Worked Example Header Plate

Worked Example Header Plate

Uploaded by

Nikola PejatovicCopyright:

Available Formats

Worked Example Header Plate

Worked Example Header Plate

Uploaded by

Nikola PejatovicOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Worked Example Header Plate

Worked Example Header Plate

Uploaded by

Nikola PejatovicCopyright:

Available Formats

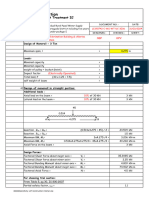

APPLICATION OF THE EUROPEAN RECOOMENDATIONS FOR

THE DESIGN OF SIMPLE JOINTS IN STEEL STRUCTURES

J.P. JASPART

1 Worked examples

1.1

1.1.1

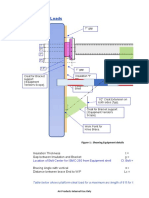

Header plate connection

Geometrical and mechanical data

e1

p1

M20

HEA200

p1

IPE300

e1

e2

Main joint data

Configuration

Column

Beam

Type of connection

Header plate

Beam to column flange

HEA 200 S 235

IPE 300 S 235

Header plate connection

230 x 200 x 10, S 235

Detailed characteristics

Column HEA 200, S235

Depth

Thickness of the web

Width

Thickness of the flange

Root radius

Area

Inertia

h

tcw

bc

tcf

r

A

I

= 190.00

= 6.50

= 200.00

= 10.00

= 18.00

= 53.83

= 3692.16

Yield strength

Ultimate strength

fyc = 235.00

fuc = 360.00

mm

mm

mm

mm

mm

cm

cm4

N/mm

N/mm

p2

e2

Beam IPE 300, S235

Depth

Thickness of the web

Width

Thickness of the flange

Root radius

Area

Inertia

h

tbw

bb

tbf

r

A

I

= 300.00

= 7.10

= 150.00

= 10.70

= 15.00

= 53.81

= 8356.11

mm

mm

mm

mm

mm

cm

cm4

Yield strength

Ultimate strength

fyb = 235.00

fub = 360.00

N/mm

N/mm

gv

hp

bp

tp

mm

mm

mm

mm

Header plate 230 x 200 x 10, S 235

Vertical gap

Depth

Width

Thickness

=

=

=

=

35.00

230.00

200.00

10.00

Direction of load transfer (1)

Number of bolts rows

Edge to first bolt row distance

Pitch between bolt row 1 and 2

Pitch between bolt row 2 and 3

last bolt row to edge distance

n1

e11

p1[1]

p1[2]

e1n

=

=

=

=

=

3

45.00

70.00

70.00

45.00

=

=

=

=

e2s

2

50.00 mm

100.00 mm

50.00 mm

=

50.00 mm

mm

mm

mm

mm

Direction perpendicular to Load transfer (2)

Number of bolts rows

n2

Edge to first bolt row distance

e21

Pitch between bolt row 1 and 2

p2'

last bolt row to edge distance

e2n

last bolt row to edge distance (column flange)

Yield strength

Ultimate strength

fyp = 235.00

fup = 360.00

N/mm

N/mm

As

d

d0

fyb

fub

mm

mm

mm

N/mm

N/mm

Bolts M20, 8.8

Resistant area

Diameter of the shank

Diameter of the holes

Yield strength

Ultimate strength

=

=

=

=

=

245.00

20.00

22.00

640.00

800.00

aw =

4.00

Welds

Throat thickness of the weld

mm

Length of the weld

lw = 230.00

mm

Safety factors

M0

M2

=

=

1.00

1.25

Applied shear force

VSd = 200 kN

1.1.2

Ductility and rotation requirements

Rotation requirements

(1)

hp db

=

=

=

hp

db

(2)

230.00 mm

h 2 tbf 2 r

300.00 2 10.70 2 15.00 = 248.60 mm

ok

available > required

we suppose that this requirement is fulfilled.

