Wheel Load Analysis

Wheel Load Analysis

Uploaded by

tsoheilCopyright:

Available Formats

Wheel Load Analysis

Wheel Load Analysis

Uploaded by

tsoheilOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Wheel Load Analysis

Wheel Load Analysis

Uploaded by

tsoheilCopyright:

Available Formats

Wheel Load Analysis

SCOPE: The Wheel Load Analysis Program was designed to calculate the overburden and vehicle loads on buried pipe with a Single Layer System (soil only) or a Double Layer Systems (timbers, pavement and soil). The information used to design this program was taken from the Battelle Petroleum Technology Report on "Evaluation of Buried Pipe Encroachments" which considered the theoretical work done by M.G. Spangler on overburden and vehicle loads on buried pipe.

REQUIRED INFORMATION:

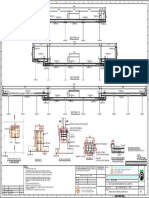

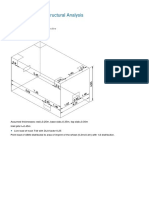

Figure1 : Approximation of Overburden Loading on Buried Pipe

1. Values for all of the following variables: H - cover, vertical depth from the ground to the top of the pipe (ft.) B - trench width (ft.) Ds - weight per unit volume of backfill (lbs./ft.) D - outside diameter of the pipe (in.) Lw - concentrated surface load (lbs.) (Wheel Load) (see Section 4, Page 11) H1 - thickness of the pavement layer (in.) (see Figure 2) SMYS - specified minimum yield stress of the pipe (psi.) P - pipe internal pressure (psi.) T - pipe wall thickness (in.) 2. The Design Class of the pipeline being analyzed (1-3) which is used to find the Maximum Allowable Combined Stress (% SMYS), see Table I.

3. The Soil Type which is used to find the friction force coefficients (Km), see Table II. 4. The Pavement Type which is used to find the impact factor (I), see Table III,

and the elastic constants for layered media analysis (E1, E2, G1, & G2), see Table IV & Figure 2.

H H2

H1

Figure2 : Pavement Soil System for Pipe Load Analysis

5.

The Crossing Construction Type which is used to find the bedding constants for buried pipe (Kb & Kz), see Table V & Figure 3.

Wc

Figure3 : Distribution of Load and Reaction on Pipeline

REQUIRED INFORMATION IF LONGITUDINAL BENDING STRESS OCCURS: 6. All the above information along with values for the following variables: X - longitudinal distance over which deflection occurs (ft.) Y - vertical deflection (in.) Table I

Maximum Allowable Combined Stress Maximum Design Class Operating Class Allowable Internal Stress (%) 1 1 2 2 3 3 1 2 2 3 3 4 72 72 62 62 50 50 Maximum Allowable Combined Stress (%) 80 80 72 72 62 62

Figure 1 shows a cross sectional view of a pipe buried in a trench. As a first estimate of the soil load on the pipe it could be assumed that the backfill soil slides down the trench walls without friction. Additionally assume that all soil above the pipe is supported by the pipe itself and that the backfill soil on either side of the pipe does not assist in this support. These assumptions are very conservative but they help a great deal in initial understanding of the method of solution. The assumptions yield a soil load on the pipe equal to the weight of the backfill soil above the pipe. This analysis provides an estimate of soil loads on the buried pipe if nothing else is known about the system. The basic analysis developed by M.G. Spangler follows similar arguments to that given above. In this analysis, Spangler includes frictional forces between the trench wall and the backfill. This permits the weight of the overburden to be partially carried by the surrounding soil and reduces the total soil load on the pipe. The resulting equations for calculating the pipe load due to overburden are as follows:

Cd = 1 - e(-2 K (H / B)) 2 K

Cd - trench coefficient. B - trench width (ft.). H - cover, vertical depth from the ground to the top of the pipe (ft.). Km - coefficient of friction force between the backfill soil and the trench wall. Cd determines how much load is carried by the pipe. If there is no soil friction Cd becomes equal to H/B and the entire backfill load must be supported by the pipeline.

