided by the WBSEDCL. Should it become necessary for any reason such as non-availability, to be verified and confirmed to use any material other than the specified Brand or Make, the TENDERER shall submit sample of the same to the WBSEDCL for approval together with test certificates and other documents necessary for examining and giving approval thereof. Tests on Materials delivered at site shall be carried out as mentioned in Clause 16.

PART-VI (FINAL) M-5 of 43

1.3.2

1.3.3

1.3.4

RAPDRP/Part B

TECHNICAL SPECIFICATION for CIVIL WORKS

1.4 1.4.1

Codes Unless mentioned otherwise, current versions of all codes, specifications and standards issued by the Bureau of Indian Standards and Indian Roads Congress, Indian Electrical Rules shall be fully applicable to these specifications. In case of any conflict in meaning between these specifications and those of BIS or IRC/IEL, the provisions of these specifications shall prevail. Rejection of Materials Any material brought to site which, in the opinion of the WBSEDCL is damaged, contaminated, deteriorated or does not comply with the requirement of this specification, shall be rejected. If the routine site tests or random site tests show that any of the materials, brought to site, do not comply in any way with the requirements of this specification, then that material shall be rejected. The TENDERER shall remove from site any and all such rejected material within the time specified by the WBSEDCL. MATERIALS FOR CONCRETE Aggregates Aggregates shall comply with the requirements of IS : 383. Coarse and Fine Aggregates for Concrete. They shall be hard, strong, dense, durable, clean and free from veins and adherent coating, vegetable matter and other deleterious substances : and shall be obtained from approved sources. Aggregates shall not contain any harmful material such as pyrites, coal, lignite, shale or similar laminated material, clay, alkali, soft fragments, sea shells and organic impurities in such quantity as to affect the strength or durability of concrete. Aggregates which are chemically reactive with alkalies of cement shall not be used. Aggregates which are not sufficiently clean shall be washed in clean fresh water to the satisfaction of the WBSEDCL. Testing All aggregates shall be subject to inspection and testing. The TENDERER shall submit samples for testing as may be required by the WBSEDCL (if asked for) free of cost by the Tenderer. Sampling and testing shall be carried out in accordance with IS : 2386, Methods of Test for Aggregates for concrete.

1.4.2 1.5 1.5.1

1.5.2

1.5.3

2.0 2.1 2.1.1

2.1.2

RAPDRP/Part B

PART-VI (FINAL)

M-6 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

2.1.3

Grading The TENDERER shall ensure that the full range of aggregate used for making concrete is graded in such a way as to ensure a dense workable mix. The delivery of aggregates will commence only when the WBSEDCL has approved the samples and the quality and grade shall be maintained consistent and equal to the approved sample.

2.1.3.1

Size and grading of fine aggregates The grading shall conform to IS : 383 and shall be within the limits of Grading Zone III. The maximum size of particle shall be 4.75 mm and shall be graded down. Sand containing more than 10% of fine grains passing through 76 mesh sieve or having the fineness modules less than 2.5 shall not be used for concrete work. GRADING LIMITS FOR FINE AGGREGATES IS Sieve Designation 10 4.75 2.36 1.18 600 300 150 mm mm mm mm micron micron micron Grading Zone I 100 90 100 60 95 30 70 15 34 5 20 0 10 Percentage Passing Grading Grading Zone II Zone III 100 100 90 - 100 90 100 75 100 85 100 55 90 75 100 35 59 60 79 8 30 12 40 0 10 0 10 Grading Zone IV 100 95 100 95 100 90 100 80 100 15 50 0 15

(When grading falls outside the limits of any particular grading zone of sieves, other than 600 micron sieve, by a total amount not exceeding 5%, it shall be regarded as falling within the grading zone) 2.1.3.2 Fine Aggregate for mortar and grout The grading of fine aggregate for mortar and grout shall be as per limits IS : 383. For Structural concrete the minimum fineness modules will be 2.5. 2.1.3.3 Size and grading of coarse aggregates The nominal maximum size of the aggregates for each mark of concrete or for each type of work shall be according to relevant clauses of IS : 456 (2000). The aggregates shall be well graded and the grading shall conform to relevant requirements of IS:383 depending upon the maximum nominal size as specified or as required.

RAPDRP/Part B PART-VI (FINAL) M-7 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

GRADING LIMITS FOR COARSE AGGREGATES

IS Sieve Designation 80 63 40 20 16 12.5 10 4.75 2.36 mm mm mm mm mm mm mm mm mm A % passing for single sized aggregate of nominal size

63 mm 40 mm 20 mm 16 mm 12.5 mm

B % passing of grades aggregate of nominal size

10 mm 40 mm 20 mm 16 mm 12.5 mm

100 85-100 0-30 0-5 -

100 85-100 0-20 0-5 -

100 85-100 0-20 0-5 -

100 85-100 0-30 0-5 -

100 85-100 0-30 0-5 -

100 85-100 0-20 0-5

100 95-100 30-70 10-35 0-5 -

100 95-100 25-55 0-10 -

100 90-100 30-70 0-10 -

100 100 90-100 40-85 0-10 -

2.1.4

Storage & Stacking Care shall be taken in the storage to avoid intrusion of any foreign materials into the aggregates and where two types of aggregates are stored close to each other, they shall be separated by a wall or plate. When stock piling care shall be taken to avoid forming pyramids resulting in segregation of different sized materials.

2.2 2.2.1

Coarse Aggregates Types Unless otherwise specified stone chips shall be used as coarse aggregate.

2.2.2

Stone Chips It shall be crushed or broken from hard stone obtained from approved quarries. The stone chips shall be hard, strong, dense, durable and angular in shape. It shall be free from soft, fliable, thin, flat, elongated or laminated and flaky pieces and free from dirt clay lumps, and other deleterious materials like coal, lignite, silt, soft fragments, and other foreign materials which may affect adversely the strength & durability of concrete. The total amount of deleterious / foreign materials shall not exceed 5% by weight according to relevant clause of IS : 383. If found necessary the stone chips shall be screened and washed before use.

2.2.3

Broken Bricks These shall be obtained by breaking well burnt or over burnt dense brick bats. They shall be homogenous in texture, well graded in size, roughly cubical in shape, clean and free from dirt, clay, slit or any other deleterious matter. Before use, these shall be screened.

RAPDRP/Part B

PART-VI (FINAL)

M-8 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

2.3 2.3.1 2.3.2 Fine Aggregates Unless specified otherwise it shall be either natural river sand or pit sand. Sand shall be clean, sharp, strong, angular and composed of hard siliceous material. It shall not contain harmful organic impurities in such form or quantities as to affect adversely the strength and durability of concrete. Sand for reinforced concrete shall not contain any acidic or other material which is likely to attack steel reinforcement. The percentage of all deleterious materials including silt, clay etc., shall not exceed 5% by weight. If directed, sand shall be screened or washed before use to the satisfaction of WBSEDCL. Lime Lime for mortars and concrete shall conform to IS:712. The total of CaO and MgO content in quick lime shall not be less than 85% (MgO shall not exceed 5%). Quickness after slaking, shall leave a residue of not more than 5% by weight on IS sieve 85. 2.5 Surkhi Surkhi used in lime concrete for flooring, terracing etc. shall conform to IS:1344. 2.6 Cement Ordinary Portland cement complying with the requirements of IS : 269 shall be used for making plain and reinforced concrete, cement grout and mortar. Other types of cement may be used depending upon the requirements of certain jobs with the approval of the WBSEDCL. These shall conform to the following standards : Portland Blast Furnace slag Cement 33/43 Grade Ordinary Portland Cement 2.6.1 Testing of Samples The TENDERER shall supply a copy of the manufacturers test certificate for each consignment of cement supplied by him and consignments shall be used on work in the order of delivery. The TENDERER shall supply samples of cement to the WBSEDCL as frequently as he may require for testing, if asked for, free of cost. The sampling of cement for testing shall be according to IS : 3535. All tests shall be in accordance with the relevant clauses of IS : 4031 & IS : 4032.

RAPDRP/Part B PART-VI (FINAL) M-9 of 43

2.4

. .

IS : 455 IS:269/ IS : 8112

TECHNICAL SPECIFICATION for CIVIL WORKS

2.6.2

TENDERER Responsibility From the time that a consignment of cement is delivered at site and approved by the WBSEDCL until such time as the cement is used on the works. The TENDERER shall be responsible for keeping the same in sound and acceptable condition. Any cement, which deteriorates while in the TENDERERS charge and is rejected as unsuitable by the WBSEDCL, shall be removed from the site and outside the limits of work within two days of ordering such removal by the WBSEDCL.

2.6.3

Stock of Cement In order to ensure due progress, the TENDERER shall at all times maintain on the site at least such stock of cement as the WBSEDCL may from time to time consider necessary. No cement shall be used upon the works until it has been accepted as satisfactory by the WBSEDCL.

