Din 3357-1

Din 3357-1

Uploaded by

gm_revankar3942Copyright:

Available Formats

Din 3357-1

Din 3357-1

Uploaded by

gm_revankar3942Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Din 3357-1

Din 3357-1

Uploaded by

gm_revankar3942Copyright:

Available Formats

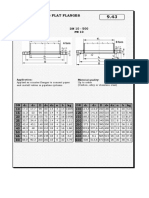

DEUTSCHE NORM

UDC 621.646.616-034

October 1989

DIN

Metal ball valves

3357

Part 1

General requirements and methods of test

Supersedes

August 1982 edition.

Kugelhhne; allgemeine Angaben fr Kugelhhne aus metallischen Werkstoffen

1 Field of application

This standard provides general information regarding the presentation of standards dealing with general purpose metal

ball valves. It specifies details to be included in the standard designation,and also requirements and methods of test for

ball valves with regard to dimensions,valve pattern, trim, body materials and marking.

2 Nominal sizes and pressure ratings

The nominal sizes shall be selected from DIN 2402 and the pressure ratings, from DIN 2401 Part 1.

Designation

The standard designation for ball valves as specified in the DIN 3357 series of standards shall take the following form:

Ball valve

DIN 3357

XXXX

PN

XXX

-

XXX

XXX

-

Term

DIN number

Hyphen

Letter symbol denoting face-to-face or centre-to-face

dlmension if different sizes are assigned to one

pressure rating

Nominal size

Symbol denoting 'pressure rating'

Nominal pressure

Hyphen

Code number (number of relevant Part of DIN 3357)

Type symbol (the type symbol covers valve pattern, material and trim)

Dimensions

4.1 Face-to-face and centre-to-face dimensions

The face-to-face or centre-to-face dimension shall be selected from DIN 3202 Part 1(flanged end ball valves),DIN 3202

Part 2 (weld end ball valves), DIN 3202 Part 3 (wafer type ball valves), DIN 3202 Part 4 (threaded end ball valves), or from

DIN 3202 Part 5 (ball valves with compression ends).

4.2

Space requirement

In DIN 3357 Parts 2 to 7,the space requirement dimensions are specified as the maximum dimensions of the enveloping

body enclosing a ball valve with handwheel.

In the case of ball valves which are not capable of being operated by a handwhee1,the height required is the distance between bottom end of valve body and top end of stem.

Continued on pages 2 to 7

th Verlag GmbH, Berlin, has the exclusive right of sale for German Standards [DIN-Nonnen).

09.90

www.bzxzw.com

DIN 3357 Pari 1 Eng/. Price -group

.

Sales No.u107

Page 2 DIN 3357 Part 1

4.3 Vahreends

Valve ends may be designed as

a) flanged ends, with mating dimensions as specified in DIN 2501 Part 1;

b) weld ends, with mating dimensions as specified in DIN 3239 Part 1;

c) threaded ends, with internal thread as specified in DIN 2999 Part 1;

d) threaded ends, with NPT internal thread as specified in ANSI B 2.1;

e) compression ends, as specified in DIN 2353;

r) threaded ends, with internal and external thread as specified in I S 0 228 Part 1;

g) ball type nipple screwed union, as specified in DIN 7601.

5 mpes and trim

5.1 Body construction

Table 1.

One piece body

Sealed

Axial entry

Top entry

Split body

With open

bottom

Single or multiple

split

Wafer type

body

(three piece)

5.2 Stem seal

The stem seal shall be of the self-sealing type.

5.3

Seat seal

The seat seal shall be of the self-sealing type.

5.4 Trim material

The type of trim required foragiven ballvalveshall - B defined by specifyingtheca sgoryofthe stem,seat and boi-,'connec.>r

seal.The maximum working pressure correspondingto the pressure rating can only be fully utilizedforthe temperatureranges

associated with the particular seal category.

