1007 DISQ 0 E SS 27011 Specification For Power Generators (GEN 01, GEN 02 and GEN 03)

1007 DISQ 0 E SS 27011 Specification For Power Generators (GEN 01, GEN 02 and GEN 03)

Uploaded by

Anonymous XbmoAFtICopyright:

Available Formats

1007 DISQ 0 E SS 27011 Specification For Power Generators (GEN 01, GEN 02 and GEN 03)

1007 DISQ 0 E SS 27011 Specification For Power Generators (GEN 01, GEN 02 and GEN 03)

Uploaded by

Anonymous XbmoAFtIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1007 DISQ 0 E SS 27011 Specification For Power Generators (GEN 01, GEN 02 and GEN 03)

1007 DISQ 0 E SS 27011 Specification For Power Generators (GEN 01, GEN 02 and GEN 03)

Uploaded by

Anonymous XbmoAFtICopyright:

Available Formats

Contract

Number: P1007

File Reference

Page

1007-DISQ-0-E-SS-27011-Rev.2

1 of 32

RWE Dea

Disouq Field Development

FEED

Specification for Power Generators

GEN-01, GEN-02 and GEN-03

1007-DISQ-0-E-SS-27011

29.03.12 Issued for Design

A Saleh

A Fawzi

A Hamdan

RWE

11.03.12 Issued for Client Approval

A Saleh

A Fawzi

A Hamdan

RWE

26.10.11 Issued for Client Review

A Saleh

A Fawzi

A Hamdan

RWE

Rev

Date

Description

Issued By Checked By Approved

By

Client

Approval

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Table of Contents

1

Introduction ...............................................................................................................5

1.1

Background ..............................................................................................................5

1.2

Objective ..................................................................................................................6

1.3

Definitions .................................................................................................................7

1.4

Abbreviations ............................................................................................................8

Codes and Standards .............................................................................................10

2.1

General...................................................................................................................10

2.2

Order of Precedence ..............................................................................................10

2.3

EC Directives ..........................................................................................................10

2.4

Project Documents .................................................................................................11

2.5

International Codes and Standards.........................................................................11

Scope of Supply .....................................................................................................13

Equipment Operating Conditions ............................................................................14

4.1

Electrical Equipment Location .................................................................................14

4.2

Environmental Design Data ....................................................................................14

Design Requirements .............................................................................................15

5.1

General...................................................................................................................15

5.2

Operational Requirements ......................................................................................15

5.3

Design Features .....................................................................................................16

5.4

Excitation System ...................................................................................................16

5.5

Enclosures and Materials........................................................................................16

5.6

Cooling System ......................................................................................................17

5.7

Bearings .................................................................................................................17

5.8

Terminal Boxes .......................................................................................................17

5.9

Noise Levels ...........................................................................................................18

5.10

Emission Levels ......................................................................................................18

5.11

Generator Protection and Control Panel .................................................................18

5.12

Annunciation, Alarm and Shutdown ........................................................................19

5.13

Manual/Auto Start ...................................................................................................19

5.14

Secondary Wiring ...................................................................................................20

5.15

Cable Terminations.................................................................................................20

5.16

Electric System Metering ........................................................................................20

5.17

Contacts .................................................................................................................21

Page: 2 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

5.18

Synchronizing System ............................................................................................21

5.19

Governor ................................................................................................................22

5.20

Requirements for Parallel Operation .......................................................................22

5.21

Current Transformers .............................................................................................22

5.22

Voltage Transformers .............................................................................................22

5.23

Battery and Charger Assemblies ............................................................................23

5.24

Accessories ............................................................................................................24

5.25

Nameplates ............................................................................................................24

5.26

Electrical Immunity..................................................................................................24

5.27

Disturbance Immunity .............................................................................................24

Painting ..................................................................................................................25

QC Inspection and Testing .....................................................................................25

7.1

General...................................................................................................................25

7.2

Generator QC Tests ...............................................................................................25

7.3

Battery and Charger QC Inspection and Testing .....................................................26

7.4

Generator Control Panel QC Test ...........................................................................27

7.5

Package String QC Test .........................................................................................27

7.6

Site Acceptance QC Test........................................................................................27

Documentation .......................................................................................................28

Preparation for Shipment ........................................................................................29

10

Storage Locally and Shipping .................................................................................29

10.1

Weight ....................................................................................................................29

11

Vendor's Responsibility and Guarantees ................................................................29

12

Site Installation Assistance, Commissioning and Start-Up ......................................30

13

Spare Parts.............................................................................................................31

12.1

Pre-commissioning and Commissioning Spare Parts..............................................31

12.2

Two Years Spare Parts ...........................................................................................31

14

Health, Safety and Environmental Management .....................................................31

15

Quality Assurance...................................................................................................32

Page: 3 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Changes List

Date

Rev.

prepared

(DD.MM.YYYY)

1

06.03.12

2

29.03.12

Prepared by

Description

ASaleh

Incorporated client comments

ASaleh

Incorporated client comments

Page: 4 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

1

Introduction

1.1 Background

RWE Dea Egypt has discovered seven natural gas reserves in the Disouq Concession within

the onshore Nile Delta, starting in 2008, as shown on the concession map below. Further

exploration in the concession is ongoing. RWE Dea Egypt is the operator of the Concession

with EGAS as a partner.

The selected development comprises a central gas treatment plant near NSG-1x, where the

gas is collected, treated by means of Low Temperature Separation utilizing the Joule

Thomson effect to achieve gas quality, and compressed for export. Treated gas is transferred

via a 16 pipeline directly into the GASCO NTS pipeline.

The well fluids are gathered and fed to a common inlet separator at the central plant. All

gases and liquids will be separated and processed on the central treatment plant into sales

gas, stabilized condensate and free production water.

Treatment of gas is carried out in two trains, while treatment of condensate is in a single train.

Three trains of sales gas compression shall be installed. Fuel gas for the gas engine drive

power generators will be taken from the suction of the sales gas compressors.

Main Electrical power shall be generated and supplied by two Gas driven generators 400

Volt, 3-phase, 4 wire, 50 Hz, 2000kVA each, with one generator running and one in standby.

Both Gas driven generators will be connected to the 400 Volt AC, 50Hz Low Voltage Power

Motor Control Centre (PMCC). One Emergency Diesel Generator 400Volt, 3-phase, 4 wire,

50Hz, 500kVA shall feed the emergency loads via the Low Voltage Emergency Power Motor

Control Centre (EPMCC) in case of a loss of gas production.

One gas driven generator shall feed all plant loads with the second gas driven generator on

stand by. Main electrical power with one gas driven generator running will be distributed via

Page: 5 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

the Power Motor Control Centre (PMCC) and the Emergency Power Motor Control Centre

(EPMCC).

All generators (Gas driven and Diesel driven) shall have the ability to synchronize for

maintenance purposes.

The PMCC and EPMCC shall be designed for the parallel operation of one gas driven and

one diesel driven generator but not for continuously parallel operation of the two gas driven

generators. Synchronisation of the both gas driven generators is purely required in case of

maintenance of one gas driven generator set to prevent a production stop and to bring the

second gas driven generator online before shutting down the one driven generator set.

