Saes A 011 PDF

Saes A 011 PDF

Uploaded by

cywahaCopyright:

Available Formats

Saes A 011 PDF

Saes A 011 PDF

Uploaded by

cywahaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saes A 011 PDF

Saes A 011 PDF

Uploaded by

cywahaCopyright:

Available Formats

Engineering Standard

SAES-A-011 Crude Oil Stabilization Document Responsibility: Process Engineering Standards Committee 20 February 2013

Saudi Aramco DeskTop Standards

Table of Contents 1 Scope.................................................................... 2 2 Conflicts and Deviations........................................ 2 3 References............................................................ 2 4 Definitions.............................................................. 3 5 Crude Oil Stabilization Specification..................... 4 6 Process Design Considerations............................ 4 6.1 6.2 6.3 6.4 6.5 6.6 6.7 7.1 7.2 Stabilizer Feed Preheat Train Stabilizer Column Design Reboiler Design Thermosiphon Loop Design Reboiler Piping Steam Injection Performance Analyzer Steam Heating Hot Oil Heating

7 Stabilizer Reboiler Temperature Control............... 8

8 Crude Oil Stabilization De-bottlenecking............... 9 Appendix-1: Crude Oil Stabilization Unit Example (Sketch).......................... 11 Appendix-2: Thermosiphon Hydraulic Calculation.... 12 Appendix-3: Reboiler Temperature Control (Sketch)................................................ 20

Previous Issue: New

Next Planned Update: 20 February 2018 Page 1 of 20

Primary contact: Fernandez, Gabriel Thomas on +966-3-8809476

CopyrightSaudi Aramco 2013. All rights reserved.

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

Scope 1.1 This Standard provides the minimum and mandatory requirements governing the critical aspects of the design of the crude oil stabilization unit and its control, the reboiler, thermosiphon loop and the design of the pre-heat train (if provided). This Standard also provides the minimum requirement for debottlenecking an existing Crude Stabilization Unit. This Standard does not cover requirements for the design of Gas Oil Separation Plant (GOSP), Produced Water Treatment & Disposal and Gas Gathering Unit.

1.2 1.3

Conflicts and Deviations 2.1 Any conflicts between this Standard and other applicable Saudi Aramco Engineering Standards (SAESs), Material System Specification (SAMSSs), Standard Drawings (SASDs), or industry standards, codes, and forms shall be resolved in writing by the Company or Buyers Representative through the Manager, Process & Control Systems Department (P&CSD) of Saudi Aramco, Dhahran. Direct all requests to deviate from this Standard in writing to the Company or Buyers Representative, who shall follow internal company procedure SAEP-302 and forward such requests to the Manager, Process & Control Systems Department (P&CSD) of Saudi Aramco, Dhahran.

2.2

References The requirements contained in the following documents apply to the extent specified in this standard: 3.1 Saudi Aramco References Saudi Aramco Engineering Procedures SAEP-302 SAEP-364 Instructions for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement Process Simulation Model Development and Support

Saudi Aramco Engineering Standards SAES-C-001 SAES-D-001 SAES-E-004 Process Design of Trays and Packing Design Criteria for Pressure Vessels Design Criteria of Shell and Tube Heat Exchangers

Page 2 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

SAES-L-310 3.2

Design of Plant Piping

Industry Codes and Standards American Society of Testing and Materials ASTM D2889 ASTM D323-90 ASTM D6377-08 Standard Test Method for Calculation of True Vapor Pressures of Petroleum Distillate Fuels Standard Test Method for Vapor Pressure of Petroleum Products (Reid Method)1 Standard Test Method for Determination of Vapor Pressure of Crude Oil: VPCRx (Expansion Method)1

Definitions and Abbreviations Available Head for Thermosiphon Flow (AHTF): Available head for thermosiphon flow equals top of level in drawoff tray to the bottom of the inlet to the reboiler. BS&W: Basic (Bottom) Sediments and Water. Crude Oil Stabilizer: Distillation column with feed to the top and middle tray (if Feed Preheater provided) to strip H2S (hydrogen sulfide) and light hydrocarbons to meet H2S and TVP specifications (refer to Appendix-1 for Crude Oil Stabilizer example). GOSP: Gas Oil Separation Plant. H2S: Hydrogen Sulfide. MOC: Management of change Reboilers: Heat exchangers used to provide heat to the bottom of a distillation column. Reid Vapor Pressure (RVP): A measure of product volatility, measured in pounds per square inch (psi) at 100F. The higher the RVP, the more volatile the product is and therefore, evaporates more readily (test method ASTM D6377-08 or ASTM D323-90). Required Head Thermosiphon Flow (RHTF): Required head for thermosiphon flow is calculated by trial and error, and is the head on the inlet side of the reboiler to overcome the loop pressure drop and the static head on the return loop including the reboiler. TCV: Temperature Control valve. Thermosiphon: It is a method of circulating liquid in a vertical closed-loop circuit, without requiring a conventional pump. The circulation is a result of the density differences caused by heat transfer to the liquid from a heat source.