Table 2.

~~~~~

Seal category

Suitable materials (examples)

3

4

5

As

As

3) As

4) As

1)

2)

+ 100

- 10 to + 150

- 10to+200

- 196 to + 200

10 to

50 to

+ 400

NBR*), CRZ), PA'), POM')

EPDMZ), FEPI)

FPM3)

PTFE'), PFA1)

1 It4), metal, graphite

in DIN 7728 Part 1.

in VDI 2537.

in VDI 2531.

in DIN 3754 Part 1.

In the relevant product standards (DIN 3357Parts 2 to 7), narrower limits may be specifiedfor the temperatureranges given in

table 2.

www.bzxzw.com

DIN 3357 Part 1 Page 3

Table 3. Pressure temperature ratings for seal category 4 ball valves

The maximum working pressures specified in table 3 are minimum values and shall apply for seal materials without filler (Le.

asbestos-free materials), intermediate values being obtained by linear interpolation.The maximum working pressurefor temperatures from - 196C t o -30C are not t o be specified before the manufacturer has been consulted.

5.5

Handwheel

Unless otherwise specified in DIN 3 3 s Parts 2 to 7, ball valves shall be supplied with a handwheel.

6 Body materials

The materials listed in table 4 are materials of the pressure containing parts of the body, the choice of body material from

among the materials belonging to a particular material group being up to the manufacturer.The body port ends may also be

made of materials as specified in DIN 1629, DIN 1630, DIN 17172 and 17175.

Table 4.

Material group

Material

number

Material designation

Specified in

Lamellar graphite cast iron

0.6020

0.6025

GG-20

GG-25

DIN 1691

DIN 1691

Nodular graphite cast iron

0.7040

0.7043

0.7050

GGG-40

GGG-40.3

GGG-50

DIN 1693 Part 1

DIN 1693Part 1

DIN 1693 Part 1

Unalloyed and low alloy steel

1.O037

1.O254

1.O050

St 37-2

St 37

St 50-2

C 22.3

C 22.8

c 35

GS-C 25

C 15

C 15Pb

c 22

C 22 Pb

c 35

DIN 17100

DIN 1629

DIN 17100

VdTV Material sheet 364 5)

VdTV Material sheet 350 5)

DIN 1652

DIN 17245

DIN 17210

Not specified.

DIN 17200

Not specified.

DIN 17200

1.O460

1.O501

1.0619

1.O401

1.O403

1.O402

1.O404

1.O501

3ee cutting steel

1.O715

1.0718

9 SMn 28

9 SMnPb 28

DIN 1651

DIN 1651

Stainless steel

1.4000

1.4027

1.4301

1.4308

1.431O

1.4401

1.4404

1.4406

1.4408

1.4410

1.454 1

1.4571

1.4581

X7Cr13

G-X 20 Cr 14

X 5 CrNi 189

G-X 6 CrNi 189

X 12 CrNi 177

X 5 CrNiMo 18 10

X 2 CrNiMo 1810

X 2 CrNiMoN 18 12

G-X 6 CrNiMo 18 10

G-X 10 CtNiMo 189

X 10 CrNiTi 189

X 10 CrNiMoTi 18 10

G-X 7 CrNiMoNb 18 10

DIN 17440

DIN 17445

DIN 17440

DIN 17445

DIN 17445

DIN 17440

DIN 17440

DIN 17440

DIN 17445

DIN 17445

DIN 17440

DIN 17440

DIN 17445

i)

Obtainable from: Maxirnilian Verlag, Postfach 3 71, D-4900 Herford.

--``,,,,,````,``,,`,,``,`,,,`-`-`,,`,,`,`,,`---

www.bzxzw.com

Page 4

DIN 3357 Part 1

Table 4 (concluded).

~~

Material group

Material

number

Specified in

Material designation

Steel with low temperature toughness

1.O356

1.7219

1.6902

1.1156

TTSt 35

GS-26 CrMo 4

G-X 6 CrNi 1810

GS-Ck 24

SEW 680 6,

SEW 6856)

SEW 6856)

SEW 6856)

Fine grain structural steel

1.O508

1.O566

1.O565

TStE 315

TStE 355

WStE 36

SEW 0896)

SEW 0896)

SEW 089 6)

Copper alloys

2.0380

2.0401

2.0360

2.1020

2.1030

2.1050.01

2.1096.01

2.0340.02

2.1086.01

CuZn39Pb2

CuZn39Pb3

CuZn40*)

CuSn6

CuSn8

G-CuSn 10

G-CuSn5ZnPb

GK-CuZn37Pb

G-CuSnl OZn

DIN 17 660

DIN 17660

DIN 17 660

DIN 17662

DIN 17662

DIN 1705

DIN 1705

DIN 1709

DIN 1705

Aluminium alloys

3.2151.O1

3.2341.O1

3.2341.O2

3.2383.01

3.2383.02

3.2382.05

3.2581.O1

3.3241.01

3.2315.71

3.3206

3.3535

G-ALS~GCU~

G-AISi5Mg

GK-AISi5Mg

G-AlSi1OMg(C)

GK-AlSi1OMg(C)

GD-AlSi1OMg

G-AISi12

G-AIMg3Si

AlMgSi1 F28

AlMgSi0,5

AiMg3

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

1725 Part 2

1725 Part 2

1725 Part2

1725 Part 2

1725 Part 2

1725 Part 2

1725 Part 2

1725 Part 2

1747 Part 1

1725 Part 1

1725 Part 1

') Note. This symbol, as used in the standard designations given in DIN 3357 Parts 4 and 5, represents a group of

3)

alloys.

Obtainable from Verlag Stahleisen mbH, Postfach 82 29, D-4000 Dsseldorf.

--``,,,,,````,``,,`,,``,`,,,`-`-`,,`,,`,`,,`---

www.bzxzw.com

DIN 3357 Part 1

Page 5

7 Requirements and testing

Ball valves shall meet the requirements given in tables 5 and 6. Compliance with the requirements listed in table 5 shall be

checked by the manufacturer for every valve,compliance with those listed in table 6, by in-process testing on the basis of random sampling.

Table 5.

Testing as in

Requirement

Ser. No.

DIN 3230 - AA

Compliance with the purchase order data