A manual and fully automatic synchronization unit shall be installed on each power

generation skid. Central Treatment Process Plant loads will be connected with the Power

Motor Control Centre, the Emergency Power Motor Control Centre and the UPS distribution

panel as shown on the Single Line Diagrams MCC, PMCC, EPMCC and UPS (1007-DISQ-0G-DW-30089).

Preliminary Process Plant loads as result of the FEED are shown on Electrical Load List

(1007-DISQ-0-G-LL-30090).

One gas driven generator as main and normal power supply will feed process plant loads

such as:

Motors.

Package units.

Buildings normal lighting distribution panels and welding socket outlets in the

Workshop, Warehouse, Control building, Fire pump station, Substation

building and chemical storage building.

External lighting distribution panels.

Control building UPS. (located in Control Building)

Compressors UPS. (located on Compressor Skid)

Flare UPS (Located near the Flare)

Plant loads are preliminary estimations as result of FEED design and will be finally

determined during detail design by the detail design contractor and the vendors of packages..

In Normal operation with the one gas driven generator running the emergency loads shall be

fed via the PMCC and EPMCC. In case of loss of this normal supply, the emergency diesel

generator shall start automatically to feed the emergency loads of the process plant only

without black out.

The Emergency power motor control centre shall feed the emergency plant loads as shown

on the single line diagrams1007-DISQ-0-E-DW-30089.

Preliminary Emergency plant loads are shown on electrical load list 1007-DISQ-0-G-LL30090.

1.2

Objective

This specification defines the minimum requirements for the design, construction, painting,

inspection, testing, documentation, preparation for shipment, pre-commissioning and

commissioning and start-up of Gas and Diesel generator(s)and associated control panel(s) to

Page: 6 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

be used for main and emergency power generation (as specified in data sheet). These

generator(s) shall be coupled to two Gas driver(s) and one Diesel driver to form uniform

packages as generating sets with fully automated and manual synchronization panels, control

panel with small UPS, main CB, switchboard, F&G detection, Automated Fire Extinguishing

and ESD system and independent starting system for engines with batteries and

electronically controlled charger.

Each Power Gen set package to be fully functional stand alone as well as integrated into the

power and control system architecture of the Central Treatment Plant as shown on the single

line diagrams and control system architecture drawing.

Each package to be configured and equipped with all required control equipment and

protection systems for single as well as parallel operation and load sharing with automatic

and manual start locally as well as remotely.

Each Package control system shall communicate with the central treatment plant control

system via redundant communications link and if required via internal packages

communications link between all three packages (to be confirmed by vendor).

On board ESD system shall be designed as standalone SIL rated safety system (vendor shall

confirm SIL level in accordance to package HAZOP) which can receive SIL rated hardwired

ESD signal from ICSS for package shut down in case of ESD plant shut down.

The package F&G system shall be designed as standalone SIL rated safety system, shall

activate the package Fire fighting system and report its status to the plant F&G system as

part of the ICSS.

Interfaces and utilities are to be minimised for each package as follows:

1. Electrical Power output ( 400 Volt, 3-phase and Neutral , 50 Hz ) 2000kVA each gas

engine and 500kVA diesel engine

2. One Auxiliary Power input ( 400 Volt, 3-phase, Neutral, Earth, 50 Hz ) for each

package for all auxiliary circuits for control and power circuits on the package

3. Hardwired ESD signal from ESD system of ICSS to each Package Control ESD

system

4. Hardwired F&G status signals from each package to F&G system of central ICSS

5. Redundant Communications link for data transfer to/from the central DCS

6. Instrument Air as required

7. Interconnecting communications and shutdown links between the three genset

packages as required

For an overview of the Electrical System refer to Single Line Diagrams for MCC, PMCC,

EPMCC and UPS (1007-DISQ-0-G-DW-30089). For an overview of the Control system refers

to Control System Architecture Central Treatment Plant (1007-DISQ-0-G-DW-30036).

For the Electrical System Design Philosophy utilised throughout the project refer to document

number (1007-DISQ-0-G-MA-30088) and for the Control system Philosophy refer to

document number (1007-DISQ-0-G-MA-30092).

1.3

Definitions

The following definitions are generic to the Disouq Field Development Project and may be

referred to in this document:

Page: 7 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Company

RWE Dea Nile Branch

FEED Engineer

ONSPEC

Detail Design Contractor

Contractor appointed by the Company for the

detail engineering and construction phase of

the project.

Purchaser

Company.

Supplier/Vendor

The manufacturer, seller or supplier of

equipment.

Project

Disouq Field Development Project

Independent Verification Body

Inspection Body or Authority appointed by the

Company

1.4

Abbreviations

A

Ampere

A.C.

Alternating Current

ATEX

Directive for the supply and use of equipment in potentially explosive

atmospheres (Atmosphere EXplosive)

AVR

Automatic Voltage Regulator

BS

British Standard

CB

Circuit Breaker

CT

Current Transformer

D.C.

Direct current

DCS

Distributed Control System

EC

European Commission

EGAS

Egyptian Natural Gas Holding Company

EMC

Electromagnetic Compatibility

ESD

Emergency Shut Down

FEED

Front End Engineering and Design

F&G

Fire and Gas

GASCO

Egyptian Natural Gas Company

HAZOP

Hazard and Operability Study

HBCF

High Breaking Capacity Fuse

HMI

Human Machine Interface

HRCF

High Rupturing Capacity Fuse

ICSS

Integrated Control and Safety System

IEC

International Electrotechnical Commission

I/O

Input / Output

IDC

Inter Discipline Check

IP

Ingress Protection

ISO

International Organisation for Standardisation

ITP

Inspection and Test Plan

Page: 8 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

kVA

kVar

kW

LCU

LED

L.V.

MCC

MCCB

mm

NTS

PE

p.f.

QA

QC

QP

RTD

RWE Dea

SIL

TTA

UCP

Ue

Ui

Un

C.T.

V.T.

kilovolt Ampere ( apparent power )

kilovolt Ampere reactive ( reactive power )

kilowatt (active power )

Local Control Unit

Light Emitting Diode

Low Voltage (1000V A.C.)

Motor Control Centre

Moulded Case Circuit Breaker

millimetre

National Transmission System

Protective Earth

power factor

Quality Assurance

Quality Control

Quality Plan

Resistance Temperature Detector

Rheinisch Westfaelisches Elektrizitaetswerk Deutsche Erdoel

Aktiengesellschaft

Safety Integrity Level

Type Tested Assembly

Unit Control Panel

Rated Operational Voltage

Standard Insulation Voltage

Nominal Voltage

Current Transformer

Voltage Transformer

Page: 9 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Codes and Standards

2.1 General

The design, construction and supply of the equipment shall be in accordance with the

relevant sections of the latest editions, including addendums, of the international codes and

standards and shall comply with the latest revisions of project documentation detailed below.

In general, the electrical work shall be in accordance with the IEC standards. Where no

appropriate IEC standard exists, British Standards shall be used.

Electrical components for incorporation into the installation shall comply with the

relevant IEC standards. These shall be selected to exclude readily combustible insulating and

constructional material and excessive heat generation. Electrical and mechanical reliability is

of the utmost importance. All electrical components shall be tested to the relevant IEC

standards.