Page 3 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

Trap out tray: Tray designed for total draw of liquid. True Vapor Pressure (TVP): True Vapor Pressure; it is the vapor pressure of the hydrocarbon mixture at its operating temperature (test method ASTM D2889). 5 Crude Oil Stabilization Specification 5.1 The crude oil shall be stabilized to meet a TVP specification of 13.0 psia at a pipeline transport and/or storage temperature of 140F. If process design basis dictates a different transport and/or storage temperature then the stabilization process shall ensure that, at the pipeline transport and/or storage temperature the TVP shall be below 13.0 psia. In addition the H2S content in the stabilized oil stream shall not exceed 30 ppm (w/w). If required, the maximum TVP limit shall be reduced to lower than 13 psia, such that the H2S content is not exceeded beyond 30 ppm (w/w). The column design and reboiler duty shall be based on the higher duty required between the TVP and H2S specifications. However, process facility design will vary depending on the RVP specified for the crude. Additional cooling facilities may have to be added to ensure TVP of 13.0 psia is not exceeded while simultaneously meeting the RVP specifications.

Commentary: It shall be understood that it is not always possible to meet both the H 2S and the TVP specification simultaneously. However, the TVP shall not exceed 13.0 psia while trying to meet H2S specification. Similarly, the H2S specification shall not be exceeded, it may be necessary to lower the TVP below 13.0 psia specification to meet the H2S specification.

5.2

Process and Equipment Design Considerations 6.1 Stabilizer Feed Preheat Train 6.1.1 6.1.2 Crude oil Stabilization process design shall incorporate energy conservation to recover the heat from the hot stabilizer bottom stream. If crude oil stabilization is done within the battery limits of the GOSP, then hot stabilized oil shall ensure heating the crude entering dehydration/desalting unit to a temperature not to exceed 140F, in order to facilitate the breaking of emulsions and promote better separation performance. This may be done with or without a preheater on the crude feed to the stabilizer.

Page 4 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018 Note:

SAES-A-011 Crude Oil Stabilization

Higher temperatures are not recommended to ensure enough margin shall be provided to avoid vaporization in Dehydrator/Desalter at operating pressures.

6.1.3

Where the GOSP and stabilization process are far removed from each other (i.e., Stabilizer is not a part of the GOSP) then hot stabilized oil shall be used to preheat the feed to the column (Stabilizer). Where feed pre-heating is used, splitting of the feed in a cold stream (by-passing pre-heater) and a hot stream shall be considered in order to provide optimum heat transfer and column design. The preheat train shall be designed to provide optimum heat recovery (energy saving optimization) and operational flexibility (equipment sparing philosophy). In addition, if necessary process design may require flexibility to cool the stabilized crude to the pipeline by fin fan coolers, in the case summer crude inlet temperatures are not low enough to allow pipeline transport at <140F. Deep stabilization (higher bottoms temperature) shall also be considered in order to meet TVP of 13.0 psia at the higher pipeline temperature. Where this option is used, impact on RVP spec. shall be checked. The optimum combination shall be determined during the project proposal phase based on flexibility and available economics. The process simulations shall be based on the latest version of the approved simulation software. The process simulation software that will be used in a project shall be concurred by P&CSD. Simulation development shall conform to the guidelines given in SAEP-364.

6.1.4

6.1.5

6.2

Stabilizer Column Design 6.2.1 The crude oil stabilizer shall be designed in accordance with SAES-D-001 and to operate at not less than 3.0 psig and not more than 5 psig at the top of the column. For operating pressures higher than 5.0 psig, concurrence shall be obtained from the Primary Contact of this Standard. The low pressure operation of the stabilizer column ensures low reboilers duty, low bottoms temperature, thereby reduced rate of fouling. Multiple feeds to the column shall be based on feed preheater design but in any case they shall not be more than two. The column trap out tray (feed tray to the reboilers) shall be designed as a chimney tray within the column, despite the number of tray passes or reboilers connected to the column. The different reboilers shall be fed from the common trap out tray. Separate trap out trays for individual reboiler feeds shall not be designed, even if balanced outside the column.