~~~

Type, pattern and trim material

On delivery, valves shall be in their as ordered condition.

DIN 3230 - AB

Marking

The marking on the valves shall comply with the

standard and be legible.

DIN 3230 - AC

Surfaces

The surfaces shall exhibit no defects likely to impair

safety or proper functioning of the valve.

DIN 3230

Protective coatings

The parts that require protection shall be provided

with a protective coating.

DIN 3230 - AP

Actuation

The valve shall be capable of being actuated properly

on delivery. In the as installed position of the valve,

the stem positions shall be clearly identifiable.

- AE

~~

DIN 3230

- AG

~~

Strength of valve body

In the strength test, the body shall show no signs of

deformation for the specified test duration.

DIN 3230 BA, the test duration being equal

DN s, with a minimum of 10s.

to 10

In the case of PN 4 valves, the strength test may

be carried out together with the tightness test,

using air.

Tightness of body and stem seal

In the tightness test, the body connector seal shall be

tight for the specified duration of test. Leakage rate 1

shall apply to the tightness of the stem seal.

DIN 3230 BO, the test duration being equal

DN s, with a minimum of 10s.

to -

Seat tightness

Seat leakage rate 1 shall apply for seal categories 1 to

4, and leakage rate 2 for seal category 5 valves when

subjected to the nominal pressure or the maximum

differential pressure.

If the production cycle time is shorter than the test

juration specified in DIN 3230 Part 3,the test duration for all valves shall be equal to the cycle time, ranJom samples being taken and tested to test level 3

'or the test duration specified in DIN 3230 Part 3.

--``,,,,,````,``,,`,,``,`,,,`-`-`,,`,,`,`,,`---

www.bzxzw.com

10

DIN 3230 - BN or BO

Page 6 DIN 3357 Part 1

Table 6.

Ser. No.

Requirement

Testing as in

Dimensions

The dimensions as specified in the dimensional

standards shall lie within the permissibletolerances.

