Fe Cdiagram

Fe Cdiagram

Uploaded by

George SingerCopyright:

Available Formats

Fe Cdiagram

Fe Cdiagram

Uploaded by

George SingerOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Fe Cdiagram

Fe Cdiagram

Uploaded by

George SingerCopyright:

Available Formats

Metallurgy &

Material Science

Dr.S.Jose

Professor, Dept of Mechanical Engg.,

TKM College of Engineering, Kollam

2

Diffusion in crystals

Theory of Alloys

Equilibrium Diagrams

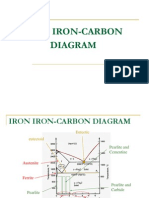

Iron Carbon Phase diagram

TTT Diagram

Heat Treatment

Recovery, Recrystallisation & Grain

Growth

Module II

Allotropes of Iron

Fe Fe

3

C

Phase Diagram

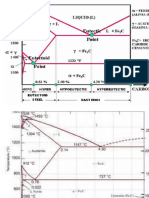

Five individual phases

aferrite (BCC) Fe-C solid solution

g-austenite (FCC) Fe-C solid solution

d-ferrite (BCC) Fe-C solid solution

Fe

3

C (Iron Carbide) or cementite

an inter-metallic compound

Liquid Fe-C solution

Three invariant reactions

A horizontal line always indicates an invariant

reaction in binary phase diagrams

Peritectic reaction at 1495C and 0.18%C,

d-ferrite + L g-iron (austenite)

Eutectic reaction at 1147C and 4.3 %C,

L g-iron + Fe

3

C (cementite) [ledeburite]

Eutectoid reaction at 727C and 0.77%C,

g-iron aferrite+Fe

3

C (cementite) [pearlite]

Peritectic Reaction

Metals

Ferrous metals Non-ferrous metals

Steels Cast Irons

Plain carbon steels

Low alloy steels

High alloy steels

Stainless & Tool steels

Grey Iron

White Iron

Malleable & Ductile Irons

Low carbon steels

Medium carbon steels

High carbon steels

Fe-C alloy classification

Fe-C alloy classification

Fe-C alloys are classified according to wt.% C

present in the alloys

Commercial pure irons % C < 0.008

Low-carbon steels 0.008 - %C - 0.3

Medium carbon steels 0.3 - %C - 0.8

High-carbon steels 0.8- %C - 2.14

Cast irons 2.14 < %C

Cast irons

Cast irons that were slowly cooled to room

temperature consists of cementite, look whitish

white cast iron.

If it contains graphite, look grayish gray cast

iron.

It is heat treated to have graphite in form of

nodules malleable cast iron.

If inoculants are used in liquid state to have

graphite nodules spheroidal graphite (SG)

cast iron.

Eutectoid Reaction

727

3

o

C

Fe C g a +

0.77

0.022 6.67

cool

Pearlite

Eutectoid steel

Hypoeutectoid steel

Proeutectoid

Ferrite

Pearlite

Microstructure of 0.38 wt% C

hypoeutectoid steel

Hypereutectoid steel

Pearlite

Proeutectoid

cementite

Microstructure of 1.4 wt% C

hypereutectoid steel

Eutectoid

steel

a+Fe

3

C

Pearlite

Hypoeutectoid

steel

a+Fe

3

C

Pearlite +

proeutectoid ferrite

Hypereutectoid

steel

a+Fe

3

C

Pearlite +

proeutectoid

cementite

Phase vs. Microconstituents

A phase or a mixture of phases which has a

distinct identity in a microstructure is called a

microconstituent

Pearlite is not a phase.

It is a microconstituent and is a mixture of two

phases a- Ferrite and Fe

3

C.

a-Ferrite

Known as a -iron

Pure iron at room temperature

Body-centered cubic structure

Soft & ductile and imparts these

properties to the steel.

Less than 0.01% carbon will dissolve in

ferrite at room temperature

High temperature form is d ferrite, but

the two forms are identical.

Pure ferritic steels are rare

Austenite

Known as g -iron

Face-centered cubic

Much softer than ferrite

Not present at room temperatures.