The term Km provides a coefficient of friction force between the backfill soil and the trench wall. A high value of Km implies that friction between the backfill and trench wall is high and the weight of the backfill is supported largely by the wall friction. A low value implies that there is little friction encountered and the backfill is allowed to settle more such that the weight must be supported by the pipe. Table II provides values of Km used in the program for five different soil types. Also in Table II are examples of values for Ds, the density which is the weight per unit of backfill, which may be used if an actual value is not known. Note: If a value for Ds is already given use that value instead of the one in Table II. Table II Friction Force Coefficients For Various Soils Soil Type Km Ds (lbs/ft) (1) Granular Materials without Cohesion (2) Sand and Gravel (3) Saturated Top Soil (4) Clay (5) Saturated Clay 0.1924 0.165 0.150 0.130 0.110 90-100 110-120 110-120 110-120 120-130

The soil types and coefficients given in this table represent the range that could normally be expected. Saturated clay has little internal friction so that it has the smallest value for Km. This implies that almost all of the soil load is carried by the pipe. Granular materials have a great deal more internal friction. Their value of Km is higher which leads us to the conclusion that the pipe carries less of the backfill load. Spangler, in his work, recommends using the value for clay in most instances. Higher values may be used when there is adequate evidence that the internal friction is higher and warrants a higher value of Km. Spangler's recommendation provides a conservative estimate for common buried pipe situations. Marsh and bog areas, however, have friction properties more similar to saturated clay such that a value for Km equal to 0.110 should be used in these areas.

Wc = 1 - e(-2 K (H / B)) Ds B2 * 0.0833 2 K

Wc - load per unit length of the pipe due to overburden (lbs./in.). B - trench width (ft.). Ds - density which is the weight per unit of backfill (lbs./ft.). H - cover, vertical depth from the ground to the top of the pipe (ft.). Km - coefficient of friction force between the backfill soil and the trench wall.

A Pavement Type must be determined in order to select an Impact Factor (I) to be used in the Wv equation. Table III provides Impact Factor values for the three different pavement types used in this program. A Pavement Type is also used to select the elastic constants for layered media analysis. The variables E1 & G1 will be used to represent the elastic constants for the top layer and E2 & G2 will be used to represent the elastic constants for the soil. See Figure 2 for a visual explanation of the elastic constants for the top layer and the soil. These values will also be used in the Wv equation. Table IV provides the values for the three different pavement materials used in this program. Table III Impact Factor Pavement Type Factor (I) No Pavement Asphalt Timber Mats (2" x 12" minimum) Concrete 1.5 1.3 1.2 1.0

Wv =

0.0104 Lw D I (E1 G1) (E2 G2) ( H 2)

H - 0.5 H2 * 12

0.7

Wv - average load per unit length of pipe for vehicular load (lbs./in.). D - outside diameter of the pipe (in.). E1 - modulus of elasticity of the top (timber or pavement) layer (lbs./in.). E2 - modulus of elasticity of the soil cover (lbs./in.). G1 - Poisson's ratio of the top (timber or pavement) layer. G2 - Poison's ratio of the soil cove H - thickness of the pavement layer plus the depth of the soil from the pavement interface to thetop of the pipe (ft.). (See Figure 2) H1 - thickness of the pavement layer ("0" is used when there is no pavement) (in.). H2 - depth of the soil from the pavement interface to the top of the pipe (ft.). I - impact factor. Lw - concentrated surface load (a value of 16,000 lbs. is recommended when the maximum is unknown), wheel load in lbs.. Examination of equation Wv shows that this equation also may be used with a Single Layer System because the Pavement Material on the Top Layer chosen is "Soil", which makes E1 equal to E2, G1 equal to G2, and H1 equal to zero which cancels out the second and third part of the equation. Thus when there is no pavement layer the revised equation will provide a solution for soil cover only. Table IV provides the

values for E1, E2, G1 & G2 that will be used in the program. Table IV Elastic Constants for Layered Media Analysis Pavement Material E (psi.) G

