Nylock Nut T

Nylock Nut T

Uploaded by

aiyubi2Copyright:

Available Formats

Nylock Nut T

Nylock Nut T

Uploaded by

aiyubi2Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Nylock Nut T

Nylock Nut T

Uploaded by

aiyubi2Copyright:

Available Formats

www.afssimmonds.net | info@afssimmonds.

net

Nylstop Series

The Original Nylon

Locking Nut

The Nylstop nut is designed to stop nut and bolt disengagement during use.

The internal nylon ring deforms around the threads as the nut is twisted on

to the bolt, ensuring a tight, vibration resistant grip on the bolt.

Benefits

Vibration resistant The deformation of the nylon ring holds the fastener in place even

under extreme vibration

Corrosion resistance The standard product is Zinc Nickel plated achieving a minimum

720 hours on salt spray test

Re-usability Can be fastened and unfastened a minimum of 15 times without

compromising minimum required performance (ISO 2320)

Consistency - The Nylstop nuts permits a complete

automation of installation because of constant quality

and very low scatter of the locking torque.

This allows installation without concerns of

defective or non-conforming nuts and reduces

the cost of monitoring and tight inspection.

Chemical resistance The nylon 6.6

polyamide used is completely insensitive to a

myriad of acids, solvents and oil based liquids

Temperature resistance Operating temperature range between

-40

o

C and 140

o

C (peak condition)

Also available:

CN/CF 70 Self locking, high quality, one piece, bearing nut

All the benefits of the standard Nylstop nut, with the additional benefit over a typical bearing nut of one

piece installation speed. No need for costly and time-consuming extra parts, reducing installation time.

Popular applications: Any industrial application

Diameters: M2.5 M52

Materials: Steel CL8 & CL10, Stainless Steel A2 & A4

Standard Coating: Zinc Nickel

Available in 2 different height varieties (P-Normal, T-Low)

www.afssimmonds.net | info@afssimmonds.net

Alcoa Fastening Systems

St Cosme Operations, 9 rue de Cressonnieres

72110 Saint Cosme en Varais, France

Tel: +33 (0) 2.43.31.41.00 Fax: +33 (0) 2.43.31.41.41

BSI Registered

FM 500602 ISO 9001:2000

TS 507118-000 ISO/TS 16949:2002

FM 500661 EN 9100:2003

FM 50061 AS 9100 Rev. B

EMS 500663 ISO 14001:2004

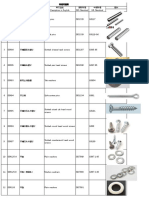

Nylstop Self Locking Nut - Type T

1.15A

A B

H

T D

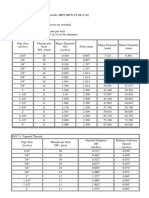

Class 6 Class 8 Stainless Nominal Pitch Part Number A B H T Weight in Kg

Steel Steel Steel (mm) Diam (replace ** with material code) h 13 Min Max Min 100 pcs (steel)