DIN 3230 -AD, test level 2

Condition of end faces

The surface condition of the end faces shall comply

with the specifications of the relevant flange

standard.

DIN 3230 -AF, test level 2

--``,,,,,````,``,,`,,``,`,,,`-`-`,,`,,`,`,,`---

Additional requirements and methods of test which are specified in the relevant technical rules (e.g. DIN 3230 Parts 4 to 6,

TRD 3,AD-Mefkblgtter (AD Instruction sheets) 7)) shall be agreed at the time of ordering.

9 Marking

Marking of valves shall be as specified in EN 19.

Standards referred to and other documents

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

DIN

1629

1630

1651

1652

1691

1693 Part 1

1705

1709

1725 Part 1

1725 Part2

1747 Part 1

2353

2401 Part 1

Seamless circular unalloyed steel tubes subject to special requirements; technical delivery conditions

High performance seamless circular unalloyed steel tubes; technical delivery conditions

Free cutting steels; technical delivery conditions

Bright unalloyed steel; technical delivery conditions

Cast iron with lamellar graphite (grey cast iron); properties

Cast iron with nodular graphite; unalloyed and low alloy grades

Copper-tin and copper-tin-zinc casting alloys; castings

Copper-zinc casting alloys; castings

Aluminium wrought alloys

Aluminium casting alloys; sand casting, gravity die casting, pressure die casting, investment casting

Wrought aluminium and aluminium alloy rod and bar; properties

Solderless compression fittings; screwed union assemblies

Components subject to internal or external pressure; pressure and temperature specifications; concepts and pressure ratings

Pipelines; nominal sizes, concept and grading

DIN 2402

DIN 2501 Part i Flanges; mating dimensions

DIN 2999 Part 1 Pipe threads for tubes and fittings: parallel internal thread and taper external thread; dimensions

DIN 3202 Part 1 Face-to-faceand centre-to-face dimensions; flanged valves

DIN 3202 Part2 End-to-face and centre-to-end dimensions; weld end valves

DIN 3202 Part 3 Face-to-facedimensions; wafer type valves

DIN 3202 Part 4 Face-to-faceand centre-to-face dimensions; valves with female thread connection

DIN 3202 Part5 Face-to-faceand centre-to-face dimensions; valves with compression ends

DIN 3230Part3 Technical delivery conditions for valves, summary of test methods

DIN 3230 Part4 Technical delivery conditions for valves; drinking water valves; requirements and testing

DIN 3230 Part5 Technical delivery conditions for valves; valves for gas applications; requirements and testing

DIN 3230Part6 Technical delivery conditions for valves; valves for combustible liquids; requirements and testing

DIN 3239 Part 1 Valve welding ends

DIN 3357 Part 2 Ball valves; full bore steel ball valves

DIN 3357 Part 3 Ball valves; reduced bore steel ball valves

DIN 3357 Part4 Ball valves; full bore non-ferrous metal ball valves

DIN 3357 Part5 Ball valves; reduced bore non-ferrous metal ball valves

DIN 3357Part6 Ball valves; full bore cast iron ball valves

DIN 3357Part7 Ball valves; reduced bore cast iron ball valves

DIN 3754 Part 1 Gasket materials; compressed asbestos fibre sheets; dimensions, requirements and testing

*

7)

Obtainable from Beuih Verlag GmbH, BurggrafenstraBe 6,D-1000 Berlin 30 and Carl Heymanns Verlag KG,Luxemburger

Stra6e 449, D-5000 Kln 1.

