Troubleshooting and Service Manual 120V-240V

Troubleshooting and Service Manual 120V-240V

Uploaded by

kloberg123Copyright:

Available Formats

Troubleshooting and Service Manual 120V-240V

Troubleshooting and Service Manual 120V-240V

Uploaded by

kloberg123Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Troubleshooting and Service Manual 120V-240V

Troubleshooting and Service Manual 120V-240V

Uploaded by

kloberg123Copyright:

Available Formats

1

Troubleshooting & Service for EL/VS Systems

60 Hz

2

Balboas Patented M7 Technology

TOPSIDE CONTROL PANEL

The control panel activates functions at the touch of a button.

Each function will echo from the circuit board to the LCD in

a corresponding manner. The panel will also display diag-

nostic messages that enable the service technician to easily

troubleshoot the system.

M7 TECHNOLOGY

M7 is a patented Balboa technology that uses two sensors

inserted at the opposite ends of the heater element to

determine ow, dry re conditions, etc. The two sensors

located within the heater housing compare the inlet water

temperature with the outlet water temperature. It works no

matter which direction the water ows through the heater.

The sensors in combination with specic software allow the

spa to be controlled without the use of external pressure

switches, ow switches, or temperature sensors.

ML700 Top Side Panel

Panel Construction

VS501 with a Cut-a-way

View of the Heater

Sensor

Sensor

3

Table of Contents

Balboas Patented M7 Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Balboa Service Tools and Parts Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Information -- Product Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting & Servicing Spa and Electrical Equipment . . . . . . . . . . . . . . . . . . . . . . . 7

G.F.C.I. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

If Correct Wiring is Verified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

To Disconnect the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Voltage Checks: Breaker Box, G.F.C.I. & System Box . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spa Behavior -- Start-up Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Priming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Heater Start up Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Diagnosing M7 Topside Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Checking the System Power Input Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ML Series Panels -- For Use with EL and GL Systems . . . . . . . . . . . . . . . . . . . . . . . . 21

ML900 Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ML700 Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ML550, 551, 554 Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ML200, 240, 260, 400 Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

VL Series Panels -- For use with VS and GS Systems . . . . . . . . . . . . . . . . . . . . . . . . 32

VS/GS Panel -- 300 & 500 Series and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

EL and GL Series Mach 3 -- Persistent Memory & Power Up . . . . . . . . . . . . . . . . . . . . . 38

EL - GL, about Persistent Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Power Up Display Sequence, Software ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

VS-GS Persistent Memory with VL Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Testing the Circuit Board Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Balboas Quick Test

TM

Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

To Use the Balboa Quick Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Testing the Sensor Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Changing a System Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

How to Remove a System Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

How to Replace a System Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Removing the Heater Assembly from a Spa System . . . . . . . . . . . . . . . . . . . . . . . . . 43

Panel Message Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4

300/300F/500Z Series Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

500DZ Series Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

500SZ Series Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Balboa QuickCheck

TM

Part No. 70002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ground-Fault Circuit Interrupter/Circuit Breaker (G.F.C.I.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

120 Volt Residential Wiring Schematic with G.F.C.I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

240 Volt Residential Wiring Schematic with G.F.C.I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ground in System Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Heater Element Specications Are Shown on the Heater Tube Label . . . . . . . . . . . . . . . . . . . . . . . . . 6

ML260, ML240, ML200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ML400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ML550 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ML551 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ML554 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ML700 Top Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Recommended Parts For Service Calls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Molex Type, ML/GL Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

On Every System, an Identication Label Is Placed on top of the Casing . . . . . . . . . . . . . . . . . . . . . . . . 6

On Every System, a Wiring Diagram Is Placed Inside the Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Panel Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Phone Plug RJ Type, VL/GS Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Phone Plug RJ Type, VL/VS Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Terminal Block 1 & F5 Fuse on a VS500Z Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

VS500 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

VS501 with a Cut-a-way View of the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Diagrams (in alphabetical order)

5

Balboa Service Tools and Parts Checklist

Service Tools Required

Ammeter (50A)

Balboa Six-in-one Screwdriver

Digital Multi-meter

Padlock (to lock electrical disconnect during service)

Pliers: Slip Joint & Needle nose

Recommended Parts

For Service Calls

Extra Board(s)

Extra Panel(s)

Fuses

Jumpers

Heater Assembly

20618

JUMPER LOGIC

COMMON FUSES USED

30074 FUSE 1 AMP FAST BLOW GLASS

30075 FUSE 5 AMP FAST BLOW GLASS

30122 FUSE 10A BLOWER

30595 FUSE 10A POWER INPUT

30076 FUSE 15 AMP FAST BLOW CERAMIC

30596 FUSE 15A POWER INPUT

30142 FUSE 20A POWER INPUT

30123 FUSE 20A PUMP

30137 FUSE 25A POWER INPUT

21447 FUSE 25A POWER INPUT HIGH SURGE

30136 FUSE 30A POWER INPUT

MORE COMMON BOARDS:

22972 BOARD BARE VS500 (shown)

21998 BOARD BARE GL2000

27116 BOARD BARE EL5000

53649 ML700

Heater Assembly

Precision Thermometer - Digital Fever Type

Quick CheckTM Test Kit

Silicone Tube

Small Wire Cutters

Two 3/8 Open End Wrenches (one wrench should be

ground down to 5/32 [0.156] thickness in order to

access the nut between the heater strap and

heater element connector)

6

On Every System, an Identication

Label Is Placed on top of the Casing

Heater Element Specications Are Shown

on the Heater Tube Label

On Every System, a Wiring Diagram

Is Placed Inside the Door

Important Information -- Product Identication

Two Types of Plug-in Connectors:

Molex Type,

ML/GL Connector

Phone Plug RJ Type,

VL/GS Connector

7

Troubleshooting & Servicing Spa and Electrical Equipment

DANGER

Risk of electric shock. Before working with any electrical

connections, make certain that the Main Power breaker from

the house breaker box has been turned off.

WARNING

All electrical work must be performed by a qualied

electrician and must conform to all local codes.

IMPORTANT

Due to the danger of severe electrical shock, locate all

power disconnects before servicing a spa. Precautions must

be taken whenever working with breaker boxes, G.F.C.I.s, or

service disconnects.

Always refer to the wiring diagram which is included

with each system on the inside of the system box cover.

Use this diagram for voltage measurement points, and

for proper reconnection of wires.

HIGH VOLTAGE CAN SERIOUSLY INJURE OR KILL!

ONLY EXPERIENCED TECHNICIANS SHOULD SERVICE THIS EQUIPMENT.

DO NOT remove the protective covers from any electrical enclosure, or attempt to service any

related electrical device, unless you are a qualified electrician or service professional.

Safety Tips

Keep children and pets away.

Be aware of your surroundings. Standing in water while

repairing a spa puts you at serious risk.

Avoid working in cramped or crowded conditions.

Consider placing a padlock on the service panel to lock

out anyone who might power up the system.

A terminal marked GROUND is provided within

the System Control Center enclosure. To reduce

the risk of electrical shock, connect this terminal

to the grounding terminal

of the electric supply panel

with a continuous green

insulated copper wire

equivalent in size to the

circuit conductors supplying

this equipment, but no

smaller than #12 AWG.

Ground in System Enclosure

8

G.F.C.I. Troubleshooting

IF CORRECT WIRING IS VERIFIED

Check to see if the proper G.F.C.I. is installed.

Check the label in the system box near TB1 to determine

the maximum amperage draw for the system.