More easily hot worked

Cementite

Iron Carbide - an intermetallic compound

Hard, brittle, white

melts at 1837C , density of 7.4 g/cc

On the phase diagram, cementite corresponds

to a vertical line at 6.7% C

Engineers care only about compounds with less

carbon

Its presence in steels causes an increase in

hardness and a reduction in ductility and

toughness

Pearlite

A laminated structure formed of alternate

layers of ferrite and cementite with average

composition 0.83% carbon

Pearly lustre in the microscope

Interference of light in its regular layers

Most common constituent of steel

It combines the hardness and strength of

cementite with the ductility of ferrite and is the

key to the wide range of the properties of

steels.

The laminar structure also acts as a barrier to

crack movement as in composites. This gives

it toughness

Phase Transformations

Involve some alteration of microstructure

1. No change in number or composition of the

phases present, diffusion- dependent.

Solidification of pure metals, allotropic

transformation.

2. Some alteration in composition and no of

phases, diffusion dependent. Eutectoid

reaction

3. A metastable phase is produced,

diffusionless. Martensitic transformation.

At least one new phase is formed

Do not occur instantaneously

Begin by the formation of small particles

of new phase nucleation

Homogenous occurs uniformly throughout

the parent phase.

Hetrogenous preferentially at grain

boundaries, impurities, dislocations

Size of these particles increase in size

until completion - growth

Phase Transformations

Dependent on

Temperature

Time

Composition

Require some finite time for completion

Equilibrium is rarely achieved in solids

Metastable intermediate between

initial and equilibrium states.

Phase Transformations

Time-Temperature

Transformation Diagram

Time-Temperature

Transformation Diagram

Complete

Time-Temperature

Transformation Diagram

Time-Temperature

Transformation Diagram

T T T

Diagram

Pearlite 727 - 540C

Bainite 540 - 210C

Martensite below 210C

Transformation of Austenite in

Eutectoid steel

Transformations involving

austenite

CCT diagram

Usually materials are cooled continuously, thus

Continuous Cooling Transformation diagrams

are appropriate than TTT diagrams

For continuous cooling, the time required for a

reaction to begin and end is delayed, thus the

isothermal curves are shifted to longer times

and lower temperatures.

Main difference between TTT and CCT

diagrams: no space for bainite in CCT diagram

as continuous cooling always results in

formation of pearlite.

CCT diagram

CCT diagram

You might also like

- Valery Marinov, Manufacturing TechnologyDocument168 pagesValery Marinov, Manufacturing TechnologyAbir Roy100% (3)

- Carbon and Its Compounds Shobhit NirwanDocument9 pagesCarbon and Its Compounds Shobhit NirwanRishabh Joshi78% (9)

- Iron Carbon DiagramDocument10 pagesIron Carbon DiagramsivakumarNo ratings yet

- Iron-Carbon Phase Diagram: By: Awad Elaraby ID:052022009Document33 pagesIron-Carbon Phase Diagram: By: Awad Elaraby ID:052022009Mahmoud RefaatNo ratings yet

- University of Babylon, College of Engineering, Engineering Metallurgy, Maithem H-RasheedDocument13 pagesUniversity of Babylon, College of Engineering, Engineering Metallurgy, Maithem H-RasheedAris BulaongNo ratings yet

- Presentation On Heat TreatmentDocument43 pagesPresentation On Heat Treatmentgosaye desalegnNo ratings yet

- Materi Kuliah Heat TreatmentDocument16 pagesMateri Kuliah Heat TreatmentGama Kus RohkmatullohNo ratings yet

- Iron Carbon Phase DiagramDocument4 pagesIron Carbon Phase DiagramMizanur RahmanNo ratings yet

- Iron-Iron Carbide (Fe-Fe3C) Phase Diagram: M. Tech. (FFT) Technology of Ferrous CastingDocument7 pagesIron-Iron Carbide (Fe-Fe3C) Phase Diagram: M. Tech. (FFT) Technology of Ferrous CastingRajulapati Sunil KumarNo ratings yet

- Iron Carbon Diagram (ChE Handbook)Document21 pagesIron Carbon Diagram (ChE Handbook)Mohamed Ismail100% (1)

- Heat Treatment of MetalsDocument18 pagesHeat Treatment of MetalsalikytrnNo ratings yet

