Aj 601

Aj 601

Uploaded by

Rama Krishna Reddy DonthireddyCopyright:

Available Formats

Aj 601

Aj 601

Uploaded by

Rama Krishna Reddy DonthireddyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Aj 601

Aj 601

Uploaded by

Rama Krishna Reddy DonthireddyCopyright:

Available Formats

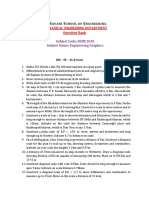

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited

Plant

Naphtha Cracker unit

Location

Panipat, Haryana, India

Always refer to this number

441

04184

AJ-601

Dept./Sect.

Project

Specification

THIS DOCUMENT/DRAWING IS THE PROPERTY OF ABB LUMMUS GLOBAL B.V. INCLUDING ALL PATENTED AND PATENTABLE FEATURES AND/OR CONFIDENTIAL INFORMATION AND ITS USE IS CONDITIONED UPON THE USERS AGREEMENT NOT TO REPRODUCE

THE DOCUMENT/DRAWING, IN WHOLE OR IN PART, NOR THE MATERIAL DESCRIBED THEREON, NOR TO USE THE DOCUMENT/DRAWING FOR ANY PURPOSE OTHER THAN AS SPECIFICALLY PERMITTED IN WRITING BY ABB LUMMUS GLOBAL B.V.

Doc. No.

DE-04184-AJ-0601

Rev. 0

Specification For:

PILING

AJ-601

2005-03-11

REV.

DATE

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

For Feed Package

DESCRIPTION

JLE

PREPARED

GL

CHECKED

AJ-601.DOC

JLE

APPROVED

Page 1 of 1

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

INDEX

SECTION

PAGE

1.

GENERAL

1.1

SCOPE

1.2

DEFINITIONS

1.3

REGULATORY REQUIREMENTS

1.4

APPLICABLE CODES AND STANDARDS

1.5

UNITS

1.6

SITE CONDITIONS

1.7

ENVIRONMENTAL CLASS

2.

SELECTION OF PILES

2.1

GENERAL

2.2

TYPE OF PILES

2.3

SPACING OF PILES

3.

GENERAL REQUIREMENTS

3.1

DESIGN

3.2

MARKING

3.3

HANDLING

3.4

RECEIVING AND STORAGE

3.5

STAKING OUT

4.

STEEL PILES

4.1

MATERIALS

4.2

SURFACE TREATMENT

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

10

AJ-601.DOC

Page 2 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

INDEX (Contd)

SECTION

PAGE

5.

PREFABRICATED REINFORCED CONCRETE PILES

10

5.1

MATERIALS

10

5.2

DESIGN OF REINFORCEMENT

10

5.3

FABRICATION

11

5.4

TOLERANCES

11

6.

PREFABRICATED PRESTRESSED CONCRETE PILES

11

6.1

MATERIALS

11

6.2

DESIGN OF REINFORCEMENT

12

6.3

FABRICATION

12

6.4

TOLERANCES

13

7.

CAST-IN-SITU CONCRETE PILES

13

7.1

GENERAL

13

7.2

MATERIALS

13

7.3

DESIGN OF REINFORCEMENT

13

7.4

TOLERANCES

13

8.

PREDRILLING

13

9.

PILE DRIVING

14

9.1

GENERAL

14

9.2

DRIVING EQUIPMENT

14

9.3

SEQUENCE OF PILE DRIVING

14

9.4

DRIVING PROCEDURE

15

9.5

PILE PENETRATION AND DRIVING RECORDS

16

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 3 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

INDEX (Contd)

SECTION

PAGE

9.6

DRIVING TOLERANCES

17

9.7

MISDRIVEN OR DAMAGED PILES

17

9.8

PILE LENGTHENING

17

10.

PILE TESTING

18

10.1

GENERAL

18

10.2

PILE CAPACITIES

18

10.3

EQUIPMENT

19

10.4

INSTRUMENTATION

20

10.5

LOADING PROCEDURE

20

10.6

RESULTS

23

11.

QUALITY ASSURANCE AND CONTROL

23

11.1

GENERAL

23

11.2

DOCUMENTS

24

11.3

INSPECTION

24

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 4 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

1.

GENERAL

1.1

SCOPE

1.1.1

This specification covers the minimum requirements for the design, materials, fabrication and

installation of driven and bored piles.

1.1.2

Related Engineering Specifications

A-611 Concrete Materials and Construction.

AK-601 Earthworks.

1.2

J-601

Civil/Structural Design.

IA-601 Buildings (Minimum Design Requirements for Architectural Work).

JB-611 Structural Steelwork (Materials, Fabrication and Erection).

DEFINITIONS

For the purpose of this specification, the following definitions shall hold:

Client

Indian oil Corporation Ltd.

Contractor

The party which carries out engineering (if applicable), supply of

materials, fabrication and installation/construction.

Supplier

Any manufacturer or supplier who is appointed by the client or

contractor and responsible for the supply of materials or equipment or

services.

Shall

Is to be understood as mandatory.

Should

Is to be understood as strongly recommended.

May be

Is to be understood as giving a freedom of choice.

1.3

REGULATORY REQUIREMENTS

1.3.1

The work covered in this specification shall comply with all relevant governmental and local

laws, specifications, regulations and standards.

1.3.2

For subjects not covered by regulations, codes and standards or specifications, the design,

material, fabrication and erection shall be based on good economical engineering practice,

subject to approval by client.

1.4

APPLICABLE CODES AND STANDARDS

The following codes (including applicable addenda) and standards shall constitute the minimum

requirements for this specification. The latest edition of codes, standards, etc., shall be used.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 5 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

1.4.1

1.4.2

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

Codes and Standards

IS:456

Code of Practice for Plain and Reinforced Concrete

IS:1200-Part 23

Method of measurement of Building and Civil engineering works

Piling.

IS:1786

High Strength deformed Steel bars and Wires for Concrete

Reinforcement.

IS:2062

Steel for General Structural Purposes.

IS:2386-Part 1 thru Part 8

Methods of Test for Aggregates for Concrete.

IS:5121

Safety Code for Piling and other Deep Foundations.

IS:8112

Specification for 43 Grade ordinary Portland Cement.

IS:10262

Recommended guide lines for Concrete Mix design.

IS:10790-Part 1 and Part 2

Methods of sampling of Steel for Prestressed and Reinforced

concrete.

In case of conflict between above-mentioned codes and standards and this specification,

contractor shall inform client, who will advise.

Where European or American codes/standards are referred to in this specification, equivalent

local codes and standards may be substituted, subject to approval by client.