2.6.4

Storage of Cement The cement shall be stored in such manner as to permit easy access for proper inspection and in a suitable weather tight, well ventilated place to protect it from dampness caused by ingress of moisture from any source. Different types of cement shall be stored separately. Cement bags shall be stacked at least 15 to 20 cm clear of the floor bearing a space of 60 cm around the exterior walls. The cement shall not be stacked more than 10 bags high. Each consignment of cement shall be stacked separately to permit easy access for inspection.

2.7

Water Water used for mixing concrete and mortar and for curing shall be clean and free from injurious amounts of oil, acid, alkali, salts, sugar, organic materials or other substances that may be deleterious to concrete or steel.

2.8 2.8.1

Admixture for Concrete Approval Admixtures to concrete shall not be used without the written consent of the WBSEDCL. When permitted, the TENDERER shall furnish full details from the manufacturer and shall carryout such test as the WBSEDCL may require before any admixture is used in the work.

RAPDRP/Part B

PART-VI (FINAL)

M-10 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

2.8.2 2.8.2.1 Usage Admixtures may be used taking prior approval from the WBSEDCL to modify one or more of the following properties of FRESH CONCRETE. a) b) c) d) e) f) g) h) 2.8.2.2 To increase workability without increasing water content or to decrease the water content at the same workability. To retard or accelerate both initial and final setting times. To reduce or prevent settlement. To create slight expansion in concrete and mortar. To modify the rate or capacity for bleeding or both To reduce segregation of concrete, mortars & grouts. To improve penetration and or pumpability of concrete, mortars and grouts. To reduce rate of slump loss

Admixtures may also be used to modify one or more of the following properties of HARDENED CONCRETE. a) b) c) d) e) f) g) h) i) To retard or reduce heat generation during early hardening. To accelerate the rate of strength development. To increase the strength of concrete or mortar (Compressive, tensile or flexural). To increase the durability or resistance to severe conditions of exposure including the application deicing salts. To decrease the permeability to liquids. To control the expansion caused by the reaction of alkalis with certain aggregate constituents. To control the expansion caused by the reaction of alkalis with certain aggregate constituents. To produce cellular concrete. To increase the bond of concrete to steel reinforcement.

PART-VI (FINAL) M-11 of 43

RAPDRP/Part B

TECHNICAL SPECIFICATION for CIVIL WORKS

j) k) l) m)

To increase the bond between old and new concrete. To improve impact resistance and abrasion resistance To inhibit the corrosion of embedded metal To produce coloured concrete or mortar

While modifying any particular property, care shall be taken to ensure that other properties are not affected adversely. 2.8.3 2.8.3.1 Types Integral Water proofer Admixtures used as integral water proofer shall be free of chlorides and sulphates and shall conform to IS : 2645. The application and dozes shall be as per manufacturers specification. 2.8.3.2 Finely Divided mineral admixtures a) CEMENTITIOUS Natural Cements like Hydraulic lime, slag cements (mixtures of blast furnace slag and lime) and granulated blast furnace slag. POZZOLANIC A Siliceous or siliceous and aluminium material which in itself possesses little or no. cementitious value, but will, in finely divided form and in presence of moisture, chemically react with calcium hydroxide at ordinary temperatures to form compounds possessing cementitious properties, e.g. Fly ashes, volcanic glass, diatomaceous earth and certain shales and clays either heat treated or natural. OTHER Finely divided quartz. silica sands dolomitic and calcitic limestone, marble, granite and other rocks, asbestos waste hydrated lime.

b)

c)

These being extremely fine powers, their mineral admixtures will influence the fresh paste in a manner similar to cement. They can be used to augment the cement in mixtures deficient in fines. Many concretes contain large amount of Portland cement than necessary for strength requirements to provide workability or pumpability. A portion or all of this excess cement may be replaced with a suitable mineral admixture. They are usually used in the proportion of 15-35% by weight of the cement and in proportioning the concrete should be considered as part of the cementing medium, provided they are uniformly blended with cement.

RAPDRP/Part B

PART-VI (FINAL)

M-12 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

The placability of concrete containing blast furnace slag is generally greater than indicated by static slump test or water / cement ratio. In medium or rich concretes, the increase in water requirements caused by their use may reduce strength. Pozzolanic admixtures usually increase the strength of concrete especially at later ages. The addition of fly-ash, natural pozzolana and granulated slag in sufficient quantities will increase the sulphate resistance of concrete. 2.8.3.3 Accelerating admixtures 1) Calcium Chlorides will also affect the following properties : a) May increase drying, shrinkage and creep. The longer the concrete is allowed to cure, the less will be the effect on shrinkage and creep. May lower the resistance of concrete to freezing and thawing and to attack by sulphates and other injurious solutions. May increase the rate of temperature residue to the heat of hydration and in large sections may therefore increase the stresses caused by thermal contraction. Can cause corrosion of adequately embedded reinforcing steel in the concrete. Where large concentrations of stray currents are present, such as in concrete used in structures for electric railroads, power houses or electrolytic reduction plants. Galvanised metal embedded in concrete containing calcium chloride may be expected to corrode at an accelerated rate. Combinations of metals such as aluminium alloy, conduit and steel reinforcing should not be used in concrete containing calcium chloride as electrolytic corrosion may take place.

b)

c)

d)

e) f)

Calcium Chloride will not increase the flexural strength of concrete to the same degree as the compressive strength and decreases in the flexural strength are generally obtained at or after 28 days. The total chloride content in the concrete should be limited as specified in IS : 456 (2000). 2) Calcium aluminate cement blended with Portland cement : Strength will be reduced significantly, shrinkage and swelling on immersion will increase drastically and durability will be poor.

RAPDRP/Part B PART-VI (FINAL) M-13 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

2.8.3.4 Air-entraining admixture a) The water reduction is possible due to entrained air. The volume of this water reduction is less than the volume of entrained air, therefore to compensate for the volume of entrained air, the fine aggregate volume must also be reduced. Despite reduction in the water / cement ratio usually obtained by the use of air entrainers, it may reduce strength, particularly, in concretes of high or moderate cement content.

b)

2.8.3.5

Water reducing and set controlling admixtures a) Admixtures of the Hydroxylated carboxylic acid type may tend to increase the bleeding rate and segregation in concrete deficient in fines (aggregate fines of cement). When prolonged retardation is employed care must be taken to prevent the drying of the concrete. The water reducing admixture should be added at the same time in the mixing cycle, in order to obtain a uniform setting time among the batches. Then admixtures in many cases will increase the slump loss. Increases in the Flexural strength of concrete containing water reducing admixtures are usually attained but they are not proportionately as great as the increase in the compressive strength.

b) c)

d) e)

2.8.4 2.8.4.1

General Suitable remedial measures as recommended by the manufacturers and approved by the WBSEDCL shall be taken to eliminate any disadvantages arising from the mix of admixtures. While using the admixtures the maximum amount of chloride and sulphate expressed either in percentage of cement or concrete shall not exceed the limit as specified in the relevant I.S. codes.

2.8.4.2

RAPDRP/Part B

PART-VI (FINAL)

M-14 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

3.0 3.1 STEEL For Reinforcement Reinforcing bars for concrete shall be round steel bars of the following types as may be shown on the drawing : a) Plain mild steel bars conforming to Grade I of IS : 432 Mild Steel and Medium Tensile Steel and Hard Drawn Steel wire for Concrete Reinforcement. High Yield strength deformed bars conforming to IS : 1786 (Fe 415). Specification for High Strength Deformed Steel Bars & Wires for Concrete Reinforcement.

b)

All reinforcement bars shall be of uniform cross sectional area and be free from loose mill scales, dust, loose rust, coats of paint, oil or other coatings which may destroy or reduce bond. 3.2 For binding wire Binding wire for reinforcement shall be annealed steel wire 18-20 BWG or not less than 0.9 mm diameter conforming to IS : 280 Specification for Mild Steel Wire. 3.3 For structural work and insert Steel structural work and for preparation of inserts and embedments shall conform to IS:2062 Specification for Steel for general structural purposes. 3.4 Steel Tubes Steel Tubes for use in light structural work and inserts shall be of light or medium class and of grade YST 25 conforming to IS : 1161 Specification for Steel Tubes for Structural Purposes 3.5 Testing Test certificates, if asked for, from manufacturer shall be submitted for each consignment free of cost. Additional test, if necessary, shall be done according to the list of tests prescribed by the WBSEDCL.

