0 ratings0% found this document useful (0 votes)

556 viewsSteel Preheating Chart

Steel Preheating Chart

Uploaded by

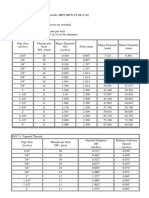

Khuram ShahzadThis document provides a chart for recommended preheating temperatures for welding various steel alloys based on their carbon content. It lists steel groups including plain carbon steel, carbon moly steels, manganese steels, high tensile steels, nickel steel, medium nickel chromium steel, moly chromium and chromium nickel steels, low chrome moly steels, medium chrome moly steel, and high chrome steels. For each alloy, it specifies the carbon content range and recommended preheat temperature to eliminate cracking, reduce distortion, and prevent shrinkage stresses during welding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Steel Preheating Chart

Steel Preheating Chart

Uploaded by

Khuram Shahzad0 ratings0% found this document useful (0 votes)

556 views1 pageThis document provides a chart for recommended preheating temperatures for welding various steel alloys based on their carbon content. It lists steel groups including plain carbon steel, carbon moly steels, manganese steels, high tensile steels, nickel steel, medium nickel chromium steel, moly chromium and chromium nickel steels, low chrome moly steels, medium chrome moly steel, and high chrome steels. For each alloy, it specifies the carbon content range and recommended preheat temperature to eliminate cracking, reduce distortion, and prevent shrinkage stresses during welding.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides a chart for recommended preheating temperatures for welding various steel alloys based on their carbon content. It lists steel groups including plain carbon steel, carbon moly steels, manganese steels, high tensile steels, nickel steel, medium nickel chromium steel, moly chromium and chromium nickel steels, low chrome moly steels, medium chrome moly steel, and high chrome steels. For each alloy, it specifies the carbon content range and recommended preheat temperature to eliminate cracking, reduce distortion, and prevent shrinkage stresses during welding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

556 views1 pageSteel Preheating Chart

Steel Preheating Chart

Uploaded by

Khuram ShahzadThis document provides a chart for recommended preheating temperatures for welding various steel alloys based on their carbon content. It lists steel groups including plain carbon steel, carbon moly steels, manganese steels, high tensile steels, nickel steel, medium nickel chromium steel, moly chromium and chromium nickel steels, low chrome moly steels, medium chrome moly steel, and high chrome steels. For each alloy, it specifies the carbon content range and recommended preheat temperature to eliminate cracking, reduce distortion, and prevent shrinkage stresses during welding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