6.2.2 6.2.3

Page 5 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

The column tray design, including the trap out tray, shall be performed by tray vendor. 6.2.4 6.2.5 6.2.6 6.2.7 6.2.8 6.3 The column shall be designed with trays, primarily due to the fouling nature of crude (packings shall not be used). Column and trays design shall be conformed with SAES-C-001 requirements. The re-boiled fluid (vapor/liquid mixture) returned from the reboilers shall be designed to enter below the trap out tray. The reboilers hydrocarbon feed and return lines shall be equipped with through conduit valves to facilitate isolation. The crude oil stabilizer shall be designed to operate at 40% turndown in each operating case.

Reboiler Design 6.3.1 The Reboiler/s shall be designed as once through thermosiphon Reboiler/s and not as circulating thermosiphon reboilers. Such a design reduces the vapor loading to the bottom tray; the benefits are reduced column diameter and less likelihood of flooding. Reboilers shall be designed in accordance with SAES-E-004 and to operate horizontally with crude on the shell side and heating medium on the tube side of the heat exchanger unless approved otherwise by the Chairman of Process Engineering Standards Committee. Multiple Reboilers shall not be designed to operate in series. This is required to eliminate high pressure drop in the thermosiphon loop. Acceptable Reboiler configurations are as follows: a) 2 x 50% Reboilers: Normal design shall provide 2 x 50% reboiler installed capacity, with one ready spare tube bundle in warehouse. Reboiler design could be optimized based on existing reboiler designs to provide common spare bundle/s. Such a design shall provide dedicated nozzle on the column and independent piping to each reboiler. The trap out tray shall be common (to any nozzle) and piping to the reboilers shall not be externally connected to make-up 100% reboiler design flow. Reboiler outlet piping shall also be segregated. All such piping shall be geometrically symmetrical. 2 x 100% Reboilers: Design philosophy where 2 x 100% reboilers are provided must consider that only one reboiler shall operate

Page 6 of 20

6.3.2

6.3.3

b)

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

during normal operation. Operating two in parallel for such design will lead to excessive fouling and thermosiphon loop instability. Such a design shall provide dedicated nozzle and independent piping to each reboiler. The trap out tray shall be common (to any nozzle) and piping to the reboilers shall not be externally connected to make up 100% flow to each reboiler. Reboiler outlet piping shall also be segregated. All such piping shall be geometrically symmetrical. c) 4 x 25% Reboilers: Such a design shall provide one ready spare tube bundle in warehouse. The reboilers shall be arranged two (50% capacity) on either side of the column. The trap out tray shall be common (to any nozzle) and feed to the reboilers on each side through a common line from the column externally split to feed each of the 25% reboilers on one side. If this is done, then the outlet or return to the column from each side shall be connected to provide a single line to the column. All such piping shall be geometrically symmetrical.

6.4

Thermosiphon Loop Design 6.4.1 Design shall ensure vapor equalizing line is provided as shown in Appendix-2, Figure-2. This design equalizes the pressure in the line to the reboilers with the pressure in the column, above the trap out pan and assures continuous and stable flow in the thermosiphon loop. The connection on the thermosiphon loop shall be made at the top of the line above the vertical section as shown in Appendix-2, Figure-2. This is to ensure that the equalizing line connection is not made in the liquid section of the thermosiphon loop. Design shall ensure that there is no slug flow in the thermosiphon loop. Changing line diameter is one way to eliminate the slug flow. Design contractor shall ensure detailed hydraulic calculations are provided as per the procedure provided in Appendix-2. Hydraulic information for Available Head for Thermosiphon Flow (AHTF) and Required Head for Thermosiphon Flow (RHTF) shall be included in this check.

6.4.2 6.4.3

6.5

Reboiler Piping 6.5.1 6.5.2 The piping design shall be independent to each reboiler and symmetrical as mentioned in paragraph 6.3.3 above. Reboiler piping and Thermosiphon Loop Design shall be designed as described in Appendix-2.

Page 7 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

6.5.3 6.6

The piping shall be designed in accordance to SAES-L-310.

Steam Injection 6.6.1 Where steam is available, steam shall be injected into the crude upstream of the reboiler to facilitate higher vaporization within the reboiler at lower processing temperature, due to the partial pressure effect of steam. Process simulation shall determine the optimum steam injection rate to meet the TVP and H2S specifications; however, as a guideline 12.0 lbs/hr of steam is required per 1000 barrels/day of crude processed. 60 psig saturated steam with less than five degrees Fahrenheit (<5F) superheat shall be used.

6.6.2

6.6.3 6.7

Performance Analyzer BS&W, H2S and RVP analyzer shall be provided on the oil stabilized stream in order to monitor the quality of oil leaving the unit and detect eventual upset conditions.