(1) No Pavement (Soil Only) (2) Asphalt (3) Timber Mats (2" x 12" (4) Concrete

1.5 x 104 1.0 x 105 1.2 x 106 2.0 x 10 6

0.35 0.40 0.25 0.15

Sc = (Wc + Wv)

3 Kb E D T E T3 + 3 Kz P D3

Sc D E Kb Kz types. P T Wc Wv

- circumferential stress due to pipe wall deflection (PSI). - outside diameter of the pipe (in.). - pipe material modulus of elasticity (2.9 x 107). - bending coefficient which is a function of the crossing construction types. - deflection coefficient which is a function of the crossing construction - pipe internal pressure (PSI). - pipe wall thickness (in.). - load per unit length of pipe due to overburden (lbs./in.). - average load per unit length of pipe for vehicular load (lbs./in.).

Note that the equation Sc includes pressure in the denominator so that bending stresses are reduced by increasing pressure. Equation Sc, as well as equation St, have two constants which depend upon the bedding material upon which the pipe is placed. This bedding material is based on the crossing construction type. When the pipe is placed on a rigid bedding such as an Open Cut-Rock, little soil deformation occurs so that the load application area on the bottom is very small. However if the pipe is placed on soil, the support conforms to the pipe somewhat and the load is distributed over a larger area (See Figure 3). The latter case produces less pipe stress and is preferable. Spangler's formulation includes both of these possibilities in order to provide a conservative estimate for the rigid bedding case without penalizing the soil bedding case. It does so by varying the constants Kb and Kz. Spangler's recommended values for the constants are provided in Table V.

Table V

Bedding Constants for Buried Pipe Width of Uniform Soil Reaction (Degrees) _ Crossing Construction Type Kz Kb

0 30 90

(1) Open Cut-Rock (2) Open Cut (3) Bored

0.110 0.108 0.096

0.294 0.235 0.157

Sh =

PD 2T

Sh D P T

- hoop stress due to internal pressure (PSI). - outside diameter of the pipe (in.). - pipe internal pressure (PSI). - pipe wall thickness (in.).

St = PD 3 Kb E D T + (Wc + Wv) 2T E T3 + 3Kz P D3

St is the total circumferential stress in the pipe wall due to pressure (hoop) stress and bending stresses resulting from circumferential flexure caused by external loads measured in PSI. The first term on the right hand side of the equation is the formula for hoop stress due to internal pressure (Sh) and the second term is the formula for circumferential stress due to pipe wall deflection (Sc). Longitudinal Bending Stress (Sb) is when the overburden and vehicle loads on buried pipelines will cause pipe settlement into the soil in the bottom of the trench. This settlement occurs because soil is not as stiff as the pipe and will deform easily as the pipe is "pushed" downward. Under uniform soil conditions and overburden loading, the pipe will settle evenly into the trench bottom along its entire length. Soil is not generally uniform, however, and regions of "softer" soil will occur adjacent to regions of stiff soil, so that the pipe will settle unevenly and hence bending will occur. A load that is applied on only one portion of a pipeline will cause the section of pipe under the load to settle more than the unloaded pipe, such that bending will also result. Longitudinal bending stress occurs in tension on the outside of the bend and in compression on the inside of the bend. Tensile stress is represented with a positive value for Sb; conversely, compressive stress takes a negative value for Sb. The longitudinal bending stress is calculated as follows:

Sb =

EDY 48 X 2

Sb D E X Y

- longitudinal bending stress (PSI). - outside diameter of the pipe (in.). - pipe material modulus of elasticity (2.9 x 107). - longitudinal distance over which deflection occurs (ft.). - vertical deflection (in.).

