DM

DM

Uploaded by

Lorraine BautistaCopyright:

Available Formats

DM

DM

Uploaded by

Lorraine BautistaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

DM

DM

Uploaded by

Lorraine BautistaCopyright:

Available Formats

Dubai Municipality Standards

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

DMS 026: 2011

Technical Requirements for the

Operation of Ready Mixed Concrete Plants

Issue Date

30/05/2011

Revision

01

Revision Description

Issue for use

This document is the property of Dubai Municipality and its issue is controlled. No part of this document

should be reproduced or copied without the prior written permission of Dubai Central Laboratory Department.

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

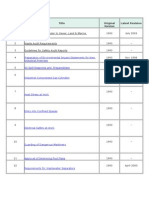

Table of Contents

Foreword

General provisions

Page

ii

1

Definitions

Requirements for production and transport facilities

Requirements for product realization

Requirement for personnel

11

12

Publications referred to

Rev.(01)

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Foreword

With a view to have a comprehensive set of Dubai Municipality Standards which would be

consistent and fulfill local needs and yet be at par with International requirements, Dubai

Central Laboratory is developing standards taking guidance as much possible and required

from International and Regional Norms.

This Dubai Municipality Standard (DMS) describes the Technical Requirements for the

Operation of Ready Mixed Concrete Plants for certification purposes.

The standard has been prepared under DCL Certification Scheme for Ready-Mixed Concrete

Plants and Central Batching Units for use of DCL ICS and by other interested

persons/organizations. The standard is issued after validation.

Amendments issued since publication

Amd No.

Rev.(01)

Date

Text affected

ii

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

General provisions

1.1

Compliance with ISO 9001 Quality Management Systems and these technical

requirements shall be the primary bases for certifying ready-mixed concrete plants

and Central Batching Units under the DCL Certification Scheme

1.2

These technical requirements relates to the:

Production facilities,

Product realization and factory production control,

Transport and Delivery, and

Performance and conformity of the ready-mixed concrete (to the user-supplied

specifications).

1.3

These technical requirements are generic and shall be used in combination with the

applicable concrete specifications as defined below [2.3].

1.4

All the measuring devices shall be calibrated as per required frequency.

1.5

Where ever software is used it shall be validated.

1.6

All the required facilities of testing shall be made available to meet the standard test

method and specification requirements.

Definitions

2.1

Concrete

Material formed by mixing cement, coarse and fine aggregate, and water, with or

without the incorporation of admixtures and additions, which develops its properties

by hydration of cement.

2.2

Ready-mixed concrete

Concrete delivered in a fresh state by a person or body who is not the user. The

concrete may be produced off site or on site.

Rev.(01)

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

2.3

Ready Mixed Concrete plant

Plant for mixing, storing and supplying measured quantities of concrete.

2.4

Concrete specifications

Applicable concrete specifications as agreed between the purchaser and the readymixed plant, include (but not limited to) the following:

2.5

BS EN 206-1

BS EN 206-9

ASTM C 94/C94M

BS 8500-1

BS 8500-2

ACI 305

CIRIA C577 and CS136

User-defined specifications subjected to DM approval

Regional (GCC), national (UAE), or local (DMS) standards, if available.

Purchaser

This term is refers to the purchaser/user of the concrete and also the specifier of the

concrete specifications and other project specific requirements.

2.6

Constituent materials

Refers to the main components of ready-mixed concrete which are cement, aggregate,

and water.

2.7

Admixture

Material added during the mixing process in small quantities related to the mass of

cement to modify the properties of fresh or hardened concrete.

2.8

Additives

Finely divided material used in concrete in order to improve certain properties or to

achieve special properties.

2.9

Rev.(01)

Batch

2

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Quantity of fresh concrete produced in one cycle of operation of a mixer

3

Requirements for production and transport facilities

3.1

Material storage and handling

3.1.1 Cement

Cement and other cementitious materials shall be stored in weather tight bins or

silos protected from external- and cross-contamination and allowing free

movement to discharge opening.

3.1.2 Aggregates

The plant shall have a system for unloading and stockpiling aggregates such as

to prevent harmful segregation and breakage.