Stabilizer Reboiler Temperature Control The heating medium for the shell and tube heat exchanger reboiler shall be preferably 60 psig steam or hot oil where steam is not available. The use of hot water system is not allowed. 7.1 Steam Heating 7.1.1 Where steam is used for heating, the design shall use 60 psig saturated steam with less than five degrees Fahrenheit (<5F) superheat. Higher pressure steam results in high tube skin temperatures and increased fouling. The reboiler shall be designed with condensate subcooling to a temperature <180F to prevent condensate from flashing in the condensate collection header. It is common knowledge that continuous flashing and condensing of steam in the return header after the temperature control valve (TCV) (Appendix-3) causes continuous hammering of the return condensate lines, and can result in mechanical failure of the header. Higher subcooled temperatures are acceptable in so far as the return header back pressure is maintained to attain condensate temperature 10F below the flashing temperature in the entire length of the header, prior to discharging into the condensate drum. The condensate header must enter

7.1.2

Page 8 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

the drum horizontally. If a back pressure control valve is used it shall be located close to the condensate drum. 7.1.3 The temperature control scheme shall be designed according to Appendix-3. The reboiler crude oil outlet temperature is controlled by steam heating and flooding the tubes with condensate. The TCV on the condensate line is normally controlled by the fluid temperature from the reboiler to the column. However, the TCV will not let uncondensed steam out as the controller has a temperature override from the condensate temperature out of the reboiler. For multiple systems connected to a common condensate header, a condensate backpressure controller may be provided and shall be located close to the condensate return drum. The pressure setting shall ensure there is a minimum of +10F gap between the equilibrium condensate temperatures for the pressure setting on the header and the condensate from the reboilers (return condensate temperatures being lower); this will prevent hammering in the line from flashing condensate.

7.1.4

7.2

Hot Oil Heating Where steam is not available hot oil heating shall be provided. Hot oil shall be selected with an autoignition temperature of 50C above its maximum operating temperature. However, the reboiler inlet temperature for hot oil shall not exceed 390F.

Crude Oil Stabilization De-bottlenecking 8.1 8.2 A process study including process simulation shall be conducted to establish the equipment and/or piping limitation at new operating conditions. Column diameter and tray geometry shall be verified in order to avoid upset conditions (such as column flooding or weeping) under new operating conditions according to requirements of SAES-C-001. Tray design verification shall be confirmed by tray vendor. Reboiler and feed pre-heater design shall be verified under new operating conditions. In particular thermal exchange rate calculation shall be performed for each exchanger in order to verify if exchange surface area is fitting new operating conditions. A flare and relief system study shall be conducted in order to verify the impact on the flare system due to new operating conditions of Crude Stabilization Unit.

8.3

8.4

Page 9 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

8.5

A Management of Change (MOC) shall be completed for any design change of Crude Stabilization Unit.

20 February 2013

Revision Summary New Saudi Aramco Engineering Standard.

Page 10 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

Appendix-1: Crude Stabilization Unit Example (Sketch)

Page 11 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

Appendix-2: Termosiphon Hydraulic Calculation

Procedure Design Contractor shall perform detailed hydraulic calculations in order to estimate the Available Head for Thermosiphon Flow (AHTF) and the Required Head for Thermosiphon Flow (RHTF). Hydraulic calcutation shall be performed for each design and operating case as per Table-1 procedure (refer to Figure 1): Table-1

AHTF Calculation STEP-1 Consider the draw-off tray height in accordance to draw-off tray liquid level (if any) specified by tray vendor STEP-2 Consider the reboiler inlet piping height STEP-3 Calculate AHTF as sum of draw-off tray height (STEP-1) and reboiler inlet piping height (STEP-2) RHTF Calculation STEP-1 Assume as first trial that RHTF is equal to AHTF STEP-2 Calculate pressure drop in every section of reboiler inlet line (from the draw-off tray outlet nozzle to the reboiler inlet nozzle) at design flowrate according to STEP-1 assumption STEP-3 Calculate pressure drop across reboiler STEP-4 Calculate pressure drop in every section of return line (from reboiler outlet nozzle to the return line inlet nozzle) at design flowrate STEP-5 Calculate pressure drop in the entire loop as sum of STEP-2, STEP-3 and STEP-4 STEP-6 Calculate static head in the return line using mixed phase density STEP-7 Calculate the static head in the reboiler inlet line as sum of pressure drop in the entire loop (STEPVariable Unit

h0

ft

h1 AHTF = h0 + h1

ft ft

RHTF(1st trial) = h0 + h1

ft

p1

psi

pReb p2

psi

psi

pTot = p1 + pReb + p2 H2 = Mix h2 H1 = pTot + H2 (NOTE 1)

psi

psi

psi

Page 12 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

AHTF Calculation 5) and static head I in the return line (STEP-6) STEP-8 Calculate the updated RHTF dividing static head in the reboiler inlet line (STEP-7) by density of liquid flowing in the line STEP-9 Subtract first trial RHTF to updated RHTF to find step error STEP-10 If step error is less than 0.01 ft then updated RHTF is the final result and stop the calculation. Otherwise recalculate STEP-2 assuming that the liquid level in the reboiler inlet line is equal to updated RHTF and find new updated RHTF recalculating STEP-5, STEP-7, STEP-8 and STEP-9 with new p1 from STEP-2 (NOTE 2). Repeat this procedure until step error requirement is satisfied.

