0 ratings0% found this document useful (0 votes)

148 viewsBattery

Battery

Uploaded by

michaelliu123456This document provides instructions for safely handling, installing, charging, and maintaining nickel-cadmium batteries. Key points include:

- Never allow flames or sparks near batteries when charging due to risk of fire or explosion from emitted gases.

- Wear protective equipment like gloves and goggles when working with batteries due to risk of skin and eye irritation from electrolytes.

- Store batteries indoors in a cool, dry, well-ventilated area away from direct sunlight to maximize shelf life.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Battery

Battery

Uploaded by

michaelliu1234560 ratings0% found this document useful (0 votes)

148 views0 pagesThis document provides instructions for safely handling, installing, charging, and maintaining nickel-cadmium batteries. Key points include:

- Never allow flames or sparks near batteries when charging due to risk of fire or explosion from emitted gases.

- Wear protective equipment like gloves and goggles when working with batteries due to risk of skin and eye irritation from electrolytes.

- Store batteries indoors in a cool, dry, well-ventilated area away from direct sunlight to maximize shelf life.

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides instructions for safely handling, installing, charging, and maintaining nickel-cadmium batteries. Key points include:

- Never allow flames or sparks near batteries when charging due to risk of fire or explosion from emitted gases.

- Wear protective equipment like gloves and goggles when working with batteries due to risk of skin and eye irritation from electrolytes.

- Store batteries indoors in a cool, dry, well-ventilated area away from direct sunlight to maximize shelf life.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

148 views0 pagesBattery

Battery

Uploaded by

michaelliu123456This document provides instructions for safely handling, installing, charging, and maintaining nickel-cadmium batteries. Key points include:

- Never allow flames or sparks near batteries when charging due to risk of fire or explosion from emitted gases.

- Wear protective equipment like gloves and goggles when working with batteries due to risk of skin and eye irritation from electrolytes.

- Store batteries indoors in a cool, dry, well-ventilated area away from direct sunlight to maximize shelf life.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 0

Important recommendations

I Never allow an exposed flame or

spark near the batteries, particularly

while charging.

I Never smoke while performing any

operation on the battery.

I For protection, wear rubber gloves,

long sleeves, and appropriate splash

goggles or face shield.

I The electrolyte is harmful to skin and

eyes. In the event of contact with

skin or eyes, wash immediately with

plenty of water. If eyes are affected,

flush with water, and obtain

immediate medical attention.

I Remove all rings, watches and other

items with metal parts before

working on the battery.

I Use insulated tools.

I Avoid static electricity and take

measures for protection against

electric shocks.

I Discharge any possible static

electricity from clothing

and/or tools by touching an

earth-connected part "ground"

before working on the battery.

1. Receiving the shipment

Unpack the cells immediately upon

arrival. Do not overturn the package.

Transport seals are located under the

cover of the vent plug.

I If the cells are shipped filled and

charged, the cells are ready for

asssembly. Remove the plastic

transport seals only before use.

I If the cells are shipped empty and

discharged, do not remove the plastic

transport seals until ready to fill the

cells.

The cells must never be charged with

the transport seals in place as this can

cause permanent damage.

2. Storage

Store the battery indoors in a dry, clean,

cool location (0C to +30C / +32F to

+86F) and well ventilated space on open

shelves.

Do not store in direct sunlight or expose

to excessive heat.

Block battery Ni-Cd range

SBLE, SBM, SBH types for standard

SBL, SBM, SBH types for non standard

Installation and operating instructions

I Cells filled and charged

If cells are stored filled, they must be

fully charged prior to storage.

Cells may be stored filled and charged

for a period not exceeding 12 months

from date of dispatch from factory.

Storage of a filled battery at temperatures

above +30C (+86F) can result in loss of

capacity. This can be as much 5% per

10C (18F) above +30C (+86F) per year.

I Cells empty and discharged

Saft recommends to store cells empty

and discharged. This ensures compliance

with IEC 60623 section 4.9 (storage).

Cells can be stored like this for many

years.

I When deliveries are made in cardboard

boxes, store without opening the boxes.

I When deliveries are made in plywood

boxes, open the boxes before the

storage. The lid and the packing material

on top of the cells must be removed.

3. Electrolyte / cell oil

I Cells delivered filled and charged:

Check the level of electrolyte. It should

not be more than 20 mm below the

maximum level mark (upper). If this is

not the case, adjust the level with distilled

or deionized water. Cells delivered filled

have already cell oil in place.

In case of spillage of electrolyte during

the transport, the cells have to be

topped-up with E22 electrolyte. Fill the

cells about 20 mm above the minimum

level mark (lower) with electrolyte. Wait

4 hours and adjust if necessary before

commissioning.

I Cells delivered empty and discharged:

If the electrolyte is supplied dry, prepare it

according to its separate instructions sheet.