Each size and type shall have separate bins or compartments with provisions

against inter-mixing.

Bins and stockpiles shall be protected from contamination and shall have

appropriate identification to prevent inter-mixing of different materials.

3.1.3 Water

The plant shall have adequate supply of water under constant or regulated pressure

to ensure accurate measurement of discharged volume.

3.1.4 Admixtures

The plant shall provide adequate storage and handling of admixtures to prevent

contamination and appropriate to the manufacturer's handling instructions for the

admixture.

3.2

Recommendations for hot weather concreting

ACI 305 shall be complied and the temperature of concrete at the point and the

time of delivery should be maintained at 25C in peak summer to ensure that the

temperature of the placed concrete does not exceed 32C with the following

measures inter alia may be required to control the temperature:

Rev.(01)

Shade aggregate, cement silos, water tanks and concrete plant.

3

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Paint concrete plant white.

Run concrete plant with flaked ice before mixing or transporting concrete.

Use chillers to cool the mixing water.

Add flaked ice as a proportion of the water.

The time between adding the water to the concrete mix and placing it at the

construction site shall not exceed 90 minutes, in cases where extended time is

required, the responsible engineer at the construction site may approve the

extension of the placing time provided that acceptable provisions are taken to

keep the fresh concrete inside the mixers in good workable condition.

All the precautions to be taken shall be subject to Engineers or clients approval the

ready mix supplier shall demonstrate all approved precautions.

The temperature of concrete shall not exceed as per client agreement.

3.3

Batching equipment

3.3.1 Weighing equipment

Weighing scales may be mechanical or electronic (load cell) with accuracy

within 0.15% of total capacity or 0.4% of the applied load, whichever is

greater.

The load indication of the scale shall be readable from the batching control

room, either directly or through remote indicating devices.

The scales shall undergo full calibration at least once every six months; and

each time the scale is moved or relocated.

For purposes of regular checking of the accuracy of the weighing scales, the

plant shall have set of calibrated test weights equivalent to 10 % of the

capacity of the weighing scales. The test weights shall be accurate to 0.01%.

Weigh batchers shall be equipped with precision charging and discharging

mechanism to ensure accuracy of the quantity of the material to within the

tolerance required by the applicable concrete specifications.

Rev.(01)

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

3.3.2 Volumetric equipment

Volumetric batching devices (can be through a water meter or through a

calibrated volumetric tank) for water shall be equipped with cut-off

mechanism capable of stopping the flow within the tolerances required by the

applicable concrete specifications.

The volume indicating device shall be readable from the batching control

room, either directly or through a remote indicating device.

Dispensers for admixtures - Dispensers for admixtures, shall be capable of

dispensing the correct quantity of the admixture to the accuracy as specified in

the applicable concrete specification.

3.3.3 Batching control system

The weigh batchers and volumetric batchers shall have automatic control

mechanism for stopping the flow of materials when the desired quantity has

been reached.

The discharged quantity shall be accurate to within the

tolerances given in the applicable concrete specifications.

The system shall have provisions for ensuring that materials are not

unintentionally discharged into the mix.

Data Loggers and Recorders - The plant shall be equipped with automatic data

loggers and recorders to keep records of the data during the batching process.

3.4

Plant mixer

The plant mixer shall be capable of mixing the concrete completely (central

mixing) or partially (shrink mixing).

Central mixing shall be capable of producing uniform distribution of the

constituent materials and a uniform consistency of the concrete within the

specified mixing time and at the mixing capacity.

Shrink mixing shall be capable of partially blending the concrete ingredients

to reduce their total bulk volume before discharging into a truck mixer.

Rev.(01)

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Plant mixers shall be equipped with a metal plate indicating the rated capacity

and mixing speed.

Plant mixer shall be equipped with a timing device that will prevent the

premature discharge of the batch before the mixing time has elapsed.

3.5

Truck mixers

3.5.1 Truck mixers shall be so equipped as to enable the concrete to be delivered in a

homogenous state. In addition, If water or admixtures are to be added on site under

the responsibility of concrete producer as agreed by the engineer or client but under

no circumstances water shall be added in transit.