I I 4 0.70 M4T ** 7 1.8 4.7 2.3 0.080

I I 5 0.80 M5T ** 8 2.6 5.6 3.2 0.130

I I I 6 1.00 M6T ** 10 2.4 6.1 3.0 0.210

I 7 1.00 M7T ** 11 2.5 6.5 3.0 0.265

I I I 8 1.25 M8T ** 13 3.7 8.8 4.6 0.480

I 8 1.00 M8x100T ** 13 3.7 8.8 4.6 0.480

I I I 10 1.50 M10T ** 16 5.2 11.1 6.5 0.930

I I 10 1.25 M10x125T ** 16 5.2 11.1 6.5 0.930

I 10 1.00 M10x100T ** 16 5.2 11.1 6.5 0.930

I I I 12 1.75 M12T ** 18 5.7 11.7 7.1 1.200

I I 12 1.50 M12x150T ** 18 5.7 11.7 7.1 1.200

I I 12 1.25 M12x125T ** 18 5.7 11.7 7.1 1.200

I I 14 2.00 M14T ** 21 6.2 13.1 7.7 1.900

I I 14 1.50 M14x150T ** 21 6.2 13.1 7.7 1.900

I I 16 2.00 M16T ** 24 6.4 14.0 8.0 2.600

I I 16 1.50 M16x150T ** 24 6.4 14.0 8.0 2.600

I I 18 2.50 M18T ** 27 7.2 15.5 9.0 3.320

I 18 1.50 M18x150T ** 27 7.2 15.5 9.0 3.320

I I 20 2.50 M20T ** 30 8.0 16.6 10.0 4.600

I 20 1.50 M20x150T ** 30 8.0 16.6 10.0 4.600

I I 22 2.50 M22T ** 34 8.8 17.6 11.0 5.400

I 24 3.00 M24T ** 36 9.6 20.0 12.0 7.600

I 27 3.00 M27T ** 41 10.8 22.2 13.5 10.600

I 30 3.50 M30T ** 46 12.0 25.7 15.0 17.600

I 33 3.50 M33T ** 50 13.2 26.2 16.5 19.600

Standard Protections Steel - ZnNi 720 hours salt spray test

Please consult us for other materials, specials, treatments

Dimensions: according to NFE 25412

Performances: according to NFE 25400, 25408, and ISO 2320

The nuts indicated with a black dot are standard manufactured

Material Code

Code 06 steel class 06

Code 08 steel class 08

Code 52 stainless steel A2

Code 54 stainless steel A4

All dimensions are in mm unless stated.

You might also like

- Fasteners DIN - ISODocument2 pagesFasteners DIN - ISOcarbo60No ratings yet

- TL - 226 - EN - 2013-08-01 Paintworks On Materials Used in The Vehicle Interior Trim RequirementsDocument12 pagesTL - 226 - EN - 2013-08-01 Paintworks On Materials Used in The Vehicle Interior Trim Requirementsjacek.sadlonNo ratings yet

- Din 19704 - 2 2014Document38 pagesDin 19704 - 2 2014Husam Al-QadasiNo ratings yet

- 螺丝代号对照表Document38 pages螺丝代号对照表里差No ratings yet

- Circlip CatalogueDocument18 pagesCirclip CatalogueCALVINNo ratings yet

- Standard Series Limits Size-Unified and American Screw Threads PDFDocument19 pagesStandard Series Limits Size-Unified and American Screw Threads PDFrefaeNo ratings yet

- (Inches) (Inches) : (BSPT, BSPTR, PT, KR, R, RC)Document2 pages(Inches) (Inches) : (BSPT, BSPTR, PT, KR, R, RC)ainul yakinNo ratings yet

- General Tolerances - DIN - IsO - 2768Document1 pageGeneral Tolerances - DIN - IsO - 2768Luis Eduardo García MaltosNo ratings yet

- Unf ThreadDocument1 pageUnf Threadhisaj4uNo ratings yet

- Carriage Bolt Square Neck Round Head ScrewsDocument1 pageCarriage Bolt Square Neck Round Head ScrewsBalaji Kanduri100% (1)

- Cotter Pins - Split PinsDocument2 pagesCotter Pins - Split Pinsguri317No ratings yet

- Shackle Din 82101Document1 pageShackle Din 82101viahulNo ratings yet

- Metric BoltsDocument52 pagesMetric BoltsDGW100% (1)

- Angle Section DimensionsDocument4 pagesAngle Section DimensionsAnonymous q0irDXlWAmNo ratings yet

- Unifai Screw INCHDocument21 pagesUnifai Screw INCHAnonymous RgGtg29No ratings yet

- High Strength Low Alloy SteelDocument1 pageHigh Strength Low Alloy SteelBudi HermanaNo ratings yet

- Metric Washer FlatDocument4 pagesMetric Washer Flatjontylee87No ratings yet

- Totten CatalogDocument19 pagesTotten CatalogxpertsteelNo ratings yet

- Hardness Conversion ChartDocument3 pagesHardness Conversion ChartJRodNo ratings yet

- Weight For Bolt With Nut PDFDocument1 pageWeight For Bolt With Nut PDFRam RajaramanNo ratings yet

