Pipeline Hydrotest Plan

Pipeline Hydrotest Plan

Uploaded by

Sunday PaulCopyright:

Available Formats

Pipeline Hydrotest Plan

Pipeline Hydrotest Plan

Uploaded by

Sunday PaulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Pipeline Hydrotest Plan

Pipeline Hydrotest Plan

Uploaded by

Sunday PaulCopyright:

Available Formats

PIPELINE HYDROTESTING

PROCEDURE

CONTRACT NO.: ..

A 20 May 12 19 For Approval QC Engineer QA/QC Engineer Project Manager

Rev. Date Pages Descriptio

Prepare! "#:

$o%a&a! $asri

Revie'e! "#:

A. Prasa!

Approve! "#:

(esa& Sai!

Pro)ect : (ara Pro)ect

Co&pa# : *+'ait Oi, Co&pa#

Cotractor : HOT Egieerig a! Costr+ctio Co&pa# *SCC

Doc+&et No. : HOT-.CP-

PIPELINE HYDROTESTING

PROCEDURE

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 2 of 19

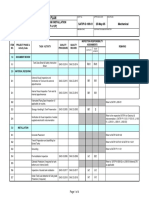

RE/ISION LOG

RE$%&' RE$%DA(E RE$)ED PA*E RE$)'& DE)CRP('&

A 20 May 12 Fir!t i!!"e )"+,itte- for approval

CONTENTS

SL.NO SECTION PAGE

0.1 PURPOSE 2

3.1 SCOPE 2

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 1 of 19

4.1 RE5ERENCE 2

2.1 RESPONS"ILITIES 2

6.1 PIPELINE DESIGN DATA 2

7.1 CONSTRUCTION 5LO( CHART 6

8.1 TEST PAC*AGE 7

9.1 E.UIP$ENTS AND INSTRU$ENTS 7

:.1 PIG $ATERIAL 5OR PIPELINES 8

01.1 SA5ETY 8

00.1 (ATER SOURCE 9

03.1 INTERNAL CLEANING 9

04.1 CALIPER PIGGING (ITH GPS $APPING OPERATION 01

02.1 (ATER 5ILLING 01

06.1 TE$PERATURE STA"ILI;ATION 00

07.1 PIPELINE HYDROTEST 03

08.1 DE(ATERING 06

09.1 S(APPING 07

0:.1 DRYING 07

31.1 PURGING 07

30.1 ATTACH$ENT 07

0.1 P+rpose

(2e p"rpo!e of t2i! proce-"re i! to li!t o"t vario"! !tep! involve- in 2y-ro!tatic pre!!"re te!ting3

pigging3 -raining3 !4a++ing an- -rying of pipeline! for t2e Project title- 56arra Project 7 in line!

4it2 t2e project !pecification%

3.1 Scope

)cope of 4or8 cover! t2e 6ater )"pply3 Q"ality an- (reat,ent3 nternal Cleaning3 Pigging3

*a"ging3 Floo-ing t2ereafter pre!!"ri!ing3 -epre!!"ri!ing on !"cce!!f"l co,pletion of te!ting an-

-i!po!al of 4ater of Pipeline a! per Contract (ec2nical )pecification%

4.1 Re<erece

.'(//00

Pipe Welding, NDT, Coating

and Backfilling

Cleaning and Gauging

Filling & Air Removing

Temperature ta!li"ation

Pre##uri"ation

Pre##ure $old

Depre##uri"ation and %ater tran#fering &De%atering

Pre##ure Relief & Repair

&n'ualified

(eak Tig)tne## C)eck

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 9 of 19

A)ME # 11%9 :i;"i- tran!,i!!ion !y!te,! for .y-rocar+on!3 :i;"i-

Petrole", *a!

<'C )pecification! 01/=.=1009 Pipeline Pigging an- .y-ro!tatic te!t

>ncl"-ing a--en-",?

<'C )pecification 01/=.=100/ Pipeline De4atering -rying @ P"rging

>ncl"-ing a--en-",?

AP 1110 .y-ro!tatic (e!ting of Pipeline%

2.1 Resposi=i,ities

EAperience- !peciali!t! cre4 coor-inate- +y a ;"alifie- an- eAperience- per!on 42o !2all +e

re!pon!i+le for all te!ting an- a!!ociate- 4or8! !2all carry o"t te!ting% )"fficient eAperience-

per!onnel !2all +e re;"ire- a! per t2e re;"ire,ent to ena+le all a!pect of te!ting to +e f"lly

!"pervi!e- an- co,plete- a! per t2e progra,%

/%0 Costr+ctio 5,o' C%art

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : / of 19

8.1 Test pac>age

(e!t pac8age !2all incl"-e +"t not li,ite- to t2e follo4ing!:

a? Pipeline pre!!"re te!ting cover !2eet

+? Pre=2y-ro te!t c2ec8li!t%

c? P"nc2 li!t for Pipeline

-? Mar8e- P@D for t2e line to +e te!te-%

e? Pipeline *eneral arrange,ent -ra4ing

f? Pipeline profile -ra4ing

g? 6el- ,ap

2? Pipe #oo8

i? Cali+ration recor-! for t2e "!e- in!tr",ent!%

j? Diagra, of .y-ro te!t .ea-er3 :a"nc2er / Receiver

8? Pipeline cleaning in!pection report

l? *a"ging in!pection report

,? Filling log

n? Pre!!"riBation Recor-

o? Pre!!"re an- (e,perat"re :og

p? Pre!!"re/vol",e calc"lation for entrappe- air percentage%

;? Pre!!"re (e!t Certificate

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : C of 19

r? Pre!!"re (e!t )pecification

!? De pre!!"riBation Recor-%

t? Pipeline !4a++ing report

"? Pipeline -rying report

v? Po!t 2y-ro!tatic te!t c2ec8li!t

D%0 E?+ip&ets a! Istr+&ets

9.0 E?+ip&ets List

(e!ting e;"ip,ent! !2all -epen- "pon t2e te!t to +e carrie- o"t a! per t2e (ec2nical )pecification

of t2e Contract% (2e follo4ing e;"ip,ent! are generally "!e-%

a? Air Co,pre!!or!%

+? Filling p",p%

c? Pre!!"riBing p",p

-? C2e,ical njection P",p%

e? 6ater tan8er! a! re;"ire-

f? $ac"", (an8er!

g? Die!el generator%

e? (e,porary Pig :a"nc2er/Receiver

f? Air Con-itione- or .eate- te!t Ca+in

g? Pig! @ Pig trac8ing e;"ip,ent

2? Communication equipment

9.3 Istr+&ets

a? Dea- 6eig2t (e!ter

+? Flo4 Meter!%

c? Pre!!"re *a"ge

-? (e,perat"re *a"ge

e? Pre!!"re recor-er 4it2 9D 2o"r! rotating c2art

f? (e,perat"re recor-er 4it2 9D 2o"r! rotating c2art

g? (e,perat"re pro+e!