Variable

Unit

RHTF(2nd trial) = H1/Liq

ft

Err = RHTF(1st trial) - RHTF(2nd trial)

ft

Err < 0.01 ft

ft

NOTE 1: Gas Pressure drop through the draw-off tray has been considered negligible. NOTE 2: Only p1 changes because the level in the reboiler inlet line is different. All the other variables remain the same as first trial.

Page 13 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

Figure-1

Part A Drawoff tray liquid height (h0)

Equalizing line

Drawoff Tray Vapor Return line inlet nozzle

Part B piping outside the column

Two phase liquid + vapor (pressure drop p2)

Liquid

Reboiler inlet piping height (h1)

Stabilizer Column

Return line piping height (h2)

AHTF

RHTF

Reboiler (pressure drop pReb) One Phase Liquid (pressure drop p1)

AHTF - Available Head for Thermosiphon Flow RHTF- Required Head for Thermosiphon Flow For AHTF > RHTF, provide Equalizing Line

Page 14 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

If AHTF > RHTF then equalizing line shall be provided as shown in Figure-2. The connection on the thermosiphon loop shall be made at the top of the line above the vertical section as shown in Figure-2. This is to ensure that the equalizing line connection is not made in the liquid section of the thermosiphon loop. Figure-2

Equalizing line

Head required in tray

Liquid Flashes if no equalizing line

Vapor Return from reboiler Liquid

Head required in pipe for thermosiphon flow

To reboiler

Page 15 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

Design Example The following example will illustrate how to conduct on thermosiphon loop hydraulic verification. Refer to Figure-3. The design crude feed to the column is approximately 735,000 barrels per day (bpd) at standard conditions (60F). The oil from the bottom tray is collected in the trapout tray. There are two 36 inch outlet nozzles each diverts 50% of the flow to the reboilers (approximately 379,000 bpd at actual conditions including internal reflux) on each side of the column. In each loop, the crude flows to the shell side of two sets of horizontal thermosiphon reboilers and then returns, via a 48 inch header, to the column. In the return header to the column the flow is two phase. Refer to Figure-3 (The same is true of the other loop). The thermosiphon loop hydraulics is described in Table-2. Table-2 (NOTE 3)

AHTF Calculation STEP-1 Oil head in trap-out tray: STEP-2 Reboiler inlet piping height STEP-3 AHTF = sum of draw-off tray height (STEP-1) and reboiler inlet piping height (STEP-2) RHTF Calculation STEP-1 As first trial RHTF is equal to AHTF STEP-2a (Section S-A1 refer to Figure-3) First Trial: 36 in nominal size and approximately 86 ft long (based on Available Head 48.7 ft) Final Trial: 36 in nominal size and approximately 16.44 ft long (based on actual level in the pipe) STEP-2b (Section A1-B refer to Figure-3) 24 in identical header to one of the two reboilers and approximately 12 ft long (single phase) Variable h0 h1 Value

40.94 in

45.3 ft

AHTF = h0 + h1

48.7 ft

RHTF(1st trial) = h0 + h1

48.7 ft

p1a(1st trial) p1a(Final trial)

0.170 psi 0.142 psi

p1b

0.045 psi

Page 16 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

AHTF Calculation STEP-2c (Section B-E refer to Figure-3) 16 in identical header to each of the two nozzles on the reboiler section; approximately 5 ft long (single phase). STEP-2 (overall p reboiler inlet line) Sum of each section of reboiler inlet line (First trial) Sum of each section of reboiler inlet line (Final trial) STEP-3 Pressure drop across exchanger (section E to E1) STEP-4a (Section E1-E2 refer to Figure-3) 36 in identical header from each of the two nozzles on the reboiler; almost 5ft long (two phase). STEP-4b (Section E2-F refer to Figure-3) 36 in identical header from each of the reboilers; almost 9 ft long (two phase). STEP-4c (Section F-G2 refer to Figure-3) 48 in common section return to the column about 71 ft long STEP-4 (overall p returning line) Sum of each section of reboiler returning line STEP-5 (overall p entire loop) Sum of pressure drops calculated in STEP-2, STEP-3 and STEP-4 (First trial) Sum of pressure drops calculated in STEP-2, STEP-3 and STEP-4 STEP-6 Static head from reboiler outlet nozzle through the return line to the column (section E1 through G2)

