03 Specifications 01-05-2014 Final

03 Specifications 01-05-2014 Final

Uploaded by

ravindrarao_mCopyright:

Available Formats

03 Specifications 01-05-2014 Final

03 Specifications 01-05-2014 Final

Uploaded by

ravindrarao_mOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

03 Specifications 01-05-2014 Final

03 Specifications 01-05-2014 Final

Uploaded by

ravindrarao_mCopyright:

Available Formats

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

MANUAL OF

SPECIFICATIONS

AND

STANDARDS FOR

EPC CONTRACT 2014

MINISTRY OF RAILWAYS

(RAILWAY BOARD)

GOVERNMENT OF INDIA

R A I L B H A V A N , R A I S I N A R O A D ,0 N E W D E L H I 1 1 0 0 0 1 ( I N D I A )

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

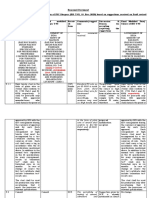

INDEX

Item

No.

Item

Page No.

General

Standards

Geotechnical Investigation

17

Earthworks

17

Road Works

19

Material for Structures

19

Handling and Storage of Materials

19

Piling Work

19

Concrete Works

20

10

Pre-stressing

21

11

Architectural and Building Works

22

12

Fixing RCC Land Boundary Pillers around Railway

Boundary

24

13

Track Works

24

14

Miscellaneous Works

27

15

Well Foundation

29

16

Structural Steel Works for Railway Bridges

29

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

1.

General

1.1

This Manual is applicable for Planning, Design & Construction of Rail

System (the Project) through EPC mode. The scope of the work shall

be as defined in the Agreement. This Manual shall be read harmoniously

with the intent of the Agreement.

1.2

The Project and the project facilities shall conform to the requirements

of design and specifications set out in this Manual, which are the

minimum prescribed. The project report and other information

provided by the Authority shall be used by the Contractor only for its

own reference and for carrying out further investigations.

The

Contractor shall be solely responsible for undertaking all the necessary

surveys, investigations and detailed designs in accordance with good

industry practice and due diligence, and shall have no claim against

the Authority for any loss, damage, risk, costs, liabilities or

obligations arising out of or in relation to the project report and other

information provided by the Authority.

1.3

At least 2 weeks prior to commencement of the work, the Contractor

shall draw up a Quality Assurance Manual (QAM) covering the Quality

System (QS), Quality Assurance Plan (QAP) and documentation for all

aspects of the Project works and send three copies each to the

Authoritys Engineer for review. The QAM shall conform to Applicable

Laws, Good Industry Practice in vogue and the provisions of the

Agreement.

1.4

The codes, standards and specifications applicable for design of the

components of the Rail System are listed in Clause 2.

1.5

The latest version of the codes, standards and specifications, which have

been published before the last date of bid submission shall be

considered applicable.

1.6

The terms Inspector and Engineer used in codes, standards or

specifications shall be deemed to be substituted by the term

Authoritys Engineer, to the extent it is consistent with the

provisions of the Agreement and this Manual. The role of the

Independent Engineer (IE) shall be defined in the Agreement.

1.7

In the absence of any specific provision on any particular issue in

the aforesaid codes, standards or specifications read in conjunction

with the Specifications and Standards contained in this Manual, the

Contractor shall be at liberty to rely on any International Standard in

consultation with Authoritys Engineer.

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

1.8

All items of building works shall conform to the standards specified in

the National Building Code (NBC) and the relevant codes issued by

BIS. For this purpose, building works shall be deemed to include

station buildings, Depot and workshop, OCC, buildings comprising

Project Facilities, traffic integration works, landscape elements and/or

any other works incidental to the building works.

The Contractor shall develop fire-fighting system in consultation with

Authoritys Engineer complying with the local fire safety regulations and

Good Industry Practice in vogue. Fire detection and suppression shall

generally be as per NBC-2005.

1.10 The design of a rail system shall be fully integrated and compatible

with all other sub-systems that constitute the Rail System so that the

overall requirements of the Rail System are met. As far as possible,

uniformity of design standards shall be maintained throughout the rail

system.

1.11 Alternative Standards and Specifications

The requirements stated in the Manual are the minimum. The

Contractor will, however, be free to adopt international practices,

alternative specifications, materials and standards to bring in

innovation in the design and construction provided they are better or

comparable with the standards prescribed in the Manual.

The

specifications and techniques which are not included in the codes,

standards or specifications shall be supported with authentic standards

and specifications reflected in other internationally recognized codes,

standards and specifications. Such a proposal shall be submitted by the

Contractor to the Authoritys Engineer. In case, the Authoritys

Engineer is of the opinion that the proposal submitted by the

Contractor is not in conformity with any of the international codes,

standards and specifications, then he will record his reasons and

convey the same to the Contractor for compliance. A record shall be

kept by the Authoritys Engineer, of the non-compliance by the

Contractor of the minimum Specifications and Standards specified in the

Manual. Adverse consequences, if any arising from any such noncompliance, shall be treated as Contractor Default and shall be dealt

in accordance with the provisions of the Agreement.

1.12 General considerations for planning, design and construction

The Contractor shall take measures to overcome the physical and

operational constraints and plan, design and construct the Project

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

using appropriate methods, management techniques and technologies.

General consideration shall, without being limited to, be as follows:

(a)

The constraints

The physical constraints in the Project could be in the form of limitation

of right of way, existing train services in the vicinity, inadequate

approach roads and underpasses, at- grade yards & stations etc. The

operation constrains arise out of the necessity or possibility of closing a

portion of the road for construction and/or diverting the traffic to

temporary diversions, thereby reducing the capacity and safety of the

existing network. The solutions evolved by the Contractor shall be such

that these constraints are overcome through appropriate planning,

design and construction method, techniques and technologies and by

adopting suitable traffic management measures.

(b)

Safety of design

All designs shall be safe to ensure that the Project or any part thereof (for

example embankment, pavement, retaining structures, bridges, tunnels,

culverts, etc.) does not collapse (global stability) nor its

serviceability/performance (for example settlement, roughness,

undulations, deflections, etc) deteriorates below acceptable level as

prescribed in relevant schedule of Agreement and as recognized by Good

Industry Practice.

(c)

Durability

The Project shall not only be safe but also durable. This would mean that

the deteriorating effects of climate and environment (for example

wetting and drying, freezing

and

thawing,

if

applicable,

temperature

differences, aggressive environment

leading to

corrosion, etc) in addition to the traffic shall be duly considered in

design and construction to make the Project durable.

(d)

Mitigating disruptive effects of construction

The planning, design and construction of the Project shall be such that the

construction does not have adverse impact on the environment and does

not disrupt the lives and business activities of the people living close to

the Project.

1.13 General considerations for rail systems design

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

The rail systems including all the subsystems designed to be utilized by

the Contractor shall be of proven technology and should have been in

service in other similar systems for at least 03 years.

1.14 Safety during Construction

1.14.1 The Contractor shall develop, implement and administer a surveillance

and safety program for providing a safe environment on or about the

Project, and shall comply with the safety requirements set forth in the

Agreement.

1.14.2 Before taking up any construction work, the Contractor shall prepare

a Traffic Management Plan for each work zone and furnish it to the

Authoritys Engineer for comments duly incorporating the following:

(i)

(ii)

Designate a Site Safety Team headed by a qualified Safety Officer.

Traffic safety devices as per IRC:SP:55 with the following

specifications:

a) Signages of retro-reflective sheet of high intensity grade.

b) Delineators in the form of cones/drums (300 to 500

mm dia and 1000 mm high) made of plastic/rubber

having retro reflective red and white band, at a spacing

of maximum 5 m along with a reflective tape (red and

white band) to be tied in between the gaps of

cones/drums. A bulb/flasher using solar energy is to be

placed on the top of the cone/drum for night delineation.

c) Barricades using iron sheet (plain) with adequate iron

railing/frame painted with retro-reflective paint in

alternate black and white (or yellow and black) strips.