2? Digital (2er,o,eter

i? )afety relief valve

9.4 Ca,i=ratio o< test Istr+&ets

All in!tr",ent! "!e- for .y-ro te!ting !2all +e cali+rate- +efore 2y-ro!tatic te!ting to ,eet t2e

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 0 of 19

acc"racy of E/= 0%1F an- !en!itivity of 0%0/F an- !2all 2ave a vali- cali+ration certificate -"ring t2e

perio- of 2y-ro te!ting% All in!tr",entation !2all operate in t2e range of 90F to 00F of t2eir

,aAi,", in-icator level -"ring operation% (2e in!tr",ent! to +e cali+rate- an- cali+ration

certificate for t2e !a,e !2all +e pre!ente- prior to te!t%

:.1 Pig &ateria, <or pipe,ies

9%1 .ig2/ Me-i", Den!ity foa, Pig !2all +e "!e- +efore cleaning pig to en!"re t2at t2e line i! free fro,

o+!tacle!%

9%2 Cleaning pig >4it2 +r"!2 an- neoprene c"p?

9%1 #atc2ing pig! 4it2 9 neoprene c"p! !"ita+le for Filling /-e4atering

9%9 Foa,/ )ponge Pig! for -rying @ !4a++ing t2e Pipeline%

01.1 Sa<et#

10%1 Proper care !2o"l- +e ta8en to !afeg"ar- per!onnel an- property -"ring te!ting%

10%2 &o 4or8 !2all +e per,itte- on !ection! of pipeline or t2e a!!ociate- connection! "n-er te!t%

10%1 Prior to pre!!"ri!ation3 proper ,ea!"re !2o"l- +e ta8en to prevent -a,age to per!onnel an-

property or -i!r"pt any ot2er eAi!ting !ervice!%

10%9 Area 42ere te!t e;"ip,ent i! place- !2all +e clearly -e,ar8e- to prevent "na"t2ori!e- entry%

10%/ 6arning notice rea-ing 5(ARNING: PIPELINE UNDER TEST7 !2all +e place- at appropriate

location! for t2e -"ration of t2e te!t%

10%C All local an- !tat"tory re;"ire,ent! are ta8en care of%

10%0 Re;"ire,ent! !tate- Contract .ealt23 )afety an- Environ,ental >.)E? Plan !2all to +e "!e- -"ring

eAec"tion of t2e 6or8! at !ite%

10%D )afety officer ,"!t +e pre!ent at !ite%

10%9 #arrica-ing of Pipeline3 Fir!t Ai- <it3 E,ergency P2one no3 infor,ing to <'C a"t2oritie! etc

10%10 (2e co,,"nication facilitie! for t2e tea, involve- in t2e te!t 2ave +een c2ec8e- an- +ac8="p

facilitie! are availa+le%

10%11 (2e per!onnel engage- in t2e te!ting 4or8! 2ave +een +riefe- on t2e e,ergence plan!%

10%12 (2e +ot2 !i-e! operator! 2ave +een in!tr"cte- +y t2e te!t engineer regar-ing t2e li,iting pre!!"re

42ic2 !2all apply to t2e te!t !ection%

00.1 (ater So+rce

11%1 (e!t ,e-i", 4ill +e +rac8i!2 4ater -o!e- 4it2 Co,pany approve- non=foa, corro!ion in2i+itor to

,an"fact"rerG! reco,,en-ation!% (2e c2e,ical -o!ing of +rac8i!2 te!t 4ater !2all follo4 t2e

re;"ire,ent of <'C Engineering *ro"p )pecification 01/=C*=1001%Calc"late- ;"antity of approve-

corro!ion in2i+itor !2all +e a--e- to t2e 4ater "!ing -o!ing p",p%

G&CP MP 101G a pro-"ct of &ational C2e,ical! @ Petrole", n-"!trie! Co=<"4ait >refer attac2e-

Pro-"ct #"lletin? 42ic2 act! a! a Corro!ion n2i+itor3 #acterici-e @ oAygen !cavenger% t i! -e!igne-

a! a !ingle pro-"ct for treat,ent of 4ater re!i-ent in pipeline! an- prevent! corro!ion -"e to

oAygen attac83 anaero+ic +acteria an- !alt 4ater% t! -o!age rate reco,,en-e- +y t2e

,an"fact"rer i! /00pp,%

11%2 All te!t re!"lt!3 reco,,en-e- in2i+itor type an- -o!age! !2all +e !ent to t2e Co,panyH!

repre!entative for approval prior to !tart of filling operation

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : D of 19

Re;"ire,ent of 4ater for Pipeline filling !2all +e -eter,ine- +y "!ing t2e for,"la%

$ I J/9 A D2 A :

62ere $ I *eo,etrical $ol",e of t2e te!t )ection >M1?

D I Pipeline nternal Dia,eter >M?

: I Pipe :ine :engt2 >M?

Q"antity of #rac8i!2 4ater re;"ire- for filling eac2 pipeline !ection i! ,entione- in cla"!e no 19%00

11%1 6ater 4ill +e arrange- fro, neare!t *C in!i-e <'C or +y 4ater tan8er!% After 2y-ro=te!t relea!e3

t2e 4ater 4ill +e tran!ferre- fro, one !ection to t2e ot2er +y te,porary connection!%

11%9 (2e corro!ion in2i+itor ,"!t +e applica+le for ,"lti="!e%

03.1 Itera, C,eaig

03.0 Co<ir&atio prior to piggig

12%1%1 A pre=te!t c2ec8 !2all +e perfor,e- +efore pigging i! co,,ence-% (2e c2ec8 li!t !2all incl"-e t2e

follo4ing!:

(2e per,it for pipeline !ection cleaning an- ga"ging 2a! +een accepte- +y t2e Co,pany%

All te,porary pipe!3 pig trap!3 an- ot2er e;"ip,ent an- in!tr",ent! "!e- to te!t t2e !ection 2ave

+een c2ec8e- in ter,! of !afety an- f"nctionality%

All 2y-rote!t 2ea-! !2all +e prete!te- to ,aAi,", te!t pre!!"re

Prior to 2y-ro=te!ting3 all ne4 pipeline! !2all +e offere- for ,ec2anical clearance%

All in!tr",ent! an- ga"ge! to +e "!e- -"ring t2e te!t 2ave +een cali+rate- !ince not ,ore t2an C

,ont2! an- 2ave vali- te!t certificate!%

All 4arning notice!3 ,ar8er tape!3 !ign!3 protective +arrica-e! an- ot2er !afety e;"ip,ent 2ave

peen po!itione-%

03.3 C,eaig Process.

12%2%1 All pipeline! !2all +e internally cleane- to en!"re t2e re,oval of con!tr"ction -e+ri! an- loo!e !cale