The truck mixers shall be provided with suitable measuring and dispensing

equipment

Re-mixing of concrete which has commenced to set shall not be allowed and

in no case shall such concrete be used in works.

Pumping concrete through delivery pipes may be permitted but only with prior

approval of the Engineer and client.

The method of Transport and Delivery and placing concrete shall be to the

approval of the Engineer or Client.

3.5.2 Truck mixers shall be equipped with a metal plate indicating the gross volume of the

drum, the loading capacity, and the minimum and maximum mixing speeds of

rotation of the drum.

3.6

Ticketing system

The plant shall have a ticketing system that is able to issue a delivery ticket with the

following information:

Rev.(01)

Name of ready-mixed concrete plant

Serial number of ticket

Truck number or vehicle identification

Name of purchaser

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Name and location of the project/site

Reference to concrete specifications/designation

Amount of concrete in cubic meters

Date and time when batch was loaded

Time at which the concrete arrives at the site

Time of the beginning and end of unloading

Additional information, when requested, or as required by the project

specification e.g.: Strength class, Exposure class ,Chloride content ,Type and

strength class of cement ,Type of admixtures and addition ,special properties,

etc.

Requirements for product realization

4.1

Planning

The plant shall develop and prepare a "quality plan" for all processes needed to ensure

that the concrete is supplied having the quality and in the quantity agreed with the

purchaser. The quality plan shall include the following:

4.2

Specifications for the input and output of the process;

Resources required and personnel responsible

Required verification and/or measurement;

Required records to provide evidence that the product meets the requirements.

Order processing

The plant shall establish a system for order processing that shall cover the following:

Review of verbal or written enquiries in order to:

Rev.(01)

Record the enquiry

Identify and record purchaser's requirements (i.e. Concrete specifications)

Identify and allocate materials and other resources

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Prepare batch instructions (note: batch instructions is the summary of

information that identifies materials and concrete mix requirements, together

with any project-specific requirements)

Prepare and issue quotation with identified alternatives, if applicable.

Review of (purchase) orders in order to:

Verify the orders against the quotations

Resolve anomalies, if any

Clarify terms and conditions

Prepare/issue batch instructions

Purchaser communication

The plant shall provide all necessary information to the purchaser related to the

supply of the concrete; and shall obtain purchaser's agreement in case of deviations

from the terms of the purchase order. The plant shall investigate complaints related to

compliance with the purchaser's specifications.

4.3

Concrete design and initial testing

This requirement relates to the initial testing in order to determine the characteristics,

in respect to fresh and hardened concrete, of a particular combination of materials

across a range of cement contents, in order to be able to provide concrete of the

desired characteristics.

The plant shall establish procedures and implement initial testing for new

concrete composition (new materials and combinations of materials) before

use.

Initial test shall be repeated if there has been change, either in the constituent

materials or in the specified requirements.

Initial tests and acceptance of results shall be carried out in accordance with

the provisions of the applicable concrete specifications.

4.4

Rev.(01)

Purchasing and control of constituent materials

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

The plant shall establish and implement and document a system for purchasing and

control of materials that shall include the following:

4.4.1 Evaluation of suppliers

The plant shall establish an effective system to ensure that its suppliers have the

capability to continue to meet its quality requirements.

4.4.2 Establishment of specifications for constituent materials

Materials shall be as per applicable concrete specifications.

4.4.3 Inspection and verification of purchased materials

All incoming materials shall be subjected to assessment for conformity to the

specifications agreed with the materials' supplier.

4.4.4 Storage of materials

Materials shall be stored in appropriate containers to ensure protection from

contamination and deterioration over time.

4.4.5 Control of non-conforming materials

Procedures shall be established to ensure that non-conforming materials are not used

unintentionally.

4.5

Concrete production

4.5.1 Batching of constituent materials

A documented batching instruction giving details of the type and quantity of

the constituent materials shall be made available where the batching is carried

out. The actual batched quantity of each constituent material shall be within

the tolerances given in the applicable concrete specifications.

The batching equipment shall conform to the requirements stated in [3.3] and

shall be operated in accordance with the applicable concrete specification.

Cements, aggregates, and additions in the form of powders shall be batched by

mass. Mixing water, lightweight aggregate, admixtures and liquid additions

may be batched by mass or by volume.