The electrolyte to be used is E22. Remove

the transport seals just before filling.

Fill the cells about 20 mm above the

minimum level mark (lower) with electrolyte.

Wait 4 to 24 hours and adjust if

necessary before commissioning.

It is recommended to add the cell oil

after the commissioning charge, with the

syringe, according to the quantity

indicated in the Tables A or B.

4. Installation

4.1. Location

Install the battery in a dry and clean

room. Avoid direct sunlight and heat.

The battery will give the best performance

and maximum service life when the

ambient temperature is between +10C

to +30C (+50F to +86F).

4.2. Ventilation

During the last part of charging, the

battery is emitting gases (oxygen and

hydrogen mixture). At normal float-

charge the gas evolution is very small

but some ventilation is necessary.

Note that special regulations for

ventilation may be valid in your area

depending on the application.

4.3. Mounting

Verify that cells are correctly

interconnected with the appropriate

polarity. The battery connection to load

should be with nickel plated cable lugs.

Recommended torques for terminal bolts

are:

M 6 = 11 1.1 N.m (97.4 9.8 lbf.in)

M 8 = 20 2 N.m (177.0 17.7 lbf.in)

M10 = 30 3 N.m (265.0 26.6 lbf.in)

The connectors and terminals should be

corrosion-protected by coating with a

thin layer of anti-corrosion oil.

Remove the transport seals and close

the vent plugs.

5. Commissioning

Verify that the transport seals are

removed, the vents are closed and the

ventilation is adequate during this

operation.

A good commissioning is important.

Charge at constant current is preferable.

If the current limit is lower than indicated

in the Tables A or B, charge for a

proportionnaly longer time.

October 2009

Block battery Ni-Cd range

SBLE, SBM, SBH types for standard

SBL, SBM, SBH types for non standard

Installation and operating instructions

For cells delivered filled by the factory:

- Cell oil is already in place.

- Check the electrolyte level and adjust

it to the maximum level mark (upper)

by adding distilled or deionized water.

For cells filled on location:

- Add the cell oil with the syringe,

according to the quantity indicated in

the Tables A or B.

- Check the electrolyte level and adjust

it the maximum level mark (upper)

by adding: electrolyte.

The battery is ready for use.

For capacity test purposes, the battery

has to be charged in accordance with

IEC 60623 section 4.

6. Charging in service

I Continuous parallel operation, with

occasional battery discharge.

Recommended charging voltage (+20C

to +25C / +68F to +77F):

For two level charge:

float level

= 1.42 0.01 V/cell for L cells

= 1.40 0.01 V/cell for M and H cells

high level

= 1.47 - 1.70 V/cell for L cells

= 1.45 - 1.70 V/cell for M and H cells.

A high voltage will increase the speed

and efficiency of the recharging.

For single level charge:

float level: 1.43 - 1.50 V/cell.

I Buffer operation, where the load

exceeds the charger rating.

Recommended charging voltage (+20C

to +25C / +68F to +77F):

1.50 - 1.60 V/cell.

7. Periodic Maintenance

I Keep the battery clean using only

water. Do not use a wire brush or

solvents of any kind. Vent plugs can be

rinsed in clean water if necessary.

I Check the electrolyte level. Never let

the level fall below the minimum level

mark (lower). Use only distilled or

deionized water to top-up.

Experience will tell the time interval

between topping-up.

Note: Once the battery has been filled

with the correct electrolyte either at

the battery factory or during the

battery commissioning, there is no

need to check the electrolyte density

periodically. Interpretation of density

measurements is difficult and could be

misleading.

I Check the charging voltage. If a battery

is parallel connected, it is important

that the recommended charging

voltage remains unchanged.

The charging voltage should be checked

and recorded at least once yearly.

If a cell float voltage is found below

1.35 V, high-rate charge is

recommended to apply to the cell

concerned.

I Check every two years that all

connectors are tight. The connectors

and terminal bolts should be corrosion-

protected by coating with a thin layer

of anti-corrosion oil.

I High water consumption is usually

caused by high improper voltage

setting of the charger.

8. Changing electrolyte

In most stationary battery applications,

the electrolyte will retain its effectiveness

for the life of the battery. However, under

special battery operating conditions, if the

electrolyte is found to be carbonated, the

battery performance can be restored by

replacing the electrolyte.

The electrolyte type to be used for

replacement in these cells is: E13.

Refer to "Electrolyte Instructions".

9. Environment

To protect the environment all used

batteries must be recycled.

Contact your local Saft representative

for further information.

I For cells filled and charged by the

factory and stored less than

6 months:

Constant current charge:

Charge for 10 h at 0.2 C

5

A

recommended (see Tables A or B).

Note: At the end of the charge, the

cell voltage may reach the level of

1.85 V per cell, thus the charger shall

be able to supply such voltage.

When the charger maximum voltage

setting is too low to supply constant

current charging, divide the battery into

two parts to be charged individually.