1.5

UNITS

1.5.1

Units shall be in accordance with the metric (SI) system:

Elevations

meter (m).

Dimensions

millimeter (mm).

Force

kilonewton (kN).

Mass

kilogram (kg).

Moment

kilonewton meter (kNm).

Stress

newton/mm (N/mm) or megapascal (MPa).

Pressure

kilopascal (kPa).

Loadings

kilonewton/m (kN/m).

1.5.2

For simplification purposes, one (1) kg weight may be taken as equal to 10 N (0.010 kN).

1.6

SITE CONDITIONS

1.6.1

For general site and design data, refer to geotechnical investigation report.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 6 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

1.6.2

The geotechnical investigation report, including pile bearing and horizontal load capacities, shall

be supplied by client. Any additional geotechnical information and/or advice required by

contractor to carry out the work shall be obtained by contractor.

1.6.3

A suitably qualified surveyor should locate existing underground obstacles in the area of interest

to determine potential conflicts with piling.

Should such conflicts be found, works shall not proceed until client advises contractor regarding

methods to overcome these conflicts.

1.7

ENVIRONMENTAL CLASS

Applicable environmental class to be in accordance with local and governmental regulations.

2.

SELECTION OF PILES

2.1

GENERAL

2.1.1

The main function of bearing piles is to transfer the loads on a foundation to deeper (soil) strata

which are capable of carrying such loads, in such a way that:

An adequate safety factor against loss of stability is provided.

The foundation settlement/deformation is less than the allowable values of the

foundation and the equipment supported.

2.1.2

The design and testing of piles shall take into account both short-term and long-term behavior of

the pile foundation.

2.2

TYPE OF PILES

2.2.1

The type of piles with regard to material (steel, cast-in-situ or precast concrete) and method of

installation shall be as called for on design drawings and as recommended by approved piling

specialist.

2.2.2

The type of pile to be used is defined by type of loading, the soil conditions, such as drivability

and corrosivity of soil, possibility of tension stresses in the pile due to heave and also the site

conditions, such as effect upon nearby plant and existing works.

Driven prefabricated piles shall be applied wherever possible.

2.2.3

The choice with regard to end bearing, friction, or partly friction and partly bearing type of piles

shall be determined in accordance with geotechnical data recommendations and shall be as

specified by the geotechnical investigation report.

2.2.4

If more than one type of pile is suitable in any particular condition, then the choice shall be

governed by relative costs.

2.2.5

Whatever type of pile is used, it should have the necessary strength when installed to transfer

the loads imposed on it to the soil.

2.2.6

Raked piles shall be avoided where possible and shall be provided to resist horizontal forces

where the latter cannot be resisted by piled foundations on vertical piles.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 7 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

2.2.7

Neutral earth resistance on pile caps, ground beams, etc., may be taken into account in

assessing the foundations ability to resist horizontal forces.

2.3

SPACING OF PILES

Rev.

Error:

The minimum center-to-center spacing of piles shall be as follows, unless otherwise specified in

the geotechnical investigation report:

For friction piles: Not less than three pile diameters.

For piles deriving their resistance from end bearing: not less than twice the least

width or diameter of the pile.

Piles deriving their resistance from both end bearing and skin friction: Not less

than three pile diameters.

3.

GENERAL REQUIREMENTS

3.1

DESIGN

3.1.1

The contractor is responsible for performing pile reinforcement calculations, all in accordance

with the applicable codes and regulations.

3.1.2

The contractor is responsible for obtaining all information required for the calculation of the pile

reinforcement. Calculations shall incorporate the following load cases and requirements:

Transport/fabrication of piles.

Loadings during pile driving.

Additional load due to negative skin friction to be added to the design capacities

for each pile.

be:

Safety factor for pile capacity (including positive or negative skin friction) shall

3.0 for end bearing.

2.5 for skin friction in compression.

2.0 for skin friction in tension.

Safety factor for transport of prefabricated piles shall be 2.0.

Safety factor for lifting (in pile driving equipment) shall be 2.0 with pile tip on the

ground and 1.4 with pile tip on a lorry.

All safety factors shall be in accordance with the latest applicable codes and

regulations and shall be confirmed by the contractor.

3.1.3

Lifting points shall be specified by the contractor.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 8 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

3.2

MARKING

3.2.1

After a prefabricated concrete pile has been cast, the date of casting, reference number, sizes

and where appropriate, the prestressing force shall be clearly inscribed on a label near the top.

3.2.2

Lifting and support point shall be indicated on the shaft of the piles.

3.2.3

Each prefabricated concrete pile shall be marked at intervals of 200 mm along the top 5 m of its

length before being driven.

3.2.4

Test piles shall be marked at intervals of 200 mm over the full length.

3.2.5

Each prefabricated concrete pile shall receive a color marking on top. Piles with standard

reinforcement shall get a green mark, while piles with extra reinforcement shall be marked in

purple.

HANDLING

3.3

3.3.1

The method and sequence of lifting, transporting from the factory to the construction site and

storing of piles shall be such that the piles are not damaged. Only the designed lifting and

support points shall be used.

During transport and storage, piles shall be stored on adequate supports located under the lifting

points of the piles.

3.3.2

Contractor has to prepare and submit handling procedures to client for approval before starting

the work.

3.3.3

Client shall inspect each pile when it is delivered on the construction site. Piles which are

damaged to such an extent that, in the opinion of client, their structural integrity is impaired or

likely to be impaired during the driving, will be rejected by client.

3.4

RECEIVING AND STORAGE

3.4.1

Storage facilities for piles must be installed on site as a part of the pile works. Upon receipt, piles

must be inspected by client, material receiving reports made and issued. In case of damage,

damaged piles shall be removed from construction site.

3.4.2

Piles shall not be stacked in more than four layers, with wooden cribbing installed so lower pile

is free from the ground.

3.4.3

All piles within a stack shall be in groups of the same type. Packings of uniform thickness shall

be provided between piles at the lifting points.

3.5

STAKING OUT

3.5.1

Contractor must stake out the locations of the piles. Stakes shall be numbered and color-coded

in accordance with the numbering on the piling drawings.

4.

STEEL PILES

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 9 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

4.1

MATERIALS

4.1.1

All materials and work shall be in accordance with engineering specification JB-611.

4.1.2

Unless otherwise specified, grade of steel for H-profiles shall be weldable ordinary structural

steel of Grade Fe 410WB, all according to IS:2062 or BS EN 10025 (Grade Fe 430B). All

structural steel pipes shall be Grade Yst-240 to code IS:1161. Pipes shall be either seamless or

mill welded. Spiral-welded pipe is not acceptable. Section sizes and lengths shall be as indicated

on the drawings.