Be sure the G.F.C.I. is rated for more amperage than the

system will draw.

For a 240 V dedicated system, a 2-pole G.F.C.I. with no

load neutral is acceptable.

For a 120/240 V system, the G.F.C.I. must include a load

neutral out.

If the white load neutral wire is routed from the G.F.C.I.

neutral bar directly to TB1 in the system box, then the

G.F.C.I. will trip when a 120 V device is activated.

For a detailed wiring checklist, please review the

previous segment of this manual on proper G.F.C.I. wiring

or the G.F.C.I. manufacturers instructions.

If the wiring is correct and the G.F.C.I. will not reset, then

unplug the pump and try to reset the G.F.C.I.

If the G.F.C.I. trips again, then unplug the blower and

reset the G.F.C.I.. If the G.F.C.I. continues to trip, then do

the same procedure for the ozone generator.

If the G.F.C.I. stops tripping after you unplugged one of

the spas components, turn off the power to the spa then

plug in each component except the one that tripped the

G.F.C.I.

Power up the system. If the G.F.C.I. no longer trips,

then you have correctly identied the problem.

Repair or replace the component as instructed by

the spa manufacturer.

If you have unplugged all of the spas components and

the G.F.C.I. still doesnt reset, then the problem is most

likely a ground fault in the heater.

TO DISCONNECT THE HEATER

First, turn off the main circuit breaker, then remove both

heater straps or wires from the system heater output,

not the heater itself.

After restoring the power, try to reset the G.F.C.I. again.

If it no longer trips after the system calls for heat, then

replace the heater.

If the G.F.C.I. still trips, look for pinched or shorted

wires at the transformer. Make sure that the screws

that attach the transformer to the system box

have not pinched or damaged the insulation of the

transformer wires.

If the transformer wires are undamaged, check for any

other pinched wires. Refer to the wiring diagram to

verify the correct wiring of the control system.

If everything looks to be in perfect working order, then

the G.F.C.I. may be defective.

Keep in mind that a majority of G.F.C.I. tripping problems can be attributed to incorrect wiring. G.F.C.I. troubleshooting usually nds

the problem.

Ground-Fault Circuit

Interrupter/Circuit

Breaker (G.F.C.I.)

WARNING: THE OWNER SHOULD TEST AND

RESET THE G.F.C.I. ON A REGULAR BASIS TO

VERIFY ITS FUNCTION.

9

Voltage Verification - Most G.F.C.I. Problems Are Due To Low Voltage

IMPORTANT:

IF THE VOLTAGE IS NOT WITHIN THE ACCEPTABLE RANGE, CALL AN ELECTRICIAN

OR THE LOCAL ELECTRIC COMPANY TO DIAGNOSE THE PROBLEM.

CHECK THE VOLTAGES AT:

1. Breaker Box Voltage Check

2. G.F.C.I. Line-In Voltage Check.

3. G.F.C.I. Load Out Voltage Check

4. System Box Check At Tb1

CHECK UNDER PEAK LOADS -- TWO TYPES OF PEAK LOADS

1. Spa System Peak Loads - Pumps, Heater, Blower & Light On

2. Household Peak Loads - May Be In Afternoon On Hot Day

Use Recording Meter If Possible - Records Max & Min Volts

MI8I8EAM 6NI8L 88IEM 8ELAIE I88E8

Communication Between Topside & System Board In Most Systems

Press Button - Message Sent To System Board

System Board Performs - Message Sent Back To Topside & Relay Opens Or Closes

LED or Icon Is Turned On or Off - Hear Or See Relay Open Or Close

In Most Cases, If This Happens, There Is No Problem With The Topside Panel Or System Board

EkAMFLE - 8FA LIhI I8 NI W8kIN - 2 8 3 EA8 8IEF8 !

1. Press Light Button

Light LED or Icon Turns ON, But Spa Light Is NOT ON

Topside & Board Are Good, Check Downstream

Light LED or Icon Is NOT ON

Topside Or System Board May Be Bad, Continue

2. Plug In Spare Topside Panel - Easier To Check For Bad Topside

Light LED or Icon Now Turns ON

Original Topside Is Bad - R&R Topside Panel

Light LED or Icon Is NOT ON

Original Topside Is Good, Do Not Replace

System Board Is Bad - R&R System Board

3. Spa Light Is Still NOT ON - Check Downstream

Same Procedure For Other Functions

Jets, Blower, Heater, Time, Program, Mode, Etc.

Voltage Checks: Breaker Box, G.F.C.I. & System Box

When checking for proper voltage, keep in mind that the acceptable voltage range is + 10% of the recommended voltage.

Acceptable voltage when 120 V is specied is between 108 and 132 V.

Acceptable voltage when 240 V is specied is between 216 and 264 V.

Diagrams are on the following pages.

120 VOLT SYSTEMS - 120V 10% - 108V - 132V

240 VOLT SYSTEMS - 240V 10% - 216V - 264V

No More Than 2% (5 Volt AC) Difference Between Voltage

at the Breaker Panel And Voltage at the System.

Diagrams Are On The Following Pages.

10

120 Volt Residential Wiring Schematic with G.F.C.I.

1

2

0

V

A

C

1

2

0

V

A

C

N

e

u

t

r

a

l

Outside Ground Rod

O

N

O

N

O

N

O

N

O

N

O

N

O

N

O

N

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

N

O

N

O

N

O

N

O

N

O

N

O

N

O

N

House Breaker Box G.F.C.I Breaker Box

4

5

6

8

9

10

11

7

Correct

Voltage

When Probes Are Placed Across

108V - 132V [1 - 3] [4 - 5] [4 - 8] [5 - 6] [5 - 9]

[6 - 8] [7 - 8] [9 - 11] [10 - 11]

0v [2 - 3] [4 - 6] [4 - 7] [5 - 8] [9-10]

108V - 132V [1 - 3] [4 - 5] [4 - 8] [5 - 6] [5 - 9]

[6 - 8] [7 - 8] [9 - 11] [10 - 11]

Correct

Voltage

When Probes Are Placed Across

11

5

Spa System Box 120VAC Service

G

C

RED AC

WHT AC

J32

J11 J15 J25 J63

J33

HTR2 HTR1

TB1

FUSE .3A 250V

CLASS G FUSE 30A F5

F4

K6

J23

J73

W1

K4

K2

K3

Balboa

F2

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

120/240VAC

16/40A MAX 60Hz

USE ONLY

COPPER

CONDUCTORS:

#6 AWG MIN.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

3

G

C

G

C

RED AC

WHT AC

J32

T1

SWITCHBANK A

J11 J15 J25 J63

J33

BALBOA INSTRUMENTS INC.

VS500Z

P/N 22972 REV D

MADE IN U.S.A

COPYRIGHT 2005

S1

J6 J7 J8

U4

HTR2 HTR1

TB1

FUSE .3A 250V

FU

S

E

3A

250V

E

.G

N

D

CLASS G FUSE 30A F5

F4

K6 K1

W2

K5

J23

J73 F1

J29

J20

TST

SEN. A SEN. B

W1

J1

W2

K4

K2

K3

Balboa

F2

J43

J18

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

H

O

T

B

LA

C

K

N

EU

TR

A

L

W

H

ITE

H

O

T

R

ED

G

C

J29

G

C

W

4

4.0 kW 4.0 kW

O

z

o

n

e

1

2

V

L

ig

h

t

J2

W7

120/240VAC

16/40A MAX 60Hz

USE ONLY

COPPER

CONDUCTORS:

#6 AWG MIN.