DIN 3357 Part 1 Page 7

DIN 7601

Ball type nipple screwed pipe unions; screwed pipe union assemblies

DIN 7728Part 1 Plastics; symbols for homopolymers, copolymers and polymer mixtures

Steels for general structural purposes; quality standard

DIN 17100

DIN 17172

Steel pipes for long-distancepipelines for combustible liquids and gases; technical delivery conditions

Seamless tubes of heat-resistantsteels; technical delivery conditions

DIN 17175

Steels for quenching and tempering; technical delivery conditions

DIN 17200

Case hardening steels; technical delivery conditions

DIN 17210

DIN 17245

Ferritic steel castings with elevated temperature properties; technical delivery conditions

Stainless steels; technical delivery conditions for plate and sheet, hot rolled strip, wire rod, drawn wire,

DIN 17440

steels bars, forgings and semi-finished products

Stainless steel castings; technical delivery conditions

DIN 17445

DIN 17660

Wrought copper alloys: copper-zinc alloys; composition

DIN 17662

Wrought copper alloys; copper-tin alloys; composition

Pipe threads where pressure-tightjoints are not made on the threads; designation,dimensions and tolerIS0 228 Part 1

ances

EN 19

Marking of general purpose industrial valves

VDI 2531

Oberflchenschutz durch Beschichtungen und Auskleidungen mit organischen Werkstoffen; Wahl der

Unerkstoffeund Verfahren (Surface protection using organic materials; selection of coating materialsand

processes)

VDI 2537

Oberflchenschutzmit organischen Werkstoffen; Oberf/chenschutzmit Bahnen auf Basis von Natur-und

Synthesekautschuk (Surface protection using organic materials; surface protectionwith rubberand elastomer sheeting)

VdThl-Werkstoffblatt

(VdTV Material sheet) 350 5) Unlegierter Walz- und Schmiedestahl (Unalloyed rolled steel and forged

steel)

VdTV-Werkstoffblatt 364 5) Flansche aus uniegiertem Stahl (Unalloyed steel flanges)

Stahl-isen-Werkstot/aZt (Iron and steel materialssheet) 0896) SchweiBbareFeinkornbaust#h/e;Gtevorschriften (Weldable

fine-grain structural steels: quality specifications)

Stahl-Eisen-Werkstoffblait 6806) Kakzhe Sthle; Gtevorschriften (Steel with low temperature toughness, quality specifications)

Stahl-Eisen-Werkstoffbla~6856 ) KaltzherStahlguB; Gtevorschriften (Steel casting with low temperature toughness, quality

specifications)

ANSI B 2.1 8 ) Pipe threads (except dry seal)

Previous editions

DIN 3357 Part 1: 12.81, 08.82.

Amendments

In comparison with the August 1982 edition,the temperaturerange for seal category4 specified in table 2 has been amended

to 196C to 200C (instead of 230C).

International Patent Classification

F 16 K 5/06

For 9,see page 3.

For 6). see page 4.

8 ) Obtainable from Beuth Verlag GmbH (Auslandsnormenvermittlung), BurggrafenstraBe 6,D-1000 Berlin 30.

You might also like

- Ansi MH2Document14 pagesAnsi MH2Mohamed Ma'mounNo ratings yet

- 029-Din en 1983 2006 Industrial Valves - Steel Ball ValvesDocument20 pages029-Din en 1983 2006 Industrial Valves - Steel Ball ValvesQuality MSIPL100% (5)

- BS en 1759-1 - 2004Document78 pagesBS en 1759-1 - 2004Tausif LodhiNo ratings yet

- BS en 19-2002 - Industrial Valves. Marking of Metallic ValvesDocument14 pagesBS en 19-2002 - Industrial Valves. Marking of Metallic Valvesnikolicjelena100% (1)

- DIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84Document2 pagesDIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84nunosobralNo ratings yet

- Dimensions Valve Face To Face en 558 1Document3 pagesDimensions Valve Face To Face en 558 1geverett2765No ratings yet

- Din 2576 PDFDocument1 pageDin 2576 PDFSabka PanayotovaNo ratings yet

- Din 28011 PDFDocument6 pagesDin 28011 PDFNagi Nayak0% (1)

- BS en 12627-2017Document14 pagesBS en 12627-2017EmkFataAliraqNo ratings yet

- Önorm en 10208-2Document6 pagesÖnorm en 10208-2jan_matej56510% (1)

- 014-Din en 1503 2001 001 Steels Specified in European StandardsDocument9 pages014-Din en 1503 2001 001 Steels Specified in European StandardsQuality MSIPLNo ratings yet