4.1.3

The grade of steel for splice plates, caps and driving points shall be the same as that of the steel

section. Connections should be all welded to the details shown on the drawings.

4.1.4

4.2

Protective coatings where required, shall be as indicated on the drawings. Length of coating shall be

indicated on the drawings.

SURFACE TREATMENT

Surfaces due to receive a protective coating shall be blast cleaned, prior to application of the

coating, which shall then be applied in accordance with the suppliers instructions. Areas

modified within the coated length, such as at cutoffs and at splices with plates welded, shall be

recoated using materials and methods compatible with the existing coating. Curing should be

allowed to take place before pile installation.

5.

PREFABRICATED REINFORCED CONCRETE PILES

5.1

MATERIALS

5.1.1

All materials and work shall be in accordance with engineering specification A-611.

5.1.2

The concrete mixes shall be in accordance with IS:456 and IS;10262. Concrete grade: M45.

5.1.3

Cement type shall be in accordance with IS:8112.

5.1.4

Aggregate shall be in accordance with IS:383 and IS:2386.

5.1.5

Reinforcing quality shall be in accordance with IS:1786 with minimum characteristic yield

strength of 415 N/mm.

5.2

DESIGN OF REINFORCEMENT

5.2.1

The cover to reinforcement, including binding wire, shall not be less than 40 mm for fully

embedded piles in the ground and not less than 50 mm for piles installed in or above open

water.

5.2.2

The steel reinforcement shall be designed in such a way that the crack width of the concrete will

remain less than 0.2 mm under all loading conditions.

5.2.3

Local bars for resisting bending moments may be added but shall be so arranged as to avoid a

sudden discontinuity of the reinforcing steel which could lead to cracking during heavy driving.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 10 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

5.2.4

Lateral reinforcement which is of particular importance in resisting driving stresses, shall be not

less than 6 mm diameter, securely fixed to the main reinforcement.

Lateral reinforcement should be not less than 0.6% of the gross volume, applied over a distance

of three pile diameters from each end of the pile.

5.2.5

Lateral reinforcement in the body of the pile shall be not less than 0.2%, spaced at not more than

half the diameter of the pile. The transition between the close spacing near the ends and the

maximum spacing should be made gradually over a length equal to about three times the

diameter.

5.2.6

If joints to main longitudinal bars are required, they shall be staggered and preferably be made

by full penetration butt-welding.

5.3

FABRICATION

5.3.1

The fabrication shall be executed in accordance with engineering specification A-611.

5.3.2

The quantities and sizes of the piles are as specified in the piling contract documents.

5.3.3

Forms shall be adequately supported to prevent settlement or sagging during fabrication.

5.3.4

Corners and driving head of square piles shall have 25 mm chamfers unless otherwise called for

on design drawings.

5.3.5

The driving head shall be perpendicular to axis of pile.

5.3.6

Main longitudinal bars shall extend to the head of the pile.

5.3.7

An electric control wire in each pile shall be installed in order to ensure that pile is undamaged after

prefabrication, transport and installation.

5.3.8

Concrete shall be placed continuously for each pile to avoid cold joints.

5.3.9

Exposed, unformed concrete surfaces should be floated and lightly toweled.

5.3.10

The piles shall be clean and smooth.

5.4

TOLERANCES

The curvature along the axis of the pile shall not exceed 1 mm/m of length.

6.

PREFABRICATED PRESTRESSED CONCRETE PILES

6.1

MATERIALS

6.1.1

All materials and work shall be in accordance with engineering specification A-611.

6.1.2

The concrete mixes shall be in accordance with IS:456 and IS;10262. Concrete grade: M35

6.1.3

Cement type shall be in accordance with IS:8112.

6.1.4

Aggregate shall be in accordance with IS:383 and IS:2386.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 11 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

6.1.5

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

Reinforcing Quality

For nonprestressed steel; according with IS:1786 with minimum characteristic yield

strength of 415 N/mm.

For prestressed steel; according to IS:1786 and IS:10790 Part 1, shall have a minimum

nominal tensile strength of 1500 N/mm.

6.2

DESIGN OF REINFORCEMENT

6.2.1

The cover to reinforcement, including binding wire, shall not be less than 40 mm for fully embedded

piles in the ground and not less than 50 mm for piles installed in or above open water.

6.2.2

The steel reinforcement shall be designed in such a way that the crack width of the concrete will

remain less than 0.05 mm under all loading conditions.

6.2.3

Local bars for resisting bending moments may be added but shall be so arranged as to avoid a

sudden discontinuity of the reinforcing steel which could lead to cracking during heavy driving.

6.2.4

Sufficient prestressing steel shall be provided in the form of high-tensile wire, strand or bar so that

the effective prestress after losses is sufficient to resist all loading conditions.

6.2.5

Under normal loading conditions tensile strength of prestressed reinforcement shall be 50% of the

maximum allowable tensile strength.

Prestressing strands should be enclosed in spirals minimum 5 mm diameter. Spiral pitch

should be a minimum of 150 mm in the middle part of the pile and 75 mm at the ends (over

a length of three pile diameters).

Minimum effective prestress after losses should be 5 N/mm.

6.3

FABRICATION

6.3.1

The fabrication shall be executed in accordance with engineering specification A-611.

6.3.2

The quantities and sizes of the piles are as specified in the piling contract documents.

6.3.3

Forms shall be adequately supported to prevent settlement or sagging during fabrication.

6.3.4

Corners and driving head of square piles shall have 25 mm chamfers unless otherwise called for on

design drawings.

6.3.5

The driving head shall be perpendicular to axis of pile.

6.3.6

All prestress wires shall be flush with the head.

6.3.7

An electric control wire in each pile shall be installed in order to ensure that pile is undamaged after

prefabrication, transport and installation.

6.3.8

Concrete shall be placed continuously for each pile to avoid cold joints.

6.3.9

Exposed, unformed concrete surfaces should be floated and lightly troweled.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 12 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

6.3.10

The piles shall be clean and smooth.

6.4

TOLERANCES

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

The curvature along the axis of the pile shall not exceed 1 mm/m length.

7.

CAST-IN-SITU CONCRETE PILES

7.1

GENERAL

The types of piles to be used shall be selected on the basis of the site and loading conditions.

Contractor may propose alternatives to the types indicated on the design drawings.

7.2

MATERIALS

7.2.1

All materials and work shall be in accordance with engineering specification A-611.

7.2.2

The concrete mixes shall be in accordance with IS:456 and IS;10262. Concrete grade: M25

7.2.3

Cement type shall be in accordance with IS:8112..