12%2%2 Cleaning !2all +e -one in one !ection3 fro, :a"nc2er to Receiver%

12%2%1 (2e 1!t r"n of cleaning proce!! !2all +e -one +y Me-i", Den!ity Cri!! Cro!! Foa, Pig e;"ippe-

4it2 Pig :ocator%

12%2%9 (2e !econ- r"n of t2e cleaning proce!! !2all +e -one +y .ig2 !eal #i -irectional c"p pig 4it2 4ire

+r"!2 e;"ippe- 4it2 pig locator%

12%2%/ A co,pre!!or 4ill +e "!e- to -rive t2e cleaning pig% (2e pig !pee- !2all +e +et4een 0%1 ,t/!ec an-

1%0 ,t/!ec% (2i! !pee- can +e controlle- +y t2rottling relea!e valve at receiving 2ea-er%

12%2%C (4o tec2nician! 4it2 proper co,,"nication 4ill +e availa+le at eac2 en- of t2e pipeline in or-er to

control pig ,ove,ent an- arrival% (2e operator! !2all i,,e-iately report to t2e (e!t Engineer any

apparently variation 42ic2 ,ay re!"lt in fail"re or -anger !"c2 a! any "n,oral ri!ing of t2e

pre!!"re +e2in- t2e pig%

12%2%0 (2e pa!!ing of t2e pig to any partic"lar area !"c2 a! .ot #en-!/#arre- (ee! ,ay +e -etecte- +y

t2e non intr"!ive pig !ignaler t2at can +e po!itione- in t2e re;"ire- place to -etect t2e ti,e at 42ic2

t2e pig 2a! pa!!e- t2at location%

12%2%D Kpon pig arrival an- -etecte- +y t2e non intr"!ive pig !ignaler3 co,pre!!or 4ill +e !toppe- an-

pre!!"re 4ill +e relea!e- to at,o!p2ere prior to re,oval of t2e pig%

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 9 of 19

12%2%9 Cleaning of t2e te!t line !2all +e 4itne!!e- +y Co,pany repre!entative an- Contractor QC

n!pector%

12%2%10Mini,", 2 r"n! 4ill +e carrie- o"t in pipeline an- a--itional r"n! !2all +e ,a-e if re;"ire- to en!"re

!ati!factory cleanne!! a! accepte- +y Co,pany repre!entative%

12%2%11After eac2 r"n of pigging3 t2e pig !2all +e in!pection +y Co,pany repre!entative!%

12%2%12(2e cleaning operation !2all +e contin"e- "ntil t2e vol",e of t2e receive- ,aterial! +y t2e la!t pig

i! le!! t2an / litter!%

12%2%11(2e follo4ing -ata !2all +e recor-e- +y pipeline pigging in!pection for, +y t2e te!t Engineer:

&",+er of pig r"n

(ype of t2e pig%

(ype of t2e -riving ,e-ia

(i,e of la"nc2ing an- receiving

$ol",e an- nat"re of ,aterial! an- !"+!tance! arriving in front of t2e pig at t2e

receiving en-%

12%2%19After cleaning operation3 t2e pipeline !2all +e protecte- +y clo!ing t2e opening! at +ot2 en-!%

12%2%1/Cleaning of non pigga+le line !2all +e carrie- o"t +y "!ing co,pre!!e- air +efore !tart 4ater filling%

03.4 Ga+gig Operatio

12%1%1 Follo4ing internal cleaning3 ga"ging r"n !2all +e ,a-e on t2e entire co,plete pipeline to

-e,on!trate t2at t2e pipe line i! free of +"c8le!3 4rin8le!3 -ent! etc%

12%1%2 *a"ging plate !2all +e ,a-e fro, al",in", plate an- !2all +e 9/F of t2e ,ini,", internal +ore of

t2e line pipe%

04.1 Ca,,iper Piggig 'it% GPS &appig operatio

11%1 After co,pletion of internal cleaning@ *a"ging3 Calliper Pigging 4it2 *P) ,apping !2all +e -one +y

Co,pany approve- )"+contractor% .'(ECC to !"+,it for co,pany approval a !eparate proce-"re

fro, t2e )"+contractor for Calliper Pigging 4it2 *P) Mapping%

02.1 (ater 5i,,ig

19%1 6ater Filling 'peration%

Filling of te!t line !2all +e carrie- o"t in t4o !tage!:

)tage 1: #rac8i!2 6ater fro, !o"rce 4ill +e p",pe- into tan8%

)tage 2: 6ater 4ill +e p",pe- fro, t2e tan8! to te!t 2ea-er "!ing filling p",p%

>Plea!e refer for connection -etail! in (e!t !e;"ence -iagra, enclo!e-?

19%2 Filling 4ater 4ill +e filtere- t2ro"g2 a !trainer fitte- 4it2 /0 ,icron filter%

19%1 Cali+rate- flo4 ,eter !2all +e in!talle- -o4n!trea, of t2e filling p",p in or-er to calc"late t2e

vol",e of te!t 4ater fille-% n2i+itor3 4ill +e injecte- into 4ater a! per ,an"fact"rer! reco,,en-e-

-o!age rate a! approve- +y Co,pany%

19%9 (2e filling operation !2all +e perfor,e- t2ro"g2 t2e te!t 2ea-er! on eac2 pipeline% (2e la"nc2er

!2all +e preloa-e- 4it2 2 no!% of +i=-irectional pig! for filling operation%

19%/ :a"nc2er !2all +e fitte- 4it2 1 noBBle! for filling 4ater%

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 10 of 19

&oBBle no% 1 4ill +e "!e- for pre filling 4ater e;"ivalent to 2/0, lengt2 of te!t !ection%

&oBBle no% 2 !2all +e "!e- for la"nc2ing fir!t pig an- in2i+ite- 4ater e;"ivalent 2/0, !ection lengt2

!2all +e p",pe- into t2e line%

&oBBle no% 1 !2all +e "!e- for la"nc2ing !econ- pig an- re;"ire- vol",e of 4ater to fill t2e te!t line

4ill +e p",pe- into t2e line%

14.6 (2e filling pig !pee- !2all +e in range 0% 9 L 0%D,/!ec% P",ping 4ill contin"e "ntil pig! are receive-

at t2e pig receiver% Air eApelle- fro, te!t !ection !2all +e vente- o"t t2ro"g2 vent valve!% (2e

valve! !2all +e ,an"ally operate- 42ile filling to ,aintain a +ac8 pre!!"re of 1%0 +ar to avoi-

"ncontrolle- r"n of pig! an- re,oval of all trappe- air at t2e 2ea-er! ri!er!%

19%0 Recor-! -"ring 4ater filling:

D"ring filling operation t2e follo4ing 4ill +e recor-e- on t2e attac2e- for, for every 10 ,in"te!%