- En 10253-4 - Butt-Welding Pipe Fitting-Stainless SteelDocument100 pagesEn 10253-4 - Butt-Welding Pipe Fitting-Stainless Steelนพโชติ เสนาพิทักษ์No ratings yet

- EN 1092-1-Flange PDFDocument18 pagesEN 1092-1-Flange PDFSimona Adriana100% (2)

- INCOTERMS Are A Set of Three-Letter Standard Trade Terms Most Commonly Used inDocument3 pagesINCOTERMS Are A Set of Three-Letter Standard Trade Terms Most Commonly Used inNyeko Francis100% (1)

- DIN 3357 Part 1 PDFDocument7 pagesDIN 3357 Part 1 PDFdunknown15No ratings yet

- Din 2526 PDFDocument1 pageDin 2526 PDFDaniel TrombimNo ratings yet

- Din 3357-4-1981Document5 pagesDin 3357-4-1981олегNo ratings yet

- En 10253 3Document50 pagesEn 10253 3Thanh Nguyen VanNo ratings yet

- 3B Awh Din En10357 1Document52 pages3B Awh Din En10357 1Tung100% (1)

- DIN en 10253 4 Corrigendum 2 2009 PDFDocument3 pagesDIN en 10253 4 Corrigendum 2 2009 PDFjirafabg123No ratings yet

- Din 1480 2005Document6 pagesDin 1480 2005PacoNo ratings yet

- Flange Dim EN1092 1 BS4504 PDFDocument18 pagesFlange Dim EN1092 1 BS4504 PDFSathykumar Murugesan100% (1)

- DD Env 1591-2-2001Document12 pagesDD Env 1591-2-2001Ahmed AbidNo ratings yet

- Stainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthDocument15 pagesStainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthOctavio Cotillo LubiánNo ratings yet

- BS 5160Document29 pagesBS 5160surangaNo ratings yet

- DIN 2527-1972, Blank FlangesDocument6 pagesDIN 2527-1972, Blank FlangesalfredopinillosNo ratings yet

- BS en 1708-1 (2010)Document76 pagesBS en 1708-1 (2010)Peter TvardzíkNo ratings yet

- Reductii Concentrice Si Excentrice STAS-8804!8!92Document1 pageReductii Concentrice Si Excentrice STAS-8804!8!92Vasilica BarbarasaNo ratings yet

- Din 2616-2-1991Document13 pagesDin 2616-2-1991mrajaygNo ratings yet

- Novus Sheet Materials PDFDocument22 pagesNovus Sheet Materials PDFermusatNo ratings yet

- BS en 736-2 189Document12 pagesBS en 736-2 189dionepsouzaNo ratings yet

- Astm b283 1996 PDFDocument10 pagesAstm b283 1996 PDFrevelkNo ratings yet

- Iso 5211 2017 en PDFDocument11 pagesIso 5211 2017 en PDFotavio.engenhariaNo ratings yet

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel FlangesDocument8 pagesDimensions, Sizes and Specification of JIS B2220 Standard Steel FlangesdjvhNo ratings yet

- BS en 558-2008Document30 pagesBS en 558-2008Fabio Peres de LimaNo ratings yet

- Din 2526Document1 pageDin 2526MartinsaikiNo ratings yet

- BS EN 736-3 Valves Terminology - Definition TermsDocument12 pagesBS EN 736-3 Valves Terminology - Definition TermsLuis Daniel ContrerasNo ratings yet

- BS EN ISO 228-1: 2003 Table 1 Thread Dimensions British Pipe Thread (Whitworth Form) - Parallel (BSPP/BSPF) - (G)Document3 pagesBS EN ISO 228-1: 2003 Table 1 Thread Dimensions British Pipe Thread (Whitworth Form) - Parallel (BSPP/BSPF) - (G)Sergio Hurtado AvellaNo ratings yet