7.2.4

Aggregate shall be in accordance with IS:383 and IS:2386.

7.2.5

Reinforcing quality shall be in accordance with IS:1786, with minimum characteristic yield

strength of 415 N/mm.

7.3

DESIGN OF REINFORCEMENT

7.3.1

Top part of pile (over minimum 6 m) shall have longitudinal reinforcement.

7.3.2

The steel reinforcement shall be designed in such a way that the crack width of the concrete will

remain less than 0.2 mm under all loading conditions.

7.3.3

The cover to reinforcement, including binding wire, shall not be less than 40 mm.

7.4

TOLERANCES

The curvature along the axis of the pile shall not exceed 1 mm/m length.

8.

PREDRILLING

8.1

In areas with underground obstacles of which the exact location is not known, predrilling should be

executed.

8.2

Predrilling comprises a number of drillings to locate these obstacles.

8.3

Drill requirements are:

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

Drill diameter shall not exceed equivalent pile diameter. Diameter shall not exceed 400 mm.

AJ-601.DOC

Page 13 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

The average drill depth shall be not deeper than 5 m above toe elevation of the pile.

Fluidized drilling will not be allowed.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 14 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

9.

PILE DRIVING

9.1

GENERAL

9.1.1

A pile driving procedure, which includes the minimum blow count, description of load tests when

required, shall be established by contractor. No pile driving activities are allowed until approval is

received from client.

9.1.2

Piles shall not be driven until the concrete has achieved the specified characteristic strength.

9.1.3

Before the start of pile driving, the required excavation work shall be done in accordance with

engineering specification AK-601.

9.1.4

The installation of piles and the sequence of driving shall be in accordance with the relevant design

drawings and requirements.

9.1.5

Piles shall be driven vertically, except where noted on the design drawings.

9.1.6

Piles shall be driven within the tolerances set forth in subsection 9.6 of this specification.

9.1.7

Piles damaged during driving shall be repaired or replaced as directed by client.

9.2

DRIVING EQUIPMENT

9.2.1

Energy of the driving hammer shall be adjustable and set to the requirements for the pile type.

9.2.2

The contractor shall submit records of the type of rig and pile hammer he intends to use, indicating

weight, energy per blow, drop height, etc.

9.2.3

Pile driving and lifting equipment ensuring stability during handling, lifting and installing of the piles,

shall be strictly as stated in contractor's tender.

9.2.4

Driving of each pile shall start with new cushion material in the pile cap.

9.2.5

In hazardous areas, plastic dollies or other approved type shall be used for safety purposes.

9.3

SEQUENCE OF PILE DRIVING

9.3.1

The sequence of driving piles shall be as agreed with client before commencement of any work and

contractor may be requested by client to adjust its sequence.

9.3.2

In general, the first pile shall be driven close to the location of a CPT (if available).

9.3.3

If pile driving has to be carried out on a sloping surface, driving shall start at the higher parts.

9.3.4

Piles in a large group should be either driven progressively from one side to the other or outward

from the center of the group. The final driving sequence shall be determined after detailed piling

plan is available.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 15 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

9.4

DRIVING PROCEDURE

9.4.1

Each pile shall be driven continuously until the specified or approved set and/or depth has been

reached and to the minimum specified blow count and, if applicable, when the pile tip has reached

the bearing zone.

9.4.2

If refusal is encountered above the bearing zone, the pile driving system and/or installation

procedure shall be adjusted in order to achieve the specified depth.

9.4.3

If a pile does not meet the specified blow count, if applicable, within the bearing zone, driving shall

continue until the specified minimum blow count is achieved over a one meter interval. Alternatively,

these piles may be accepted if selective pile load tests do support that these piles have sufficient

capacity at the specified depths.

9.4.4

During driving of piles to a specified toe elevation, the piling specialist shall carry out a continuous

check of the behavior of each pile and he will calculate, if necessary, by using HILEY or other

approved formula, that each pile will reach the capacity required at the depth specified.

9.4.5

The penetration depth into the bearing soil layer, if applicable, shall be 3 x diameter of pile or 3 x the

dimension of a side in case of a square pile.

9.4.6

At all stages during driving the piles shall be adequately supported and restrained by means of

leaders, trestles, temporary supports or other guide arrangements to maintain position and

alignment and to prevent buckling. These arrangements shall be such that damage to the pile does

not occur.

9.4.7

To prevent damage to the pile during driving, the contractor shall ensure that the pile hammer is

properly centered over the pile, the steel cover (pile cap) over the pile head fits properly (20 mm ply

maximum), the wooden filling (two (2) layers of pinewood) has the proper thickness (120 mm at

least) and that this filling is replaced as required.

9.4.8

In case the pile drifts away during the driving, the pile hammer shall be recentered over the pile to

prevent unnecessary stresses.

9.4.9

Piles shall be driven only. Pulling, jetting, jacking of piles into the required position shall not be

permitted.

9.4.10

Where penetration of the pile is suddenly resisted by underground obstructions, such as buried

rocks, the pile contractor shall stop pile driving and bring this condition immediately to the attention

of client for resolution.

9.4.11

Where piles are of the driven type and the spacing and ground conditions are such that ground

heave is likely, the resulting amount of uplift and lateral movement of the piles shall be recorded by

means of levels and positions taken on each pile each day, over a period agreed between

contractor and client.

Piles which heave more than 25 mm shall be reseated to their original elevation.

9.4.12

An elevation shall be taken on each pile as soon as it has been driven and elevations shall again be

taken on all piles after completion of driving.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 16 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

9.5

PILE PENETRATION AND DRIVING RECORDS

9.5.1

Penetration and driving records shall be kept by the contractor and shall be supplied (daily) to the

client.

9.5.2

The pile installation log book records shall include, but not be limited to, the following information:

9.5.3

a.

Pile number as shown on design drawing and sequence of installation.

b.

Number of piles installed per type with location.

c.

Type of pile.

d.

Dimensions of pile.

e.

Date of manufacture.

f.

Date and time of driving.

g.

Final tip elevation.

h.

Final top elevation.

i.

Grade elevation at time of driving.

j.

Reference elevation.

k.

Type of pile driving equipment.

l.

Make, type and weight of hammer, and suppliers rated energy per blow if applicable.

m.

Stroke of hammer.

n.

Blow counts of the last five meters, each 200 mm.

o.

For each pile nearest to a Cone Penetration Test (CPT) location, blow counts shall be

recorded over the total length of the pile, and these blow counts shall be presented in a

graph together with the relevant CPT.

p.

Special observations during pile driving, such as intervals in driving, crushing of the pile

material, replacement of casing, etc.

