0 ratings0% found this document useful (0 votes)

338 viewsFemap Nxnastran Rotor Dynamics

Femap Nxnastran Rotor Dynamics

Uploaded by

Pierluigi Romanofemap_nxnastran_rotor_dynamics

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Femap Nxnastran Rotor Dynamics

Femap Nxnastran Rotor Dynamics

Uploaded by

Pierluigi Romano0 ratings0% found this document useful (0 votes)

338 views2 pagesfemap_nxnastran_rotor_dynamics

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

femap_nxnastran_rotor_dynamics

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

338 views2 pagesFemap Nxnastran Rotor Dynamics

Femap Nxnastran Rotor Dynamics

Uploaded by

Pierluigi Romanofemap_nxnastran_rotor_dynamics

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

In a rotor dynamics analysis, the systems

critical speed is particularly important. The

critical speed corresponds to a rotation

speed that is equal to the modal frequency.

Because the critical speed is the speed at

which the system can become unstable,

engineers must be able to accurately

predict those speeds as well as detect

possible resonance problems in an analysis.

NX Nastran Rotor Dynamics combines the

versatility of NX Nastran with the ability to

analyze structures with rotating components:

Perform a rotor dynamics modal analysis

using solution sequence 110 (complex modal). Gives synchronous results (rotational speed that is

coincident with rotor critical modes) and asynchronous results (rotor modes as a function of

varying rotor speed)

Compute the response of a rotating system in frequency domain using solution sequence 111

(modal frequency response analysis). Done as either an asynchronous solution in which the rotor

speed is independent of the applied excitation, or as a synchronous solution in which the external

excitation is dependent on the rotor speed for example a mass unbalance

Include differential stiffness to compute centrifugal softening effects

Include geometric stiffening and centrifugal softening in the analysis

Solve the model in the fixed or rotating coordinate reference system

Use modal solutions (as opposed to direct solutions) in the analysis

Support general models (analysis does not have to be restricted to a line model). This is more

flexible than other programs that are limited to line models. Line models work fine for shafts with

rigid rotor disks but not for elastic parts with complicated cross sections or blades

Analyze symmetric as well as unsymmetric rotor models

NX Nastran Rotor Dynamics

NX

Summary

Rotating systems are subject to gyroscopic forces such as Coriolis and centrifugal forces that are not present in stationary systems.

NX Nastran Rotor Dynamics software provides the capability to predict the dynamic behavior of rotating systems. With the Rotor

Dynamics functionality now integrated into NX Nastran, users can now more easily simulate rotating system loads, perform synchronous

and asynchronous analysis to generate Campbell Diagram data, predict whirl frequencies and critical speeds and detect instability in

rotating components.

Benefits

Rapidly evaluate and improve the

dynamic performance of rotating

systems prior to physical

prototyping and production commit

Troubleshoot dynamics-related

noise and vibration problems

in previous designs as well as

current in-production rotating

equipment systems

Evaluate and develop optimal

in-service design modifications

to increase production process

throughput of rotating

equipment systems

Evaluate rotor imbalance and study

general excitation response

Compute critical speeds and whirl

frequencies from Campbell

diagrams

Evaluate in-flight maneuvering

loads on an engine rotor and

simulate engine blade-out

conditions

Perform multi-disciplinary

structural design analysis and

optimization within the unified NX

Advanced Simulation environment

leveraging NX integration

capabilities and using a single

common CAE interface

fact sheet

Siemens PLM Software

www.siemens.com/nx

fact sheet

Applications

The following is a list of common

industry-specific problems that can

be analyzed using the NX Nastran

Rotor Dynamics application:

Rotating shafts

This type of a rotating structure

can be analyzed using two cases

the symmetric case and the

unsymmetric case. Internal

damping and viscous damping are

considered and the critical speeds

corre-sponding to the different

eigen frequencies of the rotor shaft

as well as bending are evaluated in

each case.

Propellers

For propellers, wind turbines and

helicopter rotors, the blades are

elastic and the shaft is relatively

rigid. Structural analysis of these

rotating systems can be

performed with the Rotor Dynamics

capability. Future enhancements

could enable structural coupling

with aero effects.

Electrical generators

The structure can be analyzed in

the rotating reference system and

critical speeds and system

instability detected. Complex mode

shapes can be plotted and

displayed using any postprocessor

capable of plotting complex modes

and interfaces with NX Nastran.