2.2 Order of Precedence

In the event of any conflict between this specification and the documents listed herein, the

decreasing order of precedence shall be:

1. Purchase Order and amendments thereto

2. Data Sheets

3. This Package Specification

4. Other Referenced Project Specifications

5. Egyptian National/Local Codes and Standards

6. International Codes and Standards

2.3 EC Directives

The equipment shall be supplied in accordance with all applicable European

Community Directives. Particular attention shall be paid to:

Electromagnetic Directive

2004/108/EC & 89/336/EC

Low voltage Directive

2006/95/EC

General Product Safety Directive

2001/59/EC

CE marking

93/68/EC

ATEX 95 Equipment Directive

94/9/EC

Page: 10 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

2.4

Project Documents

Project Documents consist of the following:

Document Number

Description

1007-DISQ-0-G-DW-30089

1007-DISQ-0-E-RT-27013

1007-DISQ-0-E-SS-27027

1007-DISQ-0-E-DS-27029

1007-DISQ-0-G-MA-30088

1007-DISQ-0-E-DS-27031

1007-DISQ-0-E-DS-27032

1007-DISQ-0-J-SS-33054

1007-DISQ-0-F-G-SP-10014

1007-DISQ-0-P-RT-48138

1007-DISQ-0-G-DW-30036

1007-DISQ-0-G-MA-30092

1007-DISQ-0- G-LL-30090

1007-DISQ-0-E-SS-27023

1007-DISQ-0-P-PH-48071

1007-DISQ-0-F-DW-10012

1007-DISQ-0-M-SS-42008

1007-DISQ-00-QP--1008

1007-DISQ-00-F-QA-1007

1007-DISQ-0-L-DW-39000

1007-DISQ-0-F-SS-10018

1007-DISQ-0-L-SS-39004

Single Line Diagrams for MCC,PMCC,EPMCC and UPS

Short Circuit Calculation Report

Motor Control Centre Specification PMCC and EPMCC

Motor Control Centre Data Sheet

Electrical System Design Philosophy

Gas Engine Synchronous Generators Data Sheet

Diesel Engine Synchronous Generator Data Sheet

PLC Specification for Packages

F&G Requirement Specification

Fire & Gas Cause & Effect

Control System Architecture Central Treatment Plant

Control System Philosophy

Electrical Load List

Electrical Specifications for Packaged Equipment

Shutdown Philosophy

Hazardous Area Classification Layout

Gas /Diesel Engine Specification

Project Quality Plan

QA Plan

Plot Plan - CTP

Specification for Equipment Noise Control

Specification for Painting and Protective Coatings

2.5

International Codes and Standards

As a minimum, the equipment shall be designed, manufactured, tested and delivered in

accordance with the relevant sections of the latest editions of the international codes and

standards. Codes and standards used for this project shall be the latest revisions including all

addenda available at the time of purchase order placement and shall include but not be

limited to the following:

Document Number

IEC 60034

IEC 60034-1

IEC 60051

IEC 60038

IEC 60044-1

IEC 60044-2

IEC 60050

IEC 60072

IEC 60085

IEC 60185

IEC 60186

IEC 60255

IEC 60529

Description

Rotating Electrical Machines.

Combined Frequency and Voltage Variations

Direct-acting Indicating Analogue Electrical Measuring

Instruments and Their Accessories.

IEC Standard Voltages

Instrument Transformers. Part 1: Current Transformers

Instrument Transformers. Part 2: Inductive Voltage

Transformers

International Electrotechnical Vocabulary

Dimensions and Output Series for Rotating Machines.

Thermal Evaluation and Classes of Electrical Insulation.

Current transformers Characteristics

Voltage Transformers.

Electrical Relays.

Classification of Degrees of Protection Provided by

Enclosures.

Page: 11 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

IEC 60947

IEC 61000

ISO 8528

ISO3046

BS5000

BS7626

NEMA MG-1/22

Low Voltage Switchgear and Control Gear.

Electromagnetic Compatibility (EMC).

Reciprocating Internal Combustion Engine Driven

Alternating Current Generation

Reciprocating Internal Combustion Engines

Specification for Rotating Electrical Machines of Particular

Types or for Particular Applications

Specification for current transformers

Motors and Generators

Page: 12 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

3

Scope of Supply

The scope of work includes, but is not limited to, the following items:

The detail design, manufacture and supply of three power generators as

detailed in this specification, referenced Data Sheets and Single Line Diagrams

The detail design, manufacture and supply of all necessary ancillary equipment,

special tools and spare parts for pre-commissioning and commissioning/startup, whether specified or not, to provide a complete, functional system at Disouq

CTP site.

The preparation and supply of all documents so that detail design contractor can

easily incorporate such information and related components (e.g. generator

control panel) into the overall design of the Project

The factory inspection QC and testing of all equipment and items. The System

integration test with all power generator packages and the ICSS and a final Site

Acceptance Test inclusive performance test. This includes the provision of

appropriate test certification and procedures (Factory Acceptance- , System

integration- and Site Acceptance - Test procedures).

Preparation for transport and shipping. All items shall be securely packed and

fully protected against damage

Site supervision during installation and hook up.

Pre commissioning, commissioning, start-up and performance test of UPS

system on site

The coordination and integration of all parts which interface mechanically,

electrically or electronically with Vendor system. Also, the Vendor shall ensure

the transfer of data between himself and the Vendor of the ICSS package(s) as

required and shall attend interface meetings and system integration tests with

ICSS Vendor.

Page: 13 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

4

4.1

Equipment Operating Conditions

Electrical Equipment Location

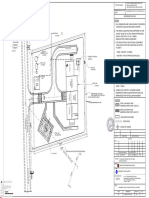

The generator(s) shall be suitable for outdoor installation in the Central Treatment plant as

shown on the Plot Plan (1007-DISQ-0-L-DW-39000). The Vendor shall provide each

generator engine combination as a standalone Skid or containerized if this is the standard

solution preferred by vendor. The generator control panel(s) shall be suitable for installation in

an air-conditioned switchgear and control room or within the package container as per

supplier standards. In all cases the control panel must be designed for safe and reliable

operation in the absence or failure of air conditioning system.

4.2 Environmental Design Data

The local climate conditions are as stated below:

Location:

Elevation:

Ambient Temperatures

Av. Air Humidity

Average Rainfall

Seismic Zone

Wind Speed & Direction

Earthquake Zone

Egypt Lower Nile Delta

+/- 5 m

0C to 35 C, max. 50 C

60 to 75%

app. 200 mm/ year with possible showers

during Nov-March

moderate risk, 10% probability to exceed

0,8 m/s ground acceleration in 50 years

Predominant NW direction; max. 39-44

m/s

Zone 2

Page: 14 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

5

5.1

Design Requirements

General

The generator shall be a brushless 400 Volt A.C., 50 Hz synchronous type, self-air cooled,

with direct connected, shaft mounted and permanent magnet exciter.

The alternator shall be rated for continuous duty in accordance with ISO8528, ISO3046,

IEC60034, BS5000 and MG-1/22 at the engines rated output and a power factor of 0.8. The

stator windings shall be provided with class F insulation while the operating temperature shall

be designed to be 120 C at the maximum output and site conditions. Rotor windings shall be

provided with class H insulation. The alternator and exciter shall be air cooled.

The set shall be provided with electronic governor and AVR systems.

The generator shall be designed for remote start / stop and status monitoring from the central

control room.