Rev.(01)

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Mixing of concrete - Mixing of the constituent materials shall be carried out in

a mixer conforming to [3.4]. Mixers shall not be loaded and operated in

excess of their rated mixing capacity.

4.6

Production control testing

Production control testing shall be carried out during the production process in

accordance with the:

4.7

Tests required,

Location of testing, and

Frequency of testing given in the applicable concrete specifications.

Identification and traceability

4.7.1 Concrete shall be described in documentation by one of the following, as applicable:

In accordance with the applicable concrete specifications

In accordance with customer specifications

In accordance with other descriptions as defined in recognized specifications.

4.7.2 The system of description of materials and finished product shall provide traceability

of all constituent materials, admixtures and additions, between suppliers' description

and those used in the product realization.

4.7.3 The documentation shall provide traceability of the entire process from verbal or

written enquiry up to the delivery tickets for the finished product (i.e. enquiry,

quotations, orders, batching instructions, delivery tickets).

Rev.(01)

10

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Requirement for personnel

5.1

Personnel affecting product quality shall be competent on the basis of appropriate

education, training, skills and experience.

5.2

The plant shall employ a Technical Personnel in a responsible position (either as

Production Manager, Technical Manager, Quality Manager or any equivalent post)

with recognized degree/diploma in civil or structural engineering, or related field,

with at least 3 years of experience in concrete production industry.

5.3

The plant shall identify and document the level of knowledge, training, and skills

required for personnel involved in different levels of operation.

5.4

The plant shall:

Ensure that relevant staff are competent to perform their functions and are

aware of the effects of those functions on quality;

Ensure that personnel have been adequately trained to carry out their assigned

duties and responsibilities;

Ensure that the testing of materials, design and control of concrete mixes, and

their constituents, are under the supervision of an experienced concrete

technologist who had adequate educational background and training.

Rev.(01)

11

Issue Date: 30/05/2011

This copy is issued for Emirates Beton Readymix, no others are entitled to use this copy.

Dubai Municipality Standards

DMS 026: 2011

Publications referred to

BS EN 206-1

Concrete - Part 1: Specification, Performance, Production and Conformity

BS EN 206-9

Concrete Part 9: Additional Rules for Self compacting Concrete (SCC)

ASTM C

94/C94M

Standard Specification for Ready-Mixed Concrete

BS 8500-1

Concrete - Complementary British Standard to BS EN 206-1 - Part 1:

Method of Specifying and Guidance for the Specifier

BS 8500-2

Concrete - Complementary British Standard to BS EN 206-1 - Part 2:

Specification for Constituent Materials and Concrete

ACI 305

Hot Weather Concreting

CIRIA C577 Guide to the Construction of Reinforced Concrete in the Arabian Peninsula

and CS136

Rev.(01)

12

Issue Date: 30/05/2011

You might also like

- Dubai Municipality Exam STEEL G+1 and G+4 UpdatedDocument20 pagesDubai Municipality Exam STEEL G+1 and G+4 UpdatedsfsghjshfdhhNo ratings yet

- Abu Dhabi Municipality Req ForBuilding ApprovalDocument61 pagesAbu Dhabi Municipality Req ForBuilding Approvalmvicentelo75% (4)

- Part-1-Road Works - RevDocument377 pagesPart-1-Road Works - RevAAF100% (2)

- Unlimited & G+12 DM Exam-Revision-01Document15 pagesUnlimited & G+12 DM Exam-Revision-01Vijith2980% (5)

- Question Paper For DM Sewerage Drainage TestDocument13 pagesQuestion Paper For DM Sewerage Drainage TestMohamed987100% (1)

- Dubai Municipality Exam Solution g4Document9 pagesDubai Municipality Exam Solution g4santhi peddanna100% (1)

- Dubai Municipality Exam WITHOUT ANSWERSDocument58 pagesDubai Municipality Exam WITHOUT ANSWERSW100% (2)

- Dubai Municipality Exam - Civil EngineerDocument3 pagesDubai Municipality Exam - Civil EngineerThasneem YaseenNo ratings yet