HOT

BLACK

NEUTRAL

W

HITE

HOT

RED

J47

G

C

E.GND

Black (Hot)

White White

Bottom view of G.F.C.I

Electric Installation 120VAC_092608.eps

Test for Voltages by placing

probes on these locations

J32 J33

TB1 K4

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

120/240VAC

16/40A MAX 60Hz

USE ONLY

COPPER

CONDUCTORS:

#6 AWG MIN.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

1

2

12

240 Volt Residential Wiring Schematic with G.F.C.I.

Correct

Voltage

When Probes Are Placed Across

108V - 132V [1 - 3] [5 - 6] [5 - 10] [12 - 14] [13 - 14]

[2 - 3] [5 - 7] [5 - 11] [12 - 15] [13 - 15]

0v [3 - 4] [5 - 8] [5 - 9] [12 - 13]

108V - 132V [1 - 3] [5 - 6] [5 - 10] [12 - 14] [13 - 14]

[2 - 3] [5 - 7] [5 - 11] [12 - 15] [13 - 15]

Correct

Voltage

When Probes Are Placed Across

216V - 264V [1 - 2] [6 - 7] [10 - 11] [14 - 15]

[5 - 6]

[5 - 7]

[12 - 14]

[12 - 15]

1

2

0

V

A

C

1

2

0

V

A

C

N

e

u

t

r

a

l

Outside Ground Rod

O

N

O

N

O

N

O

N

O

N

O

N

O

N

O

N

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

N

O

N

O

N

O

N

O

N

O

N

O

N

O

N

House Breaker Box G.F.C.I Breaker Box

5

6

7

8

10

11

12

13

15

14

9

13

Electric Installation 240VAC_092608.eps

Spa System Box 240VAC Service

G

C

RED AC

WHT AC

J32

J11 J15 J25 J63

J33

HTR2 HTR1

TB1

FUSE .3A 250V

CLASS G FUSE 30A F5

F4

K6

J23

J73

W1

K4

K2

K3

Balboa

F2

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

120/240VAC

16/40A MAX 60Hz

USE ONLY

COPPER

CONDUCTORS:

#6 AWG MIN.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

4

G

C

G

C

RED AC

WHT AC

J32

T1

SWITCHBANK A

J11 J15 J25 J63

J33

BALBOA INSTRUMENTS INC.

VS500Z

P/N 22972 REV D

MADE IN U.S.A

COPYRIGHT 2005

S1

J6 J7 J8

U4

HTR2 HTR1

TB1

FUSE .3A 250V

FU

S

E

3A

250V

E

.G

N

D

CLASS G FUSE 30A F5

F4

K6 K1

W2

K5

J23

J73 F1

J29

J20

TST

SEN. A SEN. B

W1

J1

W2

K4

K2

K3

Balboa

F2

J43

J18

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

H

O

T

B

LA

C

K

N

EU

TR

A

L

W

H

ITE

H

O

T

R

ED

G

C

J29

G

C

W

4

4.0 kW 4.0 kW

O

z

o

n

e

1

2

V

L

ig

h

t

J2

W7

120/240VAC

16/40A MAX 60Hz

USE ONLY

COPPER

CONDUCTORS:

#6 AWG MIN.

HOT

BLACK

NEUTRAL

W

HITE

HOT

RED

J47

G

C

E.GND

7

6

Test for Voltages by placing

probes on these locations

J32 J33

TB1 K4

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

120/240VAC

16/40A MAX 60Hz

USE ONLY

COPPER

CONDUCTORS:

#6 AWG MIN.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

Red (Hot)

Black (Hot)

White White

Bottom view of G.F.C.I

1

2

3

14

Wiring Checks

WIRING CHECK PRECAUTIONS

When working in a system box always be aware that it

may contain high voltage.

Always keep your ngers and hand tools away from any

wiring or circuit board when the power is on. Touching

anything in these areas can result in serious injury.

All service calls, no matter how minor, should in-

clude a complete wiring check, beginning with the

house breaker.

CHECK FOR LOOSE CONNECTIONS OR

DAMAGED WIRES

Make sure the power is off before you touch any wiring.

Once the power is off, carefully examine all wires for

cuts or defects.

SYSTEM BOX WIRE GAUGE CHECK

When inspecting the wiring for any control system, note

that connections for the incoming wires are clearly labeled

at the main terminal block.

30A service minimum ten gauge copper wire.

40A service minimum eight gauge copper wire.

50A service minimum six gauge copper wire.

These wires must connect the house breaker box,

through the local disconnect, to the main terminal block.

The wiring diagram inside the system box shows the main

terminal block as TB1.

IMPORTANT

Using non-copper wire can be dangerous, and also can be

the cause of a spas malfunction. If non-copper wire

is used at any point, we do not recommend servicing the

spa until an electrician replaces it with the proper gauge

copper wire.

IMPORTANT

This service must be single phase. Any abnormal volt-

age reading requires an electrician. Do not attempt to x

these types of problems yourself. High voltage can

seriously injure or kill.

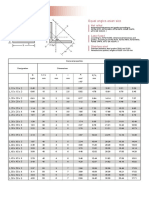

Total Ampere Rating of

Power System

Minimum wire size

Use Copper ONLY,

with 90

o

C insulation

Ampere Rating of

G.F.C.I. Circuit-breaker

0 A to 16 A #12 AWG 20

16 A to 20 A #10 AWG 25

20 A to 24 A #10 AWG 30

24 A to 28 A #8 AWG 35

28 A to 32 A #8 AWG 40

32 A to 36 A #6 AWG 45

36 A to 40 A #6 AWG 50

RED AC

WHT AC

BLK AC

J32

J61 J62

J11

J66 J65

J15 J16 J25 J63 J64

J33 J34

J36 J37

J35

TB1

CLASS G FUSE 30A F5

K4

Balboa

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

TB1

15

HEATER START UP INFORMATION

On M-7 systems, the heater goes through a testing phase

every time it starts up to assure that there is adequate

water ow. This provides sophisticated dry re and low ow

protection. It can be confusing if you don't know what to

expect. Step by step, here is what happens. (Note that the

timing/temperature details may be slightly different on some

older M7 systems.)

Prior to heating, the pump is run for at least two

minutes, and then the temperature difference between

the sensors is assessed. It must be 2F/1.0C or less for

heating to proceed, otherwise an error is issued.

The heater turns on for 6.5 to 18 seconds (depending

on heater voltage and wattage). At this point, the heat

indicator on the panel is "solid." During this time the

panel is not immediately responsive.

The heater turns off for 90 seconds, making sure that the

water ow keeps the temperature rise small and short.

(Abnormal water ows, or lack of water, will produce

a large and/or long temperature rise, and the system

faults in that situation.) At this point, the heat indicator

on the panel may appear to "shimmer" or "dim" (on some

panels this may be less obvious from certain angles and

more obvious from other angles, or in different lighting).

If the dry re test has passed, heating turns back on to

heat the spa. The heat indicator on the panel returns

to "solid".

During spa heating, a difference between the sensors

of 2F/1.0C, or perhaps 3F/1.5C (at least with 4-6kW

240V heaters), is considered normal. A signicantly

higher difference, however, is usually indicative of a

ow problem, and will cause a fault which disables

the heating for at least a minute (and then restarts the

whole above process).