The set shall contain its own starting system and be suitable for black start.

Under all condition the voltage and frequency shall be maintained within limits as specified on

the data sheet of 1.0 per unit (i.e. 400V load and 50Hz) by the generator control system.

Load share, load management and synchronization between the generator sets when in

parallel operation, shall be provided by the generator Unit Control Panels (UCPs).

Full load voltage levels for Disouq field development project system shall be as follows:

400V, 3 phase, 4-wire, 50 Hz, neutral point solidly earthed at the PMCC &

EPMCC

230V, 1 phase, 50Hz, single phase & neutral derived from phase to neutral at

sub distribution boards.

Embedded RTD's (3 per generator, one in each winding) with alarm and shutdown signals

shall be provided for stator temperature measurement, another set of spare RTD (3 per

generator, one in each winding) shall be embedded and wired to spare terminal box ready

for connection in case of any RTD failure of used one.

The generator shall be equipped with anti-condensation space heaters for operation on 230

Volts, single phase, 50 Hz. The space heaters shall be suitable for the area classification and

shall be provided with a separate terminal box.

Vendor shall provide two diagonally opposite earthing copper bars to receive all the package

Electrical equipment earthing wires by Vendor. The copper bars should be ready to receive

external earthing connections suitable for 95 mm2 earthing cable of the main earthing plant

grid.

5.2

Operational Requirements

The rated power output of the generator, rated voltage and frequency shall be as shown on

data sheet. The generator shall deliver the specified output at the maximum derating

conditions (maximum ambient temperature and full load) without exceeding 120 deg C.

The generators and associated equipment expected lifetime duration shall be minimum 25

years. The generator should deliver the rated power output specified on the data sheet on a

continuous basis of 24 hours per day, for a period of at least 4 years without maintenance

and a minimum of 2000 hours without minor service required.

Page: 15 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

5.3

Design Features

Generator shall be able to operate withstand an over speed of at least 25% of rated speed.

An over speed time of two minutes is an acceptable design and test figure.

Generator shall be designed to withstand without exceeding the maximum allowable

temperature limits:

-

A stator current of 110% of rated current for one hour every 12 hour operation

period at rated voltage, rated frequency and rated power factor.

A stator current of 150% of rated current for at least 30 seconds with the voltage

being maintained within +/-5%.

The generator control panel shall have an integrated automatic voltage regulator (AVR) with

+10% voltage adjustment range by means of a rheostat. Voltage regulation shall be within +/0.5% maximum at steady state and 15% maximum voltage dip at maximum load start

(Instantaneous) as specified in data sheet.

In the case of 3-phase symmetrical short circuit is applied at the generator terminals, the

generator regulator and exciter system should be able to sustain at least 300% of rated

generator current for 10 seconds.

The distortion factor of waveform (at no load) shall be ideally 0% and the total harmonic

content LL/LN shall not exceed 2.5%.

The combined generator, exciter and regulator efficiency at full load shall not be less than the

following with power factor 0.8:

50-100 KVA 90% efficiency.

125-300 KVA 91% efficiency.

330-600 KVA 92% efficiency.

630-2000 KVA 93% efficiency.

The emergency diesel generator should have the capability of being online at rated voltage,

speed and frequency, within 10 seconds. The time required for the gas generator to be online

shall be advised by Vendor.

5.4

Excitation System

The excitation system shall be of the brushless type with hermetically sealed rectifiers,

including A.C. main exciter, a rotating rectifier and a permanent magnet pilot exciter. Reliable

operation of the system must be secured in case of any rectifier failure.

The rated excitation current should not be less than 110% of the excitation current at the

rated output of the generator under full load and maximum ambient temperature.

The excitation system shall be able to handle the start up of all motors indicated on the Single

line diagram 1007-DISQ-0-E-DW-30089. The system shall allow adequately relay settings

for system fault current protection.

5.5

Enclosures and Materials

The generator stator frame shall be of cast steel or fabricated steel with 3 mm minimum

thickness. The frame shall have sufficient strength and rigidity to withstand handling,

transport, or due to short circuit.

Page: 16 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Mechanical degree of protection for the generator, exciter, terminal boxes and bearing

houses for Indoor installation and outdoor installation shall be IP55 (IEC).

All generators shall be marked clearly and permanently with the direction of shaft rotation.

Each generator shall be equipped with certified lifting devices and lifting procedure to enable

lifting of a generator for maintenance or after breakdown.

5.6

Cooling System

Generators shall be frame-surface or air-to-air, self-cooled. Cooling method shall be specified

as per IEC 60034-6. Accepted cooling methods are as follows:

Frame surface, self cooled, open circuit, cooling method IC 01.

Air to air, self cooled, closed circuit, and cooling method IC 411.

Air to air, self cooled, closed circuit, and cooling method IC 511.

Air to air, self cooled, closed circuit, and cooling method IC 611.

Air to Water, self cooled, closed circuit, cooling method IC 71W.

Air to Water, self cooled, closed circuit, cooling method IC 81W.

For generators 1250 KVA and above, exciter cooling method shall be IC 31

unless a higher cooling method is required.

Vendor shall indicate the selected cooling method in data sheet.

5.7

Bearings

Bearing and bearing housings shall be designed to minimize contamination of lubricant and

lubricant leaking into the winding. Lubricant shall be grease type and shall be defined by

Vendor. Two-bearing machine shall be preferred.

RTD's (2 per bearing) with alarm and shutdown signals shall be provided for bearing

temperature measurement; the RTD'S shall be wired via terminal box (if required) directly into

the package control system. Bearing shall be insulated to prevent shaft and bearing surface

damages due to shaft current circulation and shall have provisions for testing of vibration.

Sleeve Bearings type are preferred. Roller bearings type if recommended by Vendor may be

accepted subject to Company approval.

5.8

Terminal Boxes

The terminal boxes enclosure of main windings, control / measurement circuitry and

auxiliary electrical supplies shall meet or exceed the generator enclosure requirements

(IP55).

Terminal boxes must be able to accommodate without deterioration the maximum through

fault current available at the terminals and should be able to contain without external effect

the consequence of any internal box fault.

The terminal boxes shall be of ample dimension for accepting the number, type and size of

line and neutral cables and cable terminations as specified on the data sheet or the single

line diagram.

For neutral point earthing of star connected generators, a separate neutral cable box shall be

provided with adequate space to accommodate current transformers.

Page: 17 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

On four wire systems (low voltage 3 phase systems) the neutral shall be brought out to the

main cable box as well as to neutral cable box.

The main and neutral cable boxes shall include internal bus bars for cable connection and

current transformers installation. Cables are not accepted.

Auxiliary equipment terminal boxes shall be mounted on the side of the generator opposite to

that of the main terminal box.

Separate cable boxes shall be provided for the following:

Main terminals.

Neutral terminal.

Space heater terminals.

Resistance temperature detectors terminals.

Other auxiliaries if any.

5.9 Noise Levels

Maximum noise levels for equipment shall not exceed 80 DB(A ) at 1 meter from the source

and shall be in accordance with document Noise Control Specification 1007-DISQ-0-F-SS10018

5.10 Emission Levels

All emissions from the generators must comply with Egyptian Law 4 for the Environment as described

in Prime Ministers Decree 1095 for 2011.