STEEL PREHEATING CHART

Pre-Heating will eliminate crack formation,

reduce distortion and prevent shrinkage stresses

Metal Metal %C Recommended

Group Designation Preheat ( F)0

Plain Plain carbon steel Below.20 Up to 200

Carbon Plain carbon steel .20-.30 200-300

Steel Plain carbon steel .30-.45 300-500

Plain carbon steel .45-.80 500-800

Carbon Moly Carbon moly steel .10-.20 300-500

Steels Carbon moly steel .20-.30 400-600

Carbon moly steel .30-.35 500-800

Manganese Silicon structural steel .35 300-500

Steels Medium Manganese steel .20-.30 300-500

SAE T 1330 steel .30 400-600

SAE T 1340 steel .40 500-800

SAE T 1350 steel .50 600-900

12% Manganese steel 1.25 Usually not required

High Tensile Manganese moly steel .20 300-500

Steels Manten steel .30 max 400-600

Armco high Tensile steel .12 max Up to 200

Mayari R steel .20 max Up to 300

Nax high tensile .15-.25 Up to 300

Cromansil steel .14 max 300-400

Corten steel .12 max 200-400

Yoloy steel .05-.35 200-600

Nickel SAE 2015 steel .10-.20 200-300

Steel SAE 2115 steel .10-.20 200-300

2 1/2% nickel steel .10-.20 200-400

SAE 2315, 2320 steel .15-.20 200-500

SAE 2330, 2340 steel .30-.40 400-600

Medium SAE 3115, 3125 steel .15-.25 300-400

Nickel Chromium SAE 3130, 3140 steel .30-.40 500-700

Steel SAE 3150 steel .50 600-900

SAE 3215, 3230 steel .15-.30 400-600

SAE 3240, 3250 steel .40-.50 800-1000

SAE 3315 steel .15 500-700

SAE 3325, 3435 & 3450 .25-50 900-1100

Moly Chromium SAE 4140 steel .40 600-800

& Chromium Nickel SAE 4340 steel .40 700-900

Steels SAE 4615 steel .15 400-600

SAE 4630 steel .30 500-700

SAE 4640, 4820 steel .40-20 600-800

Low Chrome Moly 2% Cr. - 1/2% Mo.steel Up to .15 400-600

Steels 2% Cr. - 1/2% Mo. steel .15-.25 500-800

2% Cr. - 1% Mo. steel Up to .15 500-700

2% Cr. - 1% Mo. steel .15 max 600-800

Medium 5% Cr. - 1/2% Mo. steel Up to .15 500-800

Chrome Moly 5% Cr. - 1/2% Mo. steel .15-.25 600-900

Steel 8% Cr. - 1% Mo. steel .15 max 600-900

High Chrome 12-14% Cr. type 410 .10 300-500

Steels 16-18% Cr. type 430 .10 300-500

23-30% Cr. type 446 .10 300-500

The need for preheating increases as the following factors are changed.

1. The larger the mass being welded. 5. The greater the speed of welding.

2. The lower the temperature of the parts. 6. The higher the carbon content of the steel.

3. The lower the atmospheric temperature. 7. The greater the alloy content.

4. The smaller the weld rod in diameter. 8. The more complicated the shape.

You might also like

- Proth Psgs Manual PDFDocument106 pagesProth Psgs Manual PDFBala SingamNo ratings yet

- Broadway Ledger AnglesDocument8 pagesBroadway Ledger AnglesxpertsteelNo ratings yet

- Standard Series Limits Size-Unified and American Screw Threads PDFDocument19 pagesStandard Series Limits Size-Unified and American Screw Threads PDFrefaeNo ratings yet

- Measurements, Sizes, Shafts, KeywaysDocument91 pagesMeasurements, Sizes, Shafts, KeywaysVenkat DoraNo ratings yet

- Tapping Torque Values PDFDocument1 pageTapping Torque Values PDFNitin AggarwalNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings Bolt SpecificationDocument8 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings Bolt Specificationamir_hossein858No ratings yet

- NPT Thread ChartDocument1 pageNPT Thread ChartFredy Alvarez LucasNo ratings yet

- Socket Head Cap ScrewsDocument16 pagesSocket Head Cap ScrewsyauctionNo ratings yet

- British Thread (British Standard Whitworth) - Coarse PitchDocument1 pageBritish Thread (British Standard Whitworth) - Coarse Pitchhisaj4uNo ratings yet

- Unifai Screw INCHDocument21 pagesUnifai Screw INCHAnonymous RgGtg29No ratings yet

- Weight For Bolt With Nut PDFDocument1 pageWeight For Bolt With Nut PDFRam RajaramanNo ratings yet

- Hollow Bar ChartDocument1 pageHollow Bar Charthornet121No ratings yet

- Metric Tolerances and Thread PitchDocument2 pagesMetric Tolerances and Thread PitchEnDjo Ech Rahardjo100% (1)

- Flat Washers Standard MetricDocument4 pagesFlat Washers Standard MetricsivaNo ratings yet

- NPT Thread Chart - NPT & NPS Fittings Dimensions & SizesDocument2 pagesNPT Thread Chart - NPT & NPS Fittings Dimensions & SizesMarc EdwardsNo ratings yet

- Metric Washer FlatDocument4 pagesMetric Washer Flatjontylee87No ratings yet

- Cotter Pins - Split PinsDocument2 pagesCotter Pins - Split Pinsguri317No ratings yet

- Asme Ansi b16.11 Fittings DimensionDocument23 pagesAsme Ansi b16.11 Fittings DimensionAlvaro Enrique MuñozNo ratings yet

- How To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincDocument15 pagesHow To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincAndré BuysNo ratings yet

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranNo ratings yet

- Weldability of MaterialsDocument5 pagesWeldability of MaterialsclnNo ratings yet

- Nylock Nut TDocument2 pagesNylock Nut Taiyubi2No ratings yet

- Kim FastenerDocument5 pagesKim FastenerIT KenzioTechNo ratings yet

- Fastener Tech DetailsDocument1 pageFastener Tech DetailsRanganathan SekarNo ratings yet

- Thread - Drill & Tap ChartDocument2 pagesThread - Drill & Tap ChartullwnNo ratings yet

- Unf ThreadDocument1 pageUnf Threadhisaj4uNo ratings yet

- Basic Metric Thread Chart (M1 - M100) - Fuller Fasteners - Fuller FastenersDocument2 pagesBasic Metric Thread Chart (M1 - M100) - Fuller Fasteners - Fuller FastenersSOURABH KNo ratings yet

- Pipe Sizes ThreadsDocument2 pagesPipe Sizes ThreadsSumner TingNo ratings yet

- Metric Bolt StrengthDocument18 pagesMetric Bolt StrengthSachin ShindeNo ratings yet