- Heat Treatment of SteelDocument51 pagesHeat Treatment of SteelRAMA BAGAS ADITYA TM 2DNo ratings yet

- Practical 1Document9 pagesPractical 1Sami Onur VuralNo ratings yet

- Heat TreatmentDocument179 pagesHeat TreatmentDebye101100% (1)

- Lec 7 Fe C DiagramDocument45 pagesLec 7 Fe C DiagramAdnan MehmoodNo ratings yet

- Engineering Materials 27-29Document40 pagesEngineering Materials 27-29Sanu SouravNo ratings yet

- Fe CDocument34 pagesFe CZaza ArifinNo ratings yet

- 3 Fe-Fe3C Phase DiagramDocument33 pages3 Fe-Fe3C Phase DiagramRajat Mishra100% (1)

- Iron-Carbon DiagramDocument3 pagesIron-Carbon DiagramnaniNo ratings yet

- Review MetalDocument38 pagesReview MetalnisannisaNo ratings yet

- FALLSEM2019-20 MEE1005 ETH VL2019201001078 Reference Material I 29-Aug-2019 Fe-Fe3C Phase DiagramDocument33 pagesFALLSEM2019-20 MEE1005 ETH VL2019201001078 Reference Material I 29-Aug-2019 Fe-Fe3C Phase DiagramFazal KhanNo ratings yet

- Iron Iron-Carbide Equilibrium SystemDocument26 pagesIron Iron-Carbide Equilibrium SystemHiral HiraniNo ratings yet

- Engineering Metallurgy Chapter-8 Ref: Introduction To Physical MetallurgyDocument34 pagesEngineering Metallurgy Chapter-8 Ref: Introduction To Physical MetallurgyMD Al-AminNo ratings yet

- Iron Carbon DiagramDocument8 pagesIron Carbon Diagramashok pradhanNo ratings yet

- EMM LectureDocument38 pagesEMM Lecturelatendra kumar srivastavNo ratings yet

- Iron-Iron Carbide Phase Diagram: Effect of Pressure On Allotropy of IronDocument5 pagesIron-Iron Carbide Phase Diagram: Effect of Pressure On Allotropy of IronnareshNo ratings yet

- Weldability of Metals - NPTELDocument18 pagesWeldability of Metals - NPTELKaushal Gandhi0% (1)

- IIC DiagramDocument57 pagesIIC DiagramAbhishek ChavanNo ratings yet

- 03 - Iron - Iron CarbideDocument35 pages03 - Iron - Iron CarbidebotobotoakbarNo ratings yet

- TTT NotesDocument41 pagesTTT NotesshivanigopiNo ratings yet

- Indian Institute of Welding - Anb Refresher Course - Module 01Document65 pagesIndian Institute of Welding - Anb Refresher Course - Module 01aravindanNo ratings yet

- 1 - Heat TreatmentDocument61 pages1 - Heat TreatmentMohamed El SayadNo ratings yet

- Engineering Metallurgy: Misan University-College of EngineeringDocument26 pagesEngineering Metallurgy: Misan University-College of Engineeringbone manNo ratings yet

- Capili Jefferson 10Document5 pagesCapili Jefferson 10Christian Al EncarnacionNo ratings yet

- Iron Carbon Note 1 2023Document23 pagesIron Carbon Note 1 2023gerrard samuelNo ratings yet

- ME 216 - Engineering Materials II: Heat Treatment (Part I)Document15 pagesME 216 - Engineering Materials II: Heat Treatment (Part I)ozanNo ratings yet

- 3 Iron Carbon DiaDocument21 pages3 Iron Carbon DiaChhavi SharmaNo ratings yet

- 01 Module 01 Metals Structure (Compatibility Mode)Document41 pages01 Module 01 Metals Structure (Compatibility Mode)baluNo ratings yet

- Ch-27.5 Iron Carbon Equilibrium DiagramDocument52 pagesCh-27.5 Iron Carbon Equilibrium DiagramManojNo ratings yet

- The Iron-Carbon Phase DiagramDocument16 pagesThe Iron-Carbon Phase DiagramMeena SivasubramanianNo ratings yet