5.11 Generator Protection and Control Panel

The design, layout, dimensions and configuration of the panel(s) shall be proposed by Vendor

and approved by Company before delivery.

Generator control panel enclosure shall be as follows:

IP 41 (IEC) for indoor installation.

IP 55 (IEC) for outdoor installation.

The generator control panel shall be a free-standing, non-ventilated type with removable side

and top cover. Space heater shall be provided to prevent moisture. The heaters shall be

thermostatically controlled.

Generator control panel shall be provided with facilities to monitor status, protective relays,

and alarm and trip signals in accordance with PLC Specification for Packages Document No.

1007-DISQ-0-J-SS-33054.

Protective relays shall be multifunction microprocessor based relay .Protective relays shall be

for operation from instrument transformers having nominal 5 ampere, or 1 ampere for

secondary current relays or 110 Volt secondary for voltage relays. Control Voltage supply

shall be 24V DC from AC/DC system supplied by generator Vendor and derived from 400

Volt AC, 3-phase, Neutral and Earth auxiliary power supply of the package which will be

provided by others. The relays manufacturer shall be subject for Company approval. Relay

test facilities shall be provided on the panels such as sockets and plugs to enable testing the

relay without disconnecting the relay terminals unless the relay is with built -in test facilities.

Page: 18 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

The protective relay shall contain the following functions unless otherwise shown on the

single line diagram:

Fast lock-out relay for generator circuit breaker tripping.

Fast lock-out relay for prime mover shut down.

Under/over voltage relay.

Winding and Bearing RTD relay.

Under/over frequency relay.

Field failure relay.

Negative phase sequence relay for generators 500kW and greater.

Diode failure relay.

Reverse power relay.

Voltage restrained over current.

Differential relay.

Earth fault over current relay (Back up & stator earth fault protection).

Instantaneous Over current relay.

Generator/Engine Trip circuit supervision relay.

5.12 Annunciation, Alarm and Shutdown

The annunciation for shutdown and alarm signals shall be displayed on each

generator/engine control panel section. Vendor shall provide a list of all annunciation shut

down and alarm for the engine to Company for review and approval. Annunciators shall be

mounted on the panel face and shall have reset facilities and test lamps.

Each alarm or shutdown shall be associated by:

Horn signal.

Flashing lamps.

The fault can be acknowledged by push button which shall stop the horn signal.

5.13 Manual/Auto Start

Manual/or auto start shall be selected via an auto-off-manual key type selector switch in the

Generator control panel. The operation feature shall be as follows:

a. Manual Operation

The engine shall start manually using the start Push Button.

b. Automatic operation

The engine shall start automatically in the event of loss voltage due to failure of the duty

unit(s).

In both cases the closure of main circuit breaker shall be selected either manual or automatic

by auto/manual circuit breaker selector switch in the Generator control panel.

Page: 19 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

5.14 Secondary Wiring

Secondary wiring shall be flexible stranded copper conductor, PVC or XLPE insulated

600/1000V, flame retardant.

Minimum wire size for control wiring shall be 1.5 mm2 and for current transformer wiring 2.5

mm2.

All low voltage wires shall be neatly arranged and clipped in groups and protected by flexible

conduit or channels with covers.

Each conductor and its terminations are to be identified and marked with numbered and/or

lettered ferrules of flame resistant material.

All live terminals are to be equipped with removable covers (with tools only).

As far as practicable, signal conductors shall be segregated from power wiring and AC wiring

shall be segregated from DC wiring.

Wiring to equipment mounted on doors or hinged panels shall be carried through flexible

conduits or spiral wraps.

5.15 Cable Terminations

Cable gland plates metallic, non-magnetic material shall be readily removable for the drilling

and fitting of glands.

Wiring and terminals shall be identified in accordance with the related wiring diagrams.

Positioning of cable termination shall avoid obstruction of other cable terminations, removable

covers and shall provide easy access for terminating cables.

Cable supports shall be provided by the Vendor to avoid undue strain on the cable

termination.

All 400/230 Volt AC terminal blocks shall be provided with transparent covers.

5.16 Electric System Metering

Each generator shall have the following meters with reading provided to the local control

panel:

Engine elapsed time meter - digital type (ETM).

Generator active power (kW)

Generator apparent power (kVA)

Generator reactive power (KVAR)

Generator power factor (PF)

Generator load in percent

Generator voltmeter with selector switch (VS) seven positions.

Generator current with selector switch (AS) four positions.

Generator frequency (Hz)

Generator temperature monitor for both winding and bearing RTD.

Exciter ammeter

Page: 20 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Exciter voltmeter

5.17 Contacts

Each generator to be provided with volt free contacts for remote signals as follows:

Power generator(s) running.

Power generator(s) common alarm.

Power generator(s) common shutdown.

Power generator(s) trip circuit faulty.

Power generator(s) incoming circuit breaker trip (if applicable).

Power generator(s) incoming circuit breaker close (if applicable).

Engine(s) common alarm.

Engine(s) summary fault trip.

5.18 Synchronizing System

Each generator shall have manual and automatic start-up, synchronization and dead bus

closure. In addition, facilities for synchronizing across the bus section Circuit Breaker on the

PMCC and EPMCC shall be provided (Bus section breaker are always closed until a

maintenance or abnormal condition requires them to opened). Each synchronizing attempt,

whether auto or manual shall be subject to a permissive signal from a check synchronising

relay.

The synchronizing panel shall contain as minimum:

Synchroscope.

Synchronizing lamps.

Double frequency meter.

Double voltmeter.

Circuit breaker(s) switch trip-neutral-close.

Bus voltmeters.

Synchronizing selector.

Mode of operation.

Synchronizer relay.

Check synchronising relay with indication of permissive state, incorporating

dead bus

Closing facility.

AVR (raise/lower) switches.

Governor (raise/lower) switches.

Active, apparent and reactive load sharing.

Page: 21 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

5.19 Governor

The governor shall be of the electronic type or microprocessor based type. The requirements

for isochronous or speed droop or single operation shall be specified on data sheet. Facilities

shall be provided to allow remote control of the Governor. This system will provide load

sharing between generators sets running in parallel. The Governor shall be provided with a

manual control facility.

5.20 Requirements for Parallel Operation

Generators shall be equipped with a damper winding on the rotor. If more than one star point

of paralleling operation generators will be earthed the Vendor shall ensure that third harmonic

currents circulating through the star point connections are minimized. As generators are

operating in parallel the reactive power generated shall be controlled by an automatic power

factor controller. A droop current transformer and droop rheostat shall be provided.

5.21 Current Transformers

Current transformers shall comply with the requirements of IEC 60044 and IEC

60185.Current transformers of the bushing type shall not be used.

Metering current transformers shall be with an accuracy class 0.5. Protective relay current

transformers shall have an accuracy of 5P10 (IEC class). Accuracy shall be as necessary as

is satisfactory to operate the relays over their design range. Differential Protection current

transformers shall have an accuracy class X in accordance with IEC 60185 or equivalent.

The secondary output current shall be 5 amperes, except in the following cases:

Secondary output shall be 1 ampere for differential protection and earth leakage

protection.

Connections for remote ammeters shall be from 1 ampere interposing current

transformers.