Warning lights at 5.0 m spacing shall be mounted on

the barricades and kept lit in the dark hours and night.

(iiii) Sprinkling of water for dust control at work zones, haul roads

and plant/camp sites.

(iv) Noise/Pollution suppression measures at work zones haul roads

and plant/camp sites.

(v)

Mechanical, electrical and fire safety practices.

(vi) Safety measures like PPE (Personal Protection Equipment) for

workers engaged.

(vii) First Aid and Emergency Response Arrangements i.e. First aid Box,

Ambulance, paramedical staff, alarms, etc.

(viii) Safety training/awareness programmes.

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(ix)

(x)

(xi)

Formats to maintain the accident records/emergency response

provided during accidents.

A penalty scheme for violations in provision of adequate traffic

control devices and proper traffic management should be

proposed by the Contractor. In case of default, the amount of

penalty shall be paid by the Contractor to the Authority.

A compensation scheme including insurance cover for third

party for works/road users and road side residents in case of

death/injury/damage to the vehicle/property resulting from

accidents on the Project, irrespective of the person at a fault

should be proposed by the Contractor.

1.14.3The Contractor shall also be responsible for ensuring compliance of all

labour laws and regulations including those relating the welfare of

workers engaged both directly and indirectly on the Project, besides their

occupational safety and health.

1.15 The Contractor shall set up field laboratory for testing of materials and

finished products as stipulated in QAM. It shall make necessary

arrangements

for

additional/

conformity

testing

of

any

materials/products at the government accredited laboratory, for which

facilities at site laboratory is not available.

1.16 Environment Mitigation Measures

The Contractor shall carry out tests/monitor various parameters

impacting the environment of the Project keeping in view the guidelines of

the Ministry of Environment and Forests and submit proposals for

mitigation of adverse environment impact including provision of noise

barriers, etc. for review and comments of the Authoritys Engineer, if any

and undertake implementation of the proposals in consultation with the

Authoritys Engineer.

The Contractor shall take measures as may be necessary in accordance

with the Applicable Laws and Good Industry Practice in vogue to

control and mitigate the noise and vibration arising from the Rail System

and their impact on the users and the neighbourhood. Noise mitigation

measures shall be employed to ensure that the prescribed noise limits

within the neighbourhood buildings and rail vehicles are not exceeded.

1.17 Utilities

The details of the new utilities which are to be constructed or provided

for along or across the Project shall be as specified in relevant schedule of

the Agreement.

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

1.18 Review and comments by the Authoritys Engineer

In cases where the Contractor is required to send any drawings or

documents to the Authoritys Engineer for review and comments, and in

the event such comments are received by the Contractor, it shall

duly consider such comments in accordance with the Agreement and

Good Industry Practice in vogue for taking appropriate action thereon.

The correspondence between the Contractor and the Authoritys

Engineer shall be deemed valid only if a copy thereof endorsed to and

received by the Authority.

1.19 Definitions and Interpretation

Unless specified otherwise in this Manual, the definitions contained in the

Model EPC Agreement for Railways as published by Ministry of Railways

(Railway Board), Government of India shall apply.

2

Standards

2.1

Introduction

The Materials and workmanship specification given herein under is

based on Indian Railway Rules, Standard Codes, Manuals and

Specifications, Indian Standards and International Standards as

scheduled below. Apart from the basic data, specifications etc. all items

of works shall be governed by the Codes & Specifications as detailed

hereunder and as revised / corrected / amended up to the due date of

submission of the Bid Proposal.

The Contractor will be responsible for detailing in his specification of

the standards on which his materials and workmanship will be based,

and these will be of similar or higher standard than those listed below.

The Contractor is required to review in the first instance the relevant

Standards and Codes as mentioned. The specifications will be primarily

based on the said standards to the extent that they are applicable.

2.2

Relevant Standards

Subject to the provisions of the Agreement, all items of works shall be

governed by the following Rules, Codes, Specifications as on the bid

date. In case of any contradiction in various documents mentioned

above, the order of precedence shall be as follows:

a) Indian Railway Rules;

(i)

Indian Railway General and Subsidiary Rules.

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(ii)

(iii)

b)

c)

d)

e)

f)

g)

Indian Railway Rules for Opening New Railway Lines.

Indian Railway Standard Schedule of Dimensions for Broad

Gauge.

(iv) Other Railway Rules specified in 2.2.1.

IRS Codal provisions.

IRC Codal Provisions.

IS Codal Provisions.

Provisions in other International Codes.

Indian Explosive Act.

Indian Explosive Rules.

Note:- In case of road related structures, IRC Codal provisions will prevail

over IRS Codal provisions.

2.2.1

Indian Railway Rules, Codes and Specifications

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

Indian Railway Brides Rules.

Indian Railway Engineering Code.

Indian Railway Code for Practice of Plan/Reinforced and Prestressed concrete for general / bridge construction (Concreted

Bridge Code).

IRS : Welded Bridge Code for steel bridge girders.

IRS Standard Code of Practice for design of Sub-structure &

Foundation.

IRS: T-12 2009 Rail Specifications.

IRS Specifications for Steel Bridges Code.

RDSO Specification No. GE: IRS-2 (Final): Specification for

mechanically produced blanketing material for railway formation

including guidelines for laying.

IR Standard Specification for Fusion of Welding of Rails by

Alumino Thermit Welding Process 2006.

IRS T 29-2000 Cast Manganese Steel Crossings

IRS T 39-1985 Prestressed Concrete Sleepers

IRS GE: 1 June 2004 Ballast specification

IRS T 1966 Fish Plates and Fish Bolts

IRS Fabrication and Erection of Steel Girder Bridges & Locomotive

Turn Tables (BI-1979)

RDSO/M&C/RP-194/94 Wiper seal & dust seal.

2.2.2 Indian Road Congress (IRC) Codes and Specifications

(1)

(2)

IRC: 5 Standard Specifications and Codes of Practice for Road

Bridges Section I General features of design.

IRC: 6 Standard Specifications and Codes of Practice for Road

Bridges Section II Loads and Stresses Seismic provisions of

10

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

this standard are to be adopted for the bridge design.

IRC:18 Design Criteria for Pre-stress Concrete Road Bridges (Posttensioned concrete).

IRC: 21 Standard Specifications and Codes of Practice for Road

Bridges Section III Cement concrete (Plain & reinforced).

IRC: 22 Standard Specifications and Codes of Practice for Road

Bridges Section VI Composite Construction.

IRC:24 Standard Specifications and Codes of Practice for Road

Bridges Section V, Steel Road Bridges.

IRC: 54 1974 Lateral and Vertical Clearances for Vehicular

Traffic.

IRC: 83 (Part III) - Standard Specifications and Codes of Practice

for Road Bridges Section IX Bearings Part III, Pot, POT cum

PTFE Pin and Metallic Guide Bearings.

IRC-78:Sub-structure for Road Bridges.

IRC-87:Design and erection of false work for road bridges.

Specifications for Road and Bridge Works issued by Ministry of

Road Transport & Highways. (MORTH).

The Manual for Construction and Supervision of Bituminous Works.

The Asphalt Institute Manual MS-2.

SP 6, 7, 16, 21, 22, 23, 24, 34, 36, 52, 60, 70.

2.2.3 Indian Standard Specifications:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

IS: 34 White lead for paints.

IS: 57 Red lead for paints and other purposes.

IS: 75 Linseed oil, raw and refined.

IS: 77 Linseed oil, boiled for paints.

IS: 102 Ready mixed paints, brushing, red lead, non-settling

priming.

IS: 104 Ready mixed paint, brushing, zinc chrome, priming.

IS: 123 Ready mixed paints, brushing, finishing, semi-gloss, for

general purposes to Indian Colours etc.

IS: 280 Mild steel wire for general purposes.

IS: 383 Coarse and fine aggregate from natural sources for

concrete.

IS: 432 (Part-I & Part-I) 1982 Mild Steel, Medium Tensile Steel

Bars and Hard Drawn.

IS: 487 Brush, paint and varnish.

IS: 456 Plain and reinforced concrete.