A negative value will be used when calculating the total combined stress (S). This will result in a larger (more conservative) combined stress. Note: If longitudinal bending stress does occur, click onto the designated box next to "Longitudinal Bending Stress" . If the box is not marked then the program will assume "0" for Sb. S = (St 2 - St Sb + Sb 2 )0.5 S Sb St - total combined stress by Von Mises (PSI). - longitudinal bending stress (PSI). - total circumferential flexure caused by external loads (PSI).

Note that if longitudinal bending stress is not present then the S will equal St. The final calculation is % SMYS. This is calculated to determine if the current conditions exceed the Maximum Allowable Combined Stress determined by Transcontinental Gas Pipe Line Corporation. S % SMYS = SMYS S SMYS References: ASME B31.8 "Gas Transmission and Distribution Systems" "Evaluation of Buried Pipe Encroachments", BATTELLE, Petroleum Technology Center, 1983 - total combined stress by Von Mises (PSI). - specified minimum yield stress of the pipe (PSI).

Technical Toolboxes, Inc.

You might also like

- Research Into Good Design Practice For ReelsDocument75 pagesResearch Into Good Design Practice For Reelsatomic407100% (2)

- f201508151439617857 PDFDocument6 pagesf201508151439617857 PDFh_alimohamNo ratings yet

- Pipe 288Document22 pagesPipe 288rezajun2820No ratings yet

- PublicReviewDraft2027 ASME NUm 1 2009Document21 pagesPublicReviewDraft2027 ASME NUm 1 2009raj_kr1078No ratings yet

- Elastic Stresses in Single Mitred BendsDocument22 pagesElastic Stresses in Single Mitred BendsWang Kin HuiNo ratings yet

- Mos Prf111Document7 pagesMos Prf111Nadim527No ratings yet

- Plank Algebra 1 Curriculum MapDocument4 pagesPlank Algebra 1 Curriculum MapE. Ryan Plank100% (1)

- Stress Ribbon and Cable-Supported Pedestrian Bridges INDEXDocument9 pagesStress Ribbon and Cable-Supported Pedestrian Bridges INDEXAnonymous VkzquW39No ratings yet

- HES5340 Fluid Mechanics 2, Lab 2 - COMPRESSIBLE FLOW (Converging-Diverging Duct Test) (Semester 2, 2012) by Stephen, P. Y. BongDocument26 pagesHES5340 Fluid Mechanics 2, Lab 2 - COMPRESSIBLE FLOW (Converging-Diverging Duct Test) (Semester 2, 2012) by Stephen, P. Y. BongStephenPYBong63% (8)

- Buried Pipeline AnalysisDocument9 pagesBuried Pipeline Analysisim4uim4uim4uim4u100% (1)

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNo ratings yet

- Wheel Load FormulaDocument4 pagesWheel Load FormulaJames Chu100% (1)

- GB T1591 Q345B Carbon and Low Alloy High Strength Steel PlateDocument1 pageGB T1591 Q345B Carbon and Low Alloy High Strength Steel Platejcvalencia100% (1)

- Observations On Concrete Shear Strength: Examples Illustrate Effects of Changes in The ACI 318 Code Shear EquationsDocument6 pagesObservations On Concrete Shear Strength: Examples Illustrate Effects of Changes in The ACI 318 Code Shear EquationsVasallo54No ratings yet

- PdeDocument9 pagesPdeskywalker_handsomeNo ratings yet

- Is 7215 Tolerances For Fabrication of Steel Structures R0.183135154Document24 pagesIs 7215 Tolerances For Fabrication of Steel Structures R0.183135154rikumohan100% (1)

- Indian Raiilway - BS-105 With A&c 2Document17 pagesIndian Raiilway - BS-105 With A&c 2paimpilly100% (1)

- Floor Response SpectrumDocument7 pagesFloor Response Spectrum폴로 쥰 차No ratings yet

