100%(1)100% found this document useful (1 vote)

Cooling Tower

Cooling Tower

Uploaded by

Keshav Rao1) The document describes a computational fluid dynamics (CFD) simulation of a natural draft wet cooling tower to analyze how varying the air inlet height affects performance parameters like outlet temperature and relative humidity.

2) A 2D CFD model was created and simulations were run for air inlet heights of 5.9, 6.1, and 6.3 meters in a 117 meter tall cooling tower.

3) The results showed that an air inlet height of 6.3 meters produced the highest outlet temperature and lowest relative humidity, indicating it was the optimized model that could reduce evaporation losses the most.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

Cooling Tower

Cooling Tower

Uploaded by

Keshav Rao100%(1)100% found this document useful (1 vote)

1) The document describes a computational fluid dynamics (CFD) simulation of a natural draft wet cooling tower to analyze how varying the air inlet height affects performance parameters like outlet temperature and relative humidity.

2) A 2D CFD model was created and simulations were run for air inlet heights of 5.9, 6.1, and 6.3 meters in a 117 meter tall cooling tower.

3) The results showed that an air inlet height of 6.3 meters produced the highest outlet temperature and lowest relative humidity, indicating it was the optimized model that could reduce evaporation losses the most.

Original Description:

CFD analysis of cooling tower

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

1) The document describes a computational fluid dynamics (CFD) simulation of a natural draft wet cooling tower to analyze how varying the air inlet height affects performance parameters like outlet temperature and relative humidity.

2) A 2D CFD model was created and simulations were run for air inlet heights of 5.9, 6.1, and 6.3 meters in a 117 meter tall cooling tower.

3) The results showed that an air inlet height of 6.3 meters produced the highest outlet temperature and lowest relative humidity, indicating it was the optimized model that could reduce evaporation losses the most.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

Cooling Tower

Cooling Tower

Uploaded by

Keshav Rao1) The document describes a computational fluid dynamics (CFD) simulation of a natural draft wet cooling tower to analyze how varying the air inlet height affects performance parameters like outlet temperature and relative humidity.

2) A 2D CFD model was created and simulations were run for air inlet heights of 5.9, 6.1, and 6.3 meters in a 117 meter tall cooling tower.

3) The results showed that an air inlet height of 6.3 meters produced the highest outlet temperature and lowest relative humidity, indicating it was the optimized model that could reduce evaporation losses the most.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1/ 10

Simulation of Natural Draft Wet Cooling Tower with Variation of Air

Inlet Height through Computational Fluid Dynamics

Abstract: Current paper deals with how reduce the evaporation losses in natural draft wet cooling

tower by using 2D CFD model analysis. A software model of CFD k- is used by this model we are

analyzed how the large scale difference occurs in 2D CFD model of NDWCT. By varying the inlet

height of tower. This study is based on the 117 m total tower height with varying inlet height of 5.9,

6.1, and 6.3 meters. By these models we have check the outlet let temperature and relative humidity

and in which model outlet temperature is high and relative humidity is low that model is called

optimized model.

Keywords: Natural draft wet cooling tower, computational fluid dynamics, k- Model

Arvind Kumar Patel

Research Scholar In Mechanical Engineering Department,

Maulana Azad National Institute Of Technology

Bhopal, India

Dr. Alok Singh

Assistance Professor In Mechanical Engineering Department,

Maulana Azad National Institute Of Technology

Bhopal, India

I SSN 2319-9725

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 407

1. Introduction:

A cooling tower is a heat rejection device, which extracts waste heat to the atmosphere

through the cooling of water stream to a lower temperature. The type of heat rejection in a

cooling tower is termed "evaporative" in that it allows a small portion of water being cooled

to evaporative into a moving air stream to provide significant cooling to the rest of that water

stream. Evaporative heat rejection devices such as cooling towers are commonly used to

provide significantly lower water temperature than achievable with "air cooled" or "dry" heat

rejection devices. the design of current model is prepared with the help of fluent code" Ansys

13".by this model we are checking different operational parameter of natural draft wet

cooling tower .current design procedure is based on the two dimensional model of heat and

mass transfer, the equation used in this model is ordinary differential equation and basic

navior-stoke equation is used. Air flow is solved as continuous phase using Eulerian approach

whereas droplet trajectories are solved as dispersed phase using the Lagrangian approach.

The influence of crosswind condition to the thermal performance of natural draft wet cooling

tower was also investigated in this work.