Include dynamic load scenarios such as mass

and force imbalance and any generic Nastran

dynamic loads

Include damping as internal damping acting

on the rotating part of the structure and/or

external damping acting on the fixed part of

the structure and in the bearings. The internal

damping has a destabilizing effect. The external damping has a stabilizing effect

Calculate the complex eigenvalues for each selected rotor speed, along with the damping and the

whirl direction. The software determines the whirl direction from the complex eigenvectors; for

example, see the complex mode illustrated in the figure above

Calculate the whirl modes (system modal frequencies that vary with rotational speed) and

critical speeds

Calculate complex mode shapes

View results in the integrated NX postprocessor (visualization of complex modes)

Create Campbell diagrams of the eigen frequencies leveraging software tools such as Excel. See

Campbell figure on the previous page

Use NX Nastran to write the results of a rotor dynamics analysis to the F06 or OP2 file for

postprocessing. You can also use parameters (ROTCSV, ROTGPF) in the input file to have the software

generate additional types of ASCII output files (CSV and GPF files) which contain data that is

specially formatted for postprocessing results with other tools

Use the CSV file data to plot the damping as a function of rotor speed to help detect resonance

points and regions of instability

Capability NX Nastran Rotor Dynamics

Synchronous and asynchronous excitation Yes

Symmetric rotors Yes

Unsymmetric rotors Yes

Multiple rotors At same speed. (Multiple speeds in future release)

Inline models Yes

Non-inline models Yes

Stationary reference frame Yes

Rotating reference frame Yes

Transient simulation In future release

Frequency simulation Yes

Prerequisites

The NX Nastran Rotor Dynamics application is available as an add-on module with both the NX Nastran

Desktop and NX Nastran Enterprise versions. It requires a license of either NX Nastan Basic and NX

Nastran Response Dynamics or the NX Nastran Advanced Bundle as a prerequisite.

NX

2010 Siemens Product Lifecycle Management Software Inc. All rights reserved. Siemens and the Siemens logo are registered trademarks of Siemens

AG. D-Cubed, Femap, Geolus, GO PLM, I-deas, Insight, Jack, JT, NX, Parasolid, Solid Edge, Teamcenter, Tecnomatix and Velocity Series are trademarks or

registered trademarks of Siemens Product Lifecycle Management Software Inc. or its subsidiaries in the United States and in other countries. All other

logos, trademarks, registered trademarks or service marks used herein are the property of their respective holders. W8 10661 3/10 B

Contact

Siemens PLM Software www.siemens.com/nx

Americas 800 498 5351

Europe 44 (0) 1276 702000

Asia-Pacific 852 2230 3333

You might also like

- Basi Calculation For Pump & Tank SelectionDocument28 pagesBasi Calculation For Pump & Tank SelectionJohn Son G85% (106)

- Digital Modulations using MatlabFrom EverandDigital Modulations using MatlabRating: 4 out of 5 stars4/5 (6)

- Volvo Backhoe Loaders BL60B BL70B T4iDocument28 pagesVolvo Backhoe Loaders BL60B BL70B T4iAlex Alves50% (2)

- Helicopter Structural Design CriteriaDocument2 pagesHelicopter Structural Design CriteriaPierluigi RomanoNo ratings yet

- 1 Malvinas Training BookletDocument71 pages1 Malvinas Training BookletJessica Cristina Navarro Ravelo50% (2)

- API 650-Water SS Tank-060914Document84 pagesAPI 650-Water SS Tank-060914Hamou MelloulNo ratings yet

- Rotordynamic Capabilities in ANSYS Mechanical PDFDocument3 pagesRotordynamic Capabilities in ANSYS Mechanical PDFFarzad SadrNo ratings yet

- Femap v103 Nxnastran AeroelasticityDocument3 pagesFemap v103 Nxnastran AeroelasticityAlan DominguezNo ratings yet

- Vibration in An Unbalance Multi-Stage Rotor - A ReviewDocument17 pagesVibration in An Unbalance Multi-Stage Rotor - A ReviewA BBNo ratings yet

- EM DynamicPaperDocument10 pagesEM DynamicPaperNimish PrabhukhanolkarNo ratings yet

- Samcef For RotorsDocument4 pagesSamcef For RotorsAnonymous KdnOsd9No ratings yet