- Iron and SteelDocument65 pagesIron and SteelSunny PatilNo ratings yet

- What Is PearliteDocument4 pagesWhat Is Pearliteardy cornettoNo ratings yet

- Iron-Carbon Phase Diagram (A Review) See Callister Chapter 9Document34 pagesIron-Carbon Phase Diagram (A Review) See Callister Chapter 9Zefa Erliana YullahNo ratings yet

- 14-Weldability of Al Alloys-29-04-2024Document24 pages14-Weldability of Al Alloys-29-04-2024Aditya Raj SahuNo ratings yet

- The IronCarbide DiagramDocument11 pagesThe IronCarbide DiagramshajjikhalidNo ratings yet

- Ironiron CarbideequilibriumphasediagramDocument39 pagesIroniron CarbideequilibriumphasediagramSheikh UMARNo ratings yet

- Iron Carbon DiagramDocument23 pagesIron Carbon DiagramdeepakNo ratings yet

- Iron Carbon DiagramDocument43 pagesIron Carbon Diagramhrpatel_165No ratings yet

- Unit III - Heat TreatmentDocument62 pagesUnit III - Heat TreatmentHarsha MallaNo ratings yet

- Heat Treatment of SteelsDocument41 pagesHeat Treatment of Steelsyaswanth1992No ratings yet

- MT 305 Heat Treatment: TemperingDocument13 pagesMT 305 Heat Treatment: TemperingaarvNo ratings yet

- FeC and TTT DiagramsDocument12 pagesFeC and TTT DiagramsMohamed El-WakilNo ratings yet

- Materials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraDocument80 pagesMaterials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraAisyah Addia AzizanNo ratings yet

- Iron Carbon DiagramDocument9 pagesIron Carbon DiagramNagamuthu PandianNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- High Temperature Corrosion: Fundamentals and EngineeringFrom EverandHigh Temperature Corrosion: Fundamentals and EngineeringNo ratings yet

- Color Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueFrom EverandColor Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Fourier Series 2: Strou D Strou DDocument17 pagesFourier Series 2: Strou D Strou DGeorge SingerNo ratings yet

- Transition Skills: Managing Self-Study Time, Prioritising and PlanningDocument12 pagesTransition Skills: Managing Self-Study Time, Prioritising and PlanningGeorge SingerNo ratings yet

- List of Topics Ordering Online Manual Download Demo Updates Product Endorsements Award Review Materials Science On CD-ROM User GuideDocument19 pagesList of Topics Ordering Online Manual Download Demo Updates Product Endorsements Award Review Materials Science On CD-ROM User GuideGeorge SingerNo ratings yet

- Navigating Transitions:: Managing My Time To Become An Independent LearnerDocument2 pagesNavigating Transitions:: Managing My Time To Become An Independent LearnerGeorge SingerNo ratings yet

- Computation of Material Density: Gold Exemplar: George SingerDocument1 pageComputation of Material Density: Gold Exemplar: George SingerGeorge SingerNo ratings yet

- Material Property ChartsDocument16 pagesMaterial Property ChartsGeorge SingerNo ratings yet

- Hull College Driving Forward: Renewables TrainingDocument1 pageHull College Driving Forward: Renewables TrainingGeorge SingerNo ratings yet

- GOOD LAB Phase DiagramsDocument9 pagesGOOD LAB Phase DiagramsGeorge SingerNo ratings yet

- Task 2 ProjectsDocument2 pagesTask 2 ProjectsGeorge SingerNo ratings yet

- Kuro PDP lx-5090Document264 pagesKuro PDP lx-5090George SingerNo ratings yet

- Introductiontogastransportation 161222145926 PDFDocument26 pagesIntroductiontogastransportation 161222145926 PDFAl Jawad100% (1)

- ST 321 SpecificationDocument2 pagesST 321 SpecificationEl BaranNo ratings yet

- Catalogue PRODUCT DATA SHEETSDocument123 pagesCatalogue PRODUCT DATA SHEETSninzauNo ratings yet

- 075-092 Specs MC PDFDocument18 pages075-092 Specs MC PDFluis miguel huarita castellonNo ratings yet

- Chemistry 103 Lab Exam ReviewDocument2 pagesChemistry 103 Lab Exam ReviewAndrew Schroeder50% (2)