If piles have to be extended, the driving record will also show:

Restart driving data.

Extended length.

Final tip elevation.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 17 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

9.6

DRIVING TOLERANCES

9.6.1

Piles shall be driven to the specified positions within the following tolerances:

Rev.

Error:

The maximum deviation from the specified slope shall not exceed 1%

(10 mm/m) of the pile length or any section of the length measured when the pile is

aboveground in the leads.

On completion of the driving the horizontal tolerances of pile location shall be

within the following deviations:

50 mm for piles sizes of maximum 250 mm.

75 mm for piles sizes above 250 mm.

Above tolerances to be measured at cut-off elevations.

9.6.2

The contractor shall prepare a table showing the deviation of every pile from its exact required

position and forward this information to the client.

9.7

MISDRIVEN OR DAMAGED PILES

9.7.1

In case the location of a pile is outside the allowable tolerances, client will decide whether the pile

location is acceptable or if additional pile(s) have to be driven or structural modifications may be

required.

9.7.2

If a pile is damaged during pile driving activities, client will decide whether the pile can be repaired

or if the pile shall be cut off and abandoned. The decision of client shall be binding.

9.7.3

Damaged driven concrete piles shall be tested (when required) with the "Acoustic Wave Method",

executed by an approved geotechnical specialist.

9.8

PILE LENGTHENING

9.8.1

Nonprestressed Concrete Piles

A lap shall be formed by stripping reinforcement of surrounding concrete for a distance of forty times

the diameter of the longitudinal bars. They shall be thoroughly cleaned and all lateral reinforcement

removed.

Additional reinforcement shall be placed in position, securely fixed or welded to main bars and the

pile extended by concreting in properly formed molds to the required length.

9.8.2

Prestressed Concrete Piles

Prestressed concrete piles may only be lengthened using approved steel couplings.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 18 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

10.

PILE TESTING

10.1

GENERAL

10.1.1

A number of piles may be selected by the client for testing.

10.1.2

The results of the integrity tests shall be used as basis to decide on additional pile load tests or

replacement. Client's approval is to be obtained.

10.1.3

Tests shall be made both, before and during the schedule pile installation.

Types and pile tests are as follows:

Ultimate load test:

Vertical compression

2 x working load.

Vertical tension

2 x working load.

Horizontal

2 x working load.

Proof load test:

Vertical compression

1 x working load.

Vertical tension

1 x working load.

Horizontal

1 x working load.

Ultimate load tests should all be carried out on preliminary piles. Proof load tension tests should also

be carried out on preliminary piles. Other proof load tests should be carried out on working piles.

The locations of preliminary piles should be shown on the drawings. These should be finally cut off a

minimum of 300 mm below pile cap level.

10.2

PILE CAPACITIES

Pile capacities, i.e. allowable working loads should be confirmed by the ultimate load tests as

follows:

Pile vertical capacity:

When determined or confirmed by a loading test, the allowable pile capacity should be 50%

of the ultimate load, but should in no case exceed the load which produces a net movement

of 0.3 mm per 10 kN of gross load applied.

Pile uplift capacity:

The test should be arranged so that uplift pile capacities are measured simultaneously with

"vertical loading" capacities. Uplift capacities shall be determined as for above vertical

loads.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 19 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

Pile lateral capacity:

Piles should be tested for lateral design capacity in accordance with the following

procedure:

The test load should be 200% of the proposed working lateral load on the pile and produce,

at first cycle, no more than 12 mm lateral movement. The lateral movement at the pile

cutoff elevation should be less than 5 mm when tested with the proposed working load.

10.3

EQUIPMENT

Contractor is responsible for the design, procurement and construction of all structural details

required for the tests.

Heads of piles should be prepared to receive test equipment as follows:

For steel piles

A steel test plate of appropriate thickness for the loads should be set on the pile so

as to obtain full bearing. The size of the test plate should be not less than the width

of the pile, nor less than the area covered by the force-applying apparatus. The test

plate should be welded to the pile.

For concrete piles

Piles should be capped with a concrete head of suitable size, reinforced to

distribute the loads evenly onto the pile shafts.

For other piles

Similar preparation should take place.

Hydraulic Jack and Transfer Beam

Vertical compression or tension loads should be applied axially to the test piles, with care

taken to minimize eccentric loadings. A sufficiently strong test beam should be centered

over the test pile to achieve this, together with hydraulic jack.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

Reaction System

For vertical compression loads the beam can be reacted against either

kentledge or neighboring tension pile.

For vertical tension loads the beams can be reacted against either preliminary

or working piles.

For horizontal loads reaction may be achieved by jacking against kentledge.

With client approval two (2) piles may be jacked apart to achieve the same

result.

AJ-601.DOC

Page 20 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

10.4

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

INSTRUMENTATION

The main objective of the load tests is to derive load-displacement curves from the results.

Therefore during testing measurements should be taken for load, displacement and time.

Loads

Loads applied to the pile head can be monitored by one (1) of the following instruments:

Calibrated pressure gauge (the normal case).

Electrical oil pressure transducer in the hydraulic system.

Calibrated load cells.

Strain gauges installed on the pile.

Displacement

This can be monitored by one (1) of the following:

Micrometer (the normal case).

Accurate optical level device.

Electrical displacement transducer.

Variations in temperature should be monitored throughout the test, to ascertain the influence upon

test results. Equipment should be protected against weather conditions in an appropriate manner.

Instrumentation should be arranged in such a manner that it can be conveniently observed from a

single position.

Before the start of testing, calibration certification for instrumentation should be submitted to client.

10.5

LOADING PROCEDURE

Test piles should be of the same type and installed with the same equipment as working piles. Tests

should be carried out during the normal piling contract and with client's present and should not

require a separate mobilization.

10.5.1

Vertical Compression Load Test

It is recommended that either method A or method B be followed.

Method A

In principle the pile should be loaded to 1.5 to 2.0 times the working load in equal loading steps.

Unloading should take place after every load step, to gather information on load-displacement

behavior in general and elastic/plastic displacements in particular.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 21 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

The following steps are proposed for loading to 1.5 working load:

0.25 - 0.50 - 0 0.50 - 0.75 - 0 0.75 - 1.00 - 0 1.00 - 1.25 - 0 1.25 - 1.50 - 0, etc., times the working load.

It might be necessary to unload to, for example, 0.1 times the working load instead of 0.0 to prevent

movement at the loading frame relative to the pile.

Working load is defined as the allowable load according to pile design plus

negative friction on compression piles if applicable.

Load Step Period.

Piles can be loaded up "regularly and reasonably fast". We recommend that the shortest of

the following criteria is applied for each "new" load.