Constant voltage charge:

Charge for 24 h at 1.65 V/cell,

current limited to 0.2 C

5

A or charge

for 48 h at 1.55 V/cell, current

limited to 0.2 C

5

A (see Tables A or B).

I For cells filled on location or for filled

cells which have been stored more

than 6 months:

Constant current charge:

a) Charge for 10 h at 0.2 C

5

A

recommended (see Tables A or B)

b) Discharge at 0.2 C

5

A to 1.0 V/cell

c) Charge for 10 h at 0.2 C

5

A

recommended (see Tables A or B).

Note: At the end of the charge, the cell

voltage may reach the level of 1.85 V

per cell, thus the charger shall be able

to supply such voltage.

When the charger maximum voltage

setting is too low to supply constant

current charging, divide the battery into

two parts to be charged individually.

Constant voltage charge:

a) Charge for 30 h at 1.65 V/cell with

current limited to 0.2 C

5

A

(see Tables A or B)

b) Discharge at 0.2 C

5

A to 1.0 V/cell

c) Charge for 30 h at 1.65 V/cell

with current limited to 0.2 C

5

A

or charge for 48 h at 1.55 V/cell

current limited to 0.2 C

5

A

(see Tables A or B)

I Cell oil & electrolyte after

commissioning: wait for 4 hours after

commissioning.

Block battery Ni-Cd range

SBLE, SBM, SBH types for standard

SBL, SBM, SBH types for non standard

Installation and operating instructions

SBLE 7.5 1.5 0.08 0.24 10 M 6

SBLE 15 3.0 0.11 0.35 10 M 6

SBLE 22 4.4 0.17 0.53 15 M 6

SBLE 30 6.0 0.15 0.46 15 M 6

SBLE 40 8.0 0.29 0.90 30 M 6

SBLE 47 9.4 0.19 0.59 20 M 6

SBLE 62 12 0.23 0.70 30 M 6

SBLE 75 15 0.32 1.0 25 M 8

SBLE 95 19 0.39 1.2 25 M 8

SBLE 110 22 0.39 1.2 30 M 10

SBLE 140 28 0.49 1.5 30 M 10

SBLE 185 37 0.65 2.0 40 M 10

SBLE 230 46 0.74 2.3 50 M 10

SBLE 275 55 0.94 2.9 60 M 10

SBLE 325 65 1.13 3.5 35 2 x M 10

SBLE 375 75 1.29 4.0 40 2 x M 10

SBLE 415 83 1.39 4.3 45 2 x M 10

SBLE 460 92 1.49 4.6 50 2 x M 10

SBLE 510 102 1.68 5.2 55 2 x M 10

SBLE 550 110 1.88 5.8 60 2 x M 10

SBLE 600 120 2.04 6.3 43 3 x M 10

SBLE 650 130 2.14 6.6 47 3 x M 10

SBLE 700 140 2.23 6.9 50 3 x M 10

SBLE 750 150 2.43 7.5 53 3 x M 10

SBLE 830 166 2.81 8.7 60 3 x M 10

SBLE 925 185 2.98 9.2 50 4 x M 10

SBLE 1020 204 3.36 10.4 55 4 x M 10

SBLE 1100 220 3.75 11.6 60 4 x M 10

SBLE 1200 240 3.91 12.1 52 5 x M 10

SBLE 1300 260 4.30 13.3 56 5 x M 10

SBLE 1400 280 4.69 14.5 60 5 x M 10

SBLE 1500 300 5.05 15.6 55 6 x M 10

SBLE 1600 320 5.44 16.8 58 6 x M 10

SBLE 1660 332 5.63 17.4 60 6 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

* Value for initial filling (E22).

The cell type shows the rated capacity in ampere hours (Ah).