- AA V1 I2 Rotor Dynamic CapabilitiesDocument3 pagesAA V1 I2 Rotor Dynamic CapabilitiesmhtofighiNo ratings yet

- Rotor DynamicsDocument5 pagesRotor DynamicsavciayNo ratings yet

- Step Motors PrezentacijaDocument125 pagesStep Motors Prezentacijaltd27No ratings yet

- Ds Adams-Machinery LTR WDocument2 pagesDs Adams-Machinery LTR WAydinNo ratings yet

- PTW TMSDocument2 pagesPTW TMSKathia PlascenciaNo ratings yet

- Structural Analysis PDFDocument16 pagesStructural Analysis PDFSwaraj Deep SharmaNo ratings yet

- Best Practices Workshop (III) Adjoint SolverDocument24 pagesBest Practices Workshop (III) Adjoint SolvermnogopodNo ratings yet

- W Defa3639Document29 pagesW Defa3639Jerish JohnNo ratings yet

- Toolkits 0908 E WebDocument21 pagesToolkits 0908 E Webvothanhbinh311099No ratings yet

- Dewesoft Order Tracking Analysis Brochure enDocument4 pagesDewesoft Order Tracking Analysis Brochure en陈辉No ratings yet

- Multi ObjectiveDocument11 pagesMulti ObjectiveAdam ThomsonNo ratings yet

- Get More Accurate Results Faster XlrotorDocument5 pagesGet More Accurate Results Faster XlrotorNair YadukrishnanNo ratings yet

- Technical Paper: Precision Planetary Servo GearheadsDocument13 pagesTechnical Paper: Precision Planetary Servo GearheadsKumar SanthanamNo ratings yet

- Normalized Dynamic Simulation of 3-Phase Induction Motor Using Matlab/SimulinkDocument6 pagesNormalized Dynamic Simulation of 3-Phase Induction Motor Using Matlab/SimulinkMallikarjunBhiradeNo ratings yet

- APR11 Bearing Software BrochureDocument8 pagesAPR11 Bearing Software BrochureDagim GirmaNo ratings yet

- A Tool For Rapid Vehicle Suspension Design PDFDocument10 pagesA Tool For Rapid Vehicle Suspension Design PDFmikael bezerra cotias dos santosNo ratings yet

- 1331 - 4 Dynamics-Transients PDFDocument10 pages1331 - 4 Dynamics-Transients PDFSaddam CartmanNo ratings yet

- Excite Cranktraindesign - PD 07-04 - A4Document2 pagesExcite Cranktraindesign - PD 07-04 - A4Anonymous MB5YbaLrBENo ratings yet

- Energy Analysis To The Design of Rotor Bearing Systems LinkedDocument9 pagesEnergy Analysis To The Design of Rotor Bearing Systems LinkedEbrahim ZolfagharyNo ratings yet

- A O G E I R - D S: Nalysis F Yroscopic Ffects N Otor ISC YstemsDocument48 pagesA O G E I R - D S: Nalysis F Yroscopic Ffects N Otor ISC YstemsTarun BhardwajNo ratings yet

- Critical Speed in Rotating MachineryDocument10 pagesCritical Speed in Rotating Machineryridzim4638No ratings yet

- Stepper MotorDocument2 pagesStepper MotorAnand PrakashNo ratings yet

- Rotor-Dynamics Analysis Process: Polar Moment of Inertia About The Axis of SpinDocument16 pagesRotor-Dynamics Analysis Process: Polar Moment of Inertia About The Axis of SpinpavanpppNo ratings yet

- Ansys Turbo Machinery FlyerDocument2 pagesAnsys Turbo Machinery FlyermilanstrNo ratings yet

- GC Cam Design and Analysis PDFDocument6 pagesGC Cam Design and Analysis PDFrahulNo ratings yet

- 2 - RSD - VLSI Design FlowDocument11 pages2 - RSD - VLSI Design FlowRashmi SinghNo ratings yet

- Introduction To Motion Control Technology: EngineeringDocument4 pagesIntroduction To Motion Control Technology: EngineeringKhadija RvNo ratings yet

- SKF Microlog Module Suite: Analysis Modules Designed For Ease-Of-Use and VersatilityDocument16 pagesSKF Microlog Module Suite: Analysis Modules Designed For Ease-Of-Use and VersatilitysugiantobarusNo ratings yet