- BS10 Flange SizesDocument2 pagesBS10 Flange SizesPeter Mc KinleyNo ratings yet

- Din 93Document1 pageDin 93Márcio FragaNo ratings yet

- BS en 12266-1 PDFDocument7 pagesBS en 12266-1 PDFKaushik Sengupta20% (5)

- Abrazadera DIN 3567Document2 pagesAbrazadera DIN 3567Marisol EstradaNo ratings yet

- En10028 2Document29 pagesEn10028 2GaneshNo ratings yet

- BS en Iso 3183 2019 17 18Document2 pagesBS en Iso 3183 2019 17 18Bijaya RaulaNo ratings yet

- BS 336Document36 pagesBS 336nhatvipNo ratings yet

- Din en 13789-2003Document14 pagesDin en 13789-2003karuna346No ratings yet

- ISO Valve StandardsDocument4 pagesISO Valve StandardsLance NguyenNo ratings yet

- BS en 1984 2000Document18 pagesBS en 1984 2000Sudarshan Kv100% (2)

- +GF+ BS en 10242Document45 pages+GF+ BS en 10242stignz100% (2)

- Astm B62 2009Document3 pagesAstm B62 2009Renato MassanoNo ratings yet

- Iso 4200 en PDFDocument6 pagesIso 4200 en PDFJorge Miguel GonçalvesNo ratings yet

- En 1559-3-2011Document20 pagesEn 1559-3-2011uroslukic100% (1)

- AVK Gate Valve HandwheelDocument2 pagesAVK Gate Valve HandwheelQubit SizedNo ratings yet

- Din 3357Document7 pagesDin 3357sheik MohammedNo ratings yet

- BS 5351 - 1986Document31 pagesBS 5351 - 1986anmoljassal100% (1)

- Comparaison en 10253-4 Et DinDocument32 pagesComparaison en 10253-4 Et Dinodaue100% (2)

- DB 650 GBDocument6 pagesDB 650 GBDenial BasanovicNo ratings yet

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- Valve Data Sheet: BCXS302TDocument1 pageValve Data Sheet: BCXS302TRoo FaNo ratings yet

- Double FerruleDocument51 pagesDouble FerrulecristianmihaiNo ratings yet

- F7208HDocument15 pagesF7208HSopon SrirattanapiboonNo ratings yet

- Val-Tex Valve Flush Procedure With High Lights - N PDFDocument4 pagesVal-Tex Valve Flush Procedure With High Lights - N PDFgm_revankar39420% (1)

- Gaskets and SealsDocument4 pagesGaskets and Sealsgm_revankar3942No ratings yet

- SP-1201 - Procurement Specification For Pipeline Ball ValvesDocument52 pagesSP-1201 - Procurement Specification For Pipeline Ball Valvesgm_revankar39420% (1)

- Mj-1645-Us Expanding Gate Valve MJDocument16 pagesMj-1645-Us Expanding Gate Valve MJgm_revankar3942No ratings yet

- Disc Spring UsesDocument20 pagesDisc Spring Usesharishtoki5430No ratings yet

- Environmental Permit Application Form: Ehs Enp-03 ENF-03aDocument4 pagesEnvironmental Permit Application Form: Ehs Enp-03 ENF-03agm_revankar3942No ratings yet

- Disc Spring UsesDocument20 pagesDisc Spring Usesharishtoki5430No ratings yet

- 04 - Monoblock DBB Valves PDFDocument2 pages04 - Monoblock DBB Valves PDFgm_revankar3942No ratings yet

- EML2322L Final Design Review ChecklistDocument3 pagesEML2322L Final Design Review Checklistgm_revankar3942No ratings yet

- Body Safety Valve - KSB PDFDocument4 pagesBody Safety Valve - KSB PDFgm_revankar3942No ratings yet

- EVE Brochure Mar2013Document8 pagesEVE Brochure Mar2013gm_revankar3942No ratings yet

- 9000 PDFDocument53 pages9000 PDFgm_revankar3942No ratings yet

- Dezurik Balancing Valves Flow Curve 12quot 300mm 12-30-1jDocument1 pageDezurik Balancing Valves Flow Curve 12quot 300mm 12-30-1jgm_revankar3942No ratings yet