RAPDRP/Part B

PART-VI (FINAL)

M-15 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

3.6 3.6.1 Conduits Steel for electrical wiring Rigid steel conduits for electrical use shall conform to IS : 1653 for rigid pipes and to IS : 3480 for flexible conduits. Fittings for conduits shall conform to IS : 2667. All conduit pipes shall be finished with galvanized or stove-enamelled surface. All accessories shall be of threaded type and pipes shall be jointed by means of screwed couplers only. Bend in conduits shall be made to the dimension shown in drawing, but a minimum of 12 times the diameter. Where shown in drawing they shall be treated with anticorrosive preservative as specified. 3.6.2 Non-metallic for electrical wiring Non-metallic conduits for electrical use shall conform to IS : 2509 for rigid pipes and to IS : 6946 for flexible pipes. Fittings shall conform to IS : 3419. Bends shall be achieved by bending the pipe by inserting suitable solid or inspection type normal bends, elbows or similar fittings. 3.7 Foundation Bolts Bolts to be embedded in concrete shall, unless otherwise detailed in drawings, conforming to IS:5624 Specification for Foundation Bolts. Material for bolts shall, unless otherwise mentioned on drawings or the Schedule of Items, be of mild steel conforming to IS:226. Nuts and lock nuts shall conform to IS:1363 Specification for black Hexagon bolts, nuts & lock nuts (diameter 6 - 39 mm) and black Hexagon screws (diameter 6 24 mm) and to IS:3138 Specification for Hexagon bolts & nuts (M-42 to M-150). Plain washers shall conform to IS: 2016 Specification for plain washers and spring washers shall conform to IS:3063 Spring Washers for Bolts, Nuts & Washers. 4.0 4.1 ASBESTOS CEMENT PRODUCTS General Asbestos cement products shall be free from visible defects, uniform in colour of required density, length, thickness and diameter within the allowable tolerance. They shall be obtained from an approved source of manufacture and stored safely. Methods of test shall be according to IS:5913 - `Method of Test for Asbestos Cement Products.

RAPDRP/Part B PART-VI (FINAL) M-16 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

5.0 5.1 BRICK Bricks Bricks for masonry in foundations, walls and other locations shall be common burnt clay building bricks of 100 kg/sq. cm crushing strength when tested in accordance with IS : 1077 - Common Burnt Clay Building Bricks. They shall be sound, hard and thoroughly well burnt, but not over-burnt, with uniform size having rectangular, faces with parallel sides and sharp straight right angled edges and be of uniform colour with fine compact uniform texture. Bricks shall be of uniform deep red cherry or copper colour. They shall be free from flaws, cracks and nodules of free lime. Water absorption after 24 hours immersion in cold water shall be not more than 20% by weight. They shall not absorb more than 10% by weight of water after immersion for six hours. They shall emit a clear metallic ringing sound when struck by a mallet and shall not break when dropped on their face, from a height of 60 cm. Fractured surface shall show homogenous, fine grained uniform texture, free from cracks, air holes, laminations, grits, lumps of lime, efflorescense or any other defect which may impair their strength, durability, appearance and usefulness for the purpose intended. Under-burnt or vitrified bricks shall not be used. Samples of bricks brought to the site shall be tested periodically for compression and other tests according to IS : 3495, Parts I, II, III & IV Method of Test for Burnt Clay Building Bricks, if asked for. 5.2 Handling Bricks shall be unloaded by hand and carefully stacked and all broken bricks shall be removed from the site. 5.3 Samples and Inspections Representative samples shall be submitted by the TENDERER and approved samples retained by the WBSEDCL for comparison and future reference. Bricks shall be obtained from approved manufacturer. All bricks shall be subject to inspection on the site and shall be to the approval of the WBSEDCL who may reject such consignments as are considered by him to be inferior to the quality specified. The TENDERER shall provide all labour and plant required for the inspection and conduct such test as shall be required by the WBSEDCL with out additional charges. 5.4 Bricks Bats Bricks bats shall be obtained from well burnt bricks.

RAPDRP/Part B

PART-VI (FINAL)

M-17 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

5.5 Cement, Lime and Water Cement, lime and water shall conform to the specification in this series under the section concrete. 5.6 Sand for Masonry Mortar Sand for masonry mortars shall be natural sand and shall comply with IS : 2116 - Sand for Masonry Morters. The maximum size of sand particle for brick work shall be 2.5 mm and for rubble masonry 4.75 mm. 5.7 Sand for Plastering Sand for use in mortars for internal wall, ceiling and external plastering and rendering shall conform to A grade of IS : 1542 Sand for Plastering. 6.0 6.1 6.1.1 FLOORING & PAVING Cement & Binders Cement Cement, fine aggregates, reinforcement and water used shall comply with the requirements of concrete in series. Water Water for construction shall be clean, soft, free from loam, salt and organic materials. Hard water shall not be used. 6.2 6.2.1 6.2.1.1 6.2.1.2 Aggregates Coarse Aggregate Coarse aggregate shall conform to the requirements of this series. For in-situ terrazzo flooring, chips shall be within sizes 12 mm to 6 mm graded. The marble chips for topping of terrazzo floor shall be of 6 mm finished size and shall conform to Grade I of IS : 2114 Code of Practice for laying in-situ terrazzo floor finish. Tiles White Glazed Tile White Glazed tiles shall be of approved manufacture and quality and shall conform to IS : 777 Glazed Earthernware Tiles. They shall be true in

RAPDRP/Part B PART-VI (FINAL) M-18 of 43

6.1.2

6.3 6.3.1

TECHNICAL SPECIFICATION for CIVIL WORKS

shape, free from haircracks, glazing spot, chipped edges and corners and surface shall be perfectly flat without warps and of uniform colour. The top surface shall be glazed either gloss or matt as specified. The tiles shall be as specified in drgs. And shall not be less than 6 mm thick or as specified. The tolerance on facial dimension value shall be plus or minus 1.0 mm and plus or minus 0.5 mm on thickness. The specials such as coves, internal and external angles, beads, cornices and their corner pieces shall be of specified sizes and of thickness not less than the thickness of tiles. 6.3.2 Coloured Tiles Only Glaze shall be coloured as specified. The size and specification of tiles shall be same as for the white glazed tiles. 6.3.3 Acid Proof Tiles The ceramic unglazed vitreous acid resisting tiles shall conform to the requirements of IS:4457. The finished tile when fractured shall appear fine grained in texture, dense and homogenous. Tile shall be sound, true to shape, flat, free from flaws and any manufacturing defects affecting their utility. Tolerance in dimensions shall be within the limits specified in the IS. The tiles shall be bedded and jointed using chemical resistant master of the resin type conforming to IS:4832 (Part-II). Method of usage shall generally be as per the requirements of IS:4443. 6.4 Pigments Pigments incorporated in mortar or used for grouting shall be subject to approval of WBSEDCL 6.5 Dividing Strips Dividing Strips shall be of aluminium, glass or similar materials and of quality approved by the WBSEDCL. Glass or other metal strips shall be 1.5 mm thick penetrating to the full depth of the flooring. 7.0 7.1 TIMBER General All timber used for permanent works shall be new. It shall be well seasoned by a suitable process conforming to IS:1141 before being planed to the required sizes. It shall be sound, straight, free from sap, radial

RAPDRP/Part B PART-VI (FINAL) M-19 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

cracks, decay, fungal growth, boxed heart, pitch pockets, borer holes, splits, loose knots, flaws or any other defects and shall show a clean surface when cut. Timber shall conform to the requirements of IS : 1003. The finished components shall be given suitable preservative treatment wherever necessary. Hard wood when used shall be given chemical treatment. 7.2 Country Wood Country Wood shall be belonging to the species or trade names as described drawing or otherwise directed the WBSEDCL. It shall be the best procurable. 7.3 Teak Wood Teak Wood shall be superior, first class or second class as specified and approved by WBSEDCL, having uniform grains and free from any defect likely to impair the appearance of finished work. 7.4 Storage and Inspection Timber shall be carefully stored and the subject to inspection on site, piece by piece. The WBSEDCL may reject such pieces as are considered by him not of the quality or meeting the requirements specified herein. 7.5 Moisture Content Timber shall be accepted as well seasoned if its moisture content does not exceed the permissible limit as per IS : 287. 7.6 Flush Door Shutters, Shelves Flush door shutters, shall be wooden, as may be shown in drawing or directed by WBSEDCL. They shall be obtained from an approved source of manufacture covered on face with teak. Teak veneer or other finish as may be necessary. A full size sample door shall be offered for inspection and approval. Flush door shutters of the solid core type with plywood face panels shall conform to IS:2202 (Part-I). 8.0 8.1 FITTINGS FOR DOORS, WINDOWS, ETC. General Fittings shall be of aluminium or as specified. These shall be smooth and free from sharp edges, corners, flaws and other defects. Screw holes shall be countersunk to suit the head of specified wood screws.

RAPDRP/Part B

PART-VI (FINAL)

M-20 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Aluminium fittings shall be finished bright or anodized or as specified. Fittings shall be approved by the WBSEDCL before fixing. Anodised cadmium / chromium plated brass screws of approved quality shall be used for fixing aluminium fittings. Screws shall be driven home with screw driver and not hammered in. 8.2 8.2.1 Hinges Butt hinges These shall be of extruded aluminium alloy butt hinges as specified. 8.2.2 Parliament Hinges These shall be of cast brass or as specified and shall generally conform to IS:362. 8.3 Sliding Door Bolts These shall be of aluminium and conform to IS : 2681. They shall be capable of smooth sliding action. Alternative materials may be adopted on the approval of the WBSEDCL for specific locations. 8.4 Door Latch This shall be mild steel, brass or as specified and shall be capable of smooth sliding action. 8.5 Tower Bolts Tower bolts may be of one of the following types : Anodised aluminium barrel tower bolt with barrel and bolt of extruded sections of aluminium alloy (10/12 mm dia. Shoot) These shall generally conform to IS : 204 (Part 1 & 2) steel spring and ball shall be provided between the bolt and the barrel. 8.6 Door Handles These shall be of aluminium of specified size and of the shape and pattern as approved by the WBSEDCL. These shall generally conform to IS : 208. The size of the handle shall be determined by the inside grip of the handle. Door handles shall be of 100 mm size and window handles of 75 mm size unless otherwise specified. These shall be fixed with 25 mm long screws.