- Manufacturing Technology (ME461) Lecture10Document16 pagesManufacturing Technology (ME461) Lecture10candypop8725No ratings yet

- Intro To CNCDocument28 pagesIntro To CNCnaga100% (1)

- Etrax Rail SolutionDocument8 pagesEtrax Rail Solutionpimpowimpi4667No ratings yet

- Rotor: Rotordynamics AnalysisDocument5 pagesRotor: Rotordynamics AnalysisalexmontellNo ratings yet

- 5 Digital Position ControlDocument2 pages5 Digital Position ControlAnonymous 6pVZ96GNo ratings yet

- Artikel Specifying Magnetic Bearings PDFDocument2 pagesArtikel Specifying Magnetic Bearings PDFAgustin A.100% (1)

- Precision Machine DesignDocument56 pagesPrecision Machine DesignFelipe Soares MaiaNo ratings yet

- Literature Review of RotorDocument120 pagesLiterature Review of RotorMojtaba Hasanlu100% (1)

- Stepper Motor PDFDocument2 pagesStepper Motor PDFMohit Kumar SinglaNo ratings yet

- 3919-Article Text-14973-1-10-20180917 PDFDocument21 pages3919-Article Text-14973-1-10-20180917 PDFAbdelwahab AliouatNo ratings yet

- Dctorque-Km BR 000385 Reva Ecn3Document12 pagesDctorque-Km BR 000385 Reva Ecn3Basam RazNo ratings yet

- Modul Pelatihan Etap-2013Document8 pagesModul Pelatihan Etap-2013RafliNo ratings yet

- Torsional Vibration Analysis of Large Rotor System Using Finite-Element and Matlab ProceduresDocument6 pagesTorsional Vibration Analysis of Large Rotor System Using Finite-Element and Matlab ProceduresDynamix SolverNo ratings yet

- ShaftDesigner by IMT (English)Document2 pagesShaftDesigner by IMT (English)Monglen Z. Casiño100% (1)

- Torsional Vibration of Turbomachinery - Duncan N. Walker PDFDocument136 pagesTorsional Vibration of Turbomachinery - Duncan N. Walker PDFkolle_sdestefa100% (1)

- 1.1 Torsional Vibration: Torsional Vibration Involves Angular Oscillations of The Rotors of ADocument6 pages1.1 Torsional Vibration: Torsional Vibration Involves Angular Oscillations of The Rotors of ASç-č AbabiiNo ratings yet

- Device Coordination Relay TestingDocument20 pagesDevice Coordination Relay TestingM Adnan AshrafNo ratings yet

- "Development of A CPLD Based Novel Open Loop Stepper Motor Controller For High Performance Using VHDL" PDFDocument6 pages"Development of A CPLD Based Novel Open Loop Stepper Motor Controller For High Performance Using VHDL" PDFRuby Alexandra CruzNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- Progressive Failure Analysis Methodology For Laminated Composite StructuresDocument92 pagesProgressive Failure Analysis Methodology For Laminated Composite StructuresPierluigi RomanoNo ratings yet

- Adams Tutorial 2nd Edition - PT PDFDocument312 pagesAdams Tutorial 2nd Edition - PT PDFasdf100% (5)

- Material Steel Handbook 19720022813 1972022813Document108 pagesMaterial Steel Handbook 19720022813 1972022813paolomassarotti100% (1)

- Buckling NasaDocument110 pagesBuckling NasaPierluigi RomanoNo ratings yet

- FatigueDocument150 pagesFatiguePierluigi Romano100% (1)

- 41cralmo7 10Document2 pages41cralmo7 10Pierluigi RomanoNo ratings yet

- Modeling The Oh-64 Using Flightlab and Helicopter Simulator ConsiderationsDocument177 pagesModeling The Oh-64 Using Flightlab and Helicopter Simulator ConsiderationsPierluigi RomanoNo ratings yet

- 2006 GATech GradDocument93 pages2006 GATech GradRahul BachawalaNo ratings yet

- JSSG 2006Document497 pagesJSSG 2006Pierluigi RomanoNo ratings yet

- HTTP Simcompanion - Mscsoftware.com Resources Sites MSC Content Meta DOCUMENTATION 10000 DOC10484 Secure Patran 2013 Doc UserDocument234 pagesHTTP Simcompanion - Mscsoftware.com Resources Sites MSC Content Meta DOCUMENTATION 10000 DOC10484 Secure Patran 2013 Doc UserPierluigi RomanoNo ratings yet