IS: 516 Method of test for strength of concrete.

IS: 786 Conversion factors and conversion tables.

IS: 819 - Resistance spot welding for light assemblies in mild steel.

IS: 875 (Part 3) 1987 Code of Practice for Design Loads (Other

than Earthquakes) for Buildings and Structures Wind Loads

11

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(Second Revision).

17. IS: 887 Animal tallow.

18. IS: 975 (all 5 parts) Design loads (other than earthquakes) for

buildings and structures.

19. IS: 1024-1999 Use of Welding in Bridges and Structures subject to

Dynamic Loading code of Practice Second Revision (Reaffirmed

1998).

20. IS: 1024 Welding in bridges and structures subject to dynamic

loading.

21. IS: 1030 Grade 280-520W- Cast Steel.

22. IS: 1080-1985 Code of practice for design and construction of

shallow foundations in soils (other than raft, ring and shell).

23. IS: 1199 Indian Standard Specifications for Method of Sampling

and analysis of concrete.

24. IS: 1200 (all relevant parts) Method of measurement of building

and civil Engineering works.

25. IS: 1261 1959 Seam Welding in Mild Steel (Reaffirmed 1998)

26. IS: 1270 Metric steel tape measure.

27. IS: 1323 1982-Oxy-acctylene Welding for Structural Work in

Mild Steel (Second Revision).

28. IS: 1343 Prestressed concrete.

29. IS: 1493 Design of Bored and Cast in Situ Piles Founded in Rock.Guide lines.

30. IS: 1725-1982 Specification for soil based blocks used in general

building construction

31. IS: 1786-1985-High Strength Deformed Steel Bars & Wires for

Concrete Reinforcement (Third Revision).

32. IS: 1791 Batch type concrete mixers.

33. IS: 1893-2002 Criteria for Earthquake Resistance Design of

Structures.

34. IS: 1904-1986 Code of practice for design and construction of

foundations in soils: General Requirements.

35. IS: 1915 Steel bridge code.

36. IS: 2074 Ready mixed paint, air drying, red oxide-zinc chrome.

37. IS: 2339 Aluminum paints for general purposes, in dual container.

38. IS: 2386 (all 8 parts) Tests for aggregates for concrete

39. IS: 2502 Code of practice for bending and fixing of Bars for

concrete reinforcement.

40. IS: 2722 Indian Standard Specifications for Portable Swing Weight

batches for concrete (Single and Double Bucket type).

41. IS: 2751 Code of Practice for Welding of Mild Steel Bars used for

reinforced concrete construction.

42. IS: 2809-1972 Glossary of Terms and Symbols Relating to Soil

Engineering.

43. IS: 2911 (Part I to IV) - Code of practice for design and

12

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

construction of pile Foundations.

44. IS: 2974-1982 Part-I: Code of Practice for Design and

Construction of Machine Foundations - Part I: Foundation for

Reciprocating Type Machines.

45. IS: 3016:1965 Code of practice for Fire precaution in welding and

cutting operations.

46. IS: 3025 (all 49 parts) Methods of sampling and test for water

and waste water.

47. IS: 3085 Method of test for permeability of cement mortar and

concrete.

48. IS: 3400 (all 22 parts) Methods of tests for vulcanized rubbers.

49. IS: 3502:1994-Steel Chequered Plates Specifications (Second

Revision).

50. IS: 3696:1987 (Part I & Part-II)) Safety code for scaffolds and

Ladders.

51. IS: 3764 Safety code for excavation work.

52. IS: 3955 Design and construction of well foundations.

53. IS: 4031 (all 15 parts) Physical tests for hydraulic cement.

54. IS: 4081 Safety code for blasting and related drilling operations.

55. IS: 4082 Recommendations of stacking and storage of construction

materials at site.

56. IS: 4091-1979 Code of Practice for Design and Construction of

Foundations for Transmission Line Towers and Poles.

57. IS: 4138 Safety Code for Working on Compressed Air.

58. IS: 4326 Earthquake Resistance Design and Construction of

Building Code of Practice.

59. IS: 4634 Methods of testing performance of batch type concrete

mixers.

60. IS: 4756 Safety Code for Tunneling Work.

61. IS: 4880 (Pt.-IV) Code of Practice for Design of Tunnel

Structural Design of Concrete Lining in Rock.

62. IS: 4880 (Pt.-V) Code of Practice for Design of Tunnel Structural

Design of Concrete Lining in Soft Strata and Soils.

63. IS: 4880 (Pt.-VI) Code of Practice for Design of Tunnel Tunnel

Support.

64. IS: 4926 Indian Standard Specifications for Ready Mixed Concrete.

65. IS: 5513 Vicat apparatus.

66. IS: 5515 Compaction factor apparatus.

67. IS: 5666 Etch primer.

68. IS: 5878 (Pt.-I) Code of Practice for Construction of Tunnels

Precision Survey and Setting Out.

69. IS: 5878 (Pt.-II, Section-I) Code of Practice for Construction of

Tunnels Underground Excavation in Rock Drilling and Blasting.

70. IS: 5878 (Pt.-II, Section-II) Code of Practice for Construction of

Tunnels Underground Excavation in Rock Ventilation, Lighting,

13

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

Mucking & Dewatering.

71. IS: 5878 (Pt.-III) Code of Practice for Construction of Tunnels

Underground Excavation in Soft Strata.

72. IS: 5878 (Pt.-IV) Code of Practice for Construction of Tunnels

Tunnel Support.

73. IS: 5878 (Pt.-V) Code of Practice for Construction of Tunnels

Concrete Lining.

74. IS: 5878 (Pt.-VII) Code of Practice for Construction of Tunnels

Grouting.

75. IS: 6586 Metal spraying for protection of iron steel.

76. IS: 6911 Stainless Steel.

77. IS: 6925 Methods of test for determination of water soluble

chlorides in concrete admixtures.

78. IS: 7205-1974-Safety Code for erection of Structural Steel Work

(Fifth Reprint July, 2001).

79. IS: 7293 Safety code for working with construction machinery.

80. IS: 7320 Concrete slump test apparatus.

81. IS: 8629 (Parts I to III) 1977 Protection of Iron and Steel

Structures from Atmospheric Corrosion (Reaffirmed 2002).

82. IS: 9103 Admixtures for concrete.

83. IS: 10080 Vibration machine for casting standard cement mortar

cubes.

84. IS: 10262 Concrete mix design.

85. IS: 13920 Ductile detailing of reinforced concrete structures

subjected to seismic forces.

86. IS: 14268 Prestressing Strands.

87. IS: 14881:2001Method for Blast Vibration Monitoring Guidelines.

88. IS: 15594 Mechanical Vibration Measurement of Vibration

Generated Intervally in Railway Tunnels by Passage of the Trains.

89. SP 22 (S&T): 1992 Explanatory Hand Book on codes for Earth

Quake Engineering.

90. SP 70: 2001 Handbook on construction safety practices.

91. IS codes for soil testing:

S.No.

IS Code No.

Description

1.

2.

IS: 2720 (all parts)

IS: 2810

3.

IS: 4434

4.

IS: 4968

14

Methods of test for soils.

Glossary of terms relating to soils

dynamics.

Code of practice for in-situ vane shear

test for soils.

Method of subsurface sounding for

soils.

Part 1 Dynamic method using 50mm

cone without bentonite slurry.

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

S.No.

5.

IS Code No.

Description

IS: 4968

Method of subsurface sounding for

soils.

Part II Dynamic method using cone

without bentonite slurry.

6. IS:4968

Method of subsurface sounding for

soils.

Part III Static cone penetration test.

7. IS: 5249

Method of test for determination of insitu dynamic properties of soils.

8. IS: 460

Specification of test sieves.

Wire cloth test sieves.

9. IS:460-1985 Part 2

Specification of test sieves. Perforated

Revision 3

plate test sieves.

10. IS: 460-1983 Part3

Specification of test sieves

Revision 3

Part III Methods of examination of

apertures of test sieves.

11. IS:

1498-1970 Classification and identification of soils

Revision 1

for general engineering purposes.