Spa Behavior -- Start-up Information

PRIMING MODE

In Priming Mode, the Mode button toggles the ozone on/off

(with a 15-second time-out). This can be useful if you want to

verify ozone generator operation without waiting for a lter

cycle. This feature is not available on smaller panels where

Mode is a multi-button sequence, since such a sequence

exits Priming Mode.

GENERAL FILTER INFORMATION

On any system with a Deluxe panel, the lter times

and durations are completely programmable from the

topside control panel, and the rst lter may not run

for many hours after power-up. If you want the lter

to run sooner, you have to either reprogram the lter or

advance the time to just before the lter start.

On all other systems, the rst lter starts 6 minutes after

power-up and the duration can be chosen (either using

button sequences on the topside control panel or via a

DIP switch) between several preset choices. Note that if

you let Priming Mode exit automatically after 4 minutes,

you have 2 more minutes before the rst lter runs after

power-up. Exiting Priming Mode by pressing the Temp,

Warm, or Cool buttons, allows up to 6 minutes

available before the rst

lter runs.

IMPORTANT INFORMATION: If the lter settings have just

been changed, it may take up to 24 hours for the lter cycle

to reect the changes. This is especially likely when changing

from a very long lter duration (such as Continuous), to a

short one, or vice versa.

The low-speed pump (on non-circ) and ozone generator

(if installed) will run during the lter cycles.

The blower runs for 30 seconds at the start of each lter

cycle. This will maintain water quality in the air channel.

The pumps (other than pump 1 in non-circ, including

pump 1 in circ) will run for 5 minutes at the start of each

lter cycle.

See manufacturers owners manual or reference card for general information on operating the spa, including programming

lters and other settings that are changed from the topside control panel.

16

Diagnosing M7 Topside Control Panels

PRELIMINARY PANEL CHECK

If the problem is not obvious, look on the topside control

panel for diagnostic messages.

If no messages are seen, run through all spa functions

and note any inconsistent operation.

Most error messages are stored in the fault log. To view

the fault log, the spa must be in test mode and the spa

light must be turned on.

Once you have determined that proper voltage is running

through the circuit board and transformer, continue to the

topside control panel. A panel that is not functioning properly

may include the following symptoms: low voltage such as

missing or scrambled segments, missing icons on the LCD,

non-functional LEDs, or nonfunctional buttons. If any of these

symptoms are present, perform the following:

Turn the power off and unplug the panel from the

circuit board.

Then, plug in your test panel and restore power. If every-

thing functions normally, replace the topside panel.

Disconnect ozone generator (if applicable).

If you still see symptoms of low voltage, such as a

sluggish, blank or partially blank panel, or if the display

or the LEDs do not function at all, turn the power off;

unplug the ozone generator (if equipped); then restore

power to the system. If the problem persists, turn off the

power and replace the circuit board.

PANEL DISPLAY MESSAGES

THE PANEL DISPLAYS:

, , or

At least one of the sensors has detected water temperatures

of 118F inside the heater. Or,

THE PANEL DISPLAYS:

, , or

One of the sensors has detected the temperature

of the water coming into the heater to be 110F,

and so the water in the spa is likely to be that hot.

These indicate that the spa has shut down due to an

overheat situation.

NOTE: Overheating may occur if the low-speed pump is set

to operate for extended periods of time, or if the incorrect

pump is installed. In rare cases (usually warmer climates), the

circulation pump may also cause overheating.

MOST PROBABLE OVERHEATING CAUSES,

INSPECT THESE FIRST

Check slice or ball valves. Make sure that they

are open.

Make sure the correct pump is installed.

Clean the lter/skimmer if there is any blockage.

Check heater element alignment.

Check for debris on the heater element.

In extremely hot weather, check for proper

cabinet ventilation.

Make sure the temperature sensor is fully inserted

into the sensor tting on the heater.

Check for excessive lter duration.

Panel messages are a quick clue toward solving a variety of problems. Here are the most common messages and what

they mean.

17

NOTE: A common programming mistake is overlapping lter

times that may cause the spa to lter continuously.

Check the water level.

Check the water temperature with an accurate

temperature thermometer. Remove the spa cover and

allow the water to cool to below 108 F. Adding cool

water may be necessary. Touch any button to reset

the system. If the water is still hotter than the set

temperature, press the blower button (if applicable) to

cool the spa.

If the Problem Recurs, test the Sensor Set.

THE PANEL DISPLAYS:

, , , or

or

THE PANEL DISPLAYS:

, , , or

or

This indicates that the spa has shut down due to an open or

faulty sensor. If the problem recurs, test the sensor set. (See

Testing the Sensor Set.)

NOTE: In rare cases, rapid system overheat causes sensor

error messages. Be sure to rule out possible situations like no

ow or no water.

THE PANEL DISPLAYS:

, , or

This indicates that the sensors are out of balance.

If alternating with temperature, it may just be a temporary

condition. If ashing by itself, spa is shut down.

If the panel also displays Service Req, spa is shut down.

If the spa shuts down due to this error, one (or both) of the

sensors are probably reading several degrees off. If the

problem recurs, test the sensor set.

THE PANEL DISPLAYS:

, , or

Indicates the sensor detects a possible freeze condition.

This Freeze Condition message does not appear on M-7

software showing a Software Version ID of 01 or greater. This

is a normal spa function; no further action is necessary.

When either sensor reads below 40 F, the system

provides freeze protection. It automatically activates the

pump (and the heater if necessary) to circulate the water and

warm the plumbing. The equipment stays on until the sensors

detect that the spa temperature has risen to within 15F of

the set temperature. The other pumps and the blower will

purge for 30 seconds to 2 minutes at the end of the freeze

condition. If pump 1 was turned on due to this reason alone,

this message will appear for up to two minutes right after

very cold water is detected.

NOTE: Internal freeze protection only functions when there

is proper power running to the spa, and the control system

is operational. Using an optional freeze sensor may be

necessary in extreme climates to prevent plumbing damage,

but will only work properly if placed inside the spa skirt in the

coldest area.

All spa models are different in shape and size and

have different thermal characteristics; therefore,

Balboa Water Group cannot be held responsible

for freeze damage to the spas plumbing. Testing

is the responsibility of the spa manufacturer and

must be done to determine the best location for the

freeze sensor.

THE PANEL DISPLAYS:

, , or

This indicates that the auxiliary sensor detects a

possible freeze condition. This is a normal spa function;

no further action is necessary.

When the auxiliary sensor reads around 40F (actual

temperature dependent on specic auxiliary sensor used), the

system provides freeze protection. It automatically activates

all of the pumps and the blower to circulate water and warm

the plumbing.

18

On the third consecutive occurrence of the above mes-

sage (without a successful heating cycle in between) the

panel will display:

, , or

Spa is shut down and will not reset in 15 minutes. Press any

button to reset manually.

THE PANEL DISPLAYS:

, , or

This indicates that the temperature is completely

unknown because the pump has not yet run for 2 minutes

after Priming Mode was exited. This is only displayed for 2

minutes at power-up.

SOME TROUBLESHOOTING SCENARIOS

You nd out the system is in OHH. This alone doesn't

explain a lot. What led up to the OHH is much more

important. If it's a Prestige, review the fault log carefully.

Otherwise, see if the user has any additional information (for

example, how long before the OHH was the spa panel last

checked, and how hot was the water then). If the spa has

cooled, see whether the problem can happen again, this time

watching carefully to see if there are additional clues leading

to the OHH (for example, other messages that appear

shortly before the OHH happens).