2. Natural Draft Wet Cooling Tower:

Natural draft wet cooling tower (NDWCT) are based on the Merkel's theory of heat and mass

transfer. According to Markels theory heat an mass transfer between fluids and air depends

upon the enthalpy gradient between the state of saturation of air in the boundary layer on the

surface of the hot water and the state of air in the colder core stream.

There are three different heat and mass transfer zone:

1) spray zone 2) fill zone 3) rain zone

the water is brought into the tower form the condenser through a pump and injected into the

cooling tower approximately 8-10 m above the basin. this water is injected through nozzle.

the function of spray zone is splash the water into smaller droplets before collides with the

fin. there is a range of fill type Generally they tend to be either a splash bar fill type or film

fill type. The splash bar type acts to break up water flow into smaller droplets with splash

bars or other means. When water strikes with the fin there is a very high humidity inside the

cooling tower.

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 408

1 Overall height of cooling tower 117 m

2 Air inlet height of cooling tower 6.1 m

3 Water inlet height 8.5 m

4 Depth of cooling tower basin 2.25m

5 Diameter of cooling tower basin 81.994 m

6 Diameter of cooling tower at fill material 77.744 m

7 Diameter of cooling tower outlet 46.744 m

8 Diameter of cooling tower at throat 48.648 m

Table 1: Physical Parametre Of Cooling Tower Model

3. Steps Used In Preparing Geometry Of Cooling Tower:

In the first step geometry is created in 2D using reference data of different part of cooling

tower. The structure of whole model imagined in advance, because the possibilities in the

subsequent steps depended on the composition of different geometrical shapes.

The various assumptions were made during preparing the model.

1. 2-D symmetric model is developed; fix the fill corresponding to the real arrangement.

2. Inlet and outlet space is created in bottom and top of the tower.

3. Cooling tower shall is considered as a wall with zero thickness and its profile is

formed by curve with three point including throat.

4. Assuming symmetrical thermal and flow field in the model, only one half of the

cooling tower is modeled with a symmetry boundary condition.

Figure 1: Geometry of cooling tower model

4. Meshing Of The Model:

Appropriate resolution of the flow field inside the computational fluid dynamics After

geometry mesh is generated. During mesh generation so much care is to be taken because the

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 409

end results very much depend on quality of mesh. In order to have an domain is define into a

large number of finite volume cells.

Various steps are used in generating mesh:

1. Different part is meshed with different element sizing.

2. Fill zone must be fine meshed.

3. By used mapped face mesh the model with appropriate element sizing

4. The inner and outer surface of the wall inside the model has identical shapes but is

disconnected so the mesh size on the two walls can be differ

Thermal parameters used in fluent analysis:-

Figure 2

4.1.Cell Zone Condition:

In cell zone surface body is considered as fluid. The operating pressure is atmospheric in

upstream from the centre line of cooling tower. The gravitational acceleration is 9.81 m/s2.

Operating temperature is 298 K and operating density is 1.22 kg/m3.

4.2.Boundary Condition:

Velocity inlet boundary condition is used to define the inlet velocity and other property of air

takes normal to the boundary inlet. Turbulence is taken as intensity and length scale. Pressure

outlet of air is defined at outlet of air.

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 410

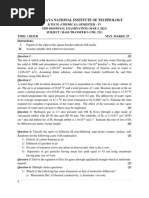

Table 2: About The Fluent Model: Model Used In Anylysis

4.3.Standard k- Model :

The Standard k- (Launder and Spalding, 1974) model is the most widely used complete

RANS model and it is incorporated in most commercial CFD codes. In this model, the model

transport equations are solved for two turbulence quantities i.e, k and . The Standard k-

model turbulence model solves the flow based on the assumption that the rate of production

and dissipation of turbulent flows are in near-balance in energy transfer We use k and to

define velocity scale and length scale L representative of the large scale turbulence as