RAPDRP/Part B

PART-VI (FINAL)

M-21 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

8.7 Mortice Lock Seven Lever Mortice lock with latch and pair of lever handles shall have steel casing and brass bolts and shall be right or left handed or as directed by the WBSEDCL. It shall be of the approved quality and shall conform to IS : 2209. The shape and pattern shall be approved by the WBSEDCL. The size of the lock shall be determined by its length. The lock for single leaf door shall have plain face and that for double leaf door a rebated face lever handles with springs shall be mounted on plates and shall weigh not less than 0.5 kg per 1 pair. These shall be of brass, finished bright chromium plated or oxidized. 8.8 Floor Door Stopper This shall be made of cast brass or anodized aluminium and shall have a rubber cushion. The type and pattern will be as approved by the WBSEDCL. 8.9 Hooks and Eyes These shall be of hard drawn brass or steel and shall generally conform to IS : 207. 8.10 Fan Light Pivots These shall be made of cast brass or C.P. steel and shall generally conform to IS : 1837. The base and socket plate shall be made from minium 3.15 mm thick brass or C.P. Steel Plate and projected pivot shall not be less than 12 mm diameter and 12 mm length cast in single pieces with the base plate. 8.11 Fan Light Catch These shall be made of cast brass or C.P. Steel and shall generally conform to IS : 364. Steel springs of the catch shall be 0.90 mm dia. 6 coils 12 mm internal diameter and 20 mm long. The pattern and the shape of the catch shall be as approved by the WBSEDCL. 8.12 Chain with Hook for Fan Light This shall be made of hard drawn brass or cast brass or C.P. Steel welded or twisted as specified and shall conform generally to IS : 3828. One end of the chain shall be provided with an eye and the other end with a staple. The minimum thickness of plates shall be 2.24 mm and the chain shall be 300 mm long made from minimum 4 mm hard drawn wire.

RAPDRP/Part B

PART-VI (FINAL)

M-22 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

8.13 Hasp and Staple Hasp and staple (safety type) shall be made of cast brass or CP steel or Aluminium and generally conform to IS : 363. The hinge pin which in all cases shall be of mild steel, shall be firm and its riveted head well formed. The movement of the hasp shall be free, easy and square and shall not have any play or shake. The hasp shall fit the staple correctly. The size shall be determined by the length of the bigger leaf of the hasp. 8.14 Hydraulic Door Closer These shall conform to IS:3564 and be of brand approved by the WBSEDCL for both bolt and right hand openings. Hardware and fixtures shall be as specified in the drawings or Schedule of Quantities. All hardware and fixtures shall be able to withstand repeated use. Door closers shall be suitable for doors weighing 61 80 kg., unless otherwise stated. Each closers shall be guaranteed against manufacturing defect for one year and any defect found within this period shall be rectified or the closer replaced free of charge. Concealed door closers shall be either floor mounted or transome mounted, suitable for installation with metal doors. It shall conform to the performance requirements and endurance tests stated in IS:3564. 8.15 Steel Frames Steel sections used for door frames, windows and ventilators shall conform to the IS:1361, 1038 & 4351. 8.16 Casement Window Fasteners These shall be made of cast brass. Casement fasteners for single leaf window shutter shall be left or right handed as specified. These shall not weigh less than 0.20 kg per fasteners. 8.17 Casement Brass Stays These shall be made of cast brass. The stay shall be made from a channel section and shallnot weigh less than that indicated below : 200 mm 250 mm 300 mm ------------------------------0.24 kg each 0.28 kg each 0.33 kg each

The shape and pattern of stays shall e approved by the Engineer.

RAPDRP/Part B

PART-VI (FINAL)

M-23 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

8.18 Quadrant Stays These shall be made of cast brass. The shape and pattern shall be approved by the Engineer. It shall not weigh less than 0.20 kg each. 9.0 9.1 WINDOW, VENTILATOR, ROLLING SHUTTER & COLLAPISBLE GATE General Materials used in the fabrication shall be as approved by the WBSEDCL or as per Indian Standard. 9.2 Steel Doors, Windows & Ventilators Steel sections used for fabrication shall be standard rolled steel sections specified in IS:1038, IS:1977, IS:7452 as appropriate or as specified in drawing and Schedule of Works. Rivets shall conform to IS:1148. 9.3 M.S. Bolts etc. M.S. Bolts, nuts, screws, washers, peg stays and other mild steel fittings shall be treated for corrosion as recommended by the relevant Indian Standards. Putty for glazing shall conform to IS:419. Glass panes and glazing shall conform to the specification detailed under this series. 9.4 Hardware Hardware and fixture shall be as specified in the drawings or Schedule of Quantities or as approved by WBSEDCL. All hardware and fixtures shall be able to withstand repeated use. 9.5 Mastic The mastic for caulking shall be of approved quality from a manufacturer approved by the WBSEDCL. In general, the mastic for fixing of metal frames shall conform to IS:1081 and/or as approved by the WBSEDCL. 9.6 Steel Rolling Shutter These shall conform to IS:6248. 9.7 Collapsible Gate These shall conform to latest IS:10521.

RAPDRP/Part B

PART-VI (FINAL)

M-24 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

9.8 Aluminium Doors, Windows & Ventilators Aluminium Sections for fabricating doors, windows, ventilators, partitions etc. shall be extrudes sections conforming to IS:1948 and IS:1949 or as manufactured by Indian Aluminium Company, limited or approved equivalent. The alloy used shall conform to Designation HE-9-WP of IS:733. 9.9 9.9.1 9.9.2 9.9.3 Materials Steel doors, windows and ventilators, and their fittings shall conform to IS:1038 1983 and be of the size and type shown on the drawings. Steel windows shall conform to IS:1361 1978 and shall be of the specified type and size. Unless otherwise specified, coupling section shall be of mild steel, handles, peg stays and pivots shall be of leaded time bronze (gun metal). Hinges for side hung shutters shall be of projecting non-friction type, unless otherwise specified. Weather bars shall not be provided unless specifically indicated on the drawings. The type, size, windows and ventilators shall be painted with one coat of red-oxide zinc chromate primer, conforming IS:2074 1992 before they are fixed. Fixed painting shall be done with two coats of ready mixed approved flat at point of approved colour. GLASS General Plain, ground, frosted glass shall be used as shown on the drawing or as specified in the Schedule of Quantities. It shall be procured from an approved source of manufacturer and be of the approved quality. All glass panes shall be free from flaws, cracks, specks, bubbles, blemishes, unless otherwise specified. All panes shall have perfectly squared corners and straight edges. 10.2 Plain Transparent Glass Plain transparent glass for glazing and framing shall conform to IS:1761. It shall be free from flaws, specks, bubbles or distortions. 10.3 Ground and Frosted Glass Glare reducing or heat absorbing glass shall be Calorex of Hindustan Pilkington or approved equivalent and special care shall be taken to grind smooth and round off the edges before fixing.

10.0 10.1

RAPDRP/Part B

PART-VI (FINAL)

M-25 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

10.4 Thickness Glass shall have the following thickness, unless otherwise stated in the Schedule of Quantities or drawings:Upto 60 cms x 60 cms - do - of larger size Big door 10.5 Inspection All glass shall be subject to inspection on the site. Glass found to suffer from defects shall be rejected. Samples submitted for inspection shall be selected so as to be representative of the consignment. 11.0 11.1 PAINT General All paints, varnishes, distemper or other surface coating materials shall be of approved quality conforming to the appropriate Indian Standard. Wherever such standard is available, and be obtained from an approved manufacturer. Under no circumstances shall the paint be diluted with Linseed oil or otherwise. 11.2 Sampling and Testing The WBSEDCL may, at his discretion, require samples of paint to be tested. In such cases testing will be according to IS:101. 11.3 Storage Paints, primers, distempers and varnishes shall be delivered in sealed containers. They shall be stored in cool dry condition to the satisfaction of the WBSEDCL. 11.4 Paints for Priming Ready mixed paints for priming coats of steel and iron work shall comply with IS:2074 Ready Mixed Paint, Red Oxide Zinc Chrome Priming. 11.5 Paints for Finishing Ready mixed oil gloss paint where specified shall comply with IS:129 Ready Mixed Paint, Brushing, Finishing semi-gloss for General purpose