- New Generation Pipeline Analysis Software PDFDocument17 pagesNew Generation Pipeline Analysis Software PDFmirnori6048100% (1)

- Cement Stabilized SandDocument15 pagesCement Stabilized SandphatmatNo ratings yet

- Slow Strain Rate Testing To Evaluate The Susceptibility of Metallic Materials To Environmentally Assisted CrackingDocument7 pagesSlow Strain Rate Testing To Evaluate The Susceptibility of Metallic Materials To Environmentally Assisted CrackingSandeep BhatiaNo ratings yet

- Fatigue DesignDocument56 pagesFatigue Designarrow_inspectNo ratings yet

- AASHTO Guide Specifications For Strength Design of Truss BridgesDocument13 pagesAASHTO Guide Specifications For Strength Design of Truss BridgesAlberto García MárquezNo ratings yet

- Pressure Vessel HandbookDocument2 pagesPressure Vessel HandbookAriq FauzanNo ratings yet

- Manual de Diseño PCIDocument8 pagesManual de Diseño PCITebo CandoNo ratings yet

- Strurel: Sysrel: Users Manual Demo - VersionDocument60 pagesStrurel: Sysrel: Users Manual Demo - VersionAmiraMešukić100% (1)

- Section A-A: Nagpur Metro Rail ProjectDocument1 pageSection A-A: Nagpur Metro Rail ProjectNagpur MetroNo ratings yet

- A283GrC VS A36 ComparisonDocument2 pagesA283GrC VS A36 ComparisonKhalilahmad Khatri100% (1)

- HSS Steel AvailabilityDocument2 pagesHSS Steel Availabilityaams_sNo ratings yet

- Steel AssignmentDocument31 pagesSteel AssignmentAnonymous 7J96P4ANNo ratings yet

- Fatigue DetailsDocument18 pagesFatigue DetailsKUMAR KANISHKANo ratings yet

- 1200 CP For Pipelines Corrosion Prevention and Metallurgy ManualDocument1 page1200 CP For Pipelines Corrosion Prevention and Metallurgy ManualamrinderNo ratings yet

- 24in Pipeline Buoyancy CalculationDocument1 page24in Pipeline Buoyancy CalculationDivesh rahul100% (1)

- CH 3 Design of Bolts in ConnectionsPartADocument22 pagesCH 3 Design of Bolts in ConnectionsPartAJakesNo ratings yet

- Dokumen - Tips - Anchor Chair Design FinalDocument26 pagesDokumen - Tips - Anchor Chair Design FinalRenalyn TorioNo ratings yet

- Pipe Bridge Design SheetDocument1 pagePipe Bridge Design SheetktejankarNo ratings yet

- Design Scope For Ballastless Track WorksDocument1 pageDesign Scope For Ballastless Track WorksDigambar JadhavNo ratings yet

- Background To UK NA - EN1990 - EN1991-2Document37 pagesBackground To UK NA - EN1990 - EN1991-2CarloDoimoNo ratings yet

- AISC Local Wheel Bending StressDocument2 pagesAISC Local Wheel Bending StressD SRINIVASNo ratings yet

- Trash Racks and Safety GratesDocument4 pagesTrash Racks and Safety GratessanbarunNo ratings yet

- Project Report On Piping StressDocument68 pagesProject Report On Piping StressAkshay GeraNo ratings yet

- Negative BuoyancyDocument5 pagesNegative BuoyancyBilly KurniawanNo ratings yet

- Blast Resistant Design of Steel StructuresDocument116 pagesBlast Resistant Design of Steel StructuresPetr KonupčíkNo ratings yet

- Expansion JointsDocument29 pagesExpansion Jointsvarma101100% (1)

- 1.1 Results of Structural Analysis: 1.1.1 Ausgrid HV PitDocument10 pages1.1 Results of Structural Analysis: 1.1.1 Ausgrid HV PitfastwritenameNo ratings yet