Table A: Standard range

SBM 11 2.2 0.10 0.30 15 M 6

SBM 15 3.0 0.11 0.33 15 M 6

SBM 22 4.4 0.15 0.46 15 M 6

SBM 30 6.0 0.15 0.46 15 M 6

SBM 43 8.6 0.31 0.95 20 M 6

SBM 56 11 0.36 1.1 20 M 6

SBM 65 13 0.32 1.0 25 M 8

SBM 84 17 0.39 1.2 25 M 8

SBM 112 22 0.45 1.4 30 M 8

SBM 138 28 0.55 1.7 40 M 10

SBM 161 32 0.61 1.9 40 M 10

SBM 184 37 0.78 2.4 50 M 10

SBM 208 42 0.94 2.9 60 M 10

SBM 231 46 0.94 2.9 60 M 10

SBM 277 55 1.13 3.5 40 2 x M 10

SBM 300 60 1.20 3.7 40 2 x M 10

SBM 323 65 1.26 3.9 40 2 x M 10

SBM 346 69 1.42 4.4 50 2 x M 10

SBM 369 74 1.55 4.8 50 2 x M 10

SBM 392 78 1.72 5.3 60 2 x M 10

SBM 415 83 1.88 5.8 60 2 x M 10

SBM 438 88 1.88 5.8 60 2 x M 10

SBM 461 92 1.84 5.7 60 2 x M 10

SBM 505 101 2.10 6.5 50 3 x M 10

SBM 555 111 2.33 7.2 50 3 x M 10

SBM 625 125 2.82 8.7 60 3 x M 10

SBM 690 138 2.78 8.6 60 3 x M 10

SBM 740 148 3.11 9.6 50 4 x M 10

SBM 830 166 3.79 11.7 60 4 x M 10

SBM 920 184 3.82 11.8 60 4 x M 10

SBM 965 193 3.69 11.4 40 6 x M 10

SBM 1040 208 4.72 14.6 60 5 x M 10

SBM 1150 230 4.66 14.4 60 5 x M 10

SBM 1220 244 5.50 17.0 60 6 x M 10

SBM 1390 278 5.60 17.3 60 6 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

SBH 8.3 1.7 0.12 0.36 10 M 6

SBH 12 2.4 0.14 0.44 15 M 6

SBH 16 3.2 0.16 0.48 15 M 6

SBH 19 3.8 0.25 0.77 15 M 6

SBH 29 5.8 0.31 0.95 20 M 6

SBH 39 7.8 0.36 1.1 25 M 8

SBH 49 9.8 0.42 1.3 30 M 8

SBH 59 12 0.49 1.5 30 M 10

SBH 69 14 0.58 1.8 40 M 10

SBH 79 16 0.58 1.8 40 M 10

SBH 88 18 0.74 2.3 50 M 10

SBH 98 20 0.71 2.2 50 M 10

SBH 118 24 0.87 2.7 60 M 10

SBH 137 28 1.20 3.7 40 2 x M 10

SBH 157 31 1.20 3.7 40 2 x M 10

SBH 177 35 1.46 4.5 50 2 x M 10

SBH 196 39 1.42 4.4 50 2 x M 10

SBH 236 47 1.84 5.7 60 2 x M 10

SBH 265 53 2.20 6.8 50 3 x M 10

SBH 294 59 2.10 6.5 50 3 x M 10

SBH 353 71 2.78 8.6 60 3 x M 10

SBH 393 79 2.82 8.7 50 4 x M 10

SBH 471 94 3.69 11.4 60 4 x M 10

SBH 491 98 3.53 10.9 50 5 x M 10

SBH 590 118 4.63 14.3 60 5 x M 10

SBH 640 128 4.21 13.0 50 5 x M 10

SBH 705 141 5.31 16.4 60 5 x M 10

SBH 765 153 5.24 16.2 60 5 x M 10

SBH 865 173 5.92 18.3 57 6 x M 10

SBH 920 184 6.28 19.4 60 6 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

Block battery Ni-Cd range

SBLE, SBM, SBH types for standard

SBL, SBM, SBH types for non standard

Installation and operating instructions

Saft

Industrial Battery Group

12, rue Sadi Carnot

93170 Bagnolet - France

Tel: +33 1 49 93 19 18

Fax: +33 1 49 93 19 64

www.saftbatteries.com

Doc N 21124-2-1009

Data in this document is subject to change without

notice and becomes contractual only after written

confirmation.

Socit anonyme au capital de 31 944 000

RCS Bobigny B 383 703 873

Pragma - Printed in France - 3k

* Value for initial filling (E22).

The cell type shows the rated capacity in ampere hours (Ah).