Current transformers shall be designed to mechanically and thermally withstand the specified

switchboard short circuit capacity. Current transformers short time thermal current shall be as

specified on data sheet. Current transformer secondary circuits shall be furnished with

terminal blocks having short circuiting provisions. All current transformers to be connected to

current test block.

Current transformer shall have the following specification:

Dynamic current shall not be less than 2.5 times the rated short time thermal

current.

Maximum continuous current shall be equal to 120% of the rated primary

current.

Vendor shall be responsible for design of the current transformers such that to carry the relay

burden and avoid CT saturation during normal operation, overload and short circuit

conditions.

5.22 Voltage Transformers

Voltage transformers shall comply with the requirements of IEC 60186.Voltage transformers

shall be with an accuracy class 0.5 (IEC class).

Page: 22 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Voltage transformers shall be mounted in isolated compartments with draw out facilities.

Voltage transformers shall be equipped with withdrawable primary fuses with an interrupting

capacity not less than rated interrupting capacity of the incoming circuit breakers.

Voltage transformers secondary protection shall be by miniature circuit breakers which shall

be mounted in a compartment separate from the transformers and primary fuses. All voltage

transformers to be connected to voltage test block.

5.23 Battery and Charger Assemblies

The battery & charger assemblies shall be a standard product proven performance type of

assembly and shall comply with IEC requirements and data sheet.

DC system power capacity shall cover all the DC power requirements for the engine driven

generator set. The DC power requirements for the package and DC system capacity shall be

specified by Vendor during quotation.

Nickel/Cadmium batteries in a plastic container with ample capacity for supplying the DC

loads for eight (8) hours with the battery charger off shall be provided. The system shall have

dual set of battery charger and one battery set.

Each charger shall be sized to supply the DC load and re-charge the complete discharged

battery bank in approximately 8 hours.

Sizing of battery and charger shall be based on:

D.C feed power to control panel 8 hours.

D.C feed power to D.C starting motor.

D.C feed power to all other control & auxiliaries.

20 % spare power.

Two separate DC systems shall be supplied. One DC system for the generator control panel

and engine controls, the second DC system for engine starting. Starter Batteries shall be

installed in the engine generator enclosure.

Provisions should be taken to prevent batteries discharging into charger on charger fault. The

DC required for the package shall be from the battery and charger system through D.C.

distribution panel integral with the chargers.

The D.C. distribution panel shall include main incoming circuit breaker moulded case current

limiting type and branch miniature circuit breaker 2-poles. All circuit breakers shall be

provided with over current and short circuit protection.

Batteries shall be in a separate ventilating battery room or battery case, while the charger and

relevant D.C panel shall be located in control room of the package. Batteries shall be in a

separate enclosure and free standing. Battery charger case should be equipped with

ventilating thermostatically controlled fan(s).

DC output shall be 24V DC (or Vendor standard) to suit the required DC voltage for starting

the engine and feed the generator control/protection panel & other engine auxiliaries.

AC input to the battery charger shall be 400/230 Volt (4 wire), 3 phase, 50 Hz, derived by

vendor from package auxiliary circuit provided by Company. Moulded case circuit breaker

shall be provided by Vendor at the incomer(s) of the battery charger system.

Each charger shall be provided with but not limited to the following alarms and indicating

lights:

Page: 23 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Failure of input power to the battery charger.

Failure of the output power from the battery charger.

D.C. system earth fault.

AC power "ON".

High rate charge.

Indicating instruments of switchboard quality shall be provided as follows:

A.C input voltage, with phase selector switch.

D.C output voltage.

D.C output current.

D.C charging current.

5.24 Accessories

Each battery system shall be supplied with all standard accessories, tools and spares

required for the installation, including the following:

Inter-cell connections and shrouds.

Two terminal connection lugs.

One thermometer with vent plug and wall-mount holder.

One syringe hydrometer with wall mount holder.

Cell bridging connection.

Cell Testing voltmeter 3-0-3V.

One single cell lifting sling (or other suitable handling provisions).

Insulated spanners.

Acid resistant and insulating floor if containerized solution

First Aid and Safety kit for battery rooms including Eye flush bottle station

5.25 Nameplates

Stainless steel nameplates with information listed in IEC-60034 clause 27 shall be provided in

English language.

5.26 Electrical Immunity

All Equipment shall be able to generally withstand the impact of the imposed electrical tests

as defined in referenced IEC.

5.27 Disturbance Immunity

The package shall be suitably screened to optimize electromagnetic compatibility (EMC).The

package shall be type tested in accordance with IEC 61000 part 4, level 3 - typical industrial

environments, as detailed below:

IEC 61000-4-2- Electrostatic Discharge - level 3 - 8 kV air discharge.

IEC 61000-4-3-Radiated Electromagnetic Field (RFI) - level 3-10 V/m.

Page: 24 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

IEC 61000-4-4-Electrical Fast Transient - level 3 - 4 kV common mode.

IEC 61000-4-5-Surge - 2 kV line - earth and 1 kV line line.

The manufacturer shall provide type test certificates from a recognized testing authority to

verify that the whole equipment is effectively screened against EMC in line with the applicable

IEC standards.

6

Painting

All equipment shall be finish painted or coated in accordance with Protective Coating

Specification (1007-DISQ-0-L-SS-39004).

A sufficient quantity of touch-up paint (10%) shall be supplied with the equipment to repair

minor damage to the paint finish after site installation.

7

QC Inspection and Testing

The Vendor is to co-operate with Company Inspection Representative to carry out the tests

as specified by IEC60034. The Vendor shall perform QC inspection and testing at Factory

Acceptance Tests, System QC Integration Tests with ICSS System connected and Site

Acceptance Tests in the presence of Company Representative and/or Independent

Verification Service Company. These are to include, but not limited to, the following:

7.1 General

Physical check of general appearance, finish, mechanical assembly including

good welding, full nuts on bolted parts, undamaged condition and general

worthiness.

Dimensional check, particularly overall length, breadth, height and fixing centres

against the Vendor's certified drawings.

Check of cable termination locations, direction, type and materials against

specification and

Vendor's certified drawings.

QC Inspection and Testing shall be carried out in general in accordance to

audited Quality Control Inspection and Test plan, additional Factory Acceptance

Test, System Integration Test and Site Acceptance Tests shall be carried out in

accordance to QC Test Procedures and QC plan which will be prepared by

vendor and reviewed and approved in advance by company

7.2 Generator QC Tests

Measurement of winding resistance (cold).

Full-Load Heat Run Test With Zero Power Factor Method or Equivalent

o

1/2 load test (1 hour minimum at 0 p.f)

3/4 load test (1 hour minimum at 0 p.f)

Full load test (1 hour minimum at 0 p.f)

Over load test (110% full load for 1 hour at 0 p.f).

Temperature rise test and calculating winding temperature rise.

Measurement of winding resistance (hot).

Page: 25 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Bearing inspection and temperature rise.

Vibration Test.

Noise level test.

Waveform test.

Engine Test

Insulation Resistance On

Generator windings (before heat run and after heat run & dielectric test).

Exciter windings (before heat run and after heat run & dielectric test).

Heater

Built in temperature detectors

Bearing insulation

Dielectric Test On

o

Generator windings.

Exciter windings.

Heater.

Built in temperature detectors.