Ductility requirements

(1)

d

2,8

tp

f yp

f ub

d / tp =

2.00

fyp / fub =

0.29

2.00 1.52

(2)

1.1.3

ok

tbw

fybw

fubw

w

f ybw M 2

= 3.21 mm

f ubw M 0

= 7.1 mm

= 235.00 N/mm

= 360.00 N/mm

= 0.80

= 4.00 mm

a 0.4 tbw w

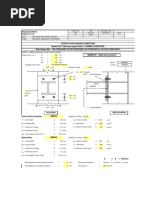

Joint shear resistance

ok

Bolts in shear

VRd 1 = 0,8 n Fv,Rd = 451.58 kN

n

=6

Fv,Rd= v A fub / M2 = 94.08 kN

v = 0.6

A

= As = 245.00 mm

fub = 800.00 N/mm

Header plate in bearing

VRd 2 = n Fb,Rd = 589.09 kN

n

=6

Fb,Rd= k1 b d tp fup / M2 = 98.18 kN

b = min(1 , 2 , 3 , 1) = 0.68

1 = e1 / 3d0 = 0.68

2 = p1 / 3d0 - 1/4 = 0.81

3 = fub / fup = 2.22

k1

= min(2.8 e2 / d0 1.7 ; 2.5)

= min(4.66 ; 2.5) = 2.5

d

tp

fub

fup

= 20.00 mm

= 10.00 mm

= 800.00 N/mm

= 360.00 N/mm

Column flange in bearing

VRd 3 = n Fb,Rd = 700.36 kN

n

=6

Fb,Rd= k1 b d tcf fucf / M2 = 116.73 kN

= min(1 , 2 , 1) = 0.81

1 = p1 / 3d0 - 1/4 = 0.81

2 = fub / fucf = 2.22

k1

= min(2.8 e2s / d0 1.7 ; 2.5)

= min(4.66 ; 2.5) = 2.5

d

tcf

fub

fucf

= 20.00 mm

= 10.00 mm

= 800.00 N/mm

= 360.00 N/mm

Gross section of the header plate in shear

VRd 4 = 2 Fv,Rd = 491.44 kN

Fv,Rd = Av fyp / (1,27 3 M0) = 245.72 kN

Av = hp tp = 23.00 cm

fyp = 235.00 N/mm

Net section of the header plate in shear

VRd 5 = 2 Fv,Rd = 545.39 kN

Fv,Rd = Av,net fup / ( 3 M2 ) = 272.69 kN

Av,net = ( hp - n1 d0 ) tp = 16.40 cm

hp = 230.00 mm

n1 = 6

d0 = 22.00 mm

tp = 10.00 mm

fup = 360.00 N/mm

Shear block of the header plate

VRd 6 = 2 Feff,Rd = 577.40 kN

1,36 p2' = 136.00 mm hp > 1,36 p2'

n1 > 1

n1 = 3

Feff,Rd = Feff,1,Rd = fup Ant / M2 + fyp Anv / ( 3 M0 ) = 288.70 kN

Ant = tp ( e2 - d0/2 ) = 390.00 mm

tp = 10.00 mm

e2 = 50.00 mm

d0 = 22.00 mm

Anv = tp ( hp e1 ( n1 0.5 ) d0 ) = 1300.00 mm

n1 = 3

hp = 230.00 mm

e1 = 45.00 mm

fyp

fup

= 235.00 N/mm

= 360.00 N/mm

Header plate in bending

VRd 7 =

hp = 230.00 mm

1,36 p2' = 136.4 mm

hp > 1,36 p2'

Beam web in shear

VRd 8 = Fv,Rd = 221.56 kN

Fv.Rd = Av fybw / ( 3 M0) = 221.56 kN

Av = hp tbw = 16.33 cm

fybw = 235.00 N/mm

Joint shear resistance

Shear resistance of the joint VRd = 221.56 kN

Failure Mode:

Beam web in shear

1.1.4

Design check

Applied shear force:

Shear resistance:

1.1.5

VSd

VRd

Joint tying resistance

Bolts in tension

Nu 1 = n Bt,u = 1176.00 kN

n=6

Bt,u = f ub A s = 196.00 kN

As = 245.00 mm

Fub = 800.00 N/mm

Header plate in bending

Nu 2 = min ( Fhp,u,1 ; Fhp,u,2 ) = 684.69 kN

= 200 kN

= 221.56 kN

Design O.K.