Fille- ;"antity%

Pre!!"re at receiver%

6ater te,perat"re%

Q"antity of in2i+itor p",pe-%

19%D Kpon arrival of filling pig at t2e receiver en-3 filling operation 4ill +e con!i-ere- a! co,plete- an-

t2e te!t !ection i! rea-y for !ta+iliBation

06.1 Te&perat+re Sta=i,i@atio

1/%1 After co,pletion of filling operation3 t2er,al !ta+iliBation of te!t !ection 4ill +e carrie- o"t% (2e

te,perat"re of t2e 4ater in!i-e t2e line can +e con!i-ere- t2e !a,e a! t2at of t2e pipeline o"t!i-e

4all%

1/%2 (4o no!% of te,perat"re recor-er! 4it2 9D 2r% gra-"ate- c2art! 4ill +e fiAe- on t2e te!t line%

1/%1 'ne recor-er 4ill +e fiAe- to pipe !"rface near la"nc2er

1/%9 't2er one to !oil at '%/, fro, pipe%

1/%/ (2e!e te,perat"re recor-er! 4ill +e provi-e- 4it2 -ifferent colo"r pen!%

1/%C (2er,oco"ple 4it2 rea- o"t !2all +e in!talle- at a -i!tance of 0%/8, fro, eac2 en- of t2e te!t

!ection%

1/%0 (2er,oco"ple !2o"l- +e fir,ly attac2e- to t2e +are pipe after re,oving corro!ion protection

coating an- covere- 4it2 in!"lating ,aterial!%

1/%D For !oil te,perat"re ,ea!"re,ent!3 t2ey !2o"l- +e +"rie- at pipe centre line -ept2 an- 0%/,

laterally fro, t2e pipe% All t2er,oco"ple along t2e pipeline !2all +e in!talle- +efore t2e !tart of t2e

filling operation%

1/%9 For a+ove gro"n- te!t !ection te,perat"re ,ea!"re,ent!3 t2e t2er,oco"ple !2o"l- +e fir,ly

attac2e- to +are ,etal an- covere- 4it2 in!"lating ,aterial! or in!talle- into line=fill 4ater%

1/%10 (e,perat"re rea-ing for pipe an- !oil3 at vario"! location!3 !2all +e ,ea!"re- every D2r!% for a

perio- of 29 2r!% an- !2all +e recor-e- in t2e 4ater filling recor- for,%

1/%11 D"ring !ta+iliBation perio-3 t2e follo4ing -ata !2all +e recor-e-

Pre!!"re rea-ing of -ea- 4eig2t te!ter

)oil te,perat"re fro, t2er,oco"ple! in!talle- along pipeline%

Pipe te,perat"re fro, t2er,oco"ple in!talle- along pipeline%

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 11 of 19

A,+ient te,perat"re

#aro,eter rea-ing

1/%12 )ta+iliBation !2all +e con!i-ere- !ati!factory 42en t2e -ifference +et4een t2e average !oil an-

average pipe !8in te,perat"re i! not ,ore t2an 1MC%

07.1 Pipe,ie H#!rotestig

07.0 Co<ir&atio prior to press+ri@atio

1C%1%1 A pre=te!t c2ec8 !2all +e perfor,e- +efore pre!!"riBing i! co,,ence-% (2e c2ec8 li!t !2all incl"-e

c2ec8! to confir, t2e follo4ing!:

)ta+iliBation 2a! +een accepte- +y all partie!%

All in!tr",ent! an- ga"ge! to +e "!e- -"ring pre!!"riBing an- te!t 2ave +een cali+rate- an- vali-

te!t certificate! 2ave +een c2ec8e-%

All e;"ip,ent an- -evice! are in goo- con-ition an- 4ell f"nctional%

A te!t ca+in e;"ippe- 4it2 a -ea- 4eig2t te!ter an- c2art recor-er i! in!talle- at a !afe -i!tance of

not le!! t2an 20, fro, te!t line%

At la"nc2er an- receiver pre!!"re recor-er! 4it2 9D 2o"r rotating c2art! 4ill +e in!talle- for

contin"o"! recor-ing or pre!!"re -"ring pre!!"riBing%

9 n",+er! of te,perat"re recor-er! are in!talle- at la"nc2er an- receiver for recor-ing !oil an-

pipe te,perat"re -"ring pre!!"riBation%

A 2ig2 pre!!"re p",p e;"ippe- 4it2 +"ilt in cali+rate- relief valve !et at /F a+ove te!t pre!!"re

!2all +e "!e- to pre!!"riBe t2e te!t line:

07.3 Ca,c+,atios o< Air Cotet

(o -eter,ine t2e re!i-"al air vol",e in t2e line t2e +elo4 -iagra, !2all +e -ra4n:

(2e t2eoretical !lope !2all +e calc"late- fro, t2e follo4ing for,"la:

N$/NP I $ O>D/t? A >1/E? A >1= P 2 ? E > 1 /Q?R

62ere:

N$ : ncre,ental of vol",e in >M

1

?

NP : ncre,ental of Pre!!"re in >#ar?

$ : Fille- $ol",e>M

1

?

D : '"t!i-e Dia,eter >M?

t : 6all (2ic8ne!!>M?

E : So"ngT ) Mo-"l"! 'f Ela!ticity>#ar?

>For Car+on !teel EI2%00A10

C

+ar?

P : Poi!!onT ) Ratio >0%1?

Q : #"l8 Mo-"l"! of 6ater I 21%1A10

1

+ar

#efore pre!!"riBation !tart!3 t2e a+ove calc"lation !2all +e -one an- t2e t2eoretical P/$ plot an-

0%2F off!et vol",e line !2all +e -ra4n%

(2e follo4ing -iagra, !2all +e "!e- a! follo4!:

.'(//00

*+ Bar

,* Bar

T

e

#

t

P

r

e

#

#

u

r

e

-

!

a

r

.

tatic

$ead

T)eoritical P/0 lope

Actual P/0 Plot

12tra Ploted

0olume 3f Water Added

+45*

6a2imum Allo%a!le

Air Content

+47+ +45+ +4+* + +47*

8 Air Content

Actual Air Content

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 12 of 19

Fig=1

1C%1 Pre!!"riBing !2all procee- at a ,aAi,", rate of 1 #ar / Min"te%

1C%9 D"ring pre!!"riBation3 t2e follo4ing rea-ing! !2all +e ta8en an- recor-e-

Dea- 4eig2t te!ter rea-ing

)tro8e co"nter rea-ing

Pre!!"re ga"ge rea-ing at receiver%

A,+ient (e,perat"re

6ater te,perat"re%

1C%/ (2e line !2all +e pre!!"riBe- to /0F of t2e final te!t pre!!"re% An act"al P/$ plot !2all +e -ra4n in

or-er to -eter,ine t2e air content in t2e te!t !ection% (2e percentage of air content !2all +e

calc"late- fro, t2e P$=*rap2 a! per Fig%01 +y plotting on grap2%

Percentage of Air I >$ol",e of Air /$ol",e of :ine? A 100

1C%C Air content !2o"l- not eAcee- 0%2F of te!t line vol",e co,paring to t2eoretical ;"antity%