Variable

Value

p1c

0.101 psi

p1(1st trial) = p1a + p1b + p1c p1(Final trial) = p1a + p1b + p1c pReb

0.316 psi 0.288 psi

2.0 psi

p2a

0.021 psi

p2b

0.052 psi

p2c

0.405 psi

p2 = p2a + p2b + p2c

0.478 psi

pTot(1st trial) = p1(1st trial) + pReb + p2 pTot(Final trial) = p1(Final trial) + pReb + p2

2.794 psi 2.767 psi

H2 = Mix h2

3.158 psi

Page 17 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

AHTF Calculation STEP-7 Static head in the reboiler inlet line (First trial) Static head in the reboiler inlet line (Final trial) STEP-8 Updated RHTF (2nd trial) Updated RHTF (Final trial) STEP-9 Step error (First trial) STEP-10 Step error (Final trial)

Variable H1(1st trial) = pTot(1st trial) + H2 (NOTE 1) H1(Final trial) = pTot(Final trial) + H2 (NOTE 1) RHTF(2nd trial) = H1(Final trial)/Liq RHTF(Final trial) = H1(Final trial)/Liq Err(1st trial) = RHTF(1st trial) - RHTF(2nd trial) Err(2nd trial) = RHTF(2nd trial) - RHTF(Final trial)

Value 5.953 psi 5.925 psi 16.52 ft 16.44 ft 32.18 ft 0.008 ft

NOTE 3: The intent of the hydraulic values in Table-2 is for illustrative purpose only.

Page 18 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

Figure-3

Page 19 of 20

Document Responsibility: Process Engineering Standards Committee Issue Date: 20 February 2013 Next Planned Update: 20 February 2018

SAES-A-011 Crude Oil Stabilization

Appendix-3: Reboiler Temperature Control (Sketch)

Page 20 of 20

You might also like

- Wall Thickness Calculation - by Engr. Adamu GabrielNo ratings yetWall Thickness Calculation - by Engr. Adamu Gabriel26 pages

- 6-HSE OSD 21 - The Safe Approach, Set-Up and Departure of Jack Up Rigs To Fixed InstallationsNo ratings yet6-HSE OSD 21 - The Safe Approach, Set-Up and Departure of Jack Up Rigs To Fixed Installations9 pages

- Map of Natural Gas Pipelines and Oil RefineriesNo ratings yetMap of Natural Gas Pipelines and Oil Refineries1 page

- Control of Black Powder in Gas and Condensate Pipelines: Materials Performance February 2019No ratings yetControl of Black Powder in Gas and Condensate Pipelines: Materials Performance February 20198 pages

- Pds Hempel's Silicone Aluminium 56910 En-GbNo ratings yetPds Hempel's Silicone Aluminium 56910 En-Gb2 pages

- Manage Gas Feedstock and NGL Quality at Treating PlantsNo ratings yetManage Gas Feedstock and NGL Quality at Treating Plants9 pages

- Prediction of Crude Oil Properties Artifitial Neural Networks PVT Correlations Koorosh Kazemi MSC ThesisNo ratings yetPrediction of Crude Oil Properties Artifitial Neural Networks PVT Correlations Koorosh Kazemi MSC Thesis94 pages

- SAES-L-850 Design of Submarine Pipelines and Risers 15 May 2019No ratings yetSAES-L-850 Design of Submarine Pipelines and Risers 15 May 20198 pages

- Theodorsen Theory For Deformable Airfoils Full Derivation100% (1)Theodorsen Theory For Deformable Airfoils Full Derivation15 pages

- A Study of Drag Reducing Agents in Multiphase Flow in Large Diameter Horizontal Pipelines100% (1)A Study of Drag Reducing Agents in Multiphase Flow in Large Diameter Horizontal Pipelines456 pages

- Shell Marine International Price List91No ratings yetShell Marine International Price List9132 pages

- Performance Record: 500 Samsung GEC, Sangil-Dong, Gangdong-Gu, Seoul, 134-090, Korea Tel. 82.2.2053.3000No ratings yetPerformance Record: 500 Samsung GEC, Sangil-Dong, Gangdong-Gu, Seoul, 134-090, Korea Tel. 82.2.2053.300021 pages

- Flow Assurance Challenges in Deepwater Brazil Pre SaltNo ratings yetFlow Assurance Challenges in Deepwater Brazil Pre Salt23 pages

- Solve Operator Training in A Challengin Refining Industry PDFNo ratings yetSolve Operator Training in A Challengin Refining Industry PDF3 pages