You nd out the system keeps showing HFL, or is now

in LF, or is shut down due to a "dry" fault. Put the spa in

test mode with the light on, so that you see the two sensor

temperatures. Are they normal (within 1F/0.5C) when

not heating? How far apart are they when heating? HFL

happens when they are 6F/3C apart (4F/2C on 120V

and other low-heater-wattage systems), see how quickly

that happens after heating starts. If it's getting close to that

right away, it's probably a consistent ow problem, but if it's

nowhere close to the HFL-causing temperature difference,

the ow problem may be intermittent or only occur in certain

specic situations.

NOTE: This auxiliary freeze protection functions at all times,

even when another fault condition has occurred and has

otherwise shut the spa down.

Any time the lower of the two temperature sensors

goes below 45F, all pumps/blowers turn on. They continue

to run for 4 minutes after the temperature reaches 45F

or above. As soon as the temperature falls below 45F

again, this process restarts. This simplied sensor freeze

protection functions at all times, even when another fault

condition (other than total sensor failure) has occurred and

has otherwise shut the spa down.

THE PANEL DISPLAYS:

, , or

This indicates that a substantial difference in

temperature between sensors has been detected

during heating.

This could indicate a ow problem. Check water level in spa.

Rell, if necessary. If the water level is okay, make sure the

pumps have been primed. On the fth occurrence of

the above message the panel will display:

, or

This indicates a persistent ow problem. The heater

is shut down while all other spa functions continue to run

normally. Power on the spa must be cycled before the heater

will function again.

THE PANEL DISPLAYS:

, , or

This indicates that there is not enough water in the

heater. Spa shuts down for 15 minutes.

This could indicate poor ow or air bubbles in the heater.

Diagnosing M7 Topside Control Panels (cont.)

19

LOW VOLTAGE

At Balboa, its been our experience that the majority of the

problems associated with electronic control systems are due

to low voltage.

BROWN OUTS

Brown outs can have an effect on the spas operation in

a variety of ways. The control panel may go blank, have

scrambled messages on the LCD, or only a few features

will function.

CHECKING THE SYSTEM POWER INPUT FUSE

Warning

These procedures are performed while the system is

powered up and running under peak loads. Be careful.

If your system uses 120V peripheral devices (below):

Measure between the white TB1 terminal and F5 power

input fuse on the side farthest away from the circuit

board edge (opposite the F5 silk screen). You should see

120 volts.

If the system is equipped with the additional F6 power

input fuse, measure F6 in the same manner. You should

also see 120 volts.

If your system uses 240V peripheral devices (below):

Measure between the red TB1 terminal and F5 power

input fuse on the side farthest away from the circuit

board edge (opposite the F5 silk screen). You should see

240 volts.

If the system is equipped with the additional F6 power

input fuse, measure F6 in the same manner. You should

also see 240 volts.

If you determine that there is no voltage at one or both

locations, then the system power input fuse(s) need to

be replaced. Only use a fuse of the same type and amp

rating when you replace any of these fuses.

Elite System

Measure ngers 5 and 6 of the circuit board. You should

see either 120V or 240V, depending upon the system

conguration.

If you determine that there is no voltage at ngers 5

and 6, then the system power input fuse needs to be

replaced. This fuse is located in the large fuse block

inside the system box. This conguration utilizes a 30A

time delay fuse.

If the system is getting the proper voltage

at TB1, but still doesnt operate, then test for

a blown power input fuse.

RED AC

WHT AC

BLK AC

J32

J61 J62

J11

J66 J65

J15 J16 J25 J63 J64

J33 J34

J36 J37

J35

TB1

CLASS G FUSE 30A F5

K4

Balboa

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

H

O

T

B

L

A

C

K

N

E

U

T

R

A

L

W

H

I

T

E

H

O

T

R

E

D

Terminal Block 1 & F5

Fuse on a VS500Z Board

TB1 Marking

on Board

F5 Fuse

20

Test the Blower

Plug in the blower.

Power up the system and activate the blower.

If the fuse blows, then there is a blower problem.

If the fuse does not blow, the combined pump and

blower amperage may be excessive. To verify this, rst

check with your spa manufacturer for amperage draw

limits on each device.

Since the blower should now be running, you can check

the amperage draw with an ammeter by measuring

around the black blower wire and compare with

manufacturers specications.

TEST THE AMPERAGE DRAW

Turn off the power,

disconnect the blower,

make sure the pump is

plugged in, and restore

power.

Start the pump and

switch to high speed (if

available), this should

draw the most current.

Make sure all jets and

valves are open.

Check the amperage

at the red pump wire.

Compare your reading

with manufacturer specications. (If the other plug-in

devices exist, they should be tested in the same way.)

If the amperage draw for each device is within

manufacturers specications, the problem could be a

nuisance spike in the pump, or water in the blower.

NOTE: These slow-blow fuses are not always discolored

when blown. Always test continuity of a fuse with

an ohmmeter.

NOTE: Miswiring of the spa is the most common reason for

this fuse to blow. However, a lightning strike in the area is a

possible, though less likely, cause of the failure.

NOTE FOR ALL SYSTEMS In each situation, the most

likely reason for the system power input fuse to blow

is a pump problem. However, on occasion, a blower

problem may also cause this fuse to blow if a 10A blower

fuse is not built in.

Once the power input fuse has been changed

Probe the red wire and the white neutral wire. Again,

voltage must be between 108 and 132 V.

Check the voltage between the black and red

wires again. Acceptable voltage range is between 216

and 264 V.

THESE READINGS SHOULD BE TAKEN UNDER

PEAK LOAD CONDITIONS.

Important

If the voltage is not in the acceptable range, call an

electrician or the local electric company to diagnose

the problem.

TO DETERMINE THE CAUSE OF A BLOWN POWER

INPUT FUSE

Perform the following sequence of tests.

Test the System

Turn the power off.

Be sure to replace the system power input fuse with the

same type.

Unplug the blower and all pumps.

Restore the power and verify system operation.

If the fuse blows, then re-check the internal system

wires and connector for burns, cracks or cuts in

insulation.

If the fuse does not blow, turn the power off and plug in

the pump.

NOTE: Be sure to test each device individually.

Test the Pump

Restore the power and activate the pump.

If the fuse blows, there is a pump problem.

If the fuse does not blow, turn off the power.

Diagnosing M7 Topside Control Panels (cont.)

21

ML Series Panels -- For Use with EL and GL Systems

M

L

9

0

0

M

L

7

0

0

M

L

5

5

4

M

L

5

5

3

M

L

5

5

1

M

L

5

5

0

M

L

4

0

0

M

L

2

6

0

M

L

2

4

0

M

L

2

0

0

Jets Aux Light Temp

Aux Light Temp Jets Aux Light Temp Jets

Aux Light Temp Jets Aux Light Temp Jets

Heat

Jets Aux Temp Light

Heat Heat

Jets 1 Jets 2 Blower Light Mode Cool Warm Jets 1 Jets 2 Blower Light Mode

Heat Heat

Warm Light Warm

Jets 1 Jets 2

Light Mode

Cool Blower

Cool

Warm Time

Mode/Prog

Blower

Jets 2

Light

Jets 1

F2

TL

F1

PL

Jets 3 Option Jets 1 Option

Invert Blower Fiber

Jets 3 Option Time Warm Jets 1 Jets 2 Jets 3 Option

Cool Mode/Prog Invert Blower Fiber Light

F2

TL

F1

PL

Molex Type,

ML/GL Connector

22

ML900 Panel Operation

Diagnostic Messages section for the ML900 is unique. Refer to the User Guide for additional information.