RAPDRP/Part B PART-VI (FINAL) M-26 of 43

. 3 mm . 4 mm . 6 mm

TECHNICAL SPECIFICATION for CIVIL WORKS

to IS Colours Aluminium paints where specified on the drawings or ordered by WBSEDCL shall comply with IS : 2339 Aluminium Paint for General Purposes in Duel Containers. Plastic Emulsion paint where specified for plastered surfaces of masonry and concrete work shall comply with IS:5411 (Part I) and (Part II) for interior use and exterior use respectively. Acid proof paint in wall and doors where specified on the drawings or ordered by WBSEDCL shall comply with latest IS codes. 11.6 White Wash & Colour Wash White wash shall be prepared from lime slaked on spot, mixed and stirred with sufficient water to make a thin cream. The work shall comply with latest IS:6278. 11.7 Cement Paint Cement paints shall comply with IS:5410 and shall be of approved brand and manufacture. The shade shall be approved by the WBSEDCL before its application. 11.8 Acrylic Emulsion Paint Washable Acrylic Exterior and Interior Emulsion Paint of approved brand and manufacture shall be used over a coat of Acrylic primer. The shade shall be approved by the WBSEDCL before application of the distemper. 11.9 Varnish Varnish for the finishing coat shall be copal finish or super quality spar varnish of approved brand. Varnish for the under coat shall be flatting varnish of the same make as the top coats and shall be to the approval of the WBSEDCL. 11.10 Polish French spirit polish shall be of an approved make conforming to IS:348. If it has to be prepared on site, the polish shall be made by dissolving 0.7 kg of approved shellac in 4.5 litres of methylated spirit without heating. To obtain required shade pigment may be added and mixed. Where wax polishing is specified, it shall be prepared by heating two parts of Bee Wax and two parts of boiled linseed oil over a slow fire. When dissolved but still warm, one part of turpentine is to be added.

RAPDRP/Part B

PART-VI (FINAL)

M-27 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

12.0 12.1 WATER PROOFING MATERIALS Integral Cement Waterproofing Compounds Integral Cement waterproofing compounds, i.e. admixture for waterproofing purposes shall fully comply with the requirements of IS:2645. Properties like permeability, setting time, compressive strength shall be in accordance with the requirements of this code when tested as per procedure laid therein. Calcium chloride content of the product laid therein. Calcium chloride content of the product used shall be made known to WBSEDCL before use. 12.2 Bitumen The bitumen bonding material for waterproofing shall conform to the requirements laid down in IS:702 or IS:73 or IS:217 or IS:454 depending upon whether industrial bitumen, paving bitumen or cutback bitumen is used. For selecting the particular type and grade of bitumen to be used the relevant item as per technological requirements. 12.3 Bitumen Primer Bitumen primer used for application to concrete and masonry surfaces along with bitumen for the purpose of water-proofing shall conform to requirements given in IS:3381 and pass tests in accordance with the procedure laid down in appropriate IS mentioned in Table-I of IS:3384. Bitumen primer should be free from water & shall preferably be made from the same grade of bitumen as used in bonding. 12.4 Bitumen Felt Bitumen felts used for water-proofing purposes shall be as specified in IS:1322. Physical properties shall conform to the requirements & tests shall be carried out as per procedure laid down in IS:1322. Base (whether fibre or hessian) type & grade of felt shall be as mentioned in the relevant items under Schedule of Items. Unless otherwise stated, Hessian base felt Type-3, Grade-2 shall be used. 12.5 Bitumen Mastic Bitumen mastic used for water-proofing of roofs shall have the physical properties as mentioned in IS:3037 when tested with the procedure laid down in appropriate IS mentioned in IS:3037. 12.6 Bitumen Compounds Bitumen compounds when used for water-proofing of porous masonry, concrete floors, walls & roofs shall conform to the requirements of

RAPDRP/Part B PART-VI (FINAL) M-28 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

IS:1580. Physical properties shall be governed by the requirements of this code when tested in accordance with the procedure laid therein. 12.7 Surface Application Materials Water proofing materials for application on mortar or concrete surface shall conform to IS:9862. The primer shall be suitable for pray or brush application. It shall have properties enabling it to penetrate through pores or cracks and fill them up, making the surface impervious. 12.8 High Polymer based Admixtures, Epoxy based Emulsion & Paints The materials used shall be high polymer based chloride and sulphide free cement & water-proofing admixtures and epoxy based water-proofing paints as per manufacturers specification & approved by the Engineer. 13.0 13.1 DRAINAGE & SANITATION (INTERNAL) General All materials, pipes, specials, fittings, fixtures etc. to be used in the work shall be of best quality and class specified in relevant IS Code. Where specified these shall be of specified manufacturer and quality and shall be procured from manufacturers names and trade mark. TENDERER shall submit to the WBSEDCL samples of all materials. Pipes, specials, fitting fixtures for approval before use in the works. Such approved samples shall be retained by the WBSEDCL until completion of works. Pipes and specials may be CI for Sanitary & HDPE Pipes for rain water. 13.2 HDPE Pipes for Rainwater HDPE pipes for rainwater shall be conforming to IS:7328 & IS:4984. 13.3 Indian Pattern Orissa Type W.C. These shall be of 1st quality of approved make and quality. otherwise specified these shall comprise:a) b) c) d)

RAPDRP/Part B

Unless

White glazed Vitreous China WC pan (580 mm x 440 mm) with integrated foot rest. Cast iron `P or `S trap with or without vent. 10.0 litres approved make mosquito proof low down PVC/vitreous cistern with valve less siphon, with standard accessories. C.P. / PVC flush pipe with clamps.

PART-VI (FINAL) M-29 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

e)

15 mm C.P. connection pipe with brass couplings at both ends and 15 mm brass C.P. angular stop cock.

13.4

Urinal These shall be of 1st quality of approved make and brand. Unless otherwise specified these shall comprise:a) b) c) d) White glazed Vitreous China urinal (456mmx365mmx265mm). 32 mm PVC waste pipe with brass couplings / 32 mm C.P. bottle trap. 15 mm C.P. connection pipes with brass couplings and 15 mm brass C.P. angular stop cock. Half round channel.

13.4

Wash Hand Basin These shall be of 1st quality of approved make and 550 mm size (approx.). Unless otherwise specified these shall comprise:a) b) c) d) e) White glazed Vitreous China two hole / single centre hole basin with 2 nos. concealed cast iron heavy duty brackets with wall plugs. 1 no. 15 mm C.P. brass pillar cock. 32 mm C.P. brass waste fittings, C.P. brass chain and rubber plug. 32 mm PVC waste pipe with brass couplings / 32 mm C.P. bottle trap. 15 mm C.P. connection pipes with brass couplings and 15 mm brass C.P. angular stop cock.

13.5

Mirror & Frame Mirror frame shall be of fibre glass or of approved shape, size, colour and make.

13.5.1

Mirror shall be of superior glass with edges rounded off or bevelled as specified. It shall be free from flaws, specks or bubble and its thickness shall not be less than 5.5 mm. The glass for the mirror shall be uniformly silver plated at the back and shall be free from silvering defects. Silvering

PART-VI (FINAL) M-30 of 43

RAPDRP/Part B

TECHNICAL SPECIFICATION for CIVIL WORKS

shall have a protective uniform covering of red lead paint. A suitable backing plate of approved quality will be provided at the back of mirror. 13.6 Glass Shelf Glass shelf unit shall consist of an assembly of glass shelf. CP brass guard rail and supporting brackets. The shelf shall be of glass of best quality with edges rounded of and shall be free from flaws, specks, bubble and of thickness not less than 5.5 mm. The shelf shall have guard rail, resting on rubber washers on glass plate. 13.7 Towel Rail Towel rail shall be of approved quality C.P. with two brackets of same material, diameter and length as specified or as directed by the WBSEDCL. 13.8 Soap Container / Soap Disc These shall be of CP brass or vitreous China with C.P. brass brackets of approved make and design. 13.9 Floor Trap Floor trap shall be of cast iron P or S type with water seal of 50 mm minimum. Grating of C.P. brass/steel shall be provided over floor trap. 13.10 Gully Trap Each gully trap shall be made of S.W.G. with `P or Q or S trap embedded in PCC with brick with brick walled chamber provided with precast R.C.C. cover slab. 13.11 C.I. Manhole Cover / PFRC Cover / FRC Cover Cast Iron manhole covers including frames shall be of light, medium or heavy duty as per IS:1726, wherever specified. PFRC/FRC cover shall be used and shall be of approved make. 14.0 14.1 WATER SUPPLY & PLUMBING (INTERNAL) General This section deals with the specification of material for pipes, fittings, fixtures etc. to be used in water supply works.