follow

5. Results And Conclusion:

Figure 3

1 Hot water temperature 316 K

2 Cold water temperature 305 K

3 Dry bulb temperature of ambient air 308.96 K

4 Wet bulb temperature of ambient air 300 K

5 Relative humidity of ambient air 49.98 %

6 Cooling range 11 K

7 Approach 5 K

8 Water flow rate 6950 lit/sec

9 Water flow rate through per nozzle 232 lit/sec

10 Number of nozzle 2898

11 Makeup water 139 lit/sec

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 411

Figure 4

Figure 5

Figure 6

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 412

Figure 7

Figure 8

6. Conclusion:

S.No. Property 5.7 m Air

inlet height

5.7 m Air

inlet height

5.9 m Air

inlet height

6.1 m Air

inlet height

1 Temperature 310.159 310.194 310.165 310.813

2 Dynamic pressure 0.2238 0.2780 0.2358 0.2973

3 Velocity 0.4884 0.5280 0.5355 0.5427

4 Relative humidity 0.9376 0.9801 0.9726 0.9259

5 Specfic heat 1044.521 1045.048 1044.31 1040.940

6 Enthalpy 12571.762 12609.604 12534.35 11425.054

7 Entropy 76.8364 76.9580 76.7175 73.0320

8 Mass fraction of water 0.03922 0.03983 0.03983 0.03495

Table 3

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 413

A two dimensional CFD model of natural draft wet cooling tower has been developed and

validated along with actual data of NTPC dadri power plant and it is found that the result was

very near and accurate to the actual data. By modeling and simulation of various air inlet

heights it was found that the result with 6.3 m air inlet height is optimum and best.

Simulation results with 6.3 m air inlet height reduce significantly the amount of makeup

water and increase the effectiveness of cooling tower. Amount of makeup water saved with

6.3 m air inlet height is 7.15*10

7

liters in a year. The effectiveness of cooling tower with

actual air inlet height is 68.75% and the effectiveness of cooling tower with optimum air inlet

height is 73.29%. Means with the optimum air inlet height the effectiveness of cooling tower

is increased by 6.194%. Also the power which is required to mix the makeup water with the

cooled water is saved. So the efficiency of power plant is also increased by significantly.

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 414

Refrences:

1. D.G. Kroger, Air-cooled Heat Exchangers and Cooling Towers, Pennwalt Corp., Tulsa,

USA, 2004.

2. ASHRAE, Cooling towers, in: ASHRAE Systems and Equipment Handbook, 2000, pp.

36.136.19.

3. H. Jaber, R.L. Webb, Design of cooling towers by the eectiveness-NTU method, J. Heat

Transfer 111 (1989) 837843.

4. J.C. Kloppers, A critical evaluation and refinement of the perfor-mance of wet-cooling

towers, PhD Thesis, University of Stellenbosch, Stellenbosch, South Africa, 2003.

5. J.C. Kloppers, D.G. Kroger, A critical investigation into the heat and mass transfer

analysis of counterflow wet-cooling towers, Int. J. Heat Mass Transfer 48 (34) (2005)

765777.

6. R.L. Webb, A critical evaluation of cooling tower design methodol-ogy, in: R.K. Shah,

E.C. Subbarao, R.A. Mashelkar (Eds.), Heat Transfer Equipment Design, Hemisphere,

New York, 1988, pp. 547 558.

7. D.R. Baker, H.A. Shryock, A comprehensive approach to the analysis of cooling tower

performance, J. Heat Transfer 83 (1961) 339350.

8. A.E. Feltzin, D. Benton, A more nearly exact representation of cooling tower theory,

Cool. Tower Inst. J. 12 (2) (1991) 825.

9. J. Khan, S. Zubair, An improved design and rating analysis of counter flow wet cooling

towers, J. Heat Transfer 123 (2001) 770778.

10. H.T.A. El-Dessouky, A. Al-Haddad, F. Al-Juwayhel, A modified analysis of counter flow

wet cooling towers, J. Heat Transfer 119 (1997) 617626.

11. F. Osterle, On the analysis of counter-flow cooling towers, Int. J. Heat Mass Transfer 34

(4/5) (1991) 13131316.

12. A.F. Mills, Heat and Mass Transfer, Richard D. Irwin Inc., Boston, 1995.

13. J.C. Kloppers, D.G. Kroger, The lewis factor and its influence on the performance

prediction of wet-cooling towers, Int. J. Therm. Sci. 44 (9) (2005) 879884.

14. M. Poppe, H. Rogener, Berechnung von Ruckkuhlwerken, VDI-Warmeatlas (1991) Mi 1

Mi 15.

15. H.J. Lowe, D.G. Christie, Heat transfer and pressure drop data on cooling tower packings

and model studies of the resistance of natural draught towers to airflow, in: Proceedings of

the International Heat Transfer Conference, Colorado, 1961, pp. 933950

July, 2013 www.ijirs.com Vol 2 Issue 5

International Journal of Innovative Research and Studies Page 415

16. N. Williamson, S. Armfield, M. Behnia, Numerical simulation of flow in a natural draft

wet cooling tower the eect of radial thermofluid fields, Appl. Therm. Eng. 28 (23)

(2008) 178189.