1C%0 (2e !lope of t2e linear part of t2e P/$ plot !2all +e co,pare- 4it2 t2e !lope of t2e t2eoretical plot

for 100F 4ater content% (2e !lope !2all not -iffer +y ,ore t2an 10F%

1C%D f air content i! greater t2an 0%2F of t2e line vol",e3 t2e pre!!"riBing can not go on% (2e te!t

!ection !2all +e -epre!!"riBe- an- a--itional pig pa!!age! !2all +e perfor,e- to re,ove t2e air

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 11 of 19

poc8et!%

1C%9 Kpon t2e acceptance of t2e air content in t2e te!t !ection3 t2e pre!!"riBation !2all contin"e "ntil

D0F of t2e ,aAi,", te!t pre!!"re i! reac2e-%

1C%10 Pre!!"re i! t2en !ta+iliBe- for a perio- of 2 2r!% D"ring t2i! 2ol- perio- t2e line ,"!t +e c2ec8e- for

any po!!i+le lea8!%

1C%11 (2e pre!!"riBation rate a+ove D0F !2all +e at a "nifor, rate no ,ore t2an 0%/ #ar/ Min"te "ntil

,aAi,", te!t pre!!"re i! reac2e-% Pre!!"re !2all +e recor-e- every 0%/ #ar%

1C%12 62en t2e pre!!"re +eco,e! 100F of te!t pre!!"re3 pre!!"riBing p",p 4ill +e !toppe- an- all

connection! fro, te!t p",p 4ill +e i!olate- fro, te!t !ection an- 29 .r% 2ol- perio- 4ill !tart% (2e

!tart of t2e 2y-rote!t !2all coinci-e 4it2 t2e 2ig2e!t te,perat"re of t2e -ay%

07.04 32 Ho+r Ho,! Perio!

#efore co,,ence,ent of 29 2o"r 2ol- perio- c2art! for te,perat"re an- pre!!"re recor-er! 4ill +e

replace- 4it2 ne4 c2art!%

D"ring 29 2r% 2ol- perio- follo4ing rea-ing! 4ill +e recor-e- at every 2alf an 2o"r%

Dea- 4eig2t te!ter rea-ing

Pre!!"re ga"ge rea-ing at :a"nc2er an- Receiver% A,+ient te,perat"re

#aro,eter rea-ing

(2er,oco"ple rea-ing! at all location! >#ot2 !oil an- pipe te,perat"re?

1C%19 (2e te!t !2all +e -ee,e- accepta+le if any pre!!"re c2ange can +e acco"nte- for +y

corre!pon-ing te,perat"re c2ange "!ing t2e follo4ing for,"la:

UP/ U ( : S=2V />DW>1=v

2

?/EtE1/#? #ar/ XC

UP : Pre!!"re c2ange >#ar?

S : $ol",etric eApan!ion coefficient of 4ater

U ( : (e,perat"re c2ange >XC?

D : Pipeline o"t!i-e Dia,eter >M?

E : So"ngG! Mo-"l"! of car+on !teel >EI2%00A10

C

+ar?

t : &o,inal Pipe (2ic8ne!! >,,?

v : Poi!!onG! Ratio >0%1?

# : #"l8 ,o-"l"! of 4ater at te,perat"re an- pre!!"re of t2e 4ater

21%1W10

1

+ar

V : Coefficient of linear eApan!ion of !teel >11%0W10

=7

A

1C%1/ (2e -ifference +et4een t2e t2eoretical pre!!"re an- ,ea!"re- te!t pre!!"re at t2e en- of 2ol-

perio- !2all not +e greater t2an Y0%2 F of te!t pre!!"re%

1C%1C For acceptance criteria3 !tatic pre!!"re c2ange! !2all +e acco"nte- +y te,perat"re c2ange!% (2e

te!t !2all +e accepte- if c2ange in pre!!"re i! 4it2in accepta+le li,it an- no lea8! are fo"n- -"ring

t2e te!t% A pre!!"re c2ange of Y0%2 F of t2e te!t pre!!"re !2all +e accepte-%

1C%10 f greater pre!!"re -rop! occ"r!3 t2e 2ol-ing perio- !2all +e eAten-e- anot2er 29 2o"r! or t2e

ca"!e of lac8 of 4ater tig2tne!! !2all +e e!ta+li!2e-% n eit2er ca"!e t2e Co,pany 4ill +e infor,e-%

1C%1D A pre!!"re v!% ti,e grap2 !2all +e prepare- for 29 .o"r 2ol- perio- to a!certain t2e act"al pre!!"re

.'(//00

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 19 of 19

c2ange!%

1C%19 'n acceptance3 Pre!!"re 4ill +e relea!e- gra-"ally at t2e rate of 1 #ar/Min"te%

1C%20 :ea8! or fail"re! 4ill not +e accepte-% All lea8! or fail"re! !2all +e rectifie-% (2e te!t !ection/:ine

!2all +e te!te- again% #efore atten-ing any repair3 te!t line !2all +e -epre!!"riBe- to !tatic pre!!"re%

After atten-ing repair! t2e line !2all +e rete!te- to en!"re3 t2ere i! no lea8! or fail"re!%

08.1 De'aterig

10%1 .y-ro te!t 4ater !2all +e -i!po!e- neare!t to -rainage of te,porary -i!po!al pit %Prior to !tart t2e

-raining of te!t 4ater per,i!!ion ,"!t +e ta8en fro, <'C )E< tea, a"t2oritie!% f t2ere i! no

!"ita+le location for -raining of te!t 4ater3 t2en vac"", tan8er! 4it2 te,porary facilitie! for

collection !2all +e "!e- for -i!po!al of te!t 4ater% t !2all +e en!"re- t2at pipeline !ection te!te- 2a!