RAPDRP/Part B

PART-VI (FINAL)

M-31 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

All materials, pipes, fittings, fixtures to be used in the works shall be of the approved quality of the class specified in IS Code. These shall be of specified manufacture and quality and shall be procured from the manufacture and their accredited stockiest and be marked with manufacturers name and trade marks. The TENDERER shall submit to the WBSEDCL samples of all pipes, fittings, fixtures for approval before being used in the works. Such approved samples shall be retained by the WBSEDCL until completion of works. Pipes and pipe fittings may be of any or combination of following types: i) M.S. galvanised pipes. ii) Cast iron spun pipes. 14.2 M.S. Galvanised Pipes and Fittings Generally pipes for installation in buildings shall be `medium quality mild steel galvanised. Pipe shall be conforming to IS:1239 part-1. Wherever specified heavy quality GI pipe may be used as approved. The details of medium quality M.S. pipes and sockets shall be as under:

Pipe nominal Bore mm Outside diameter of pipe Max. Min. Mm mm Thickness mm Dimension of ordinary sockets Outside dia Minimum (Minimum) length mm mm Mass of Pipe plain end Kg./M

15 20 25 32 40 50 65 80

21.8 27.3 34.2 42.9 48.8 60.8 76.6 89.5

21.0 26.5 33.3 42.0 47.9 59.7 75.3 88.0

2.6 2.6 3.2 3.2 3.2 3.6 3.6 4.0

27.0 32.5 39.5 49.0 56.0 68.0 84.0 98.0

37.0 39.0 46.0 51.0 51.0 60.0 69.0 75.0

1.21 1.56 2.41 3.10 3.56 5.03 6.42 8.36

Note:- Manufacturing tolerances shall be permitted on tubes and sockets in addition to above. The M.S. galvanised pipes shall be of approved make and conform to IS:1239 Part-I and of tesetd quality. The GI pipes shall be of threaded ends with a socket at one end only. The fittings for GI pipes shall be either galvanised wrought iron or galvanised malleable Iron conforming to IS:123.

RAPDRP/Part B

PART-VI (FINAL)

M-32 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

14.3 Bib Cock and Stop Cock Bid cock and stop cock for water services shall be of brass screw down type and shall conform to IS : 781. Minimum finished weight of bib cock and stop cock shall be as given below :

Size (mm) 10 15 20 25 32 40 50

Bib cock (kg.) 0.30 0.40 0.75 1.25 ----

Stop cock (kg.) 0.35 0.40 0.75 1.30 1.80 2.25 3.85

The cocks shall be of tested quality and approved quality and shape. 14.4 Valves Unless otherwise mentioned in the Schedule of Quantities these shall be of brass / gun metal globe valves conforming to IS : 778 Class I and shall be of approved manufacture with ISI mark. 14.5 Shower Rose The shower rose shall be of heavy quality chromium plated brass with flat bottom of diameter 80 mm or swivel type or as specified with uniform perforations. 14.6 Storage Tank Storage tank shall be PVC of specified sizes, capacities, make, as specified or as directed by WBSEDCL. It shall have facilities for connecting inlet, outlet overflow and washout pipes and a top cover. Where tanks are to be of RCC type, the drawings shall be got approved by the WBSEDCL. 15.0 15.1 ROAD General Roads shall be of RCC with berm width of 375mm.

RAPDRP/Part B

PART-VI (FINAL)

M-33 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

16.0 16.1 SCHEDULE OF TESTS ON MATERIALS The routine tests of materials, if required delivered at site, shall be as follows :

Material Cement i) ii) 16.1.2 Fine Aggregate i) ii) iii) 16.1.3 16.1.4 16.1.5 Coarse Aggregate Concrete Plain Mild Steel Bar i) ii) i) ii) i) ii) iii) Type of Test Setting Time Compressive Strength Moisture Content Absorption Silt Content Grain Size Analysis & IS 2386 Test Procedure IS 4031 Acceptan ce Criteria IS 269 IS 8112 IS 12269 IS 455 IS 383

Item No. 16.1.1

Aggregate Crushing Value Grain Size Analysis Slump Compressive Strength Ultimate Tensile Stress Yield Stress Elongation Ultimate Tensile Stress 0.2% Proof Stress Elongation Compressive Strength

IS 2386 IS 516 IS 1199 IS 1608

IS 383 IS 456 Gr-I of IS 432 IS 1786

16.1.6

High Yield Deformed Bar Cement Mortar Brick (Clay)

Strength i) ii) iii) i) i)

IS 1608

16.1.7 16.1.8

IS 2250 IS 3495

IS 2250 IS 1077

Compressive Strength (Part 1) ii) Water Absorption (Part-2) iii) Efflorescence (Part 3) Physical Verification Physical Verification Drying Time Consistency Residue Finish Water Content Weight per 1t. Lead Restriction

16.1.9 16.1.10 16.1.11

Wooden Panel Door Shutter i) Wooden Flush Door Shutter i) Ready Mixed Paints i) ii) iii) iv) v) vi) vii)

IS 1003 IS 2202 IS 101

IS 1003 IS 2202 IS 101

RAPDRP/Part B

PART-VI (FINAL)

M-34 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

16.1.12 16.2 Apart from the above mentioned routine tests, if necessary other tests shall be carried out by the TENDERER as desired by the WBSEDCL. The materials other than the specified in 16.1 shall be tested by the TENDERER as and when desired by the WBSEDCL. LIST OF MATERIALS : Their Approved Brand & Manufacturer

IS Code Brand / Product Name or Equivalent Manufacturer / Dealer

17.0

Sl. No.

Product / Material

1.

Water Admixture

Proofing

1) 2)

Lilax 1. Conplast x 421 2. Chemicals 3. 4. 1. 2. 3. 4.

Sahara Chemicals Fosrock Sika Qualcrete CICO ICI Paints, Kolkata Berger Paints (I) Ltd., Kolkata Asian Paints Any other make & quality approved by WBSEDCL. - do Sahara Chemicals Fosrock Chemicals Sika Qualcrete CICO - do -

2.

Acrylic Plastic Emulsion Paint

IS : 427 IS : 428 IS : 2071 IS : 5410 IS : 5411

IC 3) Plastocrete 4) CICO No. 1 1) Dulux 2) Luxol Silk

3. 4.

Primer for plastic emulsion paint Synthetic Enamel Paint

5.

Primer for Synthetic Enamel Paint

6.

Water Proof Cement Paint

1. Dulux Cement Primer 2. BP Cement Primer. 1. DULUX Gloss 2. Luxol Hi-Gloss 3. Superlac 4. Apcolite 1a) DULUX Wood Primer b) DULUX Material Primer 2a) Parrot Wood Primer b) Butterfly/Luxol Metal Primer IS : 5410 1. Snowcem / Super Snowcem 2. Seacem 3. Durocem 4. CEMPlus

1. 2. 3. 4.

1.

Killick Nixon Ltd., Calcutta 2. Seacem Paints (I) Limited 3. Berger Paints (I) Limited, Cal.

4. 5.

7. a) Acid Proof Tiles b) Acid Proof Paint 8. 9. 10. Kota Stone Marble Vitrefied Ceramic Tiles

RAPDRP/Part B

Any other manufacturer Approved by the WBSEDCL.

IS : 4457 (1982) IS:9862 (1981) IS : 4457 Granamize

PART-VI (FINAL)

WBSEDCLs approved make & quality to be procured. - do - do 1. Restiles Ceramics Ltd., Kol.

M-35 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Sl. No. Product / Material IS Code Brand / Product Name or Equivalent Manufacturer / Dealer

2. Any other similar quality approved by the WBSEDCL

RAPDRP/Part B

PART-VI (FINAL)

M-36 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Sl. No. Brand / Product Name or Equivalent

Product / Material

IS Code

Manufacturer / Dealer

11.

Mat. Finished Coloured Tiles

IS : 4457 1) 2) 3) 4) 5)

Spartek Regency Kajaria Somani Jhonson

1. 2. 3. 4. 5.

12.

Glazed (glazed earthenware tiles)

Tiles wall

IS : 13753 1) Johnson 13754 2) Somani 13755 3) Cera 13756

1. 2. 3. 4.

Spartek Ceramics India Ltd., Cal. Regency Ceramics Ltd., Cal. Kajaria Ceramics Ltd., Cal. Somani Pilkingtons Ltd., Cal. HR Johnson Ceramic Tiles (P) Ltd., Cal. HR Johnson Ceramic Tiles (P) Ltd., Cal. Somani Pilkingtons Ltd., Cal. Madhusudan Ceramics, Cal Any other similar quality approved by WBSEDCL.

13. 14.

Timber Door, Window & Ventilator Frames Steel Door / Windows

IS : 4021 IS : 1038, 1361, 4351 1. Multiwyn Industrial Corporation, Calcutta 2. Hopes Manufacturing Co. (P) Ltd., Calcutta 3. Bengal Rolling Shutters, Calcutta 4. Sree Raghunath Industries, Lilua, Howrah 5. Gee-Bee Industries, Calcutta 6. Any other similar quality approved drg. 1. Ambika Timber Works, Dist : Bankura 2. Premier Wood Craft (P) Ltd., Cal. 3. West Bengal Forest Development Corporation Ltd., Cal. 4. Any other similar quality approved by WBSEDCL.