- Stacker and Reclaimer SystemsDocument16 pagesStacker and Reclaimer SystemshobesNo ratings yet

- AMWELSH 93 Charter PartyDocument8 pagesAMWELSH 93 Charter Partyahong1000% (1)

- Ryanair: The Growth Airline of Europe: Erica Roseingrave - Senior SophisterDocument10 pagesRyanair: The Growth Airline of Europe: Erica Roseingrave - Senior Sophistercloris516No ratings yet

- 1730 - Steel Plates Sheets Strips & FlatsDocument11 pages1730 - Steel Plates Sheets Strips & FlatsKaushik SenguptaNo ratings yet

- Mahindra Logistics Business CaseletDocument3 pagesMahindra Logistics Business CaseletPritam MukherjeeNo ratings yet

- SideWall CoringDocument2 pagesSideWall CoringFortunate Ogene100% (1)

- MT Powder MetallurgyDocument74 pagesMT Powder MetallurgyAhad RazzNo ratings yet

- Procedure For Painting of Structural Steel & PipingDocument10 pagesProcedure For Painting of Structural Steel & Pipingvpsimbu86No ratings yet

- Lista Agentiilor de Turism Licentiate 19.05.2017Document176 pagesLista Agentiilor de Turism Licentiate 19.05.2017ctalexa0No ratings yet

- Project SCMDocument12 pagesProject SCMtusharNo ratings yet

- Timber Frame Solutions 03Document20 pagesTimber Frame Solutions 03sertackcdgNo ratings yet

- The Lean Production Toolbox PDFDocument4 pagesThe Lean Production Toolbox PDFhcu8050% (1)

- Manpower Consultans & Travel Agents: (Registered by Govt. of India)Document11 pagesManpower Consultans & Travel Agents: (Registered by Govt. of India)Mazhaul Islam SujanNo ratings yet

- Ceiling Wall Floor: SCG SmartboardDocument12 pagesCeiling Wall Floor: SCG SmartboardPaolo De PeraltaNo ratings yet

- WoodWorks 5 Over 1 Design Example Sept 2016Document79 pagesWoodWorks 5 Over 1 Design Example Sept 2016pazz0No ratings yet

- PackagingDocument10 pagesPackaginghit2011100% (1)

- AirportDocument55 pagesAirportSavitha Pradeep100% (1)

- Astm Standard List PDFDocument4 pagesAstm Standard List PDFSunil Pulikkal0% (1)

- KS DA 07 001 en Panorama TransportDocument186 pagesKS DA 07 001 en Panorama TransportmobelheiroNo ratings yet

- Mudra Infotech: India 0X7D/ATTDocument2 pagesMudra Infotech: India 0X7D/ATTRohit KumarNo ratings yet

- Fmo ManualDocument60 pagesFmo Manualjesusgameboy100% (1)

- Malaysia Airlines Flight 370Document52 pagesMalaysia Airlines Flight 370aquel1983No ratings yet

- Faizarul Akmal Bin JamaludinDocument24 pagesFaizarul Akmal Bin JamaludinIan Juendan CakenedduadotNo ratings yet

- Q4 Module 8Document14 pagesQ4 Module 8DerickNo ratings yet

- CV Engr. Md. HasmotuzzamanDocument7 pagesCV Engr. Md. HasmotuzzamanEngr SwapanNo ratings yet

- Iocl Shut Down PresentationDocument92 pagesIocl Shut Down Presentationsanjay4210% (1)

- What Is Logistics Management?Document383 pagesWhat Is Logistics Management?Shreya GoyalNo ratings yet

- Fruit Chain StoreDocument7 pagesFruit Chain StorebroowodunNo ratings yet

- How To Fix ACP Clading: Home Interior Design Projects Architecture Publications Testimonials Contact Us EventsDocument3 pagesHow To Fix ACP Clading: Home Interior Design Projects Architecture Publications Testimonials Contact Us EventsNasir AhmedNo ratings yet