- DM - Exam - Civil QuestionsDocument1 pageDM - Exam - Civil QuestionsSurya SundarNo ratings yet

- Dubai Municipality Electrical ExamDocument5 pagesDubai Municipality Electrical Examshahid hassan67% (3)

- Instructions For Writing Dubai Municipality ExamDocument3 pagesInstructions For Writing Dubai Municipality Examjinshad60% (10)

- DM G+4 Exam Model QuestionDocument15 pagesDM G+4 Exam Model Questionشاز إياسNo ratings yet

- Unlimited & G+12 DM Exam Rev.01Document15 pagesUnlimited & G+12 DM Exam Rev.01Lobna Tameem100% (2)

- (Computer Science & Engineering) Name: Subject: DM Date: Marks: 20Document2 pages(Computer Science & Engineering) Name: Subject: DM Date: Marks: 20MeeraNo ratings yet

- Dubai Municipality - Building Code RegulationsDocument34 pagesDubai Municipality - Building Code RegulationsHany dowedarNo ratings yet

- DUBAI MUNICIPALITY - Regulations On Building Conditions & SpecificationsDocument90 pagesDUBAI MUNICIPALITY - Regulations On Building Conditions & Specificationsscribduserforever71% (7)

- DM ExamDocument30 pagesDM ExamAi Lin Adarlo75% (8)

- Dubai Municipality Building Regulations: Translated by Santis HSE Group 2309 Al-Shatha Tower DMC-Dubai UAEDocument74 pagesDubai Municipality Building Regulations: Translated by Santis HSE Group 2309 Al-Shatha Tower DMC-Dubai UAEAhamed Ashith100% (2)

- Dubai Municipality Codes ListDocument8 pagesDubai Municipality Codes ListPerwez2150% (2)

- Dubai Engineering StanderDocument193 pagesDubai Engineering Standermzafarnawaz80% (5)

- Ass. Sub Engineer 04 04Document3 pagesAss. Sub Engineer 04 04Bipul PoudelNo ratings yet

- Dubai Engineering Qualifications Individuals Services V4.5Document62 pagesDubai Engineering Qualifications Individuals Services V4.5Dream Homes100% (1)

- Full Mock Test Series 05Document10 pagesFull Mock Test Series 05Abhilasha CIVILNo ratings yet

- DM ExamDocument4 pagesDM ExamETHANNo ratings yet

- Undertaking For DM TestDocument1 pageUndertaking For DM TestMuhammad Sabih ToorNo ratings yet

- Dubai Municipality Exam UpdatedDocument49 pagesDubai Municipality Exam UpdatedSiddiqui RanaNo ratings yet

- Dubai Municipality Building Code RegulationsDocument93 pagesDubai Municipality Building Code RegulationsRajesh K Narayanan100% (2)

- Dubai Municipality - Local Order No. 8 of 2002Document35 pagesDubai Municipality - Local Order No. 8 of 2002Muhanad SalemNo ratings yet

- Subject: NOC For G+6 Exam in Dubai MunicipalityDocument1 pageSubject: NOC For G+6 Exam in Dubai MunicipalityZeeshan YasinNo ratings yet

- Q2Document8 pagesQ2melvin lopenarioNo ratings yet

- Dubai Municipality Exam Updated-28Document1 pageDubai Municipality Exam Updated-28zash.in.akhterNo ratings yet

- Syllabus For G+1 & G+4: For G+1: Questions Are Generally Asked Regarding Low-Rise Steel Structures, Both PEBDocument1 pageSyllabus For G+1 & G+4: For G+1: Questions Are Generally Asked Regarding Low-Rise Steel Structures, Both PEBhidayat665287No ratings yet

- MMUP EXAM JMQDocument3 pagesMMUP EXAM JMQmaninambiramNo ratings yet

- Instructions - DM TestDocument1 pageInstructions - DM TestmujeebscribdNo ratings yet

- Adel Mohamed Dubai Municipality 2Document43 pagesAdel Mohamed Dubai Municipality 2ALPHYL BALASABAS100% (2)

- Instructions For Writing Dubai Municipality Exam PDFDocument3 pagesInstructions For Writing Dubai Municipality Exam PDFAkhil VNNo ratings yet