12. IS: 1607-1977

Methods for test sieving.

13. IS:5421-1981

Glossary of terms relating to test sieves

Revision 1

and tests sieving.

14. IS:1888-1982

Method of load test on soils.

Revision 2

15. IS: 1892-1979

Code of practice for site investigations

for foundations (With amendment

no.1).

16. IS:2131-1981

Method for standard penetration test

Revision 1

fir soils.

(Reaffirmed 1987).

17. IS: 2132-1972

Code of practice for thin walled tube

Revision 1

sampling of soils.

18. IS: 10074-1982

Specification for compaction mould

assembly for light and heavy

compaction test of soils.

19. IS: 10077-1982

Specification for equipment for

determination of shrinkage factors.

20. IS: 10379-1982

Code of practice for field control of

moisture and compaction of soils for

embankment and sub- grade.

21. IS: 10837-1984

Specification

for

moulds

and

accessories for determination of

density index (relative density) of

15

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

S.No.

IS Code No.

22. IS: 11196-1985

23. IS: 11229-1985

24. IS: 11209-1985

25. IS 9179-1979

26. IS 9143 : 1979

27. IS 9221 : 1979

28. IS 10782: 1983

29. IS 11315: Part

1992

30. IS 11315: Part

1985

Description

cohesion less soils.

Specification for equipment for

determination of liquid limit of soilscone penetration method.

Specification of mould assembly for

determination of permeability of soils

Specification for shear box for testing

of soils.

Method for preparation of rock

specimen for laboratory testing.

Method for the determination of

unconfined compressive strength of

rock materials.

Method for the determination of

modulus of elasticity and Poisons ratio

of rock materials in uniaxial

compression.

Method for laboratory determination

of dynamic modulus of rock core

specimens.

12 : Method for the quantitative description

of discontinuities in rock mass: Part 12

Drill core study.

11 : Method for the quantitative description

of discontinuities in rock mass: Part 11

Core recovery and rock quality.

92. IS codes for cement:

(1) Ordinary Portland Cement, 33 Grade, conforming to IS:269.

(2) Rapid Hardening Portland Cement, conforming to IS:8041.

(3) Ordinary Portland Cement, 43 Grade, conforming to IS:8112.

(4) Ordinary Portland Cement, 53 Grade, conforming to IS:12269.

(5) Sulphate Resistant Portland Cement, conforming to IS:12330.

93. IS codes for pre-stressing steel:

(1) Uncoated Stress relieved low relaxation strands conforming to

IS; 1426.

(2) Plain hard drawn steel wire conforming to IS: 1785 (Part I).

(3) High tensile steel bar conforming to IS: 2090.

16

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(4) Uncoated stress relieved strands conforming to IS: 6006.

94. IS Codes for structural steel:

(i) IS: 226 : Structural Steel (Standard Quality)

(ii) IS: 808 : Specifications for Rolled Steel Beam, Channel and

Angle Sections

(iii) IS: 961 : Structural Steel (High Tensile)

(iv) IS: 1148 : Hot rolled rivet bars (upto 40mm dia) for structural

purposes

(v) IS: 1149 : High tensile rivet bars for structural purposes

(vi)

IS: 1161 : Steel tubes for structural purposes

(vii) IS: 1239 : Mild Steel Tubes

(viii) IS: 1730 : Dimension for Steel Plate, sheet and strip for

structural and general engineering purposes

(ix)

IS: 1731 : Dimension for Steel flats for structural and general

engineering purposes

(x)

IS: 1732 : Dimension for round and square steel bars for

structural and general engineering purposes

(xi)

IS: 1852 : Rolling and cutting tolerances for hot rolled steel

products

(xii) IS: 2062 : Weldable Structural Steel

(xiii) IS: 4923 : Hollow Steel sections for structural use

(xiv) IS: 8500 : Weldable Structural Steel (medium & high strength

qualities)

(xv) IS: 11587 : Structural weather resistant steel

95. IS codes for fasteners :

(i)

IS: 1363 Hexagon head bolts, screw and nuts product grade C

(ii)

IS: 1364 Hexagon head bolts, screw & nuts product grade A &

B

(iii)

(iv)

IS: 1367 Technical supply conditions for threaded steel

fastener (Parts 1 to 18)

IS: 1929 Hot forged steel rivets for hot closing (12-36mm dia)

(v)

IS: 2155 Cold forged steel rivets for hot closing (6-16mm dia)

(vi)

IS: 3640 Hexagon fit bolts

(vii) IS: 3757 High tensile friction grip bolts

17

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(viii) IS: 6623 High strength structural nuts

(ix)

IS: 6639 Hexagon bolls for steel structure

(x)

IS: 5624 Foundation bolts

(xi)

IS: 7002 Prevailing torque type steel hexagon lock nuts

(xii) IS: 5369 Plain washers and lock washers - general

requirements

(xiii) IS: 5370 Plain washers with outside dia = 3 X inside dia

(xiv) IS: 5372 Taper washers for channels (ISMC)

(xv)

IS: 5374 Taper Washers for I beams (ISMB)

(xvi)

IS: 6610 Heavy washers for steel structures

(xvii) IS: 6649 Hardened and tempered washers For high strength

structural bolts and nuts

96. IS codes for welding consumables:

(i)

1S:814 (Part 1) Covered Electrodes for Metal Arc Welding of

structural steel for welding other than sheets

(ii)

IS: 814 (Part 2) For welding sheets

(iii)

IS: 1278 Filler rods and wires for gas welding

(iv)

IS: 1395 Low and medium alloy Steel covered electrodes for

manual Metal Arc Welding

(v)

IS: 3613 Acceptance Tests for wire flux combinations for

submerged arc welding of structural steel

(vi)

IS: 7280 Bare wire electrodes for gas shielded arc welding of

structural steel

(vii) IS: 6419 Welding rods and bare electrodes for gas shielded

arc welding of structural steel

(viii) IS: 6560 Molybdenum and chromium-molybdenum low alloy

steel welding rods and bare electrodes for gas shielded arc

welding

97. Codes for structural steel work for railway bridges:

1)

IRS: Steel Bridge Code

2)

IRS: Welded Bridge Code.

3)

IRS: Code of Practice For Electric Welding Of Mild Steel

Structures

4)

IRS: Fabrication & Erection of Steel Girder Bridges &

18

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

Locomotive Turn Tables (B1-2001).

5)

IRS: Standard Specification for Classification, Testing and

Approval of Metal-Arc Welding Electrodes, Serial No M.28-76.

6)

IRS: Standard Specification for Classification, Testing and

Approval of Submerged Arc Welding Wire-Flux Combinations

for Use On Indian Railways Serial No M.39-68.

7)

IRC: 22 (2008) Standard specifications and code of practice for

road bridges Section VI (Composite Construction).

8)

BS: 5400-6 (1999) Steel, concrete and composite bridgesSpecifications of material and workmanship, Steel.

9)

IS: 800 (1984) Code of Practice for General Construction in

Steel.

10)

IS: 808 (1989) Dimensions for Hot Rolled Steel Beam, Column,

Channel and Angle Sections.

11)

IS: 814 (1991) Covered Electrodes for Manual Metal Arc

Welding of Carbon & Carbon - Manganese Steel.

12)

IS: 816 (1969) Code of Practice for Use of Metal Arc Welding

for General Construction in Mild Steel.

13)

IS: 817 (1969) Code of Practice for Training and Testing of

Metal Arc Welder

14)

IS: 919 (1993) ISO System of Limits & Fits (Part 1 & Part 2).

15)

IS: 1148 (1982) Hot Rolled Rivet Bars (up to 40mm) for

Structural Purposes.

16)

IS: 1182 (1983) Recommended Practice for Radio Graphic

Examination of Fusion Welded Butt Joints in Steel Plates.

17)

IS: 1363 (1992) Hexagon Head Bolts, Screws and Nuts of

Product grade C (Part 1 to Part3).

18)

IS: 1364 (1992) Hexagon Head Bolts, Screws and Nuts of

Product Grades A &B (Part 1 to 5).