- ESAL and Axle LoadingDocument4 pagesESAL and Axle Loadingtrilokbist04No ratings yet

- Stability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Document11 pagesStability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Editor IJAERDNo ratings yet

- DEsign RSIDocument61 pagesDEsign RSIRajeshNo ratings yet

- Buried Pipe - CalcstressDocument17 pagesBuried Pipe - CalcstressAnjani PrabhakarNo ratings yet

- Subsea Riser Base AnalysisDocument1 pageSubsea Riser Base Analysisgvsha88No ratings yet

- Truck Loads On Pipe Buried at Shallow Depths: Strength and ForDocument6 pagesTruck Loads On Pipe Buried at Shallow Depths: Strength and ForBassem MuhannaNo ratings yet

- Loading and Design of Box Culverts To EurocodesDocument35 pagesLoading and Design of Box Culverts To Eurocodeslnanescu86% (7)

- Literature Review - The Design of Buried Flexible PipesDocument47 pagesLiterature Review - The Design of Buried Flexible PipesxbeldaNo ratings yet

- Numge2023 9Document7 pagesNumge2023 9WanNo ratings yet

- Some Observations On Piled Footing DesignDocument7 pagesSome Observations On Piled Footing DesigntaosyeNo ratings yet

- Buried Piping Analysis: DiscretizationDocument25 pagesBuried Piping Analysis: Discretizationtnas83No ratings yet

- Submit 2Document5 pagesSubmit 2dnourzadehNo ratings yet

- ACPA - Highway Live Loads On Concrete Pipe, EEUU 2007 PDFDocument11 pagesACPA - Highway Live Loads On Concrete Pipe, EEUU 2007 PDFwsamperNo ratings yet

- Evaluation of The Load On A Shield Tunnel Lining in GravelDocument6 pagesEvaluation of The Load On A Shield Tunnel Lining in GravelLevent KurtulduNo ratings yet

- 07 Chapter2Document49 pages07 Chapter2Safwat El RoubyNo ratings yet

- Concrete CasingDocument10 pagesConcrete CasingPipeline EngineerNo ratings yet

- Bera Cap Shallow Found Chp-170305220558Document38 pagesBera Cap Shallow Found Chp-170305220558HanafiahHamzahNo ratings yet

- FB DeepDocument202 pagesFB DeepJose Leo MissionNo ratings yet

- Queensland Urban Utilities Easement Guidelines V11Document23 pagesQueensland Urban Utilities Easement Guidelines V11tsoheilNo ratings yet

- Expanding APIAs Pipeline Engineering Training Program Offshore CompetenciesDocument9 pagesExpanding APIAs Pipeline Engineering Training Program Offshore CompetenciestsoheilNo ratings yet

- FiberTec PPS Application v3 01Document7 pagesFiberTec PPS Application v3 01tsoheilNo ratings yet

- The Effect of Manganese On The Microstructure and Properties of All-Wel-Metal DepositsDocument10 pagesThe Effect of Manganese On The Microstructure and Properties of All-Wel-Metal DepositstsoheilNo ratings yet

- Pipeline CoatingDocument40 pagesPipeline Coatingtsoheil100% (1)

- Internationa Paint MSDSDocument4 pagesInternationa Paint MSDStsoheil100% (1)

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- Korf HelpDocument1 pageKorf HelptsoheilNo ratings yet

- The Metallurgy of Carbon SteelDocument5 pagesThe Metallurgy of Carbon SteeltsoheilNo ratings yet

- Pipeline Steep Slope ConstructionDocument6 pagesPipeline Steep Slope ConstructiontsoheilNo ratings yet

- Competency Standards March VersionDocument12 pagesCompetency Standards March VersiontsoheilNo ratings yet

- Prefixesand Standard FormDocument4 pagesPrefixesand Standard Formsarpan abu bakarNo ratings yet