Constant for three (3) hours.

Constant until pile head movement is smaller than 0.1 mm/20 minutes.

Method B

The pile should be progressively loaded as follows:

The load should be maintained at each stage for the period indicated or until movement under the

specific loads has ceased completely, whichever is the longer period.

Movement may be considered as ceased when it is continuing at no more than the following rates:

0.1 mm/20 minutes.

Rate of Loading

% of Working Load

25

50

75

100

75

50

25

0

100

125

150

175

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

Time

1 hour

1 hour

1 hour

6 hours

10 minutes

10 minutes

10 minutes

10 minutes

6 hours

1 hour

24 hours

1 hour

AJ-601.DOC

Page 22 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Rate of Loading

% of Working Load

200

175

150

125

100

75

50

25

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

Time

6 hours

10 minutes

10 minutes

10 minutes

10 minutes

10 minutes

10 minutes

10 minutes

*

*

*

Note: * For preliminary piles only.

10.5.2

Vertical Tension Load Test

Procedure should be similar to the previous test but with the following applicable:

Criterion for movement ceasing: 0.1 mm/60 minutes.

Rate of Loading

% of Working Load

Time

50

100

150

100

50

0

10.5.3

1 hour

1 hour

6 hours

10 minutes

10 minutes

-

Load to 200% as appropriate.

Horizontal Load Test

Procedure should be similar to previous test but with the following applicable:

Criterion for movement ceasing: 0.1 mm in 60 minutes.

Rate of Loading

% of Working Load

50

100

150

100

50

0

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

Time

1 hour

1 hour

48 hours

10 minutes

10 minutes

-

Load to 200% as appropriate.

AJ-601.DOC

Page 23 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

10.6

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

RESULTS

The settlement or movement of piles under test loads shall be measured and recorded on

completion of each loading stage and every three (3) hours where the load period exceeds

one (1) hour, but does not exceed twelve (12) hours, thereafter every twelve (12) hours.

All results should be forwarded to client in an agreed format.

Any necessary interpretation of test results will be made by client. Should test results warrant, client

may modify installation procedures and criteria, or the design load capacities of piles.

11.

QUALITY ASSURANCE AND CONTROL

11.1

GENERAL

11.1.1

The appointed contractor should ensure the quality of work in respect of both workmanship and

materials. There shall be an element of self-certification (quality plan) and this shall be formalized by

submissions to client. Specific requirements are as follows:

Method Statements.

Contractor should submit method statements (plans) for the following, fully detailing

equipment and materials to be used:

Pile installation.

Pile testing.

Workmanship.

Contractor should employ qualified personnel, fully experienced in the work to be carried

out.

Materials Certificates and Tests.

11.1.2

Contractor shall submit certificates, before work starts, for all materials to be used in the works.

11.1.3

For steel piles certified mill tests reports shall be kept on file by the contractor for inspection by the

client.

11.1.4

For concrete piles (prefabricated and cast-in situ) material certificates shall be submitted for:

11.1.5

Sand, gravel and stone materials.

Cement.

Reinforcing steel.

Contractor shall cast sufficient concrete cylinders or cubes, depending on what the design has been

based and make the required tests as per the requirements stipulated in the applicable code. The

detailed record of the tests shall show the results that the specified concrete strength has been

reached. Copies of this record shall be submitted to the client within three working days.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 24 of 24

ABB Lummus Global B.V.

SPECIFICATION

Client

Error: Reference source not found

Always refer to this number

Plant

Error: Reference source not found

441

Location

Error: Reference source not found

Dept./Sect.

Doc. No.

Error:

Reference

Project

AJ-601

Specification

Error: Reference source

not found

Rev.

Error:

11.1.6

If any test specimen fails to meet the specified concrete strength, contractor shall carry out new

tests for the already cast piles of the related batch. If the new tests fail again, contractor shall bring

this condition immediately to the attention of the client for resolution.

11.1.7

In the case of proprietary products, full catalogue details should be forwarded. For steel fabrication,

shop drawings should be submitted.

11.1.8

Contractor shall employ the services of an independent materials testing laboratory. A testing

program shall be agreed at the start of the contract. Test reports demonstrating compliance with the

specification shall be submitted to client upon completion of piling work. The test reports shall be the

property of the client.

11.2

DOCUMENTS

Piling contractor shall provide following documents:

Pile Logs.

Pile logs shall be submitted daily to the client (see also section 9).

Load Test Report.

Contractor shall submit a report of the pile tests carried out, the scope of which shall be

agreed with the client (see also section 10).

Structural steel acceptance forms.

Concrete tests reports.

As-built Drawings

Contractor shall submit a marked-up drawing giving full details of actual piles installed.

11.3

INSPECTION

11.3.1

Client reserves the right of inspection of the work by the client during all phases of the work.

11.3.2

Contractor shall keep a competent representative at the work fully authorized to act for him and

receive such orders as may given for proper continuation of the work.

LGN SSPE xx-xxxx-xx.xxx (xxxx-xx-xx)

AJ-601.DOC

Page 25 of 24

You might also like

- Dt466-Dt570-Torque de Cabaza ValvuasDocument22 pagesDt466-Dt570-Torque de Cabaza ValvuasWero vences Alpargatas80% (5)

- 붙임 - 3-1. 천연가스용 볼밸브 표준규격Document25 pages붙임 - 3-1. 천연가스용 볼밸브 표준규격윤병택No ratings yet

- LTCS Minus29 Sa105 234 106Document2 pagesLTCS Minus29 Sa105 234 106DIVAKAR PANIGRAHINo ratings yet

- American Flow - VALVE-AND-HYDRANT-MANUALDocument356 pagesAmerican Flow - VALVE-AND-HYDRANT-MANUALRogNo ratings yet

- Tech Sheet 128Document1 pageTech Sheet 128Sriram RamanujamNo ratings yet

- Tech Sheet 133Document3 pagesTech Sheet 133alvaedison00No ratings yet

- Steam Surface Condenser Frequently Asked & Typical QuestionsDocument2 pagesSteam Surface Condenser Frequently Asked & Typical QuestionsFaizan AhmedNo ratings yet

- Origins of Internal Flow SystemsDocument2 pagesOrigins of Internal Flow SystemsobumuyaemesiNo ratings yet

- Engineering Standard: IPS-E-CE-120Document30 pagesEngineering Standard: IPS-E-CE-120farzadkNo ratings yet

- A 53 - A 53M - 02Document22 pagesA 53 - A 53M - 02Sourav RobinNo ratings yet

- GMAW of Creep Resistant SteelsDocument5 pagesGMAW of Creep Resistant SteelsJustin Morse100% (1)