19)

IS: 1367 (1991) Technical Supply Conditions for Threaded

Steel Fasteners.

20)

IS: 1852 (1985) Rolling & Cutting Tolerances for Hot-Rolled

Steel Product.

21)

IS: 2016 (1967) Plain Washers.

22)

IS: 2062 (2006) Hot Roiled Low, Medium and High Tensile

Structural Steel.

23)

IS: 2595 (1978) Code of Practice for Radio Graphic Testing.

19

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

2.2.4

24)

IS: 3600 (1985) Methods of Testing Fusion Welding Joints

(Part 1 to Part 9).

25)

IS: 3613 (1974) Acceptance Tests for Wire Flux Combinations

for Submerged Arc Welding.

26)

IS: 3658 (1981) Code of Practice for Liquid Penetrant Flow

Detection.

27)

IS: 3757 (1985) High Strength Structural Bolts.

28)

IS: 4000 (1992) High Strength Bolts In Steel Structures-Code of

Practice.

29)

IS: 4353 (1967) Recommendations for Submerged Arc Welding

of Mild Steel and Low Alloy Steel.

30)

IS: 4943 (1968) Assessment of Butt and Fillet Fusion Welds in

Steel Sheet, Plate and Pipe.

31)

IS: 5334 (1981) Code of Practice for Magnetic Particle Flow

Detection of Welds.

32)

IS: 5369 (1975) General Requirements for Plain Washers and

Lock Washers.

33)

IS: 5372 (1975) Taper Washers for Channels.

34)

IS: 5374 (1975) Taper Washers for I Beams.

35)

IS: 6623 (1985) Specification for High Strength Structural Nuts

36)

IS: 6649 (1985) Specifications for hardening and tempering

washers for high strength structural nuts.

37)

IS: 6755 (1980) Double Coil Helical Spring Washers.

38)

IS: 7215 (1974) Tolerances for Fabrication of Steel Structure.

39)

IS: 7318 (1974) (Part I) Approval Tests for Welders When

Welding Procedure Approval is not required -fusion Welding of

Steel.

40)

IS: 8910 (1978) General requirements of Supply of Weldable

Structural Steel.

41)

IS: 9595 (1996) Recommendations for Metal Arc Welding of

Carbon & Carbon-Manganese Steels.

Indian Standard Specifications for Electrical Works

(1) IS: 694 PVC insulated Electric cable working voltage up to and

including 11000 volts

(2) IS: 732 Codes of Practice for Electrical Wiring Installations

(3) IS: 1255 Code of Practice for Installation and Maintenance of

20

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

(24)

(25)

(26)

(27)

(28)

(29)

(30)

Power Cables up to and including 33kV rating

IS: 1293 Three Pin Plugs and Socket Outlets Rated Voltage up to

and including 250 Volts and rated Current up to and including

160 Amps.

IS: 1554 PVC Insulated (Heavy Duty) Electric Cables for Working

up to and Including 1100 Volts

IS: 1913 General and safety Requirements for Fluorescent

Lamp Luminaries Tubular

IS: 2026 Power Transformers

IS: 10561: 1983 / IEC 606 (1978) Application Guide for Power

Transformers

IS: 2309 Protection of Buildings and Allied Structures Against

Lightning Code of Practice

IS: 2705 Current Transformers

IS: 3043 Code of Practice for Earthing

IS: 3156 Voltage Transformers

IS: 3480 Flexible Steel Conduits for Electrical Wiring

IS: 3636 Code of Practice for Interior Illumination

IS: 3837 Accessories for Rigid Steel Conduit for Electric Wiring

IS: 3842 Application Guide for Electric Relays for AC Systems

IS: 3961 Recommended Current Ratings for Cables

IS: 4615 Switch Socket Outlets

IS: 5133 Boxes for the Enclosure of Electrical Accessories

IS: 5831 PVC Insulation and Sheath of Electrical Cables

IS: 6665 Code of Practice for Industrial Lighting

IS: 7098 XLPE Cables

IS: 8623 (Part-I) Factory Built Assemblies of Switchgear and

Control Gear for Voltage up to and Including 1000V AC and

1200V DC

IS: 8623 (Part-II) Bus Bar Trunking

IS: 8828 Miniature Circuit Breakers

IS: 9224 HRC Cartridge Fuse

IS: 9537 Rigid Steel Conduits for Electrical Wiring (Second

Revision)

IS: 9676 Reference Ambient Temperature for Electrical

Equipment

IS: 10028 Selection, Installation and Maintenance of

Transformers

IS: 0118 Code of Practice for Selection, Installation and

21

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(31)

(32)

(33)

(34)

(35)

(36)

(37)

(38)

(39)

(40)

(41)

(42)

(43)

(44)

Maintenance for Switchgear and Control Gear

IS: 11171 Dry Type Power Transformers

IS: 12640 Earth Leakage Circuit Breakers

IS: 12729 High Voltage Switchgear

IS: 13234 Short Circuit Calculation in Three Phase AC Systems

IS: 13947 (Part-I) Degrees of Protection

IS: 2551- 1982 Danger Notice Plates

IS: 5424- 1969 Rubber Mats for Electrical Purposes

IS: 4648-1968 Guide for Electrical Layout in Residential

Buildings

SP 31: 1986 Special Publication: Chart on Treatment for

Electric Shock

IS: 13779 Digital Measuring Instrument and Testing

Accessories

IS: 13947 Low Voltage Switchgear and Control Gear

IS: 13947 (Part-I) Circuit Breakers

IS: 15549 Stationary Valve Regulated Lead Acid Batteries

IS: 61000 2-4 Electromagnetic Capability

2.2.5 Other International Codes

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

En 1990-2002 (Eurocode Basis of Structural Design) (For

Safety, comfort deformation including twist and deflection)

EN 1991-2-2003 (Eurocode 1 Action on Structures, part 2

Traffic Loads on Bridges)- (Natural frequency range and

Loading for fatigue estimation)

EN 1992 1:2004 (Eurocode 2 Design of Concrete

Structures, Part 1 General Rules and Rules for Buildings)

EN 1992 1-1:2004 (Eurocode 3 Design of Steel Structures,

Part 1 1 -1 General Rules) (Classification of cross sections).

EN 1993 1-8:2002 (Eurocode 3 Design of Steel Structures,

Part 1 8 Design of Joints) (Classification of HSFG Bolts).

EN 1993 1-9:2002 (Eurocode 3 Design of Steel Structures,

Part 1 9 Fatigue Strength of Steel Structures).

EN 1993 2:2004 (Eurocode 3 Design of Steel Structures,

Part 2 Steel Bridges) - (Requirements for fatigue assessment,

Road and Rail Bridges).

EN 1994 2:2003 (Eurocode 4 Design of Composite Steel &

Concrete Structures, Part 2 Rules for Bridges) (Width of

effective flange, shear connectors).

22

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(9)

2.2.6

EN 1337-7 (March 2004) Structural bearings Part 7 :

Spherical and Cylindrical PTFE bearings (In case of Steel

Bridges)

UIC Codes

(1) UIC 774 3R Track Bridge interaction Recommendation for

calculation (for Forces due to LWR).

(2) UIC 772R: Bearings of rail bridges

(3) UIC 774-3R Track/Bridge interaction

2.2.7

BS Codes

(1) BS 3784 Grade A Specifications for Polytetra fluroethylene

(2) BS-5350: Standard Method of test of adhesives, Part C9, Floating

roller peel test.

(3) BS-5400: Part 1 General Statement.

(4) BS-5400: Part 2 Specifications for loads.

(5) BS-5400: Part 3 Code of Practice for Steel Bridges.

(6) BS-5400: Part 5 Code of Practice for composite Bridges.

(7) BS-5400: Part- 9 Bridge Bearings.

(8) BS-5400: Part-10 Code of Practice for Fatigue.

(9) BS-1449, 3484, 1134, 5296.