User Guide for panel ML900 is 40568-99.

Initial Start-up

When your spa is rst actuated, it will go into Priming mode

(after displaying some conguration information). Please

see Spa Behavior -- Start-up Information for additional

information.

The Priming mode will last for up to 4 minutes and then the

spa will begin to heat and maintain the water temperature

in the Standard mode. You can exit Priming mode early by

pressing Warm or Cool.

Mode/Prog

This button is used to switch between standard, economy,

and sleep modes. Press Mode/Prog to enter mode

programming, press Cool to cycle through to desired mode

(LCD ashes until conrmed), then press Mode/Prog to

conrm selection

Standard mode maintains the desired temperature. Note

that the last measured spa temperature displayed is current

only when the pump has been running for at least 1 minute.

The icon will display until the mode is changed.

Economy mode heats the spa to set temperature only during

lter cycles. The icon will display until mode is

changed. Pressing Jets 1 while in Economy mode puts the

spa in Standard-In-Economy mode, which operates the

same as Standard Mode, then reverts to Economy Mode

automatically after 1 hour. Both the and

icons display in this mode. During this time,

a press of the Mode/Prog button will revert to Economy

Mode immediately.

Sleep mode heats the spa to within 20F (11C) of the set

temperature only during lter cycles. The icon

will display until mode is changed.

Standby Mode

Pressing Warm or Cool then Jets 2 will turn off all

spa functions temporarily. This is helpful when changing

a lter. Pressing any button resets the spa. On some

systems the Jets 1 button will control the pump in

Standby Mode (Drain Mode). In this case, press any

other button to exit.

Locking the Panel

Press Time Jets 1 then Warm within 3 seconds. When

locked, the PL PL light will light. All buttons are frozen

except the Time button. To unlock the panel, press Time

Jets 1 then Cool.

Locking the Set Temperature

Press Warm or Cool then Time, Jets 1, and Warm

within 3 seconds to activate the lock. The TL TL light

will light when the set temperature is locked.

To unlock the set temperature, press Warm or Cool then

Time, Jets 1 and Cool.

Time

When time hasnt been programmed, the icon

ashes. (Time settings on EL1000 and some EL2000 systems

are not preserved in the event of power loss; time will have

to be reprogrammed upon each power up.)

Jets 3 Option Jets 1 Option

Invert Blower Fiber

Jets 3 Option Time Warm Jets 1 Jets 2 Jets 3 Option

Cool Mode/Prog Invert Blower Fiber Light

F2

TL

F1

PL

Setting the Time

Once the spa has been properly connected the first time (every power

up on the EL1000 and some EL2000 systems), notice the icon

appearing on the screen.

Press

then

Select the hour by pressing

Press

to exit the time setting procedure and enter the

optional filter cycle programming. (Exits programming

on some EL1000 and some EL2000 systems.)

Time Time

Press

to exit programming.

Press to enter.

Select minutes by pressing

Mode/Prog Mode/Prog

Time Time

Mode/Prog Mode/Prog

Mode/Prog Mode/Prog

Or

(Each press changes

the time by 1 minute)

Warm Warm

Cool Cool

Or

(Each press changes

the time by 1 minute)

Warm Warm

Cool Cool

23

other button to exit.

Locking the Panel

Press Time Jets 1 then Warm within 3 seconds.

When locked, the PL PL light will light. All buttons

are frozen except the Time button. To unlock the panel,

press Time Jets 1 then Cool.

Locking the Set Temperature

Press Warm or Cool then Time, Jets 1, and Warm

within 3 seconds to activate the lock. The TL TL light

will light when the set temperature is locked.

To unlock the set temperature, press Warm or Cool

then Time, Jets 1 and Cool.

Time

When time hasnt been programmed, the icon

ashes. (Time settings on EL1000 and some EL2000

systems are not preserved in the event of power loss;

time will have to be reprogrammed upon each power up.)

Initial Start-up

When your spa is rst actuated, it will go into Priming

mode (after displaying some conguration information).

Please see Spa Behavior -- Start-up Information for

additional information.

The Priming mode will last for up to 4 minutes and

then the spa will begin to heat and maintain the water

temperature in the Standard mode. You can exit Priming

mode early by pressing Warm or Cool.

Mode/Prog

This button is used to switch between standard, economy,

and sleep modes. Press Mode/Prog to enter mode

programming, press Cool to cycle through to desired

mode (LCD ashes until conrmed), then press Mode/

Prog to conrm selection.

Standard mode maintains the desired temperature. Note

that the last measured spa temperature displayed is

current only when the pump has been running for at least

1 minute. The icon will display until the mode

is changed.

Economy mode heats the spa to set temperature only

during lter cycles. The icon will display until

mode is changed. Pressing Jets 1 while in Economy

mode puts the spa in Standard-In-Economy mode, which

operates the same as Standard Mode, then reverts to

Economy Mode automatically after 1 hour. Both the

and icons display in this mode.

During this time, a press of the Mode/Prog button will

revert to Economy Mode immediately.

Sleep mode heats the spa to within 20F (11C) of the set

temperature only during lter cycles. The icon

will display until mode is changed.

Standby Mode

Pressing Warm or Cool then Jets 2 will turn off all

spa functions temporarily. This is helpful when changing

a lter. Pressing any button resets the spa. On some

systems the Jets 1 button will control the pump in

Standby Mode (Drain Mode). In this case, press any

Setting the Time

Once the spa has been properly connected the first time (every power

up on the EL1000 and some EL2000 systems), notice the icon

appearing on the screen.

Press

then

Select the hour by pressing

Press

to exit the time setting procedure and enter the

optional filter cycle programming. (Exits programming

on some EL1000 and some EL2000 systems.)

Time Time

Press

to exit programming.

Press to enter.

Select minutes by pressing

Mode/Prog Mode/Prog

Time Time

Mode/Prog Mode/Prog

Mode/Prog Mode/Prog

Or

(Each press changes

the time by 1 minute)

Warm Warm

Cool Cool

Or

(Each press changes

the time by 1 minute)

Warm Warm

Cool Cool

ML700 Panel Operation

Diagnostic Messages section for the ML700 is unique. Refer to the User Guide for additional information.

User Guide for panel ML700 is 40520-99.

Cool

Warm Time

Mode/Prog

Blower

Jets 2

Light

Jets 1

F2

TL

F1

PL

24

ML550, 551, 554 Panel Operation

Cool/Warm

ML500, 551, 554

Press the Cool or Warm button once to display the set

temperature. Each time either button is pressed again, the

set temperature will increase or decrease depending on

which button is pressed. After three seconds, the LCD will

automatically display the last measured spa temperature.

Mode

ML500, 551, 554

This button is used to switch between Standard, Economy,

and Sleep modes. Press Mode to enter mode programming,

press Cool to cycle through to desired mode (LCD ashes

until conrmed), then press Mode to conrm selection.

Sleep mode heats the spa to within 20F (11C) of the set

temperature only during lter cycles. will appear on

the display until mode is changed.

Standby Mode

Pressing Cool or Warm followed by Blower or Jets 2 or

Aux will turn off all spa functions temporarily. This is helpful

when changing a lter. Pressing any button exits Standby

mode. On some systems the Jets 1 button will control the

pump in Standby Mode (Drain Mode). Then press any other

button to exit. System reverts to previous mode after 1 hour.