7.3 Battery and Charger QC Inspection and Testing

The Vendor is to carry out the complete range of routine tests as specified by IEC 60034

These are to include, but not limited to the following:

Insulation resistance measurement.

Dielectric test.

Proper mechanical and electrical operation of all functional parts including

auxiliaries, meters, indicators, relays, etc.

Load Test: The battery chargers shall be operated at full load and ambient

temperature of 40 degrees Centigrade for a period of 24 hours, to ensure that

no overheating of any component occurs.

Output Characteristics: The Vendor shall demonstrate the output characteristics

of the equipment by recording input voltage, frequency, current and power

factor, and output voltage, current and ripple at the following output loads:

No load.

25 % full load.

50 % full load.

100 % full load.

110 % full load.

150 % full load for 5 seconds

Battery cells shall undergo standard QC factory tests.

Page: 26 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

7.4 Generator Control Panel QC Test

The generator control panel and auxiliaries equipment shall be subjected for the following

tests

Insulation tests.

Full functional test.

Temperature rise test.

Factory Acceptance Test, System Integration Test with ICSS and Site

Acceptance Test

7.5 Package String QC Test

The Vendor shall perform string test including, but not limited to, the following:

Engine start-up system including measurement of the starting time. A minimum

of two start and stop tests shall be performed.

Automatic start-up system if provided.

For emergency generator sets verification of the time between initiation of a start

command and acceptance of the nominal load for a cold start.

All engine alarm and shutdown functions.

All generator alarm and trip functions, including the verification of protection

relay operation.

Operation of the battery charger.

The status/ alarm / trip/ shutdown indication of the control panels.

Local manual start/ stop/ emergency stop functions.

Remote start/stop/emergency stop functions (input signals).

Operation of the AVR.

Operation of the AVR automatic transfer system.

Operation of the automatic power factor controller.

Operation of the synchronizing equipment.

Calibration of measuring and protective devices.

7.6 Site Acceptance QC Test

During running each generator set the following inspections to be performed:

Check for leaks.

Check for loose fasteners.

Activate and test the safety devices.

Oil level check.

Water level check.

Engine to control interconnects check.

Page: 27 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Check of direction of rotation.

Control panel tests.

Check of the adjustment of all safety devices & protective relay.

Check of excitation & voltage regulator.

Load test - 8 hours operation after one hour stabilization period.

Engine shutdown & safety devices shall be demonstrated.

Parallel operation test and complete function test.

System Integration Test with ICSS

Documentation

Vendor shall provide as a minimum the following documentation:

Outline and Equipment arrangement drawings

Layout drawings of all systems

P&IDs, Cause and Effect diagrams including ESD and F&G

Power and Instrument Cable list

Single line diagram

Electrical schematics and wiring diagram

Interconnection wiring diagrams

Termination diagrams

Earthing Diagrams

Relays and circuit breakers characteristics

Current and potential transformers curve.

Equipment Data Sheets and Equipment List

Data sheets for panels, generators, relays and all auxiliaries

Nameplates configuration

List of sub-Vendors

Installation, pre-commissioning and commissioning and start-up, operating and

maintenance manuals

Acceptance/performance QC test procedure

Surface preparation and painting procedure

Shipping, handling, packing and storage procedure

QC Test reports and certificates

Spare parts lists for pre-commissioning and commissioning and two years

operation turn over methodology

List of settings of protective relays

Page: 28 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

Interface List, Interface data and all details ( Hard- and Software )

Factory Acceptance Test Procedure

System Integration Test Procedure

Site Acceptance Test Procedure

ATEX 95 Certificates for equipment installed in classified areas

HAZOP study and report

Safety Integrity Level report(SIL)

Preparation for Shipment

The Vendor shall take all measures to avoid any risk of damage or deterioration during

shipping. When shipment is by sea, engine/generator set must be adequately protected

against knock and salt-water spray etc.. In every case, consideration must be taken of the

fact that engine/generator set will remain at site exposed in open air, in damp, tropical, high

sandstorm and dusty location. Suitable bracing shall be provided to support heavy

components during shipment.

The generator control panel shall be complete for service with all small wiring terminal

boards, fuses, links, labels, foundation bolts, test and earth connections and all necessary

items.

Wires for energizing space heaters during storage shall be brought out and tagged "Space

Heaters" with the voltage and connected wattage shown.

10 Storage Locally and Shipping

Equipment shall be packed in such a way that it can be stored locally, at the various sites for

a period of up to 12 months without suffering any damage or ill effect that would affect its

performance or operational life. Silica gel bags shall be included and/or electric anticondensation heaters, with terminals readily accessible from outside the packaging shall be

provided to prevent condensation damage.

10.1 Weight

All the dimensions of the equipment including the weight (via a weight certificate) shall be

provided, as access to the site is limited to road transport. Package may have to be split into

smaller shipping sections than is normal because of the limitations in access, and the weight

of each section may prove a critical item in transportation to site.

Shipping, installation and maintenance weights (including locating the centre of gravity) shall

be provided.

11 Vendor's Responsibility and Guarantees

The data sheet shall be completed by the Vendor and submitted with his quotation within the

tolerances specified in the relevant IEC 60034 codes. These values shall be the basis of a

performance guarantee.

The Vendor is responsible for complying with all codes which apply to the equipment. Any

special certification requirements or inspections by other authorities arising from the above

shall be arranged by the Vendor and the costs for the same shall be included in his quotation.

The equipment to be provided by Vendor must be in complete compliance with this

specification and references codes. Any exception or deviations, if any, must be listed

Page: 29 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

separately with the quotation for Company approval. Any exception which is not listed shall

not be considered.

A complete set of tools for service and maintenance shall be supplied in a suitable box with

service and maintenance manual guides.

12 Site Installation Assistance, Commissioning and Start-Up

Manufacturer shall provide a specialist with approved C.V. & certificates for site installation

supervision assistance, start-up and pre-commissioning and commissioning supervision.

Installation supervision shall include but not limited to the following:

Visual QC inspection.

Check and supervision of mechanical installation.

Check and supervision of Electrical installation.

Check of alignment, assembly, interwiring connections of the various units

shipped separately in order to assure that the Generator Package ready for

connection of incoming and outgoing power and control cables and ready for

operation.

During the pre-commissioning and commissioning and start-up stage, manufacturer specialist

shall carry-out, but not limited to the following:

Check of the correct execution of the connections between assembled units.

Insulation test of all power, control auxiliary circuits and equipment.

Dielectric withstand test of all power, control, auxiliary circuits and equipment.

Batteries shall be fully charged and subjected to discharge tests to prove their

electrical characteristics and capacity at site.

Test of functioning of all equipment + full load test.

Test and calibrations of all protective relays on site by relays sub-supplier

himself.

Site Acceptance Test inclusive System integration test on site.

Implementations of all recommendations specified in pre-commissioning and

commissioning and start up manual.

Each skid shall include adequate lifting and maintenance provisions. This shall include

sufficient lifting lugs, pad eyes, pulling rings and runway beams to assist with lifting and

handling of all components where access is restricted or where component maintenance

weights exceed 25kg and which may need to be removed or replaced during the design life of

the package. Permanent facilities shall only be provided in the case of components weighing

1 tonne or more and which will require frequent maintenance at least once every 12 months

or where access for temporary lifting gear is restricted.