(10) BS-5400: Part 6 Steel, Concrete and Composite BridgesSpecifications for Materials and Workmanship-Steel (In case of

Steel Bridges)

BS Codes for Electrical Works

(11) BS: 6007 Electric Cables; Single Core Unsheathed Heat Resisting

Cable for Voltage up to and Including 450/750V, for Internal

Wiring

(12) BS: 6387 Specifications for Performance Requirements for Cables

required to Maintain Integrity Under Fire Conditions

(13) BS: 6724 Specification for 600/1000V and 1900/3300V Armoured

Electric Cables having Thermosetting Insulation and Low

Emission of Smoke and Corrosive Gases when Affected by Fire

(14) BS: 7211 Specification for Thermosetting Insulated Cables (nonarmoured) for Electric Power and Lighting with Low Emission of

Smoke and Corrosive Gases when Affected by Fire

(15) BS: 7629 Specification for 300/500V Fire Resistant Electric Cables

having Low Emission of Smoke and Corrosive Gases when Affected

by Fire

The list given above is by no means exhaustive. All IS, IRC and IRS

Codes pertaining to the work shall be applicable.

Where the drawings and specifications described a portion of the

23

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

work in only general terms and not in complete detail, it shall be

understood that only the best general practice is to prevail, materials

and workmanship of the best quality are to be employed and the

instructions of the Engineer are to be complied with.

NOTE:

(i) Contractor will procure and keep one copy of these reference codes

and manuals at site office for reference and guidance.

(ii) To ensure implementation of the various rules, codal provisions

etc., the Contractor shall develop Design-basis Note and Method

Statements for all the items of Work, based on the Specifications,

applicable Codes & Standards, Good Industry Practices and shall

submit to the Authoritys Engineer for his review.

3

Geotechnical Investigation

3.1

Geotechnical investigations, as part of a comprehensive geotechnical

investigation programme, shall be conducted according to IS: 1892.

3.2

Testing of soil/rock samples has to be carried out before designing

the bank/cuttings. List of relevant IS Codes for soil testing and rock

testing are as per item No. 2 of this document.

Earthworks

4.1

General

This section deals with the Selection of Materials for Earthwork,

Execution of Earthwork in excavation and formation, Quality Control

of the Earth work, Maintenance of Records and Quality Assurance. In

principle the earth work shall be carried out as per the provisions

of Specifications for Design of Formation No. RDSO / 2007 / GE: 0014

November 2009 and Earthwork in Railway Projects, GE: G-1 July

2003 issued by RDSO/ Lucknow except for specific provisions made

herein in these Specifications.

4.1.1

Blanketing Material: For laying Blanketing

specification No. GE IRS2 is to be used.

materials,

4.2

Excavations in the vicinity of Existing Railway Tracks

RDSOs

While working / carrying out excavation in the vicinity of the existing

Railway tracks and structures (including bridges, formation etc.),

special care should be taken to ensure that formation of the existing

railway tracks is not excavated and any activity of the Contractor shall

not endanger the safety of existing running line of Indian Railways. If

24

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

excavation or any other activity involving working and or modification

and or alteration of the existing permanent way then, before

execution of such work, the Contractor shall prepare the protection

measure intended to be taken by the Contractor to ensure safety of the

existing running line, and seek the review of Engineer. However the

effectiveness of design of such protection measures is the sole

responsibility of the Contractor and the Contractor shall indemnify the

Employer / Engineer / Authority towards the losses incurred due to

failure of such protection measure. These protection measures duly

indicating the extent of alternation / modification to the existing

formation shall be incorporated in the design and drawing submitted

during Technical Design submissions as per Authoritys Requirement.

Such work shall not be undertaken unless and until these drawings are

reviewed by the Engineer and Authority.

4.2.1

Others right-of-way

At locations where the construction is close to irrigation canals and

power transmission lines which have their own right-of-way, the

Contractor must not, without instructions / review by the Engineer,

remove any materials from the right-of-way of other authorities or, by

the operation of equipment or otherwise, disturb their installations.

4.3

Ground Improvement

Field tests are required to be conducted on sub-soil strata, such as

Plate Load Test for determination of Elastic Modulus at second loading

(EV2), Standard Penetration Test to determine N-value and

Unconfined Compression Test or Vane Shear Test to determine

Unconfined Compressive Strength or Undrained Cohesion Cu. If values

of these test parameters as specified hereunder are not achieved, then

ground improvement is required

(1) For ground soil / sub-strata layers with low bearing capacities,

assessed by following evaluation parameters, shall require ground

improvement:

(i) EV2 value less than 20 MPa, Or

(ii) Undrained Cohesion (Cu) < 25 kPa, Or

(iii) N-value (determined from Standard Penetration Test: SPT)

< 5,

(2) Strengthening of the sub-strata soil layers can be carried out

using one or more of the following techniques, subject to review

of the Engineer

(i)

Removal and replacement of weak soil (Excavation and

25

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

replacement could be carried out upto 2m)

(ii) Stage construction of the fill, preloading and surcharging

(iii) Installation sub-drainage system

(iv) In-situ pile, Sand Gravel Compaction pile, Stone Columns

(v) Vibro-floatation

(vi) Lime Pile, Injection / lime slurry pressure injection / ion

exchange

(vii) Stir & mixing

(viii) Sand mat, Geosynthetics etc.

(3) In case the black cotton soil is encountered by the Contractor

during the course of geotechnical investigations, the following

remedies are suggested:

(a)

(b)

(c)

(d)

(e)

(f)

4.4

Treating top layer of the soil with quick lime so as to

reduce the harmful effects of the black cotton soil.

Providing a blanket of graded inverted filter at top of the

Embankment.

Consolidation of black cotton soil at optimum moisture

content.

Provision of bituminous carpet or similar other

intercepting material like polythene sheets etc. so as to

intercept the surface water getting in to formation.

To provide the drainage conditions of the formation at

surface and sub-surface level.

Providing a compacted layer of CNS material (Cohesive

non-swelling soil) layer suitably designed using specialized

literature, at the bottom of embankment fill and in case of

cuttings at the bottom of sub grade layer.

Quality Assurance

(1) Quality Check on Earthwork : Quality of execution of

formation earthwork shall be controlled through exercise of

checks on the borrow material, blanket material compaction

process, drainage system, longitudinal & cross sectional profiles of

the embankment.

(2) Frequency of Quality Assurance Tests

(i) CBR test for selection of formation materials and other tests

required for ensuring conformation of the materials

(blanket, subgrade, embankment fill) as per specifications

e.g. size gradation, Cu, Cc, Los Angles Tests, OMC / MDD etc.

26

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

shall be conducted at following frequency;

a)

Embankment Fill: One set of tests for every 5,000 cum

and at every change of soil strata

b)

Compacted earth / Blanket Layers: Atleast one density

check for every 200 sqm. for each blanket layer and top

one metre of sub-grade and at least one density check

for every 500 sqm. for other than blanket and one metre

of sub- grade

c) Prepared Subgrade: one set of tests for every 2,000 cum

d) Blanket Material: one set of tests for every 500 cum

(ii) Second Step Plate Load Test: This test should be done for

EV2 measurement at top of each formation layers e.g. at subsoil, compacted sub-grade, prepared sub-grade, blanket etc.

at the frequency of one test per km length of the section as

per procedure detailed in DIN 18134-2001.

4.5

Tolerances and Acceptance Criteria

(1) Soil Formation should meet the following requirements

(i) The cross fall slope to be at least 1:30 or 3% with tolerance of

0.5%.

(ii) The finished top levels of soil formation should be within +

30 mm.

(iii) The finished top of blanket layer shall be permitted to

have variation from design level by + 25mm.

Road Works

5.1

General: Road works in colonies, approach to stations, ROB

approaches and at level crossings should confirm to the relevant

standards of IRC codes as mentioned in item 2.

Material for Structures

For Specifications on materials Indian Railways Unified Standard

Specifications (works and materials -2010) Vol I and II with latest

amendment should be referred.

Handling & Storage of Materials

27

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

All materials shall be stored as per IS:4082.