- (Inches) (Inches) : (BSPT, BSPTR, PT, KR, R, RC)Document2 pages(Inches) (Inches) : (BSPT, BSPTR, PT, KR, R, RC)ainul yakinNo ratings yet

- AISI 4130: Incoloy Alloys, Fast QuoteDocument5 pagesAISI 4130: Incoloy Alloys, Fast QuoteSantanu SahaNo ratings yet

- Angle Section DimensionsDocument4 pagesAngle Section DimensionsAnonymous q0irDXlWAmNo ratings yet

- ISMC StandardDocument2 pagesISMC Standardauazar0% (1)

- JIS-B-1251 Product CatalogueDocument4 pagesJIS-B-1251 Product CataloguePrabath MadusankaNo ratings yet

- Welding Electrode ClassificationsDocument18 pagesWelding Electrode ClassificationsMansukh KahlonNo ratings yet

- Thread Pitch ChartDocument2 pagesThread Pitch ChartGeorgeMtyNo ratings yet

- Home About Us Products We Present Specification Chart Enquiry Contact UsDocument6 pagesHome About Us Products We Present Specification Chart Enquiry Contact UsOmil RastogiNo ratings yet

- High Strength Low Alloy SteelDocument1 pageHigh Strength Low Alloy SteelBudi HermanaNo ratings yet

- Welding Electrode PDFDocument1 pageWelding Electrode PDFBijaya RaulaNo ratings yet

- Sutton Tools Tapping Drill Size ChartDocument2 pagesSutton Tools Tapping Drill Size ChartChun HuNo ratings yet

- BBS 4Document1 pageBBS 4srikanth varmaNo ratings yet

- 1018 Mechanical PropertiesDocument2 pages1018 Mechanical PropertiesjangaswathiNo ratings yet

- Torque Values B7 Studs PDFDocument1 pageTorque Values B7 Studs PDFipsthethiNo ratings yet

- Filler Metal Data Handbook - CompleteDocument330 pagesFiller Metal Data Handbook - Completeessnelson100% (2)

- Metric Bolt Sizes and DimensionsDocument13 pagesMetric Bolt Sizes and DimensionsTHEARY THUN100% (1)

- Sail Is 2062 e 250 BR Mild Steel PlateDocument2 pagesSail Is 2062 e 250 BR Mild Steel PlateRakesh Chauhan100% (1)

- Tool Steel Grade and Standard DesignationDocument7 pagesTool Steel Grade and Standard DesignationMustafa SevimliNo ratings yet

- Thread ID Course - OficialDocument63 pagesThread ID Course - OficialBruno Salas100% (1)

- Thread Standard BSPDocument7 pagesThread Standard BSPĐạt TrầnNo ratings yet

- S.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMDocument12 pagesS.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMRajiv DamodarNo ratings yet

- AISI 1040: Typical AnalysisDocument2 pagesAISI 1040: Typical Analysisho_chauhanNo ratings yet

- PIPE THREADS Japanese PDFDocument2 pagesPIPE THREADS Japanese PDFOMAR CECEÑASNo ratings yet

- Filler Metal Selector GuideDocument11 pagesFiller Metal Selector GuideKrishnamoorthi VenkatesanNo ratings yet

- Din 3570-EnDocument1 pageDin 3570-EnCuong Nguyen Manh100% (1)

- Steel PipeDocument39 pagesSteel PipeJay PanalanginNo ratings yet

- Mechanical Properties For Steel FastenersDocument7 pagesMechanical Properties For Steel FastenersepriyonoNo ratings yet

- Metals Preheating Chart: Metal Group Metal Designation Approximate Percent Carbon Recommended PreheatDocument3 pagesMetals Preheating Chart: Metal Group Metal Designation Approximate Percent Carbon Recommended PreheatBruce WeathersNo ratings yet

- Piping Materials Selection TrainingDocument60 pagesPiping Materials Selection TrainingKagira Drawing Soltuion100% (5)

- Assignment 2Document6 pagesAssignment 2Ishaan IslamNo ratings yet

- 7000 (Al MG ZN) Aluminum IntroductionDocument8 pages7000 (Al MG ZN) Aluminum Introductionlsa105148No ratings yet

- (Note: All Speeds Are in Feet/min) - Multiply The Listed Speeds by A Factor of 2 To 4 When Using Carbide ToolingDocument2 pages(Note: All Speeds Are in Feet/min) - Multiply The Listed Speeds by A Factor of 2 To 4 When Using Carbide ToolingSanjay KumarNo ratings yet