Table B: Non standard range

SBL 7.5 1.5 0.08 0.24 10 M 6

SBL 16 3.2 0.11 0.35 10 M 6

SBL 30 6.0 0.15 0.46 15 M 6

SBL 37 7.4 0.22 0.69 15 M 6

SBL 45 9.0 0.19 0.59 20 M 6

SBL 48 9.6 0.28 0.86 15 M 6

SBL 59 12 0.23 0.7 30 M 6

SBL 70 14 0.32 1.0 25 M 8

SBL 90 18 0.39 1.2 25 M 8

SBL 102 21 0.39 1.2 30 M 10

SBL 131 27 0.49 1.5 30 M 10

SBL 135 27 0.55 1.7 40 M 10

SBL 167 34 0.65 2.0 50 M 10

SBL 173 35 0.65 2.0 40 M 10

SBL 199 40 0.78 2.4 60 M 10

SBL 214 43 0.74 2.3 50 M 10

SBL 237 48 0.97 3.0 40 2 x M 10

SBL 256 52 0.94 2.9 60 M 10

SBL 269 54 1.13 3.5 40 2 x M 10

SBL 301 61 1.20 3.7 50 2 x M 10

SBL 304 61 1.13 3.5 40 2 x M 10

SBL 334 67 1.26 3.9 50 2 x M 10

SBL 346 70 1.26 3.9 40 2 x M 10

SBL 366 74 1.42 4.4 60 2 x M 10

SBL 387 78 1.36 4.2 50 2 x M 10

SBL 398 80 1.55 4.8 60 2 x M 10

SBL 429 86 1.49 4.6 50 2 x M 10

SBL 470 94 1.68 5.2 60 2 x M 10

SBL 500 100 1.91 5.9 50 3 x M 10

SBL 510 102 1.88 5.8 60 2 x M 10

SBL 595 119 2.33 7.2 60 3 x M 10

SBL 600 120 2.14 6.6 47 3 x M 10

SBL 645 129 2.23 6.9 50 3 x M 10

SBL 665 133 2.56 7.9 50 4 x M 10

SBL 770 154 2.78 8.6 60 3 x M 10

SBL 795 159 3.11 9.6 60 4 x M 10

SBL 835 167 3.11 9.6 50 5 x M 10

SBL 860 172 2.98 9.2 50 4 x M 10

SBL 995 199 3.88 12.0 60 5 x M 10

SBL 1020 204 3.72 11.5 60 4 x M 10

SBL 1070 214 3.72 11.5 50 5 x M 10

SBL 1280 256 4.66 14.4 60 5 x M 10

SBL 1450 290 5.31 16.4 57 6 x M 10

SBL 1540 308 5.60 17.3 60 6 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

SBM 86 17 0.42 1.3 30 M 8

SBM 287 57 1.39 4.3 50 2 x M 10

SBM 359 72 1.62 5.0 60 2 x M 10

SBM 431 86 2.07 6.4 50 3 x M 10

SBM 540 108 2.43 7.5 60 3 x M 10

SBM 575 115 2.78 8.6 50 4 x M 10

SBM 720 144 3.24 10.0 60 4 x M 10

SBM 900 180 4.05 12.5 60 5 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

SBH 25 5.0 0.30 0.92 15 M 6

SBH 38 7.6 0.39 1.2 20 M 6

SBH 51 10 0.42 1.3 25 M 8

SBH 64 13 0.52 1.6 30 M 8

SBH 77 15 0.52 1.6 30 M 10

SBH 89 18 0.61 1.9 40 M 10

SBH 102 20 0.68 2.1 40 M 10

SBH 115 23 0.91 2.8 50 M 10

SBH 128 26 0.84 2.6 50 M 10

SBH 141 28 1.07 3.3 60 M 10

SBH 153 31 1.04 3.2 60 M 10

SBH 179 36 1.23 3.8 40 2 x M 10

SBH 204 41 1.36 4.2 40 2 x M 10

SBH 230 46 1.81 5.6 50 2 x M 10

SBH 256 51 1.68 5.2 50 2 x M10

SBH 281 56 2.14 6.6 60 2 x M 10

SBH 307 61 2.10 6.5 60 2 x M 10

SBH 345 69 2.72 8.4 50 3 x M 10

SBH 383 77 2.52 7.8 50 3 x M 10

SBH 422 84 3.17 9.8 60 3 x M 10

SBH 460 92 3.14 9.7 60 3 x M 10

SBH 510 102 3.37 10.4 50 4 x M 10

SBH 560 112 4.24 13.1 60 4 x M 10

SBH 615 123 4.21 13.0 60 4 x M 10

Cell

type

Charging

current

0.2 C

5

A

(A)

Electrolyte

per cell

Solid*

(kg)

Liquid*

(l)

Quantity

of oil

ml /vent

Cell

connect.

bolt

per pole

You might also like

- More Sample Exam Questions-Midterm2Document6 pagesMore Sample Exam Questions-Midterm2mehdiNo ratings yet

- Introduction To Engineering ManagementDocument52 pagesIntroduction To Engineering ManagementJoshua Roberto GrutaNo ratings yet

- Personal Protective Equipment (PPE)Document52 pagesPersonal Protective Equipment (PPE)Yeyeri SantosNo ratings yet

- Construction Cost Handbook Korea 2012n PDFDocument73 pagesConstruction Cost Handbook Korea 2012n PDFSharafaz ShamsudeenNo ratings yet

- Manual Rci Firetrol Plano BoardDocument9 pagesManual Rci Firetrol Plano BoardGONZALO100% (1)

- Battery Saft GTG125VDocument2 pagesBattery Saft GTG125VPrem SagarNo ratings yet

- The Basics of Business Management Vol I PDFDocument284 pagesThe Basics of Business Management Vol I PDFKnjaz Milos100% (1)

- PNG Vision 2050Document79 pagesPNG Vision 2050Raghuram Boddupalli67% (3)

- Learning OutcomesDocument48 pagesLearning OutcomesPom Jung0% (1)

- Energy Audit Presentation FinalDocument19 pagesEnergy Audit Presentation FinalPrafulla Mandlekar100% (1)