+een -epre!!"ri!e- 1 +ar a+ove !tatic 2ea- con-ition an- left fille- 4it2 in2i+ite- 4ater%

10%2 All t2e te,porary fitting! an- connection! !2all +e c"t off or -i!connecte-3 an- t2e entire pipeline

!2all +e fiAe- 4it2 all t2e re;"ire,ent! a! per t2e final approve- -ra4ing% De4atering of eac2 line

!2all +e perfor,e- +y t2e #i=Directional/C"p Pig p"!2e- +y co,pre!!e- air%

10%1 Mini,", !pee- an- +ac8pre!!"re of t2e pig! !2all +e ,aintaine- in or-er to o+tain a contin"o"!

operation 4it2 no +loc8age of t2e pig!%

10%9 At t2e receiving en- t2e -i!c2arge an- flo4 !2all +e t2rottle- -o4n to avoi- -a,age to t2e receiving

facilitie!%

10%/ (2e velocity of t2e pig -"ring -e4atering r"n !2all not eAcee- 1%/ 8,/2r O0%9 ,/!ec%R

10%CPig !2all +e trac8e- +y pig !ignal! in!talle- at la"nc2er! an- receiver%

10%0 D"ring t2e arrival of t2e pig! at t2e receiving en- of t2e pipeline t2e -i!c2arge flo4 !2all +e t2rottle-

-o4n !"c2 t2at t2e pig !pee- i! al,o!t Bero 42en entering into t2e receiver3 to avoi- -a,age to t2e

receiving facilitie!%

10%D Kpon pig arrival at trap% (2e pig 4ill +e p"lle- o"t in pre!ence of Contractor/Co,pany

repre!entative an- 4ill +e caref"lly eAa,ine-%

10%9 After t2e acceptance of -e4atering +y Co,pany3 pipeline !2all +e relea!e- for !"+!e;"ent

!4apping an- -rying activitie!%

10%10 (2e 4ater 4ill +e -irectly tran!ferre- +y te,porary !pool! to t2e 2

n-

!ection to +e 2y-ro=te!te-%

09.1 S'a==ig

1D%1 )4a++ing operation !2all +e perfor,e- only after !ati!factorily re,oving +"l8 of 4ater fro, t2e

pipeline%

1D%2 Foa,/)ponge pig !2all +e la"nc2e- t2ro"g2 pig la"nc2er an- propelle- 4it2 co,pre!!e- air%

D"ring !4a++ing operation3 t2e valve at receiver !2all +e t2rottle- for 8eeping a +ac8 pre!!"re of

0%/ +ar% (2i! 4ill +e p"lle- o"t at t2e receiving en- in t2e pre!ence of <'C repre!entative%

1D%1 Foa, pig !2all +e 4eig2e- prior to an- after co,pletion of eac2 r"n% 6eig2t! !2all +e recor-e- to

-eter,ine t2e a,o"nt of 4ater collecte- +y foa, pig%

1D%9 Foa,/)ponge pig! r"n! 4ill +e repeate-3 "ntil !ati!factory re!"lt i! o+tain an- accepte- +y <'C

tea,

1D%/ Date an- (i,e! of pig la"nc2ing an- receiving a! 4ell a! con-ition of pig! at receiver !2all +e

recor-e- in t2e attac2e- for,at!%

0:.1 Dr#ig

19%1 (2e air=-rying operation !2all +e co,,ence- 4it2in 29 2o"r! of co,pletion of t2e -e4atering an-

!4a++ing operation%

19%2 (2e inlet air i! to +e -ry an- 2ave a ,aAi,", -e4 point of =/0XC at at,o!p2ere pre!!"re% (2e

-rying !2all +e verifie- +y ,ea!"ring t2e air -e4 point at inlet an- o"tlet% (2e -e4 point !2all +e =

.'(//00

N

o

n

9

n

t

r

u

#

i

v

e

P

i

g

i

g

n

u

l

e

r

P

r

e

#

#

u

r

e

G

u

a

g

e

R

e

l

i

e

f

0

a

l

v

e

A

i

r

C

o

m

p

r

e

#

#

o

r

N

o

n

9

n

t

r

u

#

i

v

e

P

i

g

i

g

n

u

l

e

r

T

)

r

o

t

l

i

n

g

0

a

l

v

e

Receiver (aunc)er

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 1/ of 19

20X C%

19%1 D"ring -rying t2e -e4 point !2all +e contin"o"!ly recor-e- at +ot2 en-! of pipeline !ection! to

-etect pea8! in 4ater -e4 point% n partic"lar3 t2e -rying !2all +e con!i-ere- co,plete 42en t2e

re;"ire- -e4 point of= 20X C at at,o!p2eric pre!!"re !2all +e recor-e- contin"o"!ly%

19%9 After co,pletion of -rying operation3 all te,porary piping an- fitting! !2all +e re,ove-% (2e pipe

line !ection !2all +e clo!e- off%

31.1 P+rgig

20%1 P"rging !2all +e a! per approve- proce-"re to +e !"+,itte- +efore co,,i!!ioning%

30.1 Attac%&ets

21%1 Cleaning Report

21%2 Pipeline *a"ging n!pection Report

21%1 Pre!!"re an- (e,perat"re :og Filling :og%

21%9 Pre!!"riBation Recor- Pre!!"re an- (e,perat"re :og

21%/ Pre!!"re (e!t Certificate Pre!!"riBation Recor-

21%C Pre!!"re (e!t )pecification

21%0 Depre!!"riBation Recor-%

21%D Pipeline !4a++ing report%

21%9 Pipeline Drying report

21%10 Pipeline P"nc2 :i!t

21%11 Pre=2y-ro te!t c2ec8li!t

21%12 Po!t 2y-ro!tatic te!t c2ec8li!t

21%11 Pre!!"re/vol",e calc"lation for entrappe- air percentage

21%19 Pipeline *a"ging n!pection Report

21%1/ Corro!ion n2i+itor Pro-"ct #"lletin%

(2e te,porary pig la"nc2er an- receiving trap!

.'(//00

:;

7;

7;

Pipeline 1nd Flange

Bi Direction

,:

;

P

r

e

#

#

u

r

i

"

i

n

g

7; 7;

6

a

i

n

F

i

l

l

i

n

g

F

i

l

l

i

n

g

F

i

l

l

i

n

g

F

o

r

P

i

g

9

n

d

i

c

a

t

o

r

F

o

r

P

G

,

P

R

,

D

W

T

Pig upport

$<drote#t $eader (aunc)er and Reciever

-

N

o

4

5

.

-

N

o

4

7

.

-

N

o

4

,

.