15. a)

Timber Panelled & Glazed Shutters : Door Shutters b) Timer Panelled & Glazed Shutters : Window & Ventilator Shutters 16. Anodised Aluminium Hardware Fittings

IS : 1003 (Part - 1) IS : 1003 (Part 2)

IS : 204, 1) Alans 205, 208, 2) ASL 362, 363, 3) Garnish 729, 1823, 2681, 187, 5899, 7196 &

PART-VI (FINAL)

1.

Allied Anodisers, Calcutta 2. Ajanta Steel (P) Ltd., Howrah 3. Garnish Traders Pvt. Ltd.

M-37 of 43

RAPDRP/Part B

TECHNICAL SPECIFICATION for CIVIL WORKS

9899 17. CP Steel Hardware Fittings

Sl. No.

4.

IS : 207

WBSEDCLs approved make & quality. WBSEDCLs approved make & quality

Product / Material

IS Code

Brand / Product Name or Equivalent

Manufacturer / Dealer

18. Mortice Lock

19. Medium Density Fibre Boards (exterior grade) 20. Plain Transparent / Frosted Sheet Glass 21. CP Brass Coat / Robe Hook 22. Brass / Oxidised Brass Hardware Fittings 23. Magic Eye (for Entrance Doors) 24. Rolling Shutter

IS : 2209 3847 4992 5930 6607 7534 7540 8760 IS : 12406 (exterior BWP grade)

1) Godrej 2) Similar Brand

approved 2.

1.

Godrej Any other make & quality approved by the WBSEDCL

1) NUWUD 2) DURATUFF 3) HI-Bond

1. 2.

IS : 1761 1) IAG 1361

Nuchem Ltd., Cal Mangalam Timber Products Ltd., Cal. 3. Best Boards Ltd., Cal 1. Indo-Ashahi Glass Works, Cal 2. Triveni Glass Works, Cal Superior quality & make approved by the WBSEDCL. - do - do -

IS : 6248

25. Polymer water compound

based proof

1. Bengal Rolling Shutter, Cal 2. Singhivi Rolling Shutter 3. Any other make approved by the WBSEDCL. 1) Silvicon special 1. Sahara Chemicals leak proof 2. Fosrock Chemicals compound 3. Any other make approved by 2) Brushbond Coating the WBSEDCL.

3) Or equivalent

26. Polythene Sheet 27. Aluminium Self interlocking Ceiling Grid System 28. C.I. Ventilator 29. HD-PE Rain Water Pipes Material 1) Emcos as per Drain) IS : 4984 2) Oriplast 3) Reliance

Superior quality & make approved by the WBSEDCL. First Class standard quality & make approved by the WBSEDCL First Class Standard quality & make approved by the WBSEDCL (Rain 1. EMCO General Plastics Industry (P) Ltd., Calcutta 2. From the approved

M-38 of 43

RAPDRP/Part B

PART-VI (FINAL)

TECHNICAL SPECIFICATION for CIVIL WORKS

Sl. No. Product / Material IS Code Brand / Product Name or Equivalent Manufacturer / Dealer

3.

30. Water Proofing Treatment 1) 2) 107 3) 4) Permacote Lotus - 3 Silvicon Sikatop Seal 2.

1. 3. 4.

authorized dealer / approved by WBSEDCL. Reliance Industries Ltd., How. Sahara Chemicals Sika Qualcrete Enggr. Services International CICO

RAPDRP/Part B

PART-VI (FINAL)

M-39 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Sl. No. Brand / Product Name or Equivalent

Product / Material

IS Code

Manufacturer / Dealer

31. Flushing Cistern (low down) 32. Mirror

IS : 774 1) 2) 3) 4) IS : 6184 1) 2) 3) 4)

Parryware Hindusthan Cera Nycer Golden Twin Bird Silver Fish Atul

1.

Atul Glass Works, Calcutta 2. Hindusthan safety Glass Works, Calcutta 3. do 4. Atul Glass Works, Calcutta

33. Glazed Fireclay Sanitary appliances

34. Viterous Sanitary Appliances (Vitreous China)

IS : 771 Part 1, 2 (Kitchen Sink) IS : 775 (C.I. Brackets) IS : 2556 Part 1 Part 2 Part 4 Part - 14

1) RKCP 2) Sanfire Padmini

1) 2) 3) 4)

35. C.P. Fittings

36. G.I. Pipe 37. G.I. Fittings 38. Stoneware (Salt Glazed Pipe) 39. Gun Metal Valves

IS : 1239 IS : 651

IS : 778

40. M.S. Screws 41. H.C.I. Pipe

IS : 1729 3989

Hindusthan Sanitaryware & Industries Ltd., Calcutta 2. EID Parry (India) Ltd., Calcutta 3. Madhusudhan Ceramics, Calcutta 4. Neiveli Ceramics & Refractories Ltd., Calcutta 1) MARK 1. Similar approved brand 2) Jacquar 2. Jacquar & Co. (P) Ltd., 3) ESSCO Calcutta Jindal/TATA Hardware Dealers R / Kaycee Any approved Manufacturer having ISI mark Grade AA quality 1. Hind Ceramics Ltd., Calcutta 2. Ceramic Industries Ltd., Sambalpur, Orissa (Br. Cal.) 1) Leader 1. Leader Engineering Works, S2) Similar approved 3, S-4, Industrial Town, ISI Brand Jalandhar 14004. Nettlefold Guest Keen Williams 1) AMC 1. Alfa Manufacturing 2) Similar approved Co., Howrah Brand 2. Calcutta Iron & Engineering Co. Ltd., Howrah 3. Iron Foundries & Fabricators India (P) Ltd.,

Hindusthan Parryware Cera Neycer

1.

RAPDRP/Part B

PART-VI (FINAL)

M-40 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Sl. No. Product / Material IS Code Brand / Product Name or Equivalent Manufacturer / Dealer

4.

Howrah Indian Standard Casting Co., Howrah.

RAPDRP/Part B

PART-VI (FINAL)

M-41 of 43

TECHNICAL SPECIFICATION for CIVIL WORKS

Sl. No. Brand / Product Name or Equivalent

Product / Material

IS Code

Manufacturer / Dealer

42. Tubular Structure

43. WC Pan / Wash Basin / EWC / Urinal / Sink

IS : 2556 1) 2) 3) 4)

Hindusthan Parryware Cera Neycer

44. Manhole (PFRC)

Cover

Polycrete

1. Amiya Corporation, Calcutta 2. mafcon Engineering Co. (I) Ltd., Calcutta 3. Dhariwal Steel, Calcutta 1. Hindusthan Sanitaryware & Industries Ltd., Calcutta 2. EID Parry (India) Ltd., Calcutta 3. Madhusudhan Ceramics, Calcutta 4. Neiveli Ceramics & Refractories Ltd., Calcutta 1. Eastern Polycrete Industries, Kolkata. 2. Any other manufacturer approved by the WBSEDCL. Approved Manufacturer with IS Certification except Mini Steel Plant. Everest Building Product, Kolkata

45. Cement

46. Asbestos Sheets 47. Hot Dip Galvanising 48. PVC Tank IS : 4759 / IS: 2629 1) Sintex 2) Patton 3) Similar brand approved

Notes : 1) 2) Any material / product manufactured by units having BIS License but not listed here shall be deemed to have been included in the above select list. Selection of manufacturer / supplier shall be approved by the WBSEDCL prior to actual delivery of the material. The WBSEDCL reserve the right to choose any supplier out of the list furnished herewith. Without prior approval of the WBSEDCL no material shall be brought at site. Testing of material shall be done at the discretion of the WBSEDCL irrespective of the name of the suppliers / manufacturers / dealers given herein. Listing / naming of the approved manufacturers, dealers, suppliers does not preclude the rights of the WBSEDCL to get the material tested at the cost of the TENDERER as and when it is felt necessary. Depending on the quantum required, the order for supply of material may be distributed to the manufacturer / dealer as per the instruction of the WBSEDCL.