The Vendor shall ensure that adequate access and withdrawal space is provided to permit

access for maintenance.

Permanent lifting davits, runway beams, pad eyes or other suitable lifting aids shall be

provided above filter covers and for all other components weighing 1 tonne or more or which

will require frequent maintenance at least once every 12 months. Permanent overhead

Page: 30 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

runway beams and/or lifting pad eyes shall also be provided above equipment where access

restrictions and/or location of equipment components preclude the use of portable lifting gear.

The supplied equipment shall be provided with an appropriate number of suitably rated lifting

lugs to enable lifting and installation at site. All pad eyes furnished by the Vendor shall be

designed in accordance with API RP2A with a factor of safety of at least two (2) based on the

maximum static weight of the complete package. Pad eyes shall be designed for a lateral

load of at least 1.5 times the design load, to be applied simultaneously with the sling load.

Suitable, dedicated and certified lifting beams and/or spreader bars, slings and shackles shall

also be provided to enable installation of the equipment.

13 Spare Parts

The following specified spare parts shall be included in Vendor's quotation:

12.1

Pre-commissioning and Commissioning Spare Parts

Pre-commissioning and Commissioning spare parts shall be Vendor responsibility but Vendor

shall submit a detailed list with his quotation, the spare parts, shall be left for the purchaser

storage.

12.2 Two Years Spare Parts

The Vendor shall submit for each Generator set a detailed list of two years spare parts with

his quotation with wearing, turn over and replacement rate data.

14 Health, Safety and Environmental Management

The Vendor shall consider the impact on environment because of his products during

different process (e.g. designs, manufacturing, . etc.), and shall develop environment

friendly products and manufacturing processes such that the supplied equipment will be safe,

efficient and made in way that it conserve energy and other natural resources.

The electrical equipment and products shall cover (in design, engineering, manufacturing and

testing processes) any emergency, abnormal and upset conditions which would be met

during equipment operation to prevent the following:

Environmental damages.

Equipment or product damages.

Plant operation losses.

Health effects.

Loss of public & customer trust.

The electrical equipment and products shall be designed to comply with all legal requirements

and relevant international standards (in design, engineering, manufacturing and testing

processes) under any emergency, abnormal and upset conditions.

Page: 31 of 32

Onspec Engineering Solutions

Disouq Field Development Project

Specification for Power Generators

15 Quality Assurance

The Vendor and major sub-suppliers shall comply with ISO 9001,2008 International Standard,

Quality Management Systems Requirements and shall be adopted by the Vendor and

his sub-suppliers throughout the various phases of the project (Management, Engineering,

fabrication, assembly, QC testing and Inspection, Pre-commissioning and commissioning).

The Vendors Quality Management System Manual and concerned operating system

documents, quality internal audit reports, QA/QC Plan, Inspection and Test Plan (ITP),

management review minutes of meeting and ISO9001:2008 valid active certificate with the

right certificate scope will be subject to the Purchasers approval prior to issue of a Purchase

Order. Major sub-suppliers will be subject to the same approvals.

The Purchaser reserves the right to conduct a Quality Surveillance Audit at the Vendors /sub

suppliers facilities at any stage during manufacture according to the Disouq Project Quality

Plan. The responsibility for QC inspection rests with the Vendor.

The approval of any work by the Purchaser or the release of equipment for shipment shall in

no way relieve the Vendor of his responsibility for meeting the requirements of this

specification. QC Inspection and testing shall be carried out in accordance with the approved

ITP.

The Vendor shall furnish a representative ITP detailing his normal scope of QC inspection

and testing with the bid in the form of his Quality Control Plan of similar projects done before.

In the event of an order, the Vendor shall submit a detailed project specific ITP for the

Purchasers approval. The ITP shall identify all QC inspection and test activities in

accordance with Requisition and its various attachments, their acceptance criteria, and

observed or witness hold points.

The Purchaser reserves the right to carry out its own QC inspection during design and

manufacture according to the project quality plan with QA plan and the project contracting

documents, Purchase Order requirements and agreements. The Vendor shall provide free

access to his works, and to that of all sub-suppliers, for the Purchaser and Purchasers

representative. All necessary QC certification documents relating to materials, QC shop test

data, etc. shall be made available to verify that the requirements of the Purchase Order are

being met.

Page: 32 of 32

You might also like

- Qcs 2014 - Sec21 p18 - Uninterruptible Power SupplyDocument6 pagesQcs 2014 - Sec21 p18 - Uninterruptible Power Supplychandra100% (1)

- HYD 200 ManualDocument32 pagesHYD 200 ManualanapenNo ratings yet

- Electrical Tray InstallationDocument4 pagesElectrical Tray InstallationClinton OlivierNo ratings yet

- Cover Sheet FOR Cause & Effect Shutdown Matrix JOB NO.: C366-L54ADocument8 pagesCover Sheet FOR Cause & Effect Shutdown Matrix JOB NO.: C366-L54AFahad AlattarNo ratings yet

- S0442 GPS E H01 CA 0003 0 UPS Sizing CalculationDocument6 pagesS0442 GPS E H01 CA 0003 0 UPS Sizing Calculationoctieu247No ratings yet

- ECA-00-PCS-PHI-0002 - Rev3-PLC PACKAGE SYSTEMS ROTATING MACHINERY PHILOSOPHYDocument13 pagesECA-00-PCS-PHI-0002 - Rev3-PLC PACKAGE SYSTEMS ROTATING MACHINERY PHILOSOPHYhcsharma1967100% (1)

- FA 0 SCADA+ PLC Architecture (Rev. D in Work) PDFDocument9 pagesFA 0 SCADA+ PLC Architecture (Rev. D in Work) PDFমোঃ মহসিনNo ratings yet

- Section 26 32 13.13-LV Emergency Power Generation System PDFDocument18 pagesSection 26 32 13.13-LV Emergency Power Generation System PDFmasoodaeNo ratings yet

- UPS Power SupplyDocument10 pagesUPS Power SupplyNageswar MakalaNo ratings yet

- VIT154 - DrainageConcept - 2006!01!19Document12 pagesVIT154 - DrainageConcept - 2006!01!19Huynh Thanh TamNo ratings yet

- 28p5 I0010 001 Cable ScheduleDocument32 pages28p5 I0010 001 Cable SchedulePj PenachosNo ratings yet

- 0221-IMA-6002-0 (Specification For Instrument Installation)Document29 pages0221-IMA-6002-0 (Specification For Instrument Installation)Hassan Ejaz100% (1)

- Ups DB-SLDDocument1 pageUps DB-SLDKonik ShahNo ratings yet

- 0591-8550-DS-03-0011 - F2-Data Sheet For Pressure Transmitters PDFDocument52 pages0591-8550-DS-03-0011 - F2-Data Sheet For Pressure Transmitters PDFSoumiyaNo ratings yet

- C259 N00-X013 01 Electrical Specification For PackagesDocument27 pagesC259 N00-X013 01 Electrical Specification For Packagesvirgil guimanNo ratings yet

- Fichtner I & CDocument23 pagesFichtner I & CMathivanan Anbazhagan100% (2)

- Overall Single Line DiagramDocument6 pagesOverall Single Line DiagramAdith Wiendar P PutraNo ratings yet

- WHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchDocument18 pagesWHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchYasin ElaswadNo ratings yet