- HazardousDocument4 pagesHazardousharsa2110No ratings yet

- Chem2 Ch13 Skoog Lab Volumetric Analysis TitrationDocument40 pagesChem2 Ch13 Skoog Lab Volumetric Analysis TitrationBochibo Snatch100% (1)

- PDF JoinerDocument109 pagesPDF JoinerOsama GamilNo ratings yet

- Experiment 3 FinalDocument13 pagesExperiment 3 FinalRvin OngNo ratings yet

- Crystallizers:: CHC3170: Process Equipment Design - Unit IV: Deign of Crystallizer, Agitated Vessels and ReactorsDocument9 pagesCrystallizers:: CHC3170: Process Equipment Design - Unit IV: Deign of Crystallizer, Agitated Vessels and ReactorsAjith KumarNo ratings yet

- Tabla Resume N Desinfect AntesDocument1 pageTabla Resume N Desinfect Antesjose ramírez yañezNo ratings yet

- Group 3 Polymer IndustryDocument31 pagesGroup 3 Polymer IndustryShakila QamarNo ratings yet

- Test Report For Coarse Aggregate: Project InformationDocument2 pagesTest Report For Coarse Aggregate: Project Informationraja qammarNo ratings yet

- Chem 31: Reviewer For 2 DepexDocument27 pagesChem 31: Reviewer For 2 DepexAlma PabilaneNo ratings yet

- Bio DieselDocument10 pagesBio DieselystdfmNo ratings yet

- Melt Ow Index: More Than Just A Quality Control Rheological Parameter. Part IIDocument22 pagesMelt Ow Index: More Than Just A Quality Control Rheological Parameter. Part IIjulioNo ratings yet

- Concrete Repair Principles and Methods Defined in Accordance With European Standards EN1504.Document2 pagesConcrete Repair Principles and Methods Defined in Accordance With European Standards EN1504.albasis petraNo ratings yet

- Meen 360 Cheat SheetDocument1 pageMeen 360 Cheat SheetSaniya SohailNo ratings yet

- 0 Exercise Instruction Heating ValueDocument7 pages0 Exercise Instruction Heating ValueMurali MuthuNo ratings yet

- Certificate: Jawahar Navodaya Vidhyalaya, Kalukheda, Distt.-RatlamDocument13 pagesCertificate: Jawahar Navodaya Vidhyalaya, Kalukheda, Distt.-RatlamRAHUL BamaniyaNo ratings yet

- Company Grade Origin Port: Base Oil Grades Imported Into Indian Ports of Mumbai, JNPT & Chennai - January 2004Document6 pagesCompany Grade Origin Port: Base Oil Grades Imported Into Indian Ports of Mumbai, JNPT & Chennai - January 2004georgevoommen100% (1)

- Historical Chromium Prices and Price ChartDocument1 pageHistorical Chromium Prices and Price Chartkevin_lim90No ratings yet

- JEE Main 2019 Chemistry January Attempt Shift - 2 (09th January, 2019)Document15 pagesJEE Main 2019 Chemistry January Attempt Shift - 2 (09th January, 2019)Resonance Eduventures67% (18)

- SUDSTEAM 40 MAX SDS Ver1Document9 pagesSUDSTEAM 40 MAX SDS Ver1Kouassi Christian KoffiNo ratings yet

- The Haber Process: Nitrogen For The Air and Hydrogen From Natural Gas or Cracking of Hydrocarbons Make AmmoniaDocument1 pageThe Haber Process: Nitrogen For The Air and Hydrogen From Natural Gas or Cracking of Hydrocarbons Make AmmoniaIndianagrofarmsNo ratings yet

- Decorative Exterior Paints: Performance & Binder Design Trends in Asia PacificDocument27 pagesDecorative Exterior Paints: Performance & Binder Design Trends in Asia PacificAPEX SONNo ratings yet

- Wet Air Oxidation For Industrial Wastewater and Sludge TreatmentDocument13 pagesWet Air Oxidation For Industrial Wastewater and Sludge TreatmentRupam sharmaNo ratings yet

- Effect of Adding Phosphate To Drinking WaterDocument6 pagesEffect of Adding Phosphate To Drinking Watersurajit7guptaNo ratings yet