Pipe,ie H#!rotestig Proce!+re

Doc Ref : QCP/

!!"e : #

Date : 01 May 2011

Page! : 1C of 19

.'(//00

You might also like

- Method Statement - Pressing of Plate To Be Pipe - SignDocument9 pagesMethod Statement - Pressing of Plate To Be Pipe - SignrichadNo ratings yet

- Piping Tie in Procedure Rev ADocument15 pagesPiping Tie in Procedure Rev AAnh Võ91% (23)

- Method Statement For Pipe Support Fabrication and Installation 6423dp420!00!0030000 - Rev01Document21 pagesMethod Statement For Pipe Support Fabrication and Installation 6423dp420!00!0030000 - Rev01mister pogi80% (41)

- Qcf301 Hydrotest Package - (Piping) - SampleDocument1 pageQcf301 Hydrotest Package - (Piping) - Sampleminhnn75% (4)

- Hot Tap PipingDocument21 pagesHot Tap PipingRachel FloresNo ratings yet

- 004 - Method of Statement of BendingDocument9 pages004 - Method of Statement of Bendingahmed08839494100% (1)

- MIS-M-DS-04045 Closed Drain Drum Data Sheet-BDocument3 pagesMIS-M-DS-04045 Closed Drain Drum Data Sheet-Bhappale2002No ratings yet

- Gap Control For Socket Weld Back Welded Threaded FittingsDocument12 pagesGap Control For Socket Weld Back Welded Threaded Fittingslaz_k100% (1)

- Api 1104 Acceptance CriteriaDocument6 pagesApi 1104 Acceptance CriteriaWillykateKairu75% (4)

- Reaction Mechanism PDFDocument57 pagesReaction Mechanism PDFsachin pant50% (2)

- Cembinder 8 TDSDocument1 pageCembinder 8 TDSkbkshanakaNo ratings yet

- Astm G 48Document9 pagesAstm G 48nisha_khanNo ratings yet

- Ml-13 Work Procedure For Tie - in WeldingDocument9 pagesMl-13 Work Procedure For Tie - in WeldingBrijesh Katariya VCSNo ratings yet

- Hydrotest Prosedure - All ProjectDocument7 pagesHydrotest Prosedure - All ProjectRony Sevenfold SweetChild OfMine'Rezpec100% (1)

- Hydrotest Procedure For PipelineDocument12 pagesHydrotest Procedure For Pipelineaike_579% (14)

- Procedure For Mainline Hydrotest by NitrogenDocument10 pagesProcedure For Mainline Hydrotest by Nitrogenmauls291No ratings yet

- 18-Weld Joint NumberingDocument5 pages18-Weld Joint NumberingAkhilesh Kumar100% (2)

- Ms For Repair of LR TankDocument6 pagesMs For Repair of LR Tankdadz mingiNo ratings yet

- Appendix 2F Pipeline Hydro Test PlanDocument23 pagesAppendix 2F Pipeline Hydro Test PlanSanjay KumarNo ratings yet

- Hottap ProcedureDocument4 pagesHottap Procedureparas_gemilang5853100% (1)

- PSM 2 - Flooding, Cleaning, Gauging & Hydrotesting During Pre-Comm ProcessDocument29 pagesPSM 2 - Flooding, Cleaning, Gauging & Hydrotesting During Pre-Comm ProcessMohamad Shukri100% (2)

- Inline Hydro TestDocument7 pagesInline Hydro TestjeswinNo ratings yet

- Hydro Testing in Crosscountry PipelineDocument22 pagesHydro Testing in Crosscountry Pipelinemadhunikhil56% (9)

- AB-522 Standard Pneumatic Test Procedure RequirementsDocument16 pagesAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNo ratings yet

- Hydrotesting of PipelineDocument14 pagesHydrotesting of PipelineJWC Sales & Services :100% (2)

- Pipeline CrossingDocument1 pagePipeline CrossingJustin IttmannNo ratings yet

- 30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingDocument21 pages30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingkilioNo ratings yet

- Vessel Cleaning ProcedureDocument6 pagesVessel Cleaning ProcedureZool HilmiNo ratings yet

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- Pipeline Cleaning, Gauging & Hydrostatic TestingDocument6 pagesPipeline Cleaning, Gauging & Hydrostatic TestingPahala2016 toga100% (2)

- JMS - Snuffing Pipe Installation Rev 1Document17 pagesJMS - Snuffing Pipe Installation Rev 1mohd as shahiddin jafriNo ratings yet

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- 22.MS For HydrotestDocument9 pages22.MS For HydrotestASHWANINo ratings yet

- WPS-PQR For Split TeeDocument9 pagesWPS-PQR For Split TeemaheshmalaichamyNo ratings yet

- Hot Tapping Calculations PDFDocument17 pagesHot Tapping Calculations PDFMSNo ratings yet

- NBC - COLD PIPE BENDING PROCEDUREpdfDocument16 pagesNBC - COLD PIPE BENDING PROCEDUREpdfVarghese MathewNo ratings yet

- Visual Inspection Pr.Document7 pagesVisual Inspection Pr.mtariqmasood100% (1)

- Method Statement For Tie inDocument15 pagesMethod Statement For Tie inHandika Arie PratamaNo ratings yet

- Hot Tapping Proposal - R1 - OPaL - CEL PDFDocument42 pagesHot Tapping Proposal - R1 - OPaL - CEL PDFyuksenthil771984100% (3)

- Method Statement of Hot BoltingDocument4 pagesMethod Statement of Hot BoltingMur Live75% (4)

- Pipe Lowering CalculationDocument8 pagesPipe Lowering CalculationMochamad Safarudin50% (4)

- Attachment 6 - Piping Test Package (Manifold 206) - A4A0Z9 PDFDocument13 pagesAttachment 6 - Piping Test Package (Manifold 206) - A4A0Z9 PDFMd asrar ali100% (1)

- Post Weld Head Treament Piping-ProcedureDocument12 pagesPost Weld Head Treament Piping-ProcedureAnh Võ100% (1)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pages046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNo ratings yet

- Project Schedule E3-1301 PDFDocument1 pageProject Schedule E3-1301 PDFzaihasrenNo ratings yet

- Piping Release Report (Spool For Paint)Document2 pagesPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Piping Fabrication, Installation, Erection, and TestingDocument33 pagesPiping Fabrication, Installation, Erection, and Testingaop1046889% (9)

- (Package-2-Mech Works) : Clean Fuels ProjectDocument17 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Rabigh Ii Project Interconecting Package (Uo1) : Hydrostatic Test Pressure Record SheetDocument2 pagesRabigh Ii Project Interconecting Package (Uo1) : Hydrostatic Test Pressure Record SheetDilshad AhemadNo ratings yet

- PCVL Pigging Procedure (RB-B To RB-A)Document9 pagesPCVL Pigging Procedure (RB-B To RB-A)hai dang maiNo ratings yet

- MJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)Document11 pagesMJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)frusdt100% (4)

- Conpipe - CementlingDocument43 pagesConpipe - Cementlingויליאם סן מרמיגיוס50% (2)

- Hdpe Pipe Method StatementDocument6 pagesHdpe Pipe Method StatementAfiq Jamal100% (1)

- ITP Heat ExchangerDocument3 pagesITP Heat ExchangerĐỗ Thị Huyền100% (3)

- Execution Procedure For Pipe Connection Tie in and Hot TapzDocument7 pagesExecution Procedure For Pipe Connection Tie in and Hot TapzyuwantoniNo ratings yet

- Piping Hydrotest Procedure - Oil - Gas - WorldDocument3 pagesPiping Hydrotest Procedure - Oil - Gas - WorldFrank100% (7)

- Method Statement For Plumbing Piping Works Rev 01Document46 pagesMethod Statement For Plumbing Piping Works Rev 01sakhrs2000No ratings yet