17. B. Sirok, B. Blagojevic, M. Novak, M. Hochevar, F. Jere, Energy and mass transfer

phenomena in natural draft cooling towers, Heat Transfer Eng. 24 (3) (2003) 6675.

18. J. Smrekar, J. Oman, B. Sirok, Improving the eciency of natural draft cooling towers,

Energy Convers. Manage. 47 (2006) 10861100.

19. J.C. Kloppers, D.G. Kroger, Loss coecient correlation for wet-cooling tower fills, Appl.

Therm. Eng. 23 (17) (2003) 22012211.

You might also like

- A Review To Optimize The Heat Transfer Rate and Increase The Efficiency of The Cooling TowerNo ratings yetA Review To Optimize The Heat Transfer Rate and Increase The Efficiency of The Cooling Tower6 pages

- Experimental Analysis of Flash Tank Refrigeration SystemNo ratings yetExperimental Analysis of Flash Tank Refrigeration System30 pages

- Cooling Technology Institute: Design and Operation of A Counterflow Fill and Nozzle Test Cell: Challenges and Solutions100% (1)Cooling Technology Institute: Design and Operation of A Counterflow Fill and Nozzle Test Cell: Challenges and Solutions12 pages

- Gauges, Sight Glasses and Vacuum Breakers: Block 12 Pipeline AncillariesNo ratings yetGauges, Sight Glasses and Vacuum Breakers: Block 12 Pipeline Ancillaries8 pages

- Optimization of The Cooling Tower Condenser Water Leaving Temperature Using A Component-Based Model100% (1)Optimization of The Cooling Tower Condenser Water Leaving Temperature Using A Component-Based Model11 pages

- ML7420A6033, ML7425A6016 (Specification Date)No ratings yetML7420A6033, ML7425A6016 (Specification Date)4 pages

- Pressurised Deaerator Solutions-Sales Brochure100% (1)Pressurised Deaerator Solutions-Sales Brochure4 pages

- 16tj - Lj-Training - Book-2 CARRIER ABSORB100% (1)16tj - Lj-Training - Book-2 CARRIER ABSORB178 pages

- Cleanliness Factor EtaPRO Calculation TemplatesNo ratings yetCleanliness Factor EtaPRO Calculation Templates4 pages

- UNC Steam System Design Requirements (Uncssdr) October 2003No ratings yetUNC Steam System Design Requirements (Uncssdr) October 200329 pages

- Best Practice No. 68 High Steam Quality Is Essential For The Steam System100% (1)Best Practice No. 68 High Steam Quality Is Essential For The Steam System6 pages

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamNo ratings yetBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated Steam17 pages

- Install An Automatic Blowdown Control System: BackgroundNo ratings yetInstall An Automatic Blowdown Control System: Background5 pages

- Always Attach Calculation Excel Worksheet Investment ROI, IRRNo ratings yetAlways Attach Calculation Excel Worksheet Investment ROI, IRR4 pages

- P&ID Process Cooling Symbols and Their Usage PDFNo ratings yetP&ID Process Cooling Symbols and Their Usage PDF4 pages

- The Impact of Air Cooled Condensers On Plant Design and OperationsNo ratings yetThe Impact of Air Cooled Condensers On Plant Design and Operations12 pages

- Emergency Relief System Design Using DIERS Technology: The Design Institute for Emergency Relief Systems (DIERS) Project ManualFrom EverandEmergency Relief System Design Using DIERS Technology: The Design Institute for Emergency Relief Systems (DIERS) Project Manual4/5 (1)

- Analysis of Forced Draft Cooling Tower Performance Using Ansys Fluent Software PDF100% (1)Analysis of Forced Draft Cooling Tower Performance Using Ansys Fluent Software PDF13 pages

- Applied Failure Analysis Hydraulic Pumps & MotorsNo ratings yetApplied Failure Analysis Hydraulic Pumps & Motors146 pages

- Introduction To Chemical Reaction Engineering and Kinetics TQW - DarksidergNo ratings yetIntroduction To Chemical Reaction Engineering and Kinetics TQW - Darksiderg3 pages

- 2022 T310 - CHEMICAL PLANT OPERATION N4 NOV QPNo ratings yet2022 T310 - CHEMICAL PLANT OPERATION N4 NOV QP6 pages