- SOUTHLAND PIPE, Steel Pipe General Data Size Chart, Steel Pipe Sales, NationwideDocument3 pagesSOUTHLAND PIPE, Steel Pipe General Data Size Chart, Steel Pipe Sales, Nationwidea769No ratings yet

- Thread Standard BSPDocument7 pagesThread Standard BSPĐạt TrầnNo ratings yet

- Socket Head Cap ScrewsDocument16 pagesSocket Head Cap ScrewsyauctionNo ratings yet

- AWS 5.15 Cast Iron ElectrodesDocument30 pagesAWS 5.15 Cast Iron ElectrodesMed Ali SmaouiNo ratings yet

- Hex NutsDocument10 pagesHex Nutsjaskaran singhNo ratings yet

- Steel PipeDocument39 pagesSteel PipeJay PanalanginNo ratings yet

- M45913-1 RevADocument4 pagesM45913-1 RevAMAI_QualityNo ratings yet

- ASME B18.31.4M Threaded Rod MetricDocument4 pagesASME B18.31.4M Threaded Rod MetricJEff MNo ratings yet

- Limits of Size-Unified Screw ThreadsDocument7 pagesLimits of Size-Unified Screw Threadsxeron7126No ratings yet

- Section Q: Splined Hubs, Drive KitsDocument8 pagesSection Q: Splined Hubs, Drive KitshaggNo ratings yet

- Self Tapping ScrewDocument4 pagesSelf Tapping Screwskalimuthu190No ratings yet

- ASTM A 681-08 Standard Specification For Tool Steels AlloyDocument14 pagesASTM A 681-08 Standard Specification For Tool Steels AlloyTeodoroNo ratings yet

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- Kim FastenerDocument5 pagesKim FastenerIT KenzioTechNo ratings yet

- 08chapter6 ShaftfixingsDocument12 pages08chapter6 Shaftfixingsreinaldosidejunior100% (1)

- Steel Preheating ChartDocument1 pageSteel Preheating ChartKhuram ShahzadNo ratings yet

- Tapping Torque Values PDFDocument1 pageTapping Torque Values PDFNitin AggarwalNo ratings yet

- Pins and KeysDocument12 pagesPins and KeysSam GillilandNo ratings yet

- Thread Tolerances For Screws and NutsDocument2 pagesThread Tolerances For Screws and NutsBill WhiteNo ratings yet

- Self-Cutting Screws enDocument10 pagesSelf-Cutting Screws enFederico.IoriNo ratings yet

- Iso 7380Document8 pagesIso 7380Joshua SmithNo ratings yet

- Thread TolerancesDocument8 pagesThread TolerancesLê Xuân HiệpNo ratings yet

- UNC and UNF - Unified Inch Screw ThreadsDocument8 pagesUNC and UNF - Unified Inch Screw ThreadsPatrick FaelNo ratings yet

- Hague Fasteners 2014 Special Fasteners BrochureDocument16 pagesHague Fasteners 2014 Special Fasteners Brochuren1ghtfallNo ratings yet

- Asme Ansi b16.11 Fittings DimensionDocument23 pagesAsme Ansi b16.11 Fittings DimensionAlvaro Enrique MuñozNo ratings yet

- Welding Instructions For Toolholders: Material Microalloyed Heat-Treatable Steel 34Mncrb4+TiDocument1 pageWelding Instructions For Toolholders: Material Microalloyed Heat-Treatable Steel 34Mncrb4+TiVetriselvan ArumugamNo ratings yet

- Steel Pipes - Pipe Schedule ChartDocument1 pageSteel Pipes - Pipe Schedule ChartidiayNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- DIN13 ISO Metric Threads enDocument1 pageDIN13 ISO Metric Threads enwagner jr100% (1)

- Astm A 453 Grade 660Document4 pagesAstm A 453 Grade 660Bruno_jfNo ratings yet

- Track Bolts and Nuts ASME B18.1f0-2006Document9 pagesTrack Bolts and Nuts ASME B18.1f0-2006ZoebairNo ratings yet

- Fastener StandardsDocument8 pagesFastener StandardsGunnie PandherNo ratings yet