- Exxon IP 9 2 1 Additional RequirementsDocument8 pagesExxon IP 9 2 1 Additional RequirementsGilvan SilvaNo ratings yet

- API 534 Ed. 3 Ballot DraftDocument160 pagesAPI 534 Ed. 3 Ballot DraftV U P RaoNo ratings yet

- Ansi ISA S84.01Document9 pagesAnsi ISA S84.01gallegos70No ratings yet

- Soil Mechanics2 1 PDFDocument65 pagesSoil Mechanics2 1 PDFVo Dinh ThaoNo ratings yet

- Project Procedure: Document Class: ZDocument86 pagesProject Procedure: Document Class: ZNguyen Minh DungNo ratings yet

- EGE13B11Document18 pagesEGE13B11Jhonny Rafael Blanco CauraNo ratings yet

- RESE001Document31 pagesRESE001Anindya ananda putriNo ratings yet

- Improve Evaluation of Brittle Fracture Resistance For VesselsDocument6 pagesImprove Evaluation of Brittle Fracture Resistance For VesselsAnonymous 1XHScfCINo ratings yet

- Galvanized Steel Performance in Soil PDFDocument2 pagesGalvanized Steel Performance in Soil PDFshoaib1985No ratings yet

- HDPE Vs PVCDocument12 pagesHDPE Vs PVCRaya SNo ratings yet

- NL-WI-236-04 Nozzle Loads EquipmentDocument3 pagesNL-WI-236-04 Nozzle Loads EquipmentChirag ShahNo ratings yet

- GAPS Guidelines: Electrostatic PrecipitatorsDocument4 pagesGAPS Guidelines: Electrostatic PrecipitatorsAsad KhanNo ratings yet

- Calculating Heat Loss From Bare Hot SurfacesDocument5 pagesCalculating Heat Loss From Bare Hot SurfacesarjmandquestNo ratings yet

- BD0425A-57A1 - Bolt Up Procedure For Critical FlangesDocument22 pagesBD0425A-57A1 - Bolt Up Procedure For Critical Flangesvpkaranam1100% (1)

- Total Requirements PDFDocument7 pagesTotal Requirements PDFsmrndrdasNo ratings yet

- Asme MFC-3M 1989Document80 pagesAsme MFC-3M 1989Jose Luis Villegas EchalarNo ratings yet

- Parametric Study of Charging Inlet Part2Document18 pagesParametric Study of Charging Inlet Part2mayurghule19100% (1)

- ECS 3-12-5 Compact and Extended Body Steel Gate and Globe ValvesDocument8 pagesECS 3-12-5 Compact and Extended Body Steel Gate and Globe ValvesFlorin Daniel AnghelNo ratings yet

- Is 6533 Part 2 Design of Construction of Steel Chimney CodDocument23 pagesIs 6533 Part 2 Design of Construction of Steel Chimney CodnithilagNo ratings yet

- MS-DD-KMY01-MEC-GA-0002 (Shell) R3-4Document1 pageMS-DD-KMY01-MEC-GA-0002 (Shell) R3-4Muhammad Rizky ImaduddinNo ratings yet

- 12CS1G01Document5 pages12CS1G01Jhonny RinconesNo ratings yet

- Predict Storage-Tank Heat Transfer Precisely-LibreDocument6 pagesPredict Storage-Tank Heat Transfer Precisely-Libreดั๊มพ์ วาสนาทิพย์No ratings yet

- Chap 21 PDFDocument28 pagesChap 21 PDFnelson escuderoNo ratings yet

- Ecs 3-14-2 - 3 - 80097636Document5 pagesEcs 3-14-2 - 3 - 80097636Florin Daniel AnghelNo ratings yet

- Stiffening Effect of Refractory Lined Piping - Carmagen EngineeringDocument1 pageStiffening Effect of Refractory Lined Piping - Carmagen EngineeringnaeandNo ratings yet

- ECS 3-12-9 - 3 - 800871dcDocument8 pagesECS 3-12-9 - 3 - 800871dcFlorin Daniel AnghelNo ratings yet

- NRC Inspection ManualDocument9 pagesNRC Inspection ManualFluxRostrumNo ratings yet

- Preparation For An Official CTI Thermal Performance, Plume Abatement, or Drift Emission TestDocument16 pagesPreparation For An Official CTI Thermal Performance, Plume Abatement, or Drift Emission TesthjmmNo ratings yet

- Ucs 66Document44 pagesUcs 66kjsvonbNo ratings yet

- HRSG CFD AnalysisDocument185 pagesHRSG CFD Analysis조기현No ratings yet

- MSS SP-88 (1993)Document15 pagesMSS SP-88 (1993)jothishNo ratings yet

- Pressure Vessels (Project Standards and Specifications) : Page: 1 of 21Document6 pagesPressure Vessels (Project Standards and Specifications) : Page: 1 of 21Tafe AdamuNo ratings yet

- References: American National Standards Institute (ANSI), 1430 Broadway, New York 10018Document4 pagesReferences: American National Standards Institute (ANSI), 1430 Broadway, New York 10018mika cabelloNo ratings yet

- Chap 29 PDFDocument24 pagesChap 29 PDFnelson escuderoNo ratings yet

- Un 2004-03 - Ud-Au-000-Eb-00009 PDFDocument3 pagesUn 2004-03 - Ud-Au-000-Eb-00009 PDFManjeet SainiNo ratings yet

- Method of Reducing Carry-Over and Reducing Pressure Drop Through Steam Separators, EPRI NP-1607Document367 pagesMethod of Reducing Carry-Over and Reducing Pressure Drop Through Steam Separators, EPRI NP-1607MarioNo ratings yet

- Co-Firing of Biomass in Coal Fired Utility Boiler-2003-Kati SavolainenDocument13 pagesCo-Firing of Biomass in Coal Fired Utility Boiler-2003-Kati SavolainenantjobNo ratings yet

- EGE15B2Document14 pagesEGE15B2Jhonny Rafael Blanco CauraNo ratings yet

- M C S E P A S S: Aterials For Ryogenic Ervice: Ngineering Roperties of Ustenitic Tainless TeelsDocument50 pagesM C S E P A S S: Aterials For Ryogenic Ervice: Ngineering Roperties of Ustenitic Tainless TeelswholenumberNo ratings yet

- Avoid Brittle Fracture in Pressure VesselsDocument12 pagesAvoid Brittle Fracture in Pressure VesselsHieuNo ratings yet

- Pyrogel XTE DatasheetDocument2 pagesPyrogel XTE DatasheetLe Thanh HaiNo ratings yet