- Chapter 7 - Structural AnalysisDocument34 pagesChapter 7 - Structural AnalysisDenice Castro100% (1)

- Regulador de Presión LNG E4-110r03-00-0519-00Document54 pagesRegulador de Presión LNG E4-110r03-00-0519-00Andrea ValdezNo ratings yet

- Beam Analysis: LP LB LRDocument2 pagesBeam Analysis: LP LB LRLester John PrecillasNo ratings yet

- Slide 12 Sheet Forming 1Document37 pagesSlide 12 Sheet Forming 1john doeNo ratings yet

- Pipeline Design Consideration and StandardsDocument50 pagesPipeline Design Consideration and StandardsahmadNo ratings yet

- DLN Bleed HeatDocument10 pagesDLN Bleed HeatCharles WilliamsNo ratings yet

- Dnm500 Dnm500mte4c (Machine)Document104 pagesDnm500 Dnm500mte4c (Machine)andy8aNo ratings yet

- BD 12.01 PDFDocument55 pagesBD 12.01 PDFstavros_stergNo ratings yet

- CFBC Boiler Start Up ProblemsDocument40 pagesCFBC Boiler Start Up ProblemsarvindshuklaNo ratings yet

- WQ (30kW and Above) Series Intelligent Submersible Sewage Pumps-2021-4-07 (EN)Document83 pagesWQ (30kW and Above) Series Intelligent Submersible Sewage Pumps-2021-4-07 (EN)Multi Konsulindo MandiriNo ratings yet

- Tutorial 1Document3 pagesTutorial 1Nikhil ChhatriNo ratings yet

- 1584543837d2gym Katalog MasoneilanDocument24 pages1584543837d2gym Katalog MasoneilanLPG Equipment Consulting and ServicesNo ratings yet

- Pump Tech 3 Pump TypesDocument149 pagesPump Tech 3 Pump TypesGAMUCHIRAI MUGADZANo ratings yet

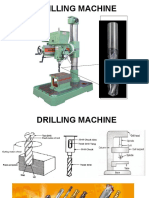

- DRILLING MACHINE SlidesDocument22 pagesDRILLING MACHINE SlidesNishchay pratapNo ratings yet

- Jenkins Bronze ValvesDocument50 pagesJenkins Bronze ValvesCristobal BernalNo ratings yet

- Mixed Convection Flow of Nanofluids Past A Permeable Vertical Surface Under Convective Boundary ConditionDocument17 pagesMixed Convection Flow of Nanofluids Past A Permeable Vertical Surface Under Convective Boundary ConditionsamuelnancyNo ratings yet

- MMZ CatalogueDocument11 pagesMMZ Cataloguerashid isaarNo ratings yet

- B.Tech. Engineering Technology: Work Integrated Learning ProgrammesDocument33 pagesB.Tech. Engineering Technology: Work Integrated Learning ProgrammesSridhar ChebroluNo ratings yet

- Carrier Ducted Split UnitDocument2 pagesCarrier Ducted Split UnitArumugam Murugesan0% (1)

- DEVILBISSDocument2 pagesDEVILBISSISACNo ratings yet

- Worldwide Turbocharger Guide 2016Document54 pagesWorldwide Turbocharger Guide 2016Uzair kazmiNo ratings yet

- Sanli Spare Parts CatalogueDocument32 pagesSanli Spare Parts Cataloguekittyhawk88No ratings yet

- Integrated Mechanical Design Questions For Practice 2003Document4 pagesIntegrated Mechanical Design Questions For Practice 2003Mohammedraffic Noor MohamedNo ratings yet

- Ns2-Yt01-p1qc-120002-Ab (Chemical Dosing System) - Motor Data SheetDocument19 pagesNs2-Yt01-p1qc-120002-Ab (Chemical Dosing System) - Motor Data Sheettrong ngoc PhanNo ratings yet

- TH-1081 07610401Document343 pagesTH-1081 07610401badmaNo ratings yet

- Nozzle RingDocument6 pagesNozzle RingShariq KhanNo ratings yet