- Enhanced Gas Recovery by CO2 Injection and Sequestration Effect ofNo ratings yetEnhanced Gas Recovery by CO2 Injection and Sequestration Effect of12 pages

- Draft Policy Recommendation On Domestic Was Tewater Management and Potential Project Prop Osal in Brunei DarussalamNo ratings yetDraft Policy Recommendation On Domestic Was Tewater Management and Potential Project Prop Osal in Brunei Darussalam13 pages

- Week 6 & 7: Propellers and Wind Turbines: Actuator Disk TheoryNo ratings yetWeek 6 & 7: Propellers and Wind Turbines: Actuator Disk Theory2 pages

- Airflow Management in Automotive Engine Cooling SystemNo ratings yetAirflow Management in Automotive Engine Cooling System8 pages

- Visvesvaraya National Institute of TechnologyNo ratings yetVisvesvaraya National Institute of Technology2 pages

- Tuberia de Acero Al Carbono API 5L / ASTM A53 / A106100% (1)Tuberia de Acero Al Carbono API 5L / ASTM A53 / A1066 pages

- Solution Manual To Chemical Reactor Anal PDFNo ratings yetSolution Manual To Chemical Reactor Anal PDF262 pages

- Sewer Shapes (Report) (CE 503) - Group (Fs Fy)No ratings yetSewer Shapes (Report) (CE 503) - Group (Fs Fy)24 pages

- A Review To Optimize The Heat Transfer Rate and Increase The Efficiency of The Cooling TowerA Review To Optimize The Heat Transfer Rate and Increase The Efficiency of The Cooling Tower

- Experimental Analysis of Flash Tank Refrigeration SystemExperimental Analysis of Flash Tank Refrigeration System

- Cooling Technology Institute: Design and Operation of A Counterflow Fill and Nozzle Test Cell: Challenges and SolutionsCooling Technology Institute: Design and Operation of A Counterflow Fill and Nozzle Test Cell: Challenges and Solutions

- Gauges, Sight Glasses and Vacuum Breakers: Block 12 Pipeline AncillariesGauges, Sight Glasses and Vacuum Breakers: Block 12 Pipeline Ancillaries

- Optimization of The Cooling Tower Condenser Water Leaving Temperature Using A Component-Based ModelOptimization of The Cooling Tower Condenser Water Leaving Temperature Using A Component-Based Model

- UNC Steam System Design Requirements (Uncssdr) October 2003UNC Steam System Design Requirements (Uncssdr) October 2003

- Best Practice No. 68 High Steam Quality Is Essential For The Steam SystemBest Practice No. 68 High Steam Quality Is Essential For The Steam System

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated Steam

- Install An Automatic Blowdown Control System: BackgroundInstall An Automatic Blowdown Control System: Background

- Always Attach Calculation Excel Worksheet Investment ROI, IRRAlways Attach Calculation Excel Worksheet Investment ROI, IRR

- The Impact of Air Cooled Condensers On Plant Design and OperationsThe Impact of Air Cooled Condensers On Plant Design and Operations

- Emergency Relief System Design Using DIERS Technology: The Design Institute for Emergency Relief Systems (DIERS) Project ManualFrom EverandEmergency Relief System Design Using DIERS Technology: The Design Institute for Emergency Relief Systems (DIERS) Project Manual

- Analysis of Forced Draft Cooling Tower Performance Using Ansys Fluent Software PDFAnalysis of Forced Draft Cooling Tower Performance Using Ansys Fluent Software PDF

- Introduction To Chemical Reaction Engineering and Kinetics TQW - DarksidergIntroduction To Chemical Reaction Engineering and Kinetics TQW - Darksiderg

- Enhanced Gas Recovery by CO2 Injection and Sequestration Effect ofEnhanced Gas Recovery by CO2 Injection and Sequestration Effect of

- Draft Policy Recommendation On Domestic Was Tewater Management and Potential Project Prop Osal in Brunei DarussalamDraft Policy Recommendation On Domestic Was Tewater Management and Potential Project Prop Osal in Brunei Darussalam

- Week 6 & 7: Propellers and Wind Turbines: Actuator Disk TheoryWeek 6 & 7: Propellers and Wind Turbines: Actuator Disk Theory

- Airflow Management in Automotive Engine Cooling SystemAirflow Management in Automotive Engine Cooling System

- Tuberia de Acero Al Carbono API 5L / ASTM A53 / A106Tuberia de Acero Al Carbono API 5L / ASTM A53 / A106