- Introduction To Ship-Shaped Offshore StructureNo ratings yetIntroduction To Ship-Shaped Offshore Structure13 pages

- Single Point Mooring SPM Systems With Buoys 2No ratings yetSingle Point Mooring SPM Systems With Buoys 28 pages

- Management of Exploration Development and Production Wastes 4-23-19No ratings yetManagement of Exploration Development and Production Wastes 4-23-19279 pages

- 20IPTC Call For Papers Brochure Extended DeadlineNo ratings yet20IPTC Call For Papers Brochure Extended Deadline8 pages

- LNG Processing and On Stream Analysis: Typical LNG Plant Flow (APCI C3/MCR)No ratings yetLNG Processing and On Stream Analysis: Typical LNG Plant Flow (APCI C3/MCR)5 pages

- SPE-192878-MS Maximizing Pipeline Flexibility With Drag Reducing AgentsNo ratings yetSPE-192878-MS Maximizing Pipeline Flexibility With Drag Reducing Agents9 pages

- Volume 8 Production Operations Section 2 Well and Reservoir ManagementNo ratings yetVolume 8 Production Operations Section 2 Well and Reservoir Management22 pages

- Commercial and Technical Considerations in The Developments of Offshore Liquefaction PlantNo ratings yetCommercial and Technical Considerations in The Developments of Offshore Liquefaction Plant12 pages

- MP-HSEQ-JD - Batch 2 Topside HSE Supervisor - OffshoreNo ratings yetMP-HSEQ-JD - Batch 2 Topside HSE Supervisor - Offshore3 pages

- The Role of An Offshore Metocean AdvisorNo ratings yetThe Role of An Offshore Metocean Advisor8 pages

- Floating Production Storage and Offloading Units and Topside Facilities100% (1)Floating Production Storage and Offloading Units and Topside Facilities19 pages

- Mont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaNo ratings yetMont Belvieu, Texas Ethane Storage Hub: Warnings For Appalachia7 pages

- GESP-FAC-EP-008-ConocoPhilips-Separator Sizing Guideline100% (1)GESP-FAC-EP-008-ConocoPhilips-Separator Sizing Guideline70 pages

- Allocation Metering: Daniel Micro Motion Coriolis MetersNo ratings yetAllocation Metering: Daniel Micro Motion Coriolis Meters8 pages

- Bitumen Blowing: For More Information On Refining See TheNo ratings yetBitumen Blowing: For More Information On Refining See The1 page

- FOR BID: Refining & NGL Projects Department North RT Refinery & Ju'Aymah NGL Projects DivisionNo ratings yetFOR BID: Refining & NGL Projects Department North RT Refinery & Ju'Aymah NGL Projects Division2 pages

- Flaresim Flaresim: Flare Radiation AnalysisNo ratings yetFlaresim Flaresim: Flare Radiation Analysis25 pages

- Die Baumeister Des Colosseum ENG Rules CompleteNo ratings yetDie Baumeister Des Colosseum ENG Rules Complete2 pages

- Series: MHZ MHF MHL MHR MHK MHS MHC MHT MHY MHW - X MRHQ MA DNo ratings yetSeries: MHZ MHF MHL MHR MHK MHS MHC MHT MHY MHW - X MRHQ MA D83 pages

- Syy1200 Crate Washer Apps-Smfi - 160822-GpaNo ratings yetSyy1200 Crate Washer Apps-Smfi - 160822-Gpa3 pages

- Using Biggs' Model of Constructive Alignment in Curriculum Design:Continued - UCD - CTAG100% (1)Using Biggs' Model of Constructive Alignment in Curriculum Design:Continued - UCD - CTAG3 pages

- Examining Interrelated Driving Forces For Sustainable School ImprovementNo ratings yetExamining Interrelated Driving Forces For Sustainable School Improvement16 pages

- HoloSketch: A Virtual Reality Sketching/animation ToolNo ratings yetHoloSketch: A Virtual Reality Sketching/animation Tool19 pages

- New Bible Bookshelf XLSX - Bible Bookshelf 2015 EditionNo ratings yetNew Bible Bookshelf XLSX - Bible Bookshelf 2015 Edition6 pages

- Statement of Purpose (Electronic Engineering) UWO0% (1)Statement of Purpose (Electronic Engineering) UWO4 pages

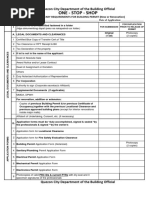

- Documentary Requirements For Building Permits OsscpNo ratings yetDocumentary Requirements For Building Permits Osscp2 pages

- Wall Thickness Calculation - by Engr. Adamu GabrielWall Thickness Calculation - by Engr. Adamu Gabriel