- Project Management Ch1Document14 pagesProject Management Ch1araml001100% (1)

- QANT520 Render Ch07 0706 ProblemsDocument10 pagesQANT520 Render Ch07 0706 ProblemsRahil VermaNo ratings yet

- Engineering EconomicsDocument4 pagesEngineering EconomicstkubvosNo ratings yet

- CMPT 641-Digital Transformation Plan - Phase 1 - Part 2Document18 pagesCMPT 641-Digital Transformation Plan - Phase 1 - Part 2raghavNo ratings yet

- Masonry Contractor - Quality Plan Sample PDFDocument27 pagesMasonry Contractor - Quality Plan Sample PDFToska ExNo ratings yet

- Worked Problems Heat ExchangersDocument18 pagesWorked Problems Heat Exchangers521 Balaji ONo ratings yet

- Ethical Issues in Wage and Salary AdministrationDocument8 pagesEthical Issues in Wage and Salary AdministrationDigvijay sinh ZalaNo ratings yet

- CTDP & CTP Certification - Handbook PDFDocument21 pagesCTDP & CTP Certification - Handbook PDFNimish Kumar BhatiaNo ratings yet

- Neral Building and Construction.Document63 pagesNeral Building and Construction.EnockNo ratings yet

- ACCA F7 For 2011Document145 pagesACCA F7 For 2011Hetul Sanghvi100% (2)

- Gau - Gpa System: GradingDocument3 pagesGau - Gpa System: GradingPrageethSanjeewa100% (1)

- Dissertation IIDocument54 pagesDissertation IIRaj MandloiNo ratings yet

- Global Training India: Globaltraining - in - Preliminary Plan For Nov and Dec 2014Document1 pageGlobal Training India: Globaltraining - in - Preliminary Plan For Nov and Dec 2014mohd84elfatihNo ratings yet

- Doctorate Level 8 Diploma in Strategic Management and Leadership (With Level 7 Logistics and Supply Chain Management) - Delivered Online by LSBR, UKDocument20 pagesDoctorate Level 8 Diploma in Strategic Management and Leadership (With Level 7 Logistics and Supply Chain Management) - Delivered Online by LSBR, UKLSBRNo ratings yet

- Evaluation of Green Building in The Existing Building of The Department of The Environment of DKI Jakarta Province in The Order of Reducing Greenhouse Gas EmissionsDocument5 pagesEvaluation of Green Building in The Existing Building of The Department of The Environment of DKI Jakarta Province in The Order of Reducing Greenhouse Gas EmissionsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review of Bio-Based Materials For Oil Spill TreatmentDocument16 pagesA Review of Bio-Based Materials For Oil Spill Treatmentivan estevesNo ratings yet

- Fire Is The Rapid Oxidation of A Material in The Exothermic Chemical Process of CombustionDocument18 pagesFire Is The Rapid Oxidation of A Material in The Exothermic Chemical Process of CombustionOniel HallNo ratings yet

- Sample Energy PlanDocument14 pagesSample Energy PlangodwanaNo ratings yet

- Smart GPC Resume and Cover LettersDocument46 pagesSmart GPC Resume and Cover LettersAnonymous egGaBIjG4No ratings yet

- How To Write An Assignment or Class Project-General InstructionsDocument4 pagesHow To Write An Assignment or Class Project-General InstructionsFatima AwanNo ratings yet

- Technical ReportDocument18 pagesTechnical ReportBenbaroNo ratings yet

- 3Document14 pages3Saurabh PatelNo ratings yet

- Applied Mec - Co.zwDocument168 pagesApplied Mec - Co.zwzexmutsawu12345No ratings yet

- OJT Final ReportDocument10 pagesOJT Final ReportKate Cynah Nerizon NapigkitNo ratings yet

- Occupational Safety and Health Standards - DocumentationDocument6 pagesOccupational Safety and Health Standards - DocumentationJericho YangNo ratings yet

- As 1921-1976 Airconditioning and Ventilation in Ships Cabins and Living Spaces of Merchant ShipsDocument7 pagesAs 1921-1976 Airconditioning and Ventilation in Ships Cabins and Living Spaces of Merchant ShipsSAI Global - APAC0% (1)

- Eureka-Archimedes Principle ActivityDocument5 pagesEureka-Archimedes Principle Activityrogpa50% (2)

- Chapter: Business Policy: ContentsDocument3 pagesChapter: Business Policy: ContentsAtaur RahmanNo ratings yet

- Fault Tree AnalysisDocument23 pagesFault Tree Analysiskenoly123No ratings yet

- Lecture Notes 3Document38 pagesLecture Notes 3Jonathan Tran100% (1)