- DIN 934 NutsDocument1 pageDIN 934 NutsleroniusNo ratings yet

- Flat Washers Standard MetricDocument4 pagesFlat Washers Standard MetricsivaNo ratings yet

- Tower Bolts - Specification: Indian StandardDocument12 pagesTower Bolts - Specification: Indian StandardRamesh MankaniNo ratings yet

- Din en Iso 2338Document1 pageDin en Iso 2338Janak MistryNo ratings yet

- Astm A514 1977Document6 pagesAstm A514 1977Elumalai Srinivasan100% (1)

- 01 Wiha Complete Product GuideDocument52 pages01 Wiha Complete Product GuidepietrokoNo ratings yet

- Nicote Cable Glands CatalogueDocument13 pagesNicote Cable Glands Cataloguekvp0107No ratings yet

- Conveyor Belt Installtion SplicingDocument71 pagesConveyor Belt Installtion SplicingMatthew Butler75% (4)

- R-KER Vinylester Resin + Steel Rods 5.8 M8 - M30: Technical Data SheetDocument7 pagesR-KER Vinylester Resin + Steel Rods 5.8 M8 - M30: Technical Data SheetChristian LazzariniNo ratings yet

- BrecoFLex Special BeltDocument28 pagesBrecoFLex Special BeltachinvanshNo ratings yet

- Re10231 2014-07Document16 pagesRe10231 2014-07aiyubi2No ratings yet

- Cat TECO Motori Ghisa EN - Rev 3 - 2022 - WEBDocument92 pagesCat TECO Motori Ghisa EN - Rev 3 - 2022 - WEBaiyubi2No ratings yet

- 05hose Clamps and ClipsDocument6 pages05hose Clamps and Clipsaiyubi2No ratings yet

- Kukmc 0377 UsDocument2 pagesKukmc 0377 Usaiyubi2No ratings yet

- Fifthwheel - JOST JSK 38CDocument2 pagesFifthwheel - JOST JSK 38Caiyubi2100% (2)

- Repair Manual JSK 38Document38 pagesRepair Manual JSK 38aiyubi2No ratings yet

- JSK 38 C-1 JSK 38 C-2": Heavy Duty Fi FTH Wheel Couplings 3 / " and 2"Document2 pagesJSK 38 C-1 JSK 38 C-2": Heavy Duty Fi FTH Wheel Couplings 3 / " and 2"aiyubi2No ratings yet

- Crosby Mckissick Sheaves CatalogDocument29 pagesCrosby Mckissick Sheaves Catalogaiyubi2No ratings yet

- DRIV-LOK Press Fit FastenersDocument28 pagesDRIV-LOK Press Fit Fastenersaiyubi2No ratings yet

- Wire Rope ThimblesDocument1 pageWire Rope Thimblesaiyubi2No ratings yet

- CROSBY Master Link & Shackles - MetricDocument2 pagesCROSBY Master Link & Shackles - Metricaiyubi2No ratings yet

- Circlips - Blue DiamondDocument6 pagesCirclips - Blue Diamondaiyubi2No ratings yet

- MIKI Spring Actuated BrakesDocument8 pagesMIKI Spring Actuated Brakesaiyubi2No ratings yet

- A-344 & A347 Welded Master Link - ImperialDocument1 pageA-344 & A347 Welded Master Link - Imperialaiyubi2No ratings yet

- MIKI Electromagnetic Toothed ClutchDocument7 pagesMIKI Electromagnetic Toothed Clutchaiyubi2No ratings yet

- MIKI Electromagnetic Clutches and BrakesDocument38 pagesMIKI Electromagnetic Clutches and Brakesaiyubi2100% (1)

- Glenwood Coupling CatalogDocument3 pagesGlenwood Coupling Catalogaiyubi2No ratings yet

- 2801.0 FSI Catalogue 1Document7 pages2801.0 FSI Catalogue 1tongaiNo ratings yet

- BS EN 362 2004 Fall From Height ConnectorsDocument20 pagesBS EN 362 2004 Fall From Height ConnectorsAluosh AluoshNo ratings yet