Jets 1

Press the Jets 1 button once to turn pump 1 on or off, and

to shift between low and high speeds if equipped. If left

running, the pump will turn off after a time-out period. The

pump 1 low speed time-out on some systems may be as

long as 4 hours.

On non-circ systems, the low speed of pump 1 runs when

the blower or any other pump is on. It may also activate

for at least 1 minute every 30 minutes to detect the spa

temperature (polling) and then to heat to the set temperature

if needed, depending upon mode. When the low speed turns

on automatically, it cannot be deactivated from the panel;

however, the high speed may be started.

Jets 2

(optional on some systems)

Press the Jets 2 button once to turn pump 2 on or off, and

to shift between low and high speeds if it is a two-speed

pump. If left running, the pump will turn off after a

time-out period.

Blower

1-speed operation: on/off,

2-speed operation: med/hi/off, or

3-speed operation: lo/med/hi/off.

If left on, the blower will automatically turn off after a time-

out period.

Please refer to the following User Guides for more detailed information:

ML551/ML554 User Guide: P/N 40632-99

ML 550 User Guide: P/N 40569-99

ML551 ML551

Heat Heat

Warm Light Warm

Jets 1 Jets 2

Light Mode

Cool Blower

ML554 ML554

Heat Heat

Warm Light Warm

Jets 1 Jets 2

Light Mode

Cool Blower

Heat

Cool Warm Jets 1 Jets 2 Blower Light Mode

ML550

25

NOTE: If your system does not have a Blower button, and

is labeled as Jets 3 instead, please refer to the respective

User Guide listed above.

Light

Some systems are equipped with both a spa light and a ber

optic light; however, only one can be accessed by this panel.

(Larger panels may be purchased so that both the spa light

and ber optic light can be utilized.) Depending upon how

your spa is equipped and congured, the Light button will

operate in one of three ways:

1) Press the Light button to turn the spa light on and off,

and to shift between dim and bright settings if your light

is dimmable.

2) If a ber-optic light with wheel is installed, press the

Light button once to start the light and wheel; press

it again to stop the wheel, and then again to turn the

light off.

3) If a ber-optic light without a separate wheel stop is

installed, press the Light button to turn it on and off.

Both a spa light and a ber optic light may be used

simultaneously on the EL8000 and EL5000 systems with a

different panel.

If any light is left on, it will automatically turn off after a

factory programmed time period.

Preset Filter Cycles

On all systems, the pump and the ozone generator will run

during ltration. At the start of each lter cycle, the blower

will run briey on its highest speed to purge the air channels.

The lowest speed of any other pumps and the mister will

also run briey. On some circ systems, pump 1 may also run

for the duration of the lter.

(Note: This panel cannot be used to program lter cycles

for systems that are programmed by time rather than by

duration. For these systems, a larger panel is needed and the

following description does not apply.)

The rst lter cycle (day) begins 6 minutes after the spa is

powered up. The second lter cycle (night) begins 12 hours

later. Filter duration is programmable for 1-12 hours ( -

). The default lter duration can vary from system to

system. To program, press Cool or Warm, then Jets 1.

Press Cool or Warm to select the lter duration. Press

Jets 1 to select the number of lter cycles. The display will

show (both day and night cycles); (day cycle

only); or (night cycle only). Press Cool or Warm to

adjust, then press Jets 1 to exit the programming mode. For

continuous ltration, use and .

Freeze Protection

If the temperature sensors within the heater detect a low

enough temperature, then the pump(s) and the blower

automatically activate to provide freeze protection.

The pump(s) and blower will run either continuously or

periodically depending on conditions.

In colder climates, an optional additional freeze sensor may

be added to protect against freeze conditions that may

not be sensed by the standard sensors. Auxiliary freeze

sensor protection acts similarly except with the temperature

thresholds determined by the switch. See your dealer

for details.

Locking Features

If this panel is used as the main panel, locking features will

not be available.

If this panel is used as a remote or additional panel, it will

lock when the main panel is locked. To unlock this panel,

unlock the main panel.

In the same way, the set temperature can be locked and

unlocked by a main panel. When the set temperature is

locked, it cannot be changed from either panel.

Clean-up Cycle (optional)

When a pump or blower is turned on by a button press, a

clean-up cycle begins 30 minutes after the pump or blower

is turned off or times out. The pump and the ozone generator

will run for one to four hours, depending on the system (on

some systems, you can change this setting.)

26

Circ Pump (optional)

If your system is equipped with a circ pump, it may be

congured to work in one of three different ways:

1) The circ pump operates continuously (24 hours) with the

exception of turning off for 30 minutes at a time when

the water temperature reaches 3F (1.5C) above the set

temperature (most likely to happen in very hot climates).

2) The circ pump stays on continuously, regardless of water

temperature.

3) The circ pump will come on when the system is checking

temperature (polling), during lter cycles, during freeze

conditions, or when another pump is on.

Ozone (optional)

On most systems, the ozone generator (if installed) runs

during lter cycles (except when pump 1 is operating at high

speed on a non-circ system) and during clean-up cycles. On

some systems, the ozone generator operates whenever the

pump runs.

If your system is congured with the optional ozone suppress

feature, the ozone generator will turn off for 1 hour any time

a function button (Jets 1, Jets 2, Blower, etc.) is pressed.

Displaying Info About Your Spa

There are several pieces of information about your spa that

can be called up from the panel, but are only needed in

special cases.

To access this information, press Cool or Warm then

Jets 1, then Light. (Each press must be within 3 seconds

of the previous press.) Then press Cool until you see

on the display. Press Jets 1 to see the SSID (a series of

3 numbers, such as 100 133 10, which indicates the precise

revision of the software in your spa), followed by the Mach

software version number (such as 2.1), followed by

and then your spas network ID number (consisting of both

letters and digits displayed in 5 steps).

If you need to see this series of numbers again, and

is once again on the display, just press Jets 1 again.

When done, press the Light button (more than once if

necessary) until you see the normal temperature display.

User Preferences

There are several aspects of spa operation that you can

customize using the User Preferences submenu.

Press Cool or Warm then Jets 1, then Light. (Each press

must be within 3 seconds of the previous press.) At this

point, if is not showing on the display, press Cool

until you see on the display. Then press Jets 1 to

enter the User Preferences submenu.

Once in the User Preferences submenu, press Cool or

Warm to cycle between these settings:

Suppress Reminders

When set to , reminders are never displayed on the

panel. When set to , reminders are displayed on the

panel periodically.

Temperature in Celsius

When set to , temperatures are displayed on the panel

in degrees Celsius. When set to , temperatures are

displayed in Fahrenheit.

24-hour Time Display

When set to , time is displayed in 24-hour (military)

format (00:00 is midnight, 23:00 is one hour before

midnight). When set to , time is displayed in 12-hour

(am/pm) format (12:00 is midnight, 11:00 pm is one hour

before midnight).

Clean-up Cycle Duration (some systems only)

When set to , Clean-up Cycles are disabled. When set

to through , the number indicates how many

hours each Clean-up Cycle will run.

Dolphin II Address

When set to , no addressing is used. Use this setting

for a Dolphin I, or for a Dolphin II which is set for no address

(which is the Dolphin II factory default). When set to

through , the number is the address (see your

Dolphin II manual for details).

ML550, 551, 554 Panel Operation (cont.)

27

Editing User Preferences

View the setting.

The left two characters (before the decimal point) tell

you what setting youre viewing or editing, the right most

character (after the decimal point) tells you the value of that

setting (for example, for Yes or for No).