Fhp,u,1 =

Fhp,u,2 =

(8 n p 2 e w ) l eff .p.t ,1 m u .p

2 m p n p e w (m p + n p )

2 l eff .p.t , 2 m u .p + n B t .u n p

mp + n p

= 852.83 kN

= 684.69 kN

n=6

mp = (p2' tw 2 x 0,8 a 2-0,5) / 2 = 41.925 mm

np = min ( e2 ; 1,25 mp ) = min ( 50 ; 52.4 ) = 50.00 mm

t 2p f up

= 9000.00 N mm/mm

mu.p =

4

leff.p1 = leff.p2 = hp = 230.00 mm

ew = 37.00 mm

Supporting member in bending (column flange)

Nu 2 = min ( Fcf,u,1 ; Fcf,u,2 ) =

Fcf,u,1 =

Fcf,u,2 =

(8 n cf 2 e w ) l eff .cf .t ,1 m u .cf

2 m cf n cf e w (m cf + n cf )

2 l eff .cf .t , 2 m u .cf + n B t .u n cf

m cf + n cf

=

=

n=6

mcf = (p2' tcw 2 x 0,8 rc) / 2 = 32.35 mm

ncf = min ( e2s ; 1,25 mp ) = min ( 50 ; 40.438 ) = 40.438 mm

t2 f

mu.cf = cf ucf = 9000.00 N mm/mm

4

leff.cf1 =

leff.cf2 =

ew = 37.00 mm

Comment :

More resistance than for the header plate (higher leff values and smaller values

of m and n).

Beam web in tension

Nu 4 = tw hp f ubw = 587.88 kN

tw = 7.10 mm

hp = 230.00 mm

fubw = 360.00 N/mm

Welds

Conditions for full-strength behaviour of the welds are fulfilled

Joint tying resistance

Tying resistance of the joint Nu = 587.88 kN

Failure mode :

Beam web in tension

You might also like

- Seismic Load - AS 1170.4Document2 pagesSeismic Load - AS 1170.4Sakthivel VNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- UFT Test Automation in Oracle E-Business Suite ProjectsDocument5 pagesUFT Test Automation in Oracle E-Business Suite Projectsaustinfru7No ratings yet

- Emsland Germany Ka26 CCPP Project DatasheetDocument6 pagesEmsland Germany Ka26 CCPP Project DatasheetNihed KilaniNo ratings yet

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Weight+&+Bolting LseDocument38 pagesWeight+&+Bolting LseAlexandre Freitas0% (1)

- SPREAER BEAM&LIFTING-line Beam-1Document6 pagesSPREAER BEAM&LIFTING-line Beam-1Sabrang LorNo ratings yet

- Flat Rectangular Plate With Four Sides Fixed Under Uniform PressureDocument4 pagesFlat Rectangular Plate With Four Sides Fixed Under Uniform PressureberylqzNo ratings yet

- 3a. MonorailDocument15 pages3a. MonorailLagnajit DasNo ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Wind Load Calculation For Multiple Framed Open Structures Design Wind PressureDocument2 pagesWind Load Calculation For Multiple Framed Open Structures Design Wind Pressurechirag01020% (1)

- Design SectionDocument19 pagesDesign SectionKrishna KumarNo ratings yet

- Anchor Bolt Loading Calculation For 101-B-10 29.02.16Document6 pagesAnchor Bolt Loading Calculation For 101-B-10 29.02.16kkaranagNo ratings yet

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design 8 7 M Diameter X 9 0 M HeightDocument15 pagesAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design 8 7 M Diameter X 9 0 M Heighthabibur Rahman KhanNo ratings yet

- Calculation For Pipe SplicingDocument2 pagesCalculation For Pipe SplicingAnonymous ZMLlQvBopNo ratings yet

- TRUNIONSDocument3 pagesTRUNIONSakisdassasNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Piping Cleat LoadsDocument35 pagesPiping Cleat LoadsRajveer SinghNo ratings yet

- Lifting lug-U-FA 121 - R0Document2 pagesLifting lug-U-FA 121 - R0manish318100% (1)

- Ellipsoidal Flange To Circular ConverterDocument3 pagesEllipsoidal Flange To Circular Converternaveenkumar_madasett100% (1)

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDocument29 pagesPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENo ratings yet

- Calculation Sheet: Form ESTD/F/0036C of Job/ Work Order No. DateDocument21 pagesCalculation Sheet: Form ESTD/F/0036C of Job/ Work Order No. Datesinu_emailNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On LugsSiva baalan100% (2)

- Calculation of Bearing Plate Dimension:: Beam SectionDocument3 pagesCalculation of Bearing Plate Dimension:: Beam Sectionk.m.ariful islam100% (1)