- Hic and SSC Test, Corrosion Testing, Salt Spray, Pitting, Nace Tm0284, Nace Tm0177, Astm b117, Astm g48Document2 pagesHic and SSC Test, Corrosion Testing, Salt Spray, Pitting, Nace Tm0284, Nace Tm0177, Astm b117, Astm g48esakkibabu1987No ratings yet

- Final Low Res 16288 Molykote Afc Brochure 001 20263 Agp0420Document16 pagesFinal Low Res 16288 Molykote Afc Brochure 001 20263 Agp0420Gaurav AnandNo ratings yet

- F 1137 - 00 - RjexmzcDocument2 pagesF 1137 - 00 - RjexmzckrutikNo ratings yet

- BS en 10245-1-2011Document22 pagesBS en 10245-1-2011John MearyNo ratings yet

- Carbothane 133 HB: Selection & Specification DataDocument5 pagesCarbothane 133 HB: Selection & Specification DatalavekushNo ratings yet

- NASA Process Specification For Nickel PlatingDocument10 pagesNASA Process Specification For Nickel PlatingRam ViswanathanNo ratings yet

- 10 Jotun Solutions To Oil & GasDocument74 pages10 Jotun Solutions To Oil & GasAntony Bruno Genewin100% (2)

- KS - Series - QuadCore - Masterformat - CSI Specification - NADocument14 pagesKS - Series - QuadCore - Masterformat - CSI Specification - NAHector Danilo Guerrero GNo ratings yet

- Flyer23 12 ZFC Zintek300 Techseal Glossy BlackDocument2 pagesFlyer23 12 ZFC Zintek300 Techseal Glossy BlackSyedMazharAliShahNo ratings yet

- Mil T 10727BDocument12 pagesMil T 10727BnightmanmxNo ratings yet

- 01salt Spray Test 1000 Hour2Document4 pages01salt Spray Test 1000 Hour2Đình Khoa PhanNo ratings yet

- Everlube 620 TDSDocument2 pagesEverlube 620 TDSValentinNo ratings yet

- Iapmo Z124.5-2013 (Sanitarios)Document24 pagesIapmo Z124.5-2013 (Sanitarios)Sandra GuerraNo ratings yet

- GalvInfoNote - 3 - 4 The Salt Spray TestDocument4 pagesGalvInfoNote - 3 - 4 The Salt Spray TestKYAW SOENo ratings yet

- Amer Coat 385Document4 pagesAmer Coat 385Mehman NasibovNo ratings yet

- 09 Samss 107Document11 pages09 Samss 107YOUSUF KHANNo ratings yet

- Dse PN MetricDocument29 pagesDse PN MetricSuman DeyNo ratings yet

- 20 Korrosionsschutz enDocument4 pages20 Korrosionsschutz enNenad DeusicNo ratings yet

- HUS 3 HF Corrosion Leaflet en W4401Document6 pagesHUS 3 HF Corrosion Leaflet en W4401Anonymous sGqb4AnNo ratings yet

- ISO 8434 6 - 2007 60 Code Cone Connectors With or Without O-RingDocument50 pagesISO 8434 6 - 2007 60 Code Cone Connectors With or Without O-RingDiyan IrawanNo ratings yet

- Katalog En2017 CDDocument359 pagesKatalog En2017 CDFábio Da Silva AlanoNo ratings yet

- Pressure Relief ValveDocument24 pagesPressure Relief Valvevinoth.kumarNo ratings yet

- Guide To Protective Coating Systems Using Iso12944 27feb2023Document12 pagesGuide To Protective Coating Systems Using Iso12944 27feb2023CeciliaNo ratings yet

- BN 562161-108 enDocument18 pagesBN 562161-108 endaria.anielskaNo ratings yet

- RD.120 Hardware Technical Leaflet - Document Version V36Document14 pagesRD.120 Hardware Technical Leaflet - Document Version V36jasmin selimićNo ratings yet

- MIL-DTL-5541 Rev F - Part4Document1 pageMIL-DTL-5541 Rev F - Part4David WongNo ratings yet