- Stainless Steel 420 Material Chemical CompositionDocument3 pagesStainless Steel 420 Material Chemical Compositionr arumugamNo ratings yet

- Comparison EngineeringDocument9 pagesComparison EngineeringpdiconpNo ratings yet

- Aquapanel R-D-Cephe Plakas-Aquapanel R-Cement Board Outdoor ENG 2021Document3 pagesAquapanel R-D-Cephe Plakas-Aquapanel R-Cement Board Outdoor ENG 2021BHINEKA ENGINEERINGNo ratings yet

- Data Sheet 2114 Docol PHS 1500 2017-04-19 277 371857150 enDocument1 pageData Sheet 2114 Docol PHS 1500 2017-04-19 277 371857150 enMichaelKubaNo ratings yet

- Operating Instruction Manual: Low Velocity Power Adjustable Powder Actuated Fastening ToolDocument16 pagesOperating Instruction Manual: Low Velocity Power Adjustable Powder Actuated Fastening ToolLuisNo ratings yet

- S2-3 - PT Transfer - Almila UzelDocument25 pagesS2-3 - PT Transfer - Almila UzelChien KsNo ratings yet

- Metals and AlloysDocument7 pagesMetals and Alloysjovi manabatNo ratings yet

- Sikagrout®-214 Ae: Product Data SheetDocument3 pagesSikagrout®-214 Ae: Product Data Sheetmohammed rinshinNo ratings yet

- Power Cables & Wires Technical ManualDocument163 pagesPower Cables & Wires Technical Manualbharatsehgal00@gmail.com100% (1)

- Ijert Ijert: Experimental Behavior of Reinforced ConcreteDocument10 pagesIjert Ijert: Experimental Behavior of Reinforced ConcreteAravindanNo ratings yet

- GRM Composite WoodDocument6 pagesGRM Composite Woodfaizal azizNo ratings yet

- Detail of Engineer Facilities Quantity Rate Diff in Amount BOQ Actual Origional Up Lifted BOQ Qty's Actual Qty'sDocument2 pagesDetail of Engineer Facilities Quantity Rate Diff in Amount BOQ Actual Origional Up Lifted BOQ Qty's Actual Qty'sfluretNo ratings yet

- Standards and Tolerances Guide 0Document60 pagesStandards and Tolerances Guide 0Warren Suley100% (1)

- Horizontal Toggle Clamp: For Non-Flat Workpieces: Contact Screw With Swing Joint Available On RequestDocument1 pageHorizontal Toggle Clamp: For Non-Flat Workpieces: Contact Screw With Swing Joint Available On RequestrnadomirNo ratings yet

- Forensic InspectionDocument14 pagesForensic InspectionAndik MunirahNo ratings yet

- Brosur Ringlock+formworkDocument56 pagesBrosur Ringlock+formworkHasibuan WildanNo ratings yet

- ch9 1Document38 pagesch9 1Karam AlmasriNo ratings yet

- PIPECALC ASME B31.4 - Rev 2Document24 pagesPIPECALC ASME B31.4 - Rev 2Mohsin Raza100% (1)

- Maiti Fly Ash ConcreteDocument19 pagesMaiti Fly Ash ConcreteBilal Ahmed BarbhuiyaNo ratings yet

- 1aluminum Tempers, Specifications and Designations - Engineers Edge PDFDocument9 pages1aluminum Tempers, Specifications and Designations - Engineers Edge PDFChukkaNo ratings yet

- Minfc33286 Jis g3503 Grade Swry11Document4 pagesMinfc33286 Jis g3503 Grade Swry11Shubham YadavNo ratings yet

- Analysis of Wear ParticlesDocument5 pagesAnalysis of Wear Particlestribo technicalNo ratings yet

- GdssadgnsoadfDocument9 pagesGdssadgnsoadfIhsanul RidhoNo ratings yet

- Method of StatementDocument1 pageMethod of StatementsaNo ratings yet

- Drilling of GFRP Composites To Achieve oDocument4 pagesDrilling of GFRP Composites To Achieve oanaya KhanNo ratings yet

- Catalogo RapplonDocument8 pagesCatalogo RapplonAlejandro Saco Herrera100% (1)

- XHHW-2: XLP Insulation, 600 VoltsDocument2 pagesXHHW-2: XLP Insulation, 600 VoltsNaveedNo ratings yet

- Pre Stressed ConcreteDocument19 pagesPre Stressed ConcretemynameisgunaNo ratings yet

- US Army Plumbing Pipe-Fitting SewerageDocument340 pagesUS Army Plumbing Pipe-Fitting SewerageSpace_Hulker100% (4)