- Partition Plate THK CalnDocument1 pagePartition Plate THK CalnMayank MittalNo ratings yet

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiNo ratings yet

- Lifting Lug DesignDocument4 pagesLifting Lug DesignRohith V VNo ratings yet

- Saddle 3Document3 pagesSaddle 3RUDHRA DHANASEKAR100% (1)

- Calc Leg Check of Cross BracingDocument4 pagesCalc Leg Check of Cross Bracingdinesh_akabariNo ratings yet

- 28 Roark Flat PlatesDocument4 pages28 Roark Flat PlatesJorge Silva100% (1)

- Pin Connected Tension MemberDocument2 pagesPin Connected Tension MemberAUNGPSNo ratings yet

- Platform Weight Calculator (Vertical Vessel)Document11 pagesPlatform Weight Calculator (Vertical Vessel)Sky LarksNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- UB254 To UB457Document7 pagesUB254 To UB457ihpeterNo ratings yet

- Combined Stress Caclulation - PveliteDocument2 pagesCombined Stress Caclulation - Pveliterajeshvyas_510% (1)

- Platform Attachement Parameter Calculation For LP Compressor Inlet Ko DrumDocument1 pagePlatform Attachement Parameter Calculation For LP Compressor Inlet Ko DrumKpNo ratings yet

- Ellipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREDocument3 pagesEllipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191No ratings yet

- Yield Stress Working StressDocument3 pagesYield Stress Working Stressdinesh11rNo ratings yet

- Columna de SotanoDocument38 pagesColumna de SotanoLivian TeddyNo ratings yet

- Steel Beam Design As Per AISC ASDDocument2 pagesSteel Beam Design As Per AISC ASDAJ NugrohoNo ratings yet

- Structural Bolts CatalogueDocument3 pagesStructural Bolts CatalogueTom CaineNo ratings yet

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191No ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Braced Legs ClaculationsDocument2 pagesBraced Legs Claculationssumit_waghmareNo ratings yet

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Base Plate (ML Gambhir)Document6 pagesBase Plate (ML Gambhir)Prakash SinghNo ratings yet

- Nozzles Loads: Flange Rating β - Value of Columns and DrumsDocument1 pageNozzles Loads: Flange Rating β - Value of Columns and DrumsBSK entertainmentNo ratings yet

- Bracing Connection CheckDocument3 pagesBracing Connection CheckPrakash Singh RawalNo ratings yet

- Top Cover Design Without StiffnersDocument2 pagesTop Cover Design Without Stiffnersmiteshpatel191No ratings yet

- Weld 3Document1 pageWeld 3canettijNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Dome Roof TableDocument1 pageDome Roof Tablejojo_323No ratings yet

- Spreader BarDocument2 pagesSpreader BarAmi PutraNo ratings yet

- TD HE S&T v2020.00Document29 pagesTD HE S&T v2020.00Claudia BonocoreNo ratings yet

- Mathcad - C02-C1Document5 pagesMathcad - C02-C1Krish Chand100% (1)

- Lifting LugDocument17 pagesLifting LugbkprodhNo ratings yet

- WE-5-2 Fin Plate ConnectionDocument10 pagesWE-5-2 Fin Plate ConnectionPedro AlmeidaNo ratings yet

- Connessione A Taglio EC3 IngleseDocument15 pagesConnessione A Taglio EC3 Inglesemihai_serban13No ratings yet

- INFASO 9.4 Example FinalDocument28 pagesINFASO 9.4 Example Finalpperic13No ratings yet

- Bracing Connection DesignDocument5 pagesBracing Connection DesignnileshmadankarNo ratings yet

- Annex EDocument1 pageAnnex ENikola PejatovicNo ratings yet

- L60 X 60 X 6Document1 pageL60 X 60 X 6Nikola PejatovicNo ratings yet

- Tech Specs Sub (SUBSTATION+CIVIL+WORKS)Document79 pagesTech Specs Sub (SUBSTATION+CIVIL+WORKS)Nikola Pejatovic100% (1)

- K Nije U Intervalu !!!! Manje Je Od KL: Yl KL Yl K - 14.0322 y KD Yd KL - 13 - 13Document3 pagesK Nije U Intervalu !!!! Manje Je Od KL: Yl KL Yl K - 14.0322 y KD Yd KL - 13 - 13Nikola PejatovicNo ratings yet