RAPDRP/Part B PART-VI (FINAL) M-42 of 43

3) 4)

5)

TECHNICAL SPECIFICATION for CIVIL WORKS

RAPDRP/Part B

PART-VI (FINAL)

M-43 of 43

You might also like

- Method Statement For Underground Piping FCDocument17 pagesMethod Statement For Underground Piping FCmister pogi94% (17)

- TCS Q 113 01 R0Document0 pagesTCS Q 113 01 R0Tori Small100% (1)

- 3 Sc&s3-Reinforced ConcreteDocument13 pages3 Sc&s3-Reinforced ConcretedophongxdNo ratings yet

- 11-Division 2-Section 02300 Sewage Works-Version 2.0Document24 pages11-Division 2-Section 02300 Sewage Works-Version 2.0Avaan Ivaan50% (2)

- Guide For Transmission Line Subsidence PDFDocument17 pagesGuide For Transmission Line Subsidence PDFjoydeep_d3232100% (1)

- L1 L2 L3 ChartsDocument1 pageL1 L2 L3 Chartsjoydeep_d3232100% (2)

- 11kV Worked Example - Seismic Design - TRF & Stayed PoleDocument11 pages11kV Worked Example - Seismic Design - TRF & Stayed Polejoydeep_d3232No ratings yet

- AC System Check SheetDocument1 pageAC System Check SheetQOBITNo ratings yet

- Sec 04 - Plain & Reinforced ConcreteDocument36 pagesSec 04 - Plain & Reinforced Concretetaz_taz3No ratings yet

- Cast in Situ Pile Method StatementDocument18 pagesCast in Situ Pile Method StatementManal Patel100% (2)

- Thinset Terrazzo FinishDocument4 pagesThinset Terrazzo Finishmuhammad iqbalNo ratings yet

- PBG SpesifikasiDocument19 pagesPBG SpesifikasikaryantoherlambangNo ratings yet

- Vol-III of IV - Laying - HPCLDocument527 pagesVol-III of IV - Laying - HPCLbolinagNo ratings yet

- Particular Specifications IlcbDocument5 pagesParticular Specifications IlcbAaron WilsonNo ratings yet

- EIL Civil SpecDocument341 pagesEIL Civil SpecRajashekar.P100% (3)

- IRS T 45 4th Rev March 2021 With Corrigendum 1 & 2Document34 pagesIRS T 45 4th Rev March 2021 With Corrigendum 1 & 2Raja SandakaNo ratings yet

- Irst 19 2012Document65 pagesIrst 19 2012krischaever100% (1)

- QT-09-2008 ConcreteDocument25 pagesQT-09-2008 ConcreteRichard WriteNo ratings yet

- GRP Pipelien MaterialDocument22 pagesGRP Pipelien MaterialSyed Ashfaq100% (1)

- 70 TMSS 01 R0Document0 pages70 TMSS 01 R0Tori SmallNo ratings yet

- Section 3 - Specification For Soil Nailing: 3.1 GeneralDocument10 pagesSection 3 - Specification For Soil Nailing: 3.1 GeneralrowatersNo ratings yet

- 01 Samss 005Document5 pages01 Samss 005Moustafa BayoumiNo ratings yet

- Pakistan Standard: ICS No.91.100.10Document13 pagesPakistan Standard: ICS No.91.100.10IkrimehIrshaidNo ratings yet

- Technical Specification: 1.0 Irrigation Canal 1.1 Clearing and GrubbingDocument6 pagesTechnical Specification: 1.0 Irrigation Canal 1.1 Clearing and GrubbingDennis Dave SidoNo ratings yet

- Fiberglass Reinforced PlasticsDocument6 pagesFiberglass Reinforced Plasticsnaimz88No ratings yet

- Indian Standard CodesDocument9 pagesIndian Standard CodesironmanNo ratings yet

- Specification CivilDocument493 pagesSpecification Civilsangey111No ratings yet

- MoRTH 1000 Materials For StructureDocument18 pagesMoRTH 1000 Materials For StructureApurv PatelNo ratings yet

- 23 TMSS 02 R0Document0 pages23 TMSS 02 R0renjithas2005No ratings yet

- CW6 Part 1Document44 pagesCW6 Part 1Steve CowanNo ratings yet

- OPSS 1010 Nov03Document15 pagesOPSS 1010 Nov03Jonathan Enrique Canales SanchezNo ratings yet

- Structural SpecificationsDocument102 pagesStructural SpecificationsAlden CayagaNo ratings yet

- Transmission Construction Standard: Saudi ElectricitycompanyDocument12 pagesTransmission Construction Standard: Saudi ElectricitycompanyTori Small0% (1)

- Irs T19-1994Document24 pagesIrs T19-1994vpmohammed0% (1)

- Adhesive Compounds'2 Component For Sealing Wire and Light in PavementDocument4 pagesAdhesive Compounds'2 Component For Sealing Wire and Light in PavementDevrim GürselNo ratings yet

- Specifications ConcreteDocument54 pagesSpecifications ConcreteAjay MalurNo ratings yet

- CW4Document19 pagesCW4Steve Cowan100% (1)

- X-X-X-X-X-X-X - X-X: Department of Public Works and HighwaysDocument7 pagesX-X-X-X-X-X-X - X-X: Department of Public Works and HighwaysMark OlandresNo ratings yet

- Sarcheshmeh Flash Smelting Furnace Project: Specification For Fabrication and Erection of SteelworkDocument36 pagesSarcheshmeh Flash Smelting Furnace Project: Specification For Fabrication and Erection of Steelworkmobin1978No ratings yet

- A223 6 44 0074Document15 pagesA223 6 44 0074mishtinilNo ratings yet

- DG BusductDocument16 pagesDG BusductanandpurushothamanNo ratings yet

- GRP Duct Material For Irrigation Works-ADM SpecificationDocument5 pagesGRP Duct Material For Irrigation Works-ADM Specificationbuddy1971No ratings yet

- HPCL Cement Lined Spec PDFDocument167 pagesHPCL Cement Lined Spec PDFvenkateshwaranNo ratings yet

- 044-1 - 1996 - Reinforced Concrete PolesDocument24 pages044-1 - 1996 - Reinforced Concrete PolesLuis Aguero CantilloNo ratings yet

- IRS T-45 3rd Rev. 2016Document28 pagesIRS T-45 3rd Rev. 2016Rajesh SinghNo ratings yet

- 4 Vol-IiiDocument139 pages4 Vol-IiiLeilani JohnsonNo ratings yet

- EGE00B20Document17 pagesEGE00B20Jhonny Rafael Blanco Caura100% (1)

- Specifications For Hdpe PipesDocument7 pagesSpecifications For Hdpe PipesEduardo Lubo100% (2)

- Highway SpecificationDocument85 pagesHighway SpecificationAkaninyeneNo ratings yet

- SECT-2300 Plain and Reinforced ConcreteDocument36 pagesSECT-2300 Plain and Reinforced ConcreteTariq JamalNo ratings yet

- Hume Pipe Laying DocumentsDocument7 pagesHume Pipe Laying DocumentsamaravathiaspNo ratings yet

- SECTION 00310 Cast-In-Place Concrete Part 1 - General 1.01 SCOPEDocument30 pagesSECTION 00310 Cast-In-Place Concrete Part 1 - General 1.01 SCOPEGkou DojkuNo ratings yet

- Saj Iacs VSM FertigungsstandardsDocument45 pagesSaj Iacs VSM FertigungsstandardsMajdi Jerbi100% (1)

- BT4 FinalsDocument80 pagesBT4 Finalsamsdeleon.12No ratings yet

- Steels Repair IACS REC 47 Pdf193Document63 pagesSteels Repair IACS REC 47 Pdf193Josep Maria Montoy CanadellNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Engineered Ceramics: Current Status and Future ProspectsFrom EverandEngineered Ceramics: Current Status and Future ProspectsTatsuki OhjiNo ratings yet

- Voltage Data For Last One (1) Year (April 2005 To March 2006)Document3 pagesVoltage Data For Last One (1) Year (April 2005 To March 2006)joydeep_d3232No ratings yet

- MKS MV HV CapacitorsDocument12 pagesMKS MV HV Capacitorsjoydeep_d3232No ratings yet

- Neutral Displacement Relay PDFDocument4 pagesNeutral Displacement Relay PDFjoydeep_d3232No ratings yet

- 1 Phase EM-Tamper-21 Conditions Digram-2-Annexure IIIDocument2 pages1 Phase EM-Tamper-21 Conditions Digram-2-Annexure IIIjoydeep_d3232No ratings yet

- PoemDocument8 pagesPoemjoydeep_d3232No ratings yet

- Industrial Revolution What Is Industrial Revolution ? How Is It Different From Other Revolution ?Document3 pagesIndustrial Revolution What Is Industrial Revolution ? How Is It Different From Other Revolution ?joydeep_d3232No ratings yet

- Adjectives: Degrees of Comparison: A. Fill in The Blanks With The Comparative Forms of The Adjectives GivenDocument2 pagesAdjectives: Degrees of Comparison: A. Fill in The Blanks With The Comparative Forms of The Adjectives Givenjoydeep_d3232No ratings yet

- 22 Standard Earthing Philosophy of GETCO R 2 25-0-711Document4 pages22 Standard Earthing Philosophy of GETCO R 2 25-0-711Ramesh AnanthanarayananNo ratings yet

- Technical Consideration For Mobile SubstationDocument8 pagesTechnical Consideration For Mobile Substationjoydeep_d3232No ratings yet

- Htls Conductor - J Power GroupDocument22 pagesHtls Conductor - J Power Groupjoydeep_d3232No ratings yet

- Motor Feeder CT CalculationDocument12 pagesMotor Feeder CT Calculationjoydeep_d323250% (2)

- Htls Conductor - J Power GroupDocument22 pagesHtls Conductor - J Power Groupjoydeep_d3232No ratings yet

- Modern Survey For KPTCL 110 KV Transmission LinesDocument27 pagesModern Survey For KPTCL 110 KV Transmission Linesjoydeep_d3232No ratings yet

- Ts For Transmission LineDocument143 pagesTs For Transmission Linejoydeep_d3232100% (3)