8

Piling Work

8.1

Description

8.1.1

The method of installing the piles, including details of the equipment

shall be submitted by the Contractor and got reviewed from the

Engineer.

8.1.2

The work shall be done as per IS:2911 except as modified herein.

8.2

Materials

The basic materials like cement, coarse aggregates, fine aggregates,

reinforcing steel, structural steel, water and concrete admixtures shall

confirm to the requirements as specified in the Clause 6: Materials for

Structures of these Specifications.

8.3

Precast Concrete Piles

The pile should be cast in one continuous operation.

8.4

Bored Cast-in-situ Concrete Piles

8.4.1

Boring for Pile

IS 1493-Design of bored and cast in-situ piles should be followed.

8.4.2

Concreting for Pile

Concreting for the piles shall be done by tremie method.

8.4.3

Pile Tests / Acceptance of Pile

For acceptance of piles, vertical and lateral load, testing of piles as

required will be carried out as per procedure laid down in IS:2911(PtIV) Code of Practice for Design and Construction of Pile FoundationLoad test on piles.

Concrete Works

9.1

General

This section refers to the construction of concrete structures including

concrete mix design, trial mix, testing and workmanship for concreting.

Prior to the start of construction, the Contractor shall design the mix as

per IS 10262 and submit to the Authoritys Engineer for review, the

proportions of materials, including admixtures to be used. Waterreducing admixtures (including plasticisers or super-plasticisers) may

28

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

be used at the Contractor's option, subject to the review of the

Authoritys Engineer. Other types of admixtures shall be prohibited,

unless specifically permitted by the Authoritys Engineer.

9.2

Materials

All the materials shall confirm to the relevant IS codes.

9.3

Ready Mixed Concrete:

(1) Ready Mixed Concrete may be used subject to prior review of the

Authoritys Engineer. It shall confirm to the specifications of

concrete as specified herein and IS:4926.

(2) The quality of admixtures like water-reducing agent, retarders,

superplasticisers-cum retarders etc. should meet the

requirement of Clause 6: Materials for Structures of these

Specifications and its suitability tested as per IS:9103 at the time

of finalizing the mix design.

9.4

Steel Reinforcement

All the materials for steel reinforcement shall confirm to the relevant IS

codes.

9.5

Backfill Material and Approach Slab:

(1)

Backfill Behind Abutment, Wing Walls, Retaining Wall and

Return Walls:

Behind abutments, wing walls and return walls/Retaining wall,

boulder filling and backfill material shall be provided as per Code

of Practice for the Design of Sub-structures and Foundations of

Bridges. Boulder filling shall consist of well hand packed

boulders & cobbles to thickness not less than 600 mm with

smaller size towards the back. Behind the boulder filling, backfill

material shall consist of granular materials of GW,GP,SW groups

as per IS:1498-1970.

(2) Approach Slabs:

In order to reduce impact effect and to obtain improved running,

properly designed approach slab may be provided on both the

approaches of non-ballasted deck bridges having spans12.2 m or

more. One end of the approach slab may be supported on the

abutment and other end on formation. Length of the approach

slab shall be minimum 4 meters.

10

Pre-stressing

29

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

10.1

Prestressing concrete shall be carried out as per IS 1343 and IS14268.

10.2

Record Keeping

In order to ensure proper manufacture and quality of the pre-stressed

concrete members, a system of records as mentioned below shall be

maintained by the Contractor besides such records as may be directed

by the Engineer during the progress of the work. Two copies of such

record shall be made and one copy duly signed by the Contractor and

the site Representative of the Engineer shall be submitted to the

Engineer.

(1)

Each pre-stressed member shall be identified by bed and

date of cast and an identification number which shall refer to

design calculation, drawing, tensioning records, concreting

records, cube strength records. Maintaining of these records shall

be the responsibility of the Contractor.

(2) Certified test report of the materials such as pre-stressing

steel, anchorages, sheathings, admixtures, expansion joints,

aggregates, etc. brought by the Contractor and used in the

structure. These reports shall show that the materials conform to

the relevant specifications. Keeping record of all these test

reports including those of cement and reinforcing steel, shall be

the responsibility of the Contractor.

(3) An accurate record of tensioning and grouting operations for each

and every cable shall be kept. These shall include but not be

limited to the following:

(i)

(ii)

(iii)

(iv)

(v)

(vi)

Date of tensioning/grouting

Cast bed identification

Description, identification and number of the girder

Manufacture, size and class of tendon.

Identification of all the tensioning equipment.

Identification and number of the cable/duct being tensioned

/ grouted.

(vii) Cube strength on the date of tensioning.

(viii) Design elongation and gauge pressure for the particular

cable under tension.

(ix) Chart indicating actual gauge pressure and corresponding

measured elongation at each end and at each stage of

tensioning with graph showing actual gauge pressure vs

measured elongation and correction value of elongation

for initial tension before marking.

(x) Slip of anchorages at each end.

30

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(xi)

The actual net elongation and shortfall or otherwise from

the design value for each cable.

(xii) All data on the date of grouting e.g. time of start and

completion, initial and final pressure of grout injection,

total cement consumption, etc.

(xiii) Any un-natural occurrences encountered during tensioning

or grouting; such as failure of equipment, snapping of

tendons, excessive slippage, blockage of ducts resulting in

heavy shortfall in elongation or excessive increase in

pressure of grout injection, or any other problem that may

have direct or indirect influence on the net stress or

effective grouting.

(4) Records of concreting operations and tests shall be kept so that

the following data be recorded for each member or each group of

members cast on one bed.

(i)

Date, time and duration of concreting.

(iii) Identification of casting bed and member.

(iii) Design Mix proportion.

(iv) Adjustments in water content in the mix due to bulkage

of sand or absorbed water in coarse aggregate

(v) Identification and numbering of work strength testing

cubes.

(vi) Various field tests conducted at site like workability test,

determination of water content in sand and coarse

aggregate, etc.

(vii) Weather condition, ambient temperature, concrete

temperature.

(viii) Method and duration of curing.

(ix) Strength of cubes at 7 days, 28 days and on the date of prestressing.

(x) Failure of equipment and interruption in continuous

concreting.

(xi) Total cement consumption.

(xii) Any un-natural occurrence that may have direct or indirect

effect on the overall quality of the work.

(5) All equipment used in the work shall be calibrated. The record

for calibration done shall show the following:(i)

Date of calibration.

(ii)

Agency and laboratory performing the calibration.

31

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(iii) Method of calibration.

(iv) A curve showing full range calibration with gauge readings

plotted against actual load.

11

Architectural and Building Works

11.1

General Requirements

The general requirements for the Building Works shall be but not

limited to the following:

(a) Building layout plan and detailed design with adequate

ventilation.

(b) Site clearance & levelling shall be as per requirement.

(c) Excavation (in soil / soft rock / hard rock) for foundations,

pipes, drains, cables and backfilling and disposal of surplus earth

shall be carried out as per requirement.

(d) Filling in plinth and under floors shall be provided as per

requirement.

(e) Anti-termite treatment (pre-construction) shall be provided as per

requirement.

(f)

Foundation work including Damp Proof Course.

(g) All masonry work shall be with cement-sand mortar.

(h) Reinforced cement concrete shall be of design mix as required.

(i)

Doors, windows & ventilators frames shall be of required quality.

(j) All doors shall have flush door shutters.

(k) All the windows shall have pelmets with curtain rods or

vanishing blinds / strips, as required and all the doors shall have

curtain rods with pelmets.

(l) All the external doors, windows & ventilators shall have wire

gauge shutters and shall also be provided with RCC sun-shade.

(m) Wood work in contact with masonry shall have preservative / anti

termite treatment.

(n) All windows and ventilators shall have glass pan shutters and MS

safety grill.

(o) Windows shall be designed such that the air-conditioners and /

or desert coolers can be fixed.

(p) All steel works shall be painted with synthetic enamel paint.

(q) All the residential buildings shall be provided with fixed type

storage cupboards as required.

32

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(r)

All the office buildings shall be provided with partitions as / if

required.