- Thesis FinalDocument66 pagesThesis FinalAbdulazizNo ratings yet

- Stuvia 2545037 Mno3704 Assignment 3 Semester 1 2023 754855Document11 pagesStuvia 2545037 Mno3704 Assignment 3 Semester 1 2023 754855matlhodimkt80% (1)

- Physics Form OneDocument103 pagesPhysics Form OneBoniphace50% (2)

- Stevedoring Foundation Skills Level 1 (CVQ)Document169 pagesStevedoring Foundation Skills Level 1 (CVQ)Arbit BitNo ratings yet

- Product/Production Relationships: Solution: This Problem Neglects The Effect of Assembly TimeDocument2 pagesProduct/Production Relationships: Solution: This Problem Neglects The Effect of Assembly TimeParamaSivanNo ratings yet

- Hempathane TopcoatDocument11 pagesHempathane TopcoatFrancisco M. RamosNo ratings yet

- Lesson 1 Occupational Safety and Health: Learning OutcomesDocument14 pagesLesson 1 Occupational Safety and Health: Learning Outcomesfaithmark ceriaco100% (1)

- Accounting: Pearson Edexcel (Modular Syllabus)Document16 pagesAccounting: Pearson Edexcel (Modular Syllabus)rahat879No ratings yet

- Hse PpeDocument5 pagesHse Ppeapi-26802090No ratings yet

- Capital Budgeting: Year Cash FlowDocument5 pagesCapital Budgeting: Year Cash FlowNaeem Uddin100% (3)

- What Is Your Educational BackgroundDocument4 pagesWhat Is Your Educational BackgroundDherick RaleighNo ratings yet

- Bosh 101Document96 pagesBosh 101Stacy Christensen100% (1)

- Scaffolding Safety Guideline: KAS-Scaffolding - Fast Then. Fast NowDocument9 pagesScaffolding Safety Guideline: KAS-Scaffolding - Fast Then. Fast Nowfaizal4yaNo ratings yet

- Vechile Emission ControlDocument19 pagesVechile Emission Controlfuel123No ratings yet

- Open Cycle Powe PlantDocument31 pagesOpen Cycle Powe PlantherdanandiNo ratings yet

- Engineering Economics Lecture Week 10-11: Huma Fawad Hitec, Taxila SEP, 2018 - JAN, 2019Document19 pagesEngineering Economics Lecture Week 10-11: Huma Fawad Hitec, Taxila SEP, 2018 - JAN, 2019Sohaib IrfanNo ratings yet

- Cash Flow ProjectionDocument8 pagesCash Flow ProjectionSuhailNo ratings yet

- Alcad Batt SpecDocument2 pagesAlcad Batt SpecIsaac VoonNo ratings yet

- ALCAD HC+P - I&O InstructionDocument2 pagesALCAD HC+P - I&O InstructionsiavoshsaifNo ratings yet

- Deep Cycle MaintenanceDocument8 pagesDeep Cycle MaintenanceJony M. TemnikarNo ratings yet

- E Installation of BatteryDocument16 pagesE Installation of BatteryPrashant KadamNo ratings yet

- Shanghai Sunrise Electronics Co., LTD.: Ss22A Thru Ss26ADocument1 pageShanghai Sunrise Electronics Co., LTD.: Ss22A Thru Ss26Amichaelliu123456No ratings yet

- Product Guide: Single Port MagjackDocument4 pagesProduct Guide: Single Port Magjackmichaelliu123456No ratings yet

- Rf2125 Linear AmplifierDocument6 pagesRf2125 Linear Amplifiermichaelliu123456No ratings yet

- SDRAMDocument86 pagesSDRAMmichaelliu123456No ratings yet

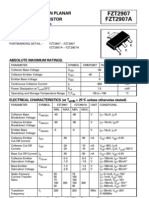

- FZT2907 FZT2907A FZT2907 FZT2907A: Sot223 PNP Silicon Planar Switching TransistorDocument2 pagesFZT2907 FZT2907A FZT2907 FZT2907A: Sot223 PNP Silicon Planar Switching Transistormichaelliu123456No ratings yet

- Ace Om 230Document3 pagesAce Om 230michaelliu123456No ratings yet

- SMR40Document4 pagesSMR40michaelliu123456No ratings yet

- UC3825ADWDocument15 pagesUC3825ADWmichaelliu123456No ratings yet

- Data SheetDocument23 pagesData Sheetmichaelliu123456No ratings yet

- New Product: Series Surface Mount T Z Transient Voltage SuppressorDocument3 pagesNew Product: Series Surface Mount T Z Transient Voltage Suppressormichaelliu123456No ratings yet

- MBR20200CT Switchmodet Power RectifierDocument5 pagesMBR20200CT Switchmodet Power Rectifiermichaelliu123456No ratings yet

- Datasheet Flatpack2 48V HE RectifiersDocument2 pagesDatasheet Flatpack2 48V HE Rectifiersmichaelliu123456No ratings yet