- U-00034-PR-CRT-0001 - Rev.ADocument46 pagesU-00034-PR-CRT-0001 - Rev.AthinhviproNo ratings yet

- SECTION 22 15 00 General Service Compressed-Air SystemsDocument8 pagesSECTION 22 15 00 General Service Compressed-Air Systemsm2110No ratings yet

- Procedure For Fab, Erec & Testing of Abovegroud PipingDocument16 pagesProcedure For Fab, Erec & Testing of Abovegroud Pipingvpsimbu86No ratings yet

- HUP & LUP CCS C64A HDB Housekeeping & Safety Audit Report 13.01.2011Document9 pagesHUP & LUP CCS C64A HDB Housekeeping & Safety Audit Report 13.01.2011Shahid Ali100% (1)

- Verify Correct Version Before Use.: PRC-5002 Rev. EDocument9 pagesVerify Correct Version Before Use.: PRC-5002 Rev. EkonazoiNo ratings yet

- MASTER Less Than 500 Core SyllabDocument11 pagesMASTER Less Than 500 Core SyllabNelum PereraNo ratings yet

- Offcon DNV Zorro SkidDocument6 pagesOffcon DNV Zorro SkiddakidofdaboomNo ratings yet

- B31.4 Calculator Ver 1Document88 pagesB31.4 Calculator Ver 1Sunday Paul100% (2)

- Offcon DNV Zorro SkidDocument6 pagesOffcon DNV Zorro SkiddakidofdaboomNo ratings yet

- Piping Design AidsDocument248 pagesPiping Design AidsSunday PaulNo ratings yet

- Spray Drying TheoryDocument36 pagesSpray Drying TheorySunday PaulNo ratings yet

- Journal Pone 0074403 s001Document3 pagesJournal Pone 0074403 s001Sunday PaulNo ratings yet

- Spray Dryer DesignDocument38 pagesSpray Dryer DesignSunday PaulNo ratings yet

- Questions API 1104 Initial - 001Document3 pagesQuestions API 1104 Initial - 001Sunday Paul100% (1)

- Dryiig DataDocument3 pagesDryiig DataSunday PaulNo ratings yet

- Guidelines For User Acceptance TestingDocument11 pagesGuidelines For User Acceptance TestingSunday Paul100% (1)

- Urfactants: What Do They Do?Document1 pageUrfactants: What Do They Do?Sunday PaulNo ratings yet

- Dimesiones Tee's EnvolventeDocument4 pagesDimesiones Tee's EnvolventeJuan Carlos Dominguez Bta0% (1)

- Temperature and Expanding Radius of PipeDocument2 pagesTemperature and Expanding Radius of PipeShreyasGadkariNo ratings yet

- Chemistry Revision 2 For Test 2: Collision Theory and Rate of ReactionDocument7 pagesChemistry Revision 2 For Test 2: Collision Theory and Rate of ReactionDaniel BerryNo ratings yet

- 2F-1 Kinetic Modelling of Biomass Gasification and CombustionDocument20 pages2F-1 Kinetic Modelling of Biomass Gasification and Combustionizzet1969No ratings yet

- Studies in Gas Solid ReactionsDocument8 pagesStudies in Gas Solid ReactionsumarlucioNo ratings yet

- Lab Methods: Aromatics, Olefins, and Saturates by FIADocument2 pagesLab Methods: Aromatics, Olefins, and Saturates by FIAjhalays7574No ratings yet

- B2.5.1 Proteins - B2.5.2 Enzymes: No Higher Tier ContentDocument3 pagesB2.5.1 Proteins - B2.5.2 Enzymes: No Higher Tier ContentRekaNo ratings yet

- PWD SR 11 12 KarnatakaDocument470 pagesPWD SR 11 12 Karnatakashravan38No ratings yet

- Application of Discrete Galvanic Anode Using Sika FerroGard-700s RebaDocument10 pagesApplication of Discrete Galvanic Anode Using Sika FerroGard-700s RebaArturo lopez abucharNo ratings yet

- Laptable: ManualDocument2 pagesLaptable: ManualDaniel BernardoNo ratings yet

- Methods TO CUT STEEL PLATEDocument4 pagesMethods TO CUT STEEL PLATEmaheshbandhamNo ratings yet

- Download ebooks file Cryogenic Valves for Liquefied Natural Gas Plants Karan Sotoodeh all chaptersDocument41 pagesDownload ebooks file Cryogenic Valves for Liquefied Natural Gas Plants Karan Sotoodeh all chapterscovelpeonyh7100% (3)

- Refrigeration and Air Conditioning Objective QuestionsDocument23 pagesRefrigeration and Air Conditioning Objective QuestionsMuhammad BilalNo ratings yet

- Student Safety Sheets ALLDocument106 pagesStudent Safety Sheets ALLEnanisshit AteightballpoolNo ratings yet

- Weld Repair of Manganese Frogs For Enhanced Safety Shared Service PDFDocument20 pagesWeld Repair of Manganese Frogs For Enhanced Safety Shared Service PDFpumud pumudNo ratings yet

- Hybrid PU Waterproofing Compound: DampflexDocument2 pagesHybrid PU Waterproofing Compound: DampflexVasanth KumarNo ratings yet

- Class 7 Science Electric Current and Its EffectsDocument7 pagesClass 7 Science Electric Current and Its Effectsshanna_heenaNo ratings yet

- Co2 System (GWS382 Final)Document178 pagesCo2 System (GWS382 Final)Phan Cao An TruongNo ratings yet

- Chapter 4 - Carbon and Its Compounds Handwritten NotesDocument19 pagesChapter 4 - Carbon and Its Compounds Handwritten NotesRanjan ChoudharyNo ratings yet

- Don Honorio Ventura State UniversityDocument53 pagesDon Honorio Ventura State UniversityAnna Kathrina Simon100% (1)

- G3 Current Modifications of Dental Adhesive Systems Forcomposite Resin Restorations A Review in Literature 2022Document17 pagesG3 Current Modifications of Dental Adhesive Systems Forcomposite Resin Restorations A Review in Literature 2022rc21004No ratings yet

- 450 AllDocument16 pages450 AllAnik AichNo ratings yet

- Instruction Manual LKH PumpDocument56 pagesInstruction Manual LKH PumpTaesoak YodongNo ratings yet

- Water Resources: Earth ScienceDocument18 pagesWater Resources: Earth ScienceRegina Mae Narciso Nazareno100% (1)

- Crystallization: Practica in Process Engineering IIDocument9 pagesCrystallization: Practica in Process Engineering IImeles hagosNo ratings yet

- Durability Index ManualDocument44 pagesDurability Index ManualSwathy ManoharNo ratings yet

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocument4 pages1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnNo ratings yet

- SSI Catalog-2011 PDFDocument16 pagesSSI Catalog-2011 PDFrafael100% (1)