- Dubai Municipality Regulations For Green BuildingsDocument77 pagesDubai Municipality Regulations For Green Buildingsfaith-7100% (4)

- ShoringDocument8 pagesShoringJeo LawrenceNo ratings yet

- DMDocument2 pagesDMsreedevi gummadi100% (2)

- DEWA Civil Rev-15Document100 pagesDEWA Civil Rev-15Joe PsNo ratings yet

- DM G+12 & Unlimited Test QuestionDocument19 pagesDM G+12 & Unlimited Test Questionmajd el chami100% (2)

- Dubai Municipality Exam Updated-21Document1 pageDubai Municipality Exam Updated-21zash.in.akhterNo ratings yet

- Fosroc LTD: Fosroc Waterproofing Systems Proofex Hydromat Waterproofing SystemDocument7 pagesFosroc LTD: Fosroc Waterproofing Systems Proofex Hydromat Waterproofing SystemWidi YuniartoNo ratings yet

- DMS 026 2018 Technical Requirements For The Operation of Ready Mixed Concrete PlantsDocument17 pagesDMS 026 2018 Technical Requirements For The Operation of Ready Mixed Concrete PlantsNAHAS ABDULSALAMNo ratings yet

- Krystol T1T2 CSC SpecificationDocument7 pagesKrystol T1T2 CSC SpecificationAhmadAlsekaweNo ratings yet

- Appendix "A1": (1) Testing at Dubai Municipality - Central Laboratory Department (Dubai DCLD)Document6 pagesAppendix "A1": (1) Testing at Dubai Municipality - Central Laboratory Department (Dubai DCLD)Zahoor Ahmed MohsanNo ratings yet

- PIC - Engineering SpecificationsDocument68 pagesPIC - Engineering SpecificationsInah Quiniquini ManaleseNo ratings yet

- Construction Standard Specification FOR Concrete Materials AND ConstructionDocument32 pagesConstruction Standard Specification FOR Concrete Materials AND ConstructionWNo ratings yet

- Storm Water - Concrete SpecsDocument39 pagesStorm Water - Concrete Specssalaitaosama1995No ratings yet

- Astm C1602 C1602M 22Document4 pagesAstm C1602 C1602M 22عبدالمعز المليانNo ratings yet

- 2023 02 19 - NCC Summary of Key RequirementsDocument8 pages2023 02 19 - NCC Summary of Key RequirementspanadiumNo ratings yet

- FPCC Qa FinalDocument149 pagesFPCC Qa FinalOumar CoulibalyNo ratings yet

- Specification For RCC ConstructionDocument40 pagesSpecification For RCC ConstructionSweel Skylling100% (2)

- 19 - Part III - Section 4.0 - Scope of WorkDocument100 pages19 - Part III - Section 4.0 - Scope of Workابومحمد الكنانيNo ratings yet

- Hardicrete Heavy Duty Surfacing No.88 1969 Third IssueDocument8 pagesHardicrete Heavy Duty Surfacing No.88 1969 Third Issuecvsatheeh1No ratings yet

- 03 06 00 - Schedules For ConcreteDocument5 pages03 06 00 - Schedules For ConcreteHardeo Dennis ChattergoonNo ratings yet

- Section 13 (Masonry) - Qcs 2010Document36 pagesSection 13 (Masonry) - Qcs 2010gendy350% (2)

- Handbook On Vacuum Dewatering Concrete FlooringDocument18 pagesHandbook On Vacuum Dewatering Concrete FlooringPrasanta Parida100% (1)

- ASTM-C1602-C1602MDocument3 pagesASTM-C1602-C1602Mpankaj rawatNo ratings yet

- DOW 1995 Check ListDocument195 pagesDOW 1995 Check Listwanjieshi0No ratings yet

- Lead Process Engineer Project in Houston TX Resume Michael RitchieDocument3 pagesLead Process Engineer Project in Houston TX Resume Michael RitchieMichael RitchieNo ratings yet

- Chapter 13 Exam Questions 5Document3 pagesChapter 13 Exam Questions 5Christian Villahermosa ToleroNo ratings yet