- Montazni Nastavak Resetka A2 ProduzeniDocument1 pageMontazni Nastavak Resetka A2 ProduzeniNikola PejatovicNo ratings yet

- Oštrač BoreraDocument59 pagesOštrač BoreradinoNo ratings yet

- FR 2 Determination of The Solubility Product Constant of Calcium HydroxideDocument6 pagesFR 2 Determination of The Solubility Product Constant of Calcium HydroxideJeff Jefferson100% (2)

- Furniture AnnexDocument6 pagesFurniture AnnexAlaa HusseinNo ratings yet

- Google Sketchup 4.0 User GuideDocument394 pagesGoogle Sketchup 4.0 User Guideathos100% (1)

- IT 101 Syllabus ObeDocument11 pagesIT 101 Syllabus ObeJONL IDULSANo ratings yet

- Principle of BendingDocument6 pagesPrinciple of BendingFarihan MailNo ratings yet

- Structural and Modal Analysis of A300 Wing PDFDocument59 pagesStructural and Modal Analysis of A300 Wing PDFDarshak Bhuptani100% (2)

- Safety Plan Bala AssociationDocument107 pagesSafety Plan Bala Associationjesus GandhiNo ratings yet

- 8206 PDFDocument74 pages8206 PDFbahabahabahaNo ratings yet

- Sub: Structural Analysis Module-24CDocument8 pagesSub: Structural Analysis Module-24CAjay MalikNo ratings yet

- Course File For: Department of Electrical and Electronics EngineeringDocument27 pagesCourse File For: Department of Electrical and Electronics EngineeringNAGASREENo ratings yet

- Tatra t815-7 Cas30Document4 pagesTatra t815-7 Cas30Forum PompieriiNo ratings yet

- Lighting Calculations: - Illuminance Level and Luminance, - UniformityDocument10 pagesLighting Calculations: - Illuminance Level and Luminance, - UniformityFırat YılmazNo ratings yet

- Ajay Mishra: B.E: Electrical & Electronics Engineering Institution Name: I.E.S I.P.S ACADEMY Semester % MarksDocument2 pagesAjay Mishra: B.E: Electrical & Electronics Engineering Institution Name: I.E.S I.P.S ACADEMY Semester % MarkssandyshikhaNo ratings yet

- Electric Current Question and Answer 1Document2 pagesElectric Current Question and Answer 1lock_jaw300% (1)

- Material Standards and Committees For The International Oil & Gas IndustryDocument40 pagesMaterial Standards and Committees For The International Oil & Gas Industrydenstar silalahiNo ratings yet

- Experiment 1 Colligative Properties of Solutions: Properties True Solution Colloid SuspensionDocument4 pagesExperiment 1 Colligative Properties of Solutions: Properties True Solution Colloid SuspensionMarivic BarandaNo ratings yet

- BLRCH400A480B52: Lembar Data ProdukDocument2 pagesBLRCH400A480B52: Lembar Data ProdukDewie HardiningrumNo ratings yet

- 1762986Document18 pages1762986Prakhar NigamNo ratings yet

- Painting SpecDocument10 pagesPainting SpecTroy HooperNo ratings yet

- Soils Report Retaining WallDocument38 pagesSoils Report Retaining WallArnold TunduliNo ratings yet

- Stereoscopy: From Wikipedia, The Free EncyclopediaDocument28 pagesStereoscopy: From Wikipedia, The Free EncyclopediaSouradeep SenNo ratings yet

- TRB Computer Teacher SyllabusDocument10 pagesTRB Computer Teacher SyllabusEs ENo ratings yet

- SAGEM FAST 3202 (Livebox) ENGLISHDocument140 pagesSAGEM FAST 3202 (Livebox) ENGLISHspam47spam47No ratings yet

- Test ManualDocument66 pagesTest ManualAakoji Devikumar100% (4)

- Beams On Elastic FoundationDocument15 pagesBeams On Elastic FoundationIngeniero EstructuralNo ratings yet

- 07 Cleaning of Empty Capsule Loader 07Document2 pages07 Cleaning of Empty Capsule Loader 07Ravi YadavNo ratings yet

- 'TDS Onduline Classic DR - 2015-01-08Document1 page'TDS Onduline Classic DR - 2015-01-08Iwan SetiawanNo ratings yet