- Data Sheet Model CB 170 enDocument7 pagesData Sheet Model CB 170 enYusuf KulmardaniNo ratings yet

- Ch4SURFACE CHEM MCQDocument4 pagesCh4SURFACE CHEM MCQAnuj PalNo ratings yet

- Gyroscopic MotionDocument8 pagesGyroscopic MotionAnonymous NFsIMHyfLtNo ratings yet

- Sikawrap®-300 C: Product Data SheetDocument4 pagesSikawrap®-300 C: Product Data SheetHenri DormoyNo ratings yet

- Exp't 51: Nitration of NitrobenzeneDocument4 pagesExp't 51: Nitration of NitrobenzenelovehopeNo ratings yet

- 01 - HYDRODYNAMICS - 05 - Hydrodynamic Analysis For Offshore LNG Terminals Chen XiaoDocument15 pages01 - HYDRODYNAMICS - 05 - Hydrodynamic Analysis For Offshore LNG Terminals Chen XiaoWael Fawzy MohamedNo ratings yet

- MEPDG Manual of PracticesDocument209 pagesMEPDG Manual of PracticesSri RamyaNo ratings yet

- Process Control Lab ManualDocument32 pagesProcess Control Lab ManualRakesh Kumar Patnaik50% (2)

- Ball Milling - Final FinalDocument12 pagesBall Milling - Final FinalKrishna TejaNo ratings yet

- The Surface Tension of Mixtures of Methanol Acetonitrile Tetrahydrofuran Isopropanol Tertiary Butanol and Dimethyl Sulfoxide With Water at 25 C PDFDocument22 pagesThe Surface Tension of Mixtures of Methanol Acetonitrile Tetrahydrofuran Isopropanol Tertiary Butanol and Dimethyl Sulfoxide With Water at 25 C PDFKatipot InkongNo ratings yet

- 000000000001019531Document320 pages000000000001019531Dante FilhoNo ratings yet

- Bibliografia: Quarterly, Summer, 1995, Pp. 7-22Document4 pagesBibliografia: Quarterly, Summer, 1995, Pp. 7-22Gtx GtxNo ratings yet

- Lab 1 (Full)Document22 pagesLab 1 (Full)Anonymous 8UOCBqiNo ratings yet

- Anti Sweat HeatersDocument2 pagesAnti Sweat HeatersbreavmacNo ratings yet

- Larsen 1977 AGGMDocument4 pagesLarsen 1977 AGGMRandiRusdianaNo ratings yet

- BS NA EN 1998-2 UK National Annex To Eurocode 8. Design of Structures For Earthquake Resistance. Bridges PDFDocument18 pagesBS NA EN 1998-2 UK National Annex To Eurocode 8. Design of Structures For Earthquake Resistance. Bridges PDFliuhoyinNo ratings yet

- Solving Linear EquationsDocument5 pagesSolving Linear EquationsArpit Jain100% (1)

- Chemistry ProjectDocument31 pagesChemistry ProjectBhawna sharma80% (5)

- 304 DesignDocument39 pages304 DesignPramod KulkarniNo ratings yet

- Experiment 1: Generation of Basic SignalsDocument19 pagesExperiment 1: Generation of Basic SignalsSevandhiNo ratings yet

- Astro Secrets 1Document385 pagesAstro Secrets 1Centre for Traditional Education100% (3)

- Pulp ProtectionDocument4 pagesPulp ProtectionNaji Z. Arandi50% (2)

- Numerical Hyperbolic SystemsDocument42 pagesNumerical Hyperbolic SystemsIésus Sousa FreireNo ratings yet

- Diazepam 2030Document2 pagesDiazepam 2030Mulayam Singh YadavNo ratings yet

- Roll Pass Design For Ribbed BarsDocument8 pagesRoll Pass Design For Ribbed BarsDiaa KassemNo ratings yet

- Workshop 4 NotesDocument7 pagesWorkshop 4 NotesJohnny BraveNo ratings yet