- Design Notes: 001 D M88 DB-950009 00Document1 pageDesign Notes: 001 D M88 DB-950009 00raobabar21No ratings yet

- ECS 3-12-2 - 3 - 800871d3Document8 pagesECS 3-12-2 - 3 - 800871d3Florin Daniel AnghelNo ratings yet

- Se 014 PDFDocument1 pageSe 014 PDFAmjad AlibrahimNo ratings yet

- Asme B36.10M-2015Document30 pagesAsme B36.10M-2015Bảo Nhân Nguyễn ĐắcNo ratings yet

- An Overview of The Recent Advances in Composite Materials and Artificial Intelligence For Hydrogen Storage Vessels DesignDocument41 pagesAn Overview of The Recent Advances in Composite Materials and Artificial Intelligence For Hydrogen Storage Vessels DesignIbrahimNo ratings yet

- TS For 33kv Transmission LineDocument19 pagesTS For 33kv Transmission LineRamaKrishna ANo ratings yet

- Ecfn Aus Ci 0100 Spe 01007 (C PDF)Document9 pagesEcfn Aus Ci 0100 Spe 01007 (C PDF)Janeth MeraNo ratings yet

- 220 & 132 KV SF6 CB - GetcoDocument36 pages220 & 132 KV SF6 CB - GetcoVenkatNo ratings yet

- MS-6.1 Piping SupportsDocument19 pagesMS-6.1 Piping SupportsLe Thanh HaiNo ratings yet

- Fe-Fe3c Diagram VerygoodDocument3 pagesFe-Fe3c Diagram VerygoodRama Krishna Reddy DonthireddyNo ratings yet

- Excel 2007 FunctionsDocument24 pagesExcel 2007 FunctionsPopescu AndreiNo ratings yet

- Standard Check ListsDocument136 pagesStandard Check ListsRama Krishna Reddy Donthireddy100% (2)

- Pipe Inspection SpecificationDocument49 pagesPipe Inspection SpecificationRama Krishna Reddy DonthireddyNo ratings yet

- Ga 603Document9 pagesGa 603Rama Krishna Reddy DonthireddyNo ratings yet

- Iocl Shell & Tube He's Spec Ea-601 Rev 0Document5 pagesIocl Shell & Tube He's Spec Ea-601 Rev 0Rama Krishna Reddy DonthireddyNo ratings yet

- Nominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODDocument5 pagesNominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODRama Krishna Reddy DonthireddyNo ratings yet

- E3 19 03 09Document7 pagesE3 19 03 09Rama Krishna Reddy DonthireddyNo ratings yet

- Chapter 3 Steady State Single Phase AC Circuit Analysis Part 2 1Document19 pagesChapter 3 Steady State Single Phase AC Circuit Analysis Part 2 1temesgen adugnaNo ratings yet

- VLSI Implementation of Blowfish Algorithm For Secure Image Data TransmissionDocument5 pagesVLSI Implementation of Blowfish Algorithm For Secure Image Data TransmissionnaveenNo ratings yet

- Unit 4Document96 pagesUnit 4Monica karthikeyavelavanNo ratings yet

- Week60 61 PDFDocument25 pagesWeek60 61 PDFVineeth SivarajNo ratings yet

- Matter and Measurement: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument48 pagesMatter and Measurement: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenVenkat BollineniNo ratings yet

- Historia de MacOSDocument2 pagesHistoria de MacOSJENNIFER Ruth Castro torresNo ratings yet

- P4 Control Statements in CDocument59 pagesP4 Control Statements in Cmehra familyNo ratings yet

- Question Bank For ReferenceDocument6 pagesQuestion Bank For ReferenceRenuka PatelNo ratings yet

- Hull Fund 9 e CH 05 Problem SolutionsDocument10 pagesHull Fund 9 e CH 05 Problem Solutionsnandkishore patankarNo ratings yet

- Feeder Accuracy PDFDocument12 pagesFeeder Accuracy PDFEE POG-III CSTPSNo ratings yet

- Matlab ManualsDocument123 pagesMatlab ManualsKashaf TehreemNo ratings yet

- Math Standard (Part-4) Revision BookletDocument76 pagesMath Standard (Part-4) Revision BookletWild HogNo ratings yet

- Trigonometry SheetbyomsirDocument12 pagesTrigonometry SheetbyomsiraryanNo ratings yet

- Chapter 2 BCO 2opDocument10 pagesChapter 2 BCO 2opBalkrishan GoswamiNo ratings yet

- Bond Prices and YieldsDocument60 pagesBond Prices and YieldsSaurabh GroverNo ratings yet

- Marketing Mix Modeling MMM Concepts and Model Interpretation IJERTV10IS060396Document11 pagesMarketing Mix Modeling MMM Concepts and Model Interpretation IJERTV10IS060396Shubham ChhajedNo ratings yet

- η= P P P η=97.09 % P P x P P P P: Problem Set No. 4 Transformer EfficiencyDocument6 pagesη= P P P η=97.09 % P P x P P P P: Problem Set No. 4 Transformer EfficiencyGeva GarradoNo ratings yet

- Circular Measures PDFDocument11 pagesCircular Measures PDFpizamNo ratings yet

- Unit 2Document6 pagesUnit 2humbleavi100% (1)

- Boeing 737 Parts Inventory Ep Tij MX 2Document6 pagesBoeing 737 Parts Inventory Ep Tij MX 2Bobby Robert MaengkomNo ratings yet

- Thesis 2020Document104 pagesThesis 2020Dinesh guhanNo ratings yet

- QC EngineerDocument4 pagesQC EngineerPankaj ShrivastvaNo ratings yet

- CFX-FSI 14.5 Lect-05 Two Way Solving PostDocument42 pagesCFX-FSI 14.5 Lect-05 Two Way Solving PostShaheen S. RatnaniNo ratings yet

- Poteins Worksheet AnswersDocument11 pagesPoteins Worksheet AnswersAbishuaNo ratings yet

- Ladder Diagram Smart Relay Lift Barang 4 LantaiDocument4 pagesLadder Diagram Smart Relay Lift Barang 4 LantaiYogo HaryantoNo ratings yet

- Learn Laravel in 1 Week: Devan SingaramDocument35 pagesLearn Laravel in 1 Week: Devan SingaramLeonard Rumisov100% (1)

- Absint : Section SectionDocument50 pagesAbsint : Section SectionsavitaNo ratings yet

- Clark Leonard HullDocument15 pagesClark Leonard Hullaulia karimahNo ratings yet

- Macro and Macro PreprocessorDocument72 pagesMacro and Macro PreprocessorNitin Birari0% (1)