- Balinit Tisaflex Machining Difficult-To-Cut Materials at The Highest LevelDocument4 pagesBalinit Tisaflex Machining Difficult-To-Cut Materials at The Highest Levelnhirpara1No ratings yet

- Similarilies and Differences in The Transformation Process Between Car Production and AirlinesDocument2 pagesSimilarilies and Differences in The Transformation Process Between Car Production and Airlineslittle manNo ratings yet

- PRSP Checkweigher GBDocument5 pagesPRSP Checkweigher GBChandra NurikoNo ratings yet

- EN10269Document7 pagesEN10269Luis R. Moreno100% (1)

- OTPL - Introduction PDFDocument31 pagesOTPL - Introduction PDFAnil Kumar H CNo ratings yet

- Warehouse ManagementDocument272 pagesWarehouse Managementsabarish0801No ratings yet

- Upgrades and Enhancements For Competitive Coal-Fired Boiler SystemsDocument8 pagesUpgrades and Enhancements For Competitive Coal-Fired Boiler SystemsShankar Jha100% (1)

- Lasform TechnologyDocument3 pagesLasform Technologygopi_krishnan_29No ratings yet

- Project Profile of Agricultural ImplementDocument10 pagesProject Profile of Agricultural ImplementdebasishroutNo ratings yet

- Potential Sources of Wear Metals in Used Lubricating Oil AnalysisDocument4 pagesPotential Sources of Wear Metals in Used Lubricating Oil Analysismaruf amaludinNo ratings yet

- Hardness Test SubmitDocument8 pagesHardness Test Submitonkod1100% (1)

- Prolect Report of Material Management of Renusager Power Divison Hindalco Industries LTDDocument122 pagesProlect Report of Material Management of Renusager Power Divison Hindalco Industries LTDRahul RoyNo ratings yet

- Press Dies Tutorial Technical Tutorial - MISUMIDocument1 pagePress Dies Tutorial Technical Tutorial - MISUMISekar SubramaniNo ratings yet

- Food Grade HexaneDocument2 pagesFood Grade HexaneAnonymous FwS0w7xh7cNo ratings yet

- Originate Industries ProfileDocument4 pagesOriginate Industries Profileyadavmihir63No ratings yet

- Environmental Health and Vessel Sanitation Preventive Procedure Instruction #11Document1 pageEnvironmental Health and Vessel Sanitation Preventive Procedure Instruction #11VizitiuAnisoaraNo ratings yet

- One Sensing Range For All Metals. Inductive Sensors (EN)Document4 pagesOne Sensing Range For All Metals. Inductive Sensors (EN)ifm electronicNo ratings yet

- Roles and Responsibilities of Plant Commissioning Rev 3Document10 pagesRoles and Responsibilities of Plant Commissioning Rev 3gst ajahNo ratings yet

- Product Catalogue For Steel Re-BarsDocument35 pagesProduct Catalogue For Steel Re-BarsCrazyBookWormNo ratings yet

- Oman's Key IndustriesDocument9 pagesOman's Key IndustriesibrahimkhansahilNo ratings yet

- Quality ManualDocument43 pagesQuality ManualSunil Jaglan0% (1)

- 08 Flotation MachinesDocument47 pages08 Flotation MachinesNataliaPBDNo ratings yet

- Pufatherm Prospekt NEUTRAL GBDocument2 pagesPufatherm Prospekt NEUTRAL GBrichashyampatilNo ratings yet

- PP Colour Selection GuideDocument5 pagesPP Colour Selection Guidejaskaran singhNo ratings yet

- Integrated Supply Chain ManagementDocument3 pagesIntegrated Supply Chain ManagementAbhishek Jain50% (2)

- Cotton IndustryDocument18 pagesCotton IndustrySakhamuri Ram'sNo ratings yet

- Bessemer Process 2Document3 pagesBessemer Process 2ShahzadAkhterNo ratings yet

- Total Quality Management: V.BALAJI, M.Tech, (P.H.D) Ap/Eee, DceDocument84 pagesTotal Quality Management: V.BALAJI, M.Tech, (P.H.D) Ap/Eee, DceArun KumarNo ratings yet