If the value is ashing, youre editing it. If the value is not

ashing, youre just viewing it.

Press Jets 1 to switch editing of the value on (ashing) or

off (not ashing). Once youre editing the value (its ashing),

use the Cool or Warm buttons to change the value to the

one you want.

After you change the value, you must press Jets 1 again to

stop the ashing before the change will register, and before

you can view or edit another setting.

If you dont interact with the menu for more than 30 seconds,

it may time out.

If you press Light to back out of the menu, or pause

long enough for it to time out, while a value was ashing,

the changes you were making to that setting are not

remembered. But changes you previously made to other

settings will be in effect.

Any User Preferences that you change will stay in effect

forever or until you change them again (unless the spas

persistent memory is reset by a service technician), and

will override the factory defaults for those settings.

G.F.C.I. PROTECTION

Your spa may be equipped with a G.F.C.I. Protection feature. If

your spa does have this feature enabled, the G.F.C.I. Trip Test

must occur to allow proper spa function.

Within 1 to 7 days after startup, the spa will trip the G.F.C.I.

to test it. (The number of days is factory programmed.) The

G.F.C.I. must be reset once it has been tripped. After passing

the G.F.C.I. Trip Test, subsequent G.F.C.I. trips will indicate a

ground fault or other unsafe condition requiring the power to

the spa to be shut off.

G.F.C.I. TRIP TEST PROCEDURE

The installer can cause the G.F.C.I. Trip Test to occur sooner

by initiating it with the following button sequence.

Press Warm, then Jets 1, then Light. (Each press must be

within 3 seconds of the previous press.) Press the Warm

button repeatedly until is displayed. Press Jets 1 to

select it. Press the Warm button until is displayed.

Press Jets 1 to initiate the G.F.C.I. Trip Test.

The G.F.C.I. should trip within several seconds and the spa

should shut down. If it does not, shut down the power and

manually verify that a G.F.C.I. breaker is installed and that

the circuit and spa are wired correctly. Verify the function

of the G.F.C.I. with its own test button. Restore power to the

spa and repeat the G.F.C.I. Trip Test.

Once the G.F.C.I. is tripped by the test, reset the G.F.C.I.

and the spa will operate normally from that point. You can

verify a successful test by navigating to the item

as described above, pressing Jets 1 and then pressing

the Warm button until you see . The code signies

G.F.C.I. Status - Passed. The system will exit this menu in 30

seconds if no buttons are pressed.

Note: The G.F.C.I. section does not apply on EL

systems used outside the United States.

This G.F.C.I. section does not apply to GL Systems.

WARNING: THE OWNER SHOULD TEST AND

RESET THE G.F.C.I. ON A REGULAR BASIS TO

VERIFY ITS FUNCTION.

28

ML200, 240, 260, 400 Panel Operation

Please refer to the following User Guides for more detailed information:

ML400 User Guide: P/N 40570-99 ML260 User Guide: P/N 40633-99

ML240 User Guide: P/N 40634-99 ML200 User Guide: P/N 40571-99

The pump responsible for heating and ltration (pump 1 low

on non-circ systems, or the circ pump on circ systems) will

be referred to simply as the pump.

Timeouts refer to a preset length of time that a function is

programmed to operate before shutting off automatically.

Certain conditions (lters or freeze) can cause a function to

operate longer, while faults can cause a function to operate

for a shorter length of time. The system keeps track of

timeouts regardless of other conditions occurring.

In multi-button sequences, if buttons are pressed too quickly

in sequence, they may not register

Initial Start-up

When your spa is rst actuated, it will go into Priming mode

(after displaying some conguration information).

The Priming mode will last for up to 4 minutes and then the

spa will begin to heat and maintain the water temperature

in the Standard mode. You can exit Priming mode early by

pressing Temp.

Temp Set (80F - 104F/26.0C - 40.0C)

The last measured temperature is constantly displayed

on the LCD. Your spas set temperature range may

vary from range shown above depending on your

manufacturers settings.

Note that the last measured spa temperature

displayed is current only when the pump has been

running for at least 1 minute.

Temp

ML400

Press the Temp button once to display the set temperature.

To change the set temperature, press the pad a second

time before the LCD stops ashing. Each press of the

Temp button will continue to either raise or lower the set

temperature.

If the opposite direction is desired, release the pad and let

the display revert to the current water temperature. Press

the pad to display the set temperature, and again to make

the temperature change in the desired direction.

After three seconds, the LCD will automatically display the

last measured spa temperature.

Mode ML400

A button combination is used to switch between standard,

economy, and sleep modes. Press Temp followed by Light

to enter mode programming, press Temp to cycle through

to desired mode (LCD ashes until conrmed), then press

Light to conrm selection.

Standard mode maintains the desired temperature. Note

that the last measured spa temperature displayed is current

only when the pump has been running for at least 1 minute.

will appear on the display momentarily when you

switch into Standard Mode.

Economy mode heats the spa to the set temperature

only during lter cycles. will appear solid when

the temperature is not current and will alternate with the

temperature when the temperature is current.

Pressing Jets while in Economy mode puts the spa in

Standard-In-Economy mode, ( ) which operates

the same as Standard Mode, then reverts to Economy

Mode automatically after 1 hour. During this time, pressing

Temp followed by Light will revert the mode to

Economy immediately.

ML400 ML400

Heat

Jets Aux Temp Light

ML260, ML240, ML200 ML260, ML240, ML200

Aux Light Temp Jets Aux Light Temp Jets

29

Sleep mode heats the spa to within 20F (11C) of the set

temperature only during lter cycles. will appear on

the display until mode is changed.

Standby Mode ML400

Pressing Temp followed by Aux or Jets 2 or Blower

will turn off all spa functions temporarily. This is helpful

when changing a lter. Pressing any button exits Standby

mode. On some systems the Jets button will control the

pump in Standby Mode (Drain Mode). In this case, press

any other button to exit. System will revert to previous mode

after 1 hour.

Jets

ML400

Press the Jets button once to turn pump 1 on or off, and

to shift between low and high speeds if equipped. If left

running, the pump will turn off after a time-out period. The

pump 1 low speed time-out on some systems may be as long

as 4 hours.

On non-circ systems, the low speed of pump 1 runs when

the blower or any other pump is on. It may also activate

for at least 1 minute every 30 minutes to detect the spa

temperature (polling) and then to heat to the set temperature

if needed, depending upon mode. When the low speed turns

on automatically, it cannot be deactivated from the panel;

however, the high speed may be started.

Jets 2 (optional on some systems) ML400

If your system has a second pump but your panel does

not have a Jets 2 button, use the Aux button to control

pump 2. Press the Jets 2 button once to turn pump 2 on

or off, and to shift between low and high speeds if it is a

two-speed pump. If left running, the pump will turn off after

a time-out period.

Blower (optional on some systems) ML400

If your system has a blower (and only one pump), but your

panel does not have a Blower button, use the Aux button

to control the blower.

1-speed operation: on/off;

2-speed operation: med/hi/off; or

3-speed operation: lo/med/hi/off.

If left on, the blower will automatically turn off after a time-

out period.

Circ Pump (optional) ML400

If your system is equipped with a circ pump, it may be

congured to work in one of three different ways:

1) The circ pump operates continuously (24 hours) with

the exception of turning off for 30 minutes at a time when

the water temperature reaches 3F (1.5C) above the set

temperature (most likely to happen in very hot climates).

2) The circ pump stays on continuously, regardless of water

temperature.