- 6-HSE OSD 21 - The Safe Approach, Set-Up and Departure of Jack Up Rigs To Fixed Installations6-HSE OSD 21 - The Safe Approach, Set-Up and Departure of Jack Up Rigs To Fixed Installations

- Control of Black Powder in Gas and Condensate Pipelines: Materials Performance February 2019Control of Black Powder in Gas and Condensate Pipelines: Materials Performance February 2019

- Manage Gas Feedstock and NGL Quality at Treating PlantsManage Gas Feedstock and NGL Quality at Treating Plants

- Prediction of Crude Oil Properties Artifitial Neural Networks PVT Correlations Koorosh Kazemi MSC ThesisPrediction of Crude Oil Properties Artifitial Neural Networks PVT Correlations Koorosh Kazemi MSC Thesis

- SAES-L-850 Design of Submarine Pipelines and Risers 15 May 2019SAES-L-850 Design of Submarine Pipelines and Risers 15 May 2019

- Theodorsen Theory For Deformable Airfoils Full DerivationTheodorsen Theory For Deformable Airfoils Full Derivation

- A Study of Drag Reducing Agents in Multiphase Flow in Large Diameter Horizontal PipelinesA Study of Drag Reducing Agents in Multiphase Flow in Large Diameter Horizontal Pipelines

- Performance Record: 500 Samsung GEC, Sangil-Dong, Gangdong-Gu, Seoul, 134-090, Korea Tel. 82.2.2053.3000Performance Record: 500 Samsung GEC, Sangil-Dong, Gangdong-Gu, Seoul, 134-090, Korea Tel. 82.2.2053.3000

- Flow Assurance Challenges in Deepwater Brazil Pre SaltFlow Assurance Challenges in Deepwater Brazil Pre Salt

- Solve Operator Training in A Challengin Refining Industry PDFSolve Operator Training in A Challengin Refining Industry PDF

- Management of Exploration Development and Production Wastes 4-23-19Management of Exploration Development and Production Wastes 4-23-19

- LNG Processing and On Stream Analysis: Typical LNG Plant Flow (APCI C3/MCR)LNG Processing and On Stream Analysis: Typical LNG Plant Flow (APCI C3/MCR)

- SPE-192878-MS Maximizing Pipeline Flexibility With Drag Reducing AgentsSPE-192878-MS Maximizing Pipeline Flexibility With Drag Reducing Agents

- Volume 8 Production Operations Section 2 Well and Reservoir ManagementVolume 8 Production Operations Section 2 Well and Reservoir Management

- Commercial and Technical Considerations in The Developments of Offshore Liquefaction PlantCommercial and Technical Considerations in The Developments of Offshore Liquefaction Plant

- MP-HSEQ-JD - Batch 2 Topside HSE Supervisor - OffshoreMP-HSEQ-JD - Batch 2 Topside HSE Supervisor - Offshore

- Floating Production Storage and Offloading Units and Topside FacilitiesFloating Production Storage and Offloading Units and Topside Facilities

- Mont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaMont Belvieu, Texas Ethane Storage Hub: Warnings For Appalachia

- GESP-FAC-EP-008-ConocoPhilips-Separator Sizing GuidelineGESP-FAC-EP-008-ConocoPhilips-Separator Sizing Guideline

- Allocation Metering: Daniel Micro Motion Coriolis MetersAllocation Metering: Daniel Micro Motion Coriolis Meters

- Bitumen Blowing: For More Information On Refining See TheBitumen Blowing: For More Information On Refining See The

- FOR BID: Refining & NGL Projects Department North RT Refinery & Ju'Aymah NGL Projects DivisionFOR BID: Refining & NGL Projects Department North RT Refinery & Ju'Aymah NGL Projects Division

- Series: MHZ MHF MHL MHR MHK MHS MHC MHT MHY MHW - X MRHQ MA DSeries: MHZ MHF MHL MHR MHK MHS MHC MHT MHY MHW - X MRHQ MA D

- Using Biggs' Model of Constructive Alignment in Curriculum Design:Continued - UCD - CTAGUsing Biggs' Model of Constructive Alignment in Curriculum Design:Continued - UCD - CTAG

- Examining Interrelated Driving Forces For Sustainable School ImprovementExamining Interrelated Driving Forces For Sustainable School Improvement

- HoloSketch: A Virtual Reality Sketching/animation ToolHoloSketch: A Virtual Reality Sketching/animation Tool

- New Bible Bookshelf XLSX - Bible Bookshelf 2015 EditionNew Bible Bookshelf XLSX - Bible Bookshelf 2015 Edition

- Documentary Requirements For Building Permits OsscpDocumentary Requirements For Building Permits Osscp