- Offers For SaleDocument45 pagesOffers For Salemichaelliu123456No ratings yet

- 安規綜合分析儀7410Document4 pages安規綜合分析儀7410michaelliu123456No ratings yet

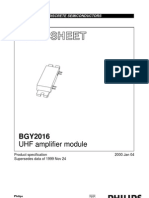

- BGY2016NDocument12 pagesBGY2016Nmichaelliu123456No ratings yet

- Datasheet Flatpack S 1U SystemsDocument2 pagesDatasheet Flatpack S 1U Systemsmichaelliu1234560% (1)

- Bmc5Ag: SpecificationsDocument1 pageBmc5Ag: Specificationsmichaelliu123456No ratings yet

- Robc Reviewed 2021Document56 pagesRobc Reviewed 2021Harmandeep SinghNo ratings yet

- Ficha INVERSORES HIBRIDOS EP3300 TLV (1KW-6KW) 2FASESDocument4 pagesFicha INVERSORES HIBRIDOS EP3300 TLV (1KW-6KW) 2FASESDeschevet VillaNo ratings yet

- SPM11Document26 pagesSPM11Narcis PatrascuNo ratings yet

- 2022-06-29 European Products Brochure (Released)Document15 pages2022-06-29 European Products Brochure (Released)ahmed.applligentNo ratings yet

- Mobile App Test CasesDocument24 pagesMobile App Test CasesBalasubrahmanyamNo ratings yet

- Ritar LFP12.8V100AH User-guide EnDocument15 pagesRitar LFP12.8V100AH User-guide EnNang Seng HomNo ratings yet

- Handleiding Ecooter User Manual 20190612Document23 pagesHandleiding Ecooter User Manual 20190612Javan Wilson dos SantosNo ratings yet

- Pes Modern Collage of Engineering, Pune: Case Study/Product Survey:-Electric VehicleDocument22 pagesPes Modern Collage of Engineering, Pune: Case Study/Product Survey:-Electric Vehicle28048 Pranav KarodpatiNo ratings yet

- Wosspa 2013 Appliance Consumption Signature Database and Recognition Test ProtocolsDocument6 pagesWosspa 2013 Appliance Consumption Signature Database and Recognition Test ProtocolsVasundhar BoddapatiNo ratings yet

- XT660d/XT665d Full Keypad Portable Radio: Professional Digital Two-Way RadioDocument1,384 pagesXT660d/XT665d Full Keypad Portable Radio: Professional Digital Two-Way RadioSebastian DörflerNo ratings yet

- Specification For Public Address (P.a) SystemDocument45 pagesSpecification For Public Address (P.a) SystemKhairul AshrafNo ratings yet

- BPAC Double Line-InstallationDocument8 pagesBPAC Double Line-InstallationsudharshanNo ratings yet

- Penlon Prima sp2 Service Manual PDFDocument108 pagesPenlon Prima sp2 Service Manual PDFkare9No ratings yet

- Apc 10kva Ups ManualDocument36 pagesApc 10kva Ups Manualraj rajNo ratings yet

- ProNautic ManualDocument9 pagesProNautic ManualJose CandedoNo ratings yet

- Redmi Buds 3 Pro-User Manual-1Document1 pageRedmi Buds 3 Pro-User Manual-1Marko IlićNo ratings yet

- Powerscale 10-50 Kva: User ManualDocument101 pagesPowerscale 10-50 Kva: User ManualaarianNo ratings yet

- XD 10 - XD 14 - XD 17 - Service ManualDocument179 pagesXD 10 - XD 14 - XD 17 - Service ManualdanielNo ratings yet

- Manual MultiPlus Compact 2000 230V EN NL FR DE ESDocument146 pagesManual MultiPlus Compact 2000 230V EN NL FR DE ESMazéNo ratings yet

- PM85 - ManualDocument68 pagesPM85 - ManualMc3lNo ratings yet

- True Power ProductsDocument8 pagesTrue Power ProductsDurban Chamber of Commerce and IndustryNo ratings yet

- Nonisolated EV Chargers Issues Review MELE2021Document11 pagesNonisolated EV Chargers Issues Review MELE2021DEBARATI DAMNo ratings yet

- GP4000 User ManualDocument1 pageGP4000 User Manualmateor_89No ratings yet

- QuadroDocument76 pagesQuadromlakiNo ratings yet

- Test Lamp TL8Document1 pageTest Lamp TL8Vincent GabrielNo ratings yet

- Insulation AnalyzerDocument2 pagesInsulation AnalyzerIvan CardenasNo ratings yet

- BQ25611D 2Document12 pagesBQ25611D 2chenzeyu22655No ratings yet

- R400 Series - Data Sheets: ModulesDocument13 pagesR400 Series - Data Sheets: ModulesIonel RacaruNo ratings yet

- Battery and ChargerDocument72 pagesBattery and Chargerlrpatra100% (1)