(s) All wood work shall be painted with synthetic enamel paint or

sprit polished as required.

(t)

Roofing, basements / underground structures (if required) shall

have appropriate water proofing treatment.

(u) All the RCC Roofs shall be accessible through lockable staircase

and shall have parapet wall of height not less than 1 meter.

(v) All the staircases shall be as per the requirements of National

Building Code.

(w) Landscaping shall be provided as per requirement.

(x) Washrooms / toilets shall be provided with;

i) white vitrified ceramic sanitary fittings

ii) looking glass of standard size

iii) exhaust fans

iv) all other fittings and fixtures as required

(y) All the kitchens / pantry rooms shall be provided with kitchen

shelves with top, fixed type storage cupboards and exhaust fans.

(aa) Kitchen sinks in residential buildings / pantry rooms shall be of

stainless steel with drain board and size not less than

460x915mm with bowl depth 178mm.

(bb) Storage Geysers (wherever required) shall be of capacity not less

than 15 liters.

(cc) Ceiling fans shall be of size not less than 1200mm.

(dd) Fire detection & alarm system including fire points shall be

provided as per requirement.

(ee) All the individual residential quarters shall be provided with:

i) Independent overhead water storage tank of capacity as

indicated in the requirement. Overhead water storage tanks

shall be kept at the roof top.

ii) Water supply lines directly from the source as well as from

overhead water storage tank.

(ff) Any other requirements as considered necessary by the Engineer

from safety and operational considerations.

(gg) The work shall be carried out as per CPWD Specifications 2009

as published by Director General of Works, Central Public Works

Department, Government of India.

33

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

12

Fixing RCC Land Boundary Pillars along Railway Boundary:

13

All the land along the track and at Stations shall be provided with precast RCC Land Boundary pillars. Land Boundary pillars shall be

engraved with the letters as advised by the Authoritys Engineer. The

Land Boundary pillars shall be fixed as per the drawings in such a way

that 750mm of the total pillar height shall be exposed above the existing

ground level. The exposed portion of the pillars shall also be duly

painted.

Track Works:

13.1

Design Standards:

1)

All equipment, materials and components shall conform to the

specifications and international standards as applicable. The

quality control and testing records related to manufacturing of each

component shall be submitted to the Engineer for review.

2)

The track layout shall be based on the provisions contained in

Indian Railways Permanent Way Manual, Track Manual & relevant

IRS specifications with latest amendments/corrections.

3)

Where the design features differ from these specifications, such

deviations are to be fully justified to the satisfaction of the Engineer.

4)

The final designs of the track layouts, including horizontal and

vertical alignment, station yard layout, LWR/CWR plans, etc. shall be

reviewed by the Authoritys Engineer and Authority before

execution of track works.

5)

For Interlocking of switches, earthing and bonding of electrical

circuit arrangements in the track, the Contractor shall maintain

necessary interface with the other agencies (if any).

13.1.1 Track structure Requirements:

(1) Rails complying Indian Railway Specification for flat bottom rails

i.e. IRS-T-12-2009 shall be used.

The rails in the Main Line tracks shall be Continuous Welded Rails

(CWR) laid on mono- block pre-stressed concrete sleepers at

nominal 600mm spacing (1660/km).

(2) PSC sleepers confirming to RDSO T2496 shall be used.

34

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

(3) Ballast confirming to Specifications of IRS GE1 2004 with latest

correction slips is to be used.

(4) Turnouts will be 1 in 12 and 1:8 (curved) with cast manganese

crossings and PSC sleeper layout. Check rails shall be installed

parallel to the running rails on curves with a radius < 220m.

(5) Insulated Liners:

In general, Metal Liners shall be provided. However, provision of

Insulated Liners may be required in track circuited area.

13.2

Switch Expansion Joints (SEJs):

Generally the rails shall be laid as long/continuous welded rails

(LWR/CWR). However the Switch Expansion Joints (SEJs) shall be

provided and laid in accordance with the International codes and

practices and shall be subject to review of Authoritys Engineer.

Switch Expansion Joints (SEJs) shall be manufactured from rail

compatible with the rail proposed for the CWR.

The indicative design of the SEJ is given in RDSO Drg. No.RT-6902 for 60

Kg (80mm) or RT-6922 for 60 Kg (65mm) & RDSOs Specifications along

with corresponding PSC sleepers & fittings thereof as per drawing no.

RDSO / T-8224.

The Contractor may propose a equivalent or superior alternative for

approval by the Engineer/Authority. In such a case, the Contractor shall

submit complete design details along with design criteria & acceptances

tests to the Engineer for his prior review before procuring the same. The

Engineer shall seek the approval from Authority before communicating

the review to the Contractor.

SEJs shall be manufactured and supplied with all PSC sleepers, fittings,

fastenings and fixtures as required for easy installation into the track.

13.3

Turnouts:

13.3.1 Turnout Design:

(1) The Contractor shall be responsible for the detailed design,

manufacturing and assembling of the turnouts and shall submit

his proposals to the Engineer / Authority for Approval. The

Contractor shall procure the turnouts from RDSO approved

Manufacturers/Supplier.

(2) The design shall be compatible with 1:12 and 1:8.5 turnouts

which incorporate curved thick web switches. The turnouts shall

35

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

be designed to withstand rail induced forces from the CWR. Anticreep devices shall be installed on the turnout rails as required.

The following indicative RDSO drawings may be used as the basis of

the Contractors design:

(i)

(ii)

(3)

1 in 12 Xing, PSC Sleepers

Layout

Switch Assembly

CMS Xing

Thick Web Switch Layout

Thick Web Switch

1 in 8.5 Xing, PSC

Sleepers

Layout

Switch Assembly

CMS Xing

Thick Web Switch Layout

Thick Web Switch

T 4218

T 4219

T 4220

T 6154

T 6155

T 4865

T 4966

T 4967

T 6279

T 6280

Speed potential of the turnouts shall not be less than the values

as per the design of currently available turnouts (laid on PSC

sleepers) on the Broad Gauge of Indian Railways. These are as

follows:

a)

1:12 turnout with thick web tongue rail

50 km/h.

b)

1:8 turnout with thick web tongue rail

25 km/h.

(4) Elastic Fastenings:

Fastenings for the turnouts shall be elastic type and compatible with

the main line rail to sleeper fastening system.

(5)

Groove Rubber Sole Pads (GRSP):

The GRSPs shall be procured from the RDSO approved suppliers.

The Contractor may submit alternative design equivalent or

superior to RDSO design for review by the Engineer and approval

by Authority.

(6) Electrical Insulation:

Minimum ballast resistance per km of track should not be less than

2 ohms per km in Station yard and 4 ohms per km in the block

section in line with the provisions of para 17.2.8 of Signal

36

Manual of Standards and Specifications for Indian Railway EPC Contract for New lines / Doubling (2014)

Engineering Manual Part II of Indian Railways.

Relevant specifications / standards shall be adopted subject to

review of the Engineer for electrical installations between inserts in

pre-stressed concrete sleepers as well as for insulated Glued Joints.

13.4

Track Work Installation:

13.4.1 Planning for Construction, Methods and Procedures for Track Work:

Mechanized method of track laying shall be used. This will involve

Laying or re-laying of rail panels of 250 / 260 meters or more welded

by mobile / stationary / flash butt welding plant under control

conditions in depots. Track linking to be done by use of rail threader,

track laying machines and use of tamping machines, dynamic track

stabilizers and shoulder ballast compactors for making track fit for traffic

movement.

The mechanized track laying shall include welding, de-stressing and

fastening, laying of concrete sleepers, ballasting including tamping &

compaction (suitable for operation of 25 tonne axle load at the

maximum permissible speed of 160 KMPH for the main lines and

connecting lines and 50KMPH for the lines other than main lines &

connecting lines), track boards & signages etc.

13.4.2 Track Laying Tolerances shall be as per relevant Para of IRPWM.

14

Miscellaneous Works:

14.1

Bridge Bearings:

14.1.1 Scope:

This work shall consist of furnishing and fixing bearings in position