Chapter-1: 1.1 Renewable Energy

Chapter-1: 1.1 Renewable Energy

Uploaded by

MohanSharmaCopyright:

Available Formats

Chapter-1: 1.1 Renewable Energy

Chapter-1: 1.1 Renewable Energy

Uploaded by

MohanSharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Chapter-1: 1.1 Renewable Energy

Chapter-1: 1.1 Renewable Energy

Uploaded by

MohanSharmaCopyright:

Available Formats

Biomass Energy

Chapter-1

INTRODUCTION

1.1 Renewable Energy

Renewable energy is generally defined as energy that comes from resources which are naturally

replenished on a human timescale such as sunlight, wind, rain, tides, waves and geothermal

heat. Renewable energy replaces conventional fuels in four distinct areas: electricity

generation, hot water/space heating, motor fuels, and rural (off-grid)energy services.

Renewable energy is electricity generated by fuel sources that restore themselves over a short

period of time and do not diminish. Although some renewable energy technologies have an

impact on the environment, renewables are considered environmentally preferable to

conventional sources and, when replacing fossil fuels, have significant potential to reduce

greenhouse gas emissions.

Fig. 1.1 Wind, solar, and biomass are three emerging renewable sources of energy

All energy sources have some impact on our environment. Fossil fuels coal, oil, and natural

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

gas do substantially more harm than renewable energy sources by most measures, including

air and water pollution, damage to public health, wildlife and habitat loss, water use, land use,

and global warming emissions.

It is still important, however, to understand the environmental impacts associated with producing

power from renewable sources such as wind, solar, geothermal, biomass, and hydropower.

The exact type and intensity of environmental impacts varies depending on the specific

technology used, the geographic location, and a number of other factors. By understanding the

current and potential environmental issues associated with each renewable energy source, we can

takes steps to effectively avoid or minimize these impacts as they become a larger portion of our

electric supply.

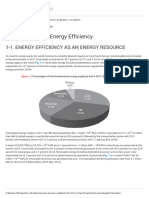

Based on REN21's 2014 report, renewables contributed 19 percent to our energy consumption

and 22 percent to our electricity generation in 2012 and 2013, respectively. Both, modern

renewables, such as hydro, wind, solar and biofuels, as well as traditional biomass, contributed in

about equal parts to the global energy supply. Worldwide investments in renewable technologies

amounted to more than US$214 billion in 2013, with countries like China and the United

States heavily investing in wind, hydro, solar and biofuels.

Renewable energy resources exist over wide geographical areas, in contrast to other energy

sources, which are concentrated in a limited number of countries. Rapid deployment of

renewable energy and energy efficiency is resulting in significant energy security, climate

change mitigation, and economic benefits. In international public opinion surveys there is strong

support for promoting renewable sources such as solar power and wind power. At the national

level, at least 30 nations around the world already have renewable energy contributing more than

20 percent of energy supply. National renewable energy markets are projected to continue to

grow strongly in the coming decade and beyond.

While many renewable energy projects are large-scale, renewable technologies are also suited

to rural and remote areas and developing countries, where energy is often crucial in human

development. United Nations' Secretary-General Ban Ki-moon has said that renewable energy

has the ability to lift the poorest nations to new levels of prosperity.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

While states identify renewable technologies differently for the purposes of meeting state targets

and goals, most include at a minimum:

Solar (photovoltaic, solar thermal)

Wind

Geothermal

Biomass

Biogas (e.g., landfill gas/wastewater treatment digester gas)

Low-impact hydroelectricity

1.2 Overview

Renewable energy flows involve natural phenomena such as sunlight, wind, tides,plant growth,

and geothermal heat, as the International Energy Agency explains:

Renewable energy is derived from natural processes that are replenished constantly. In its various

forms, it derives directly from the sun, or from heat generated deep within the earth. Included in

the definition is electricity and heat generated from solar, wind, ocean, hydropower, biomass,

geothermal resources, and biofuels and hydrogen derived from renewable resources.

Wind power is growing at the rate of 30% annually, with a worldwide installed capacity of

282,482 megawatts (MW) at the end of 2012, and is widely used inEurope, Asia, and the United

States. At the end of 2012 the photovoltaic (PV) capacity worldwide was 100,000 MW, and PV

power stations are popular in Germanyand Italy. Solar thermal power stations operate in the

USA and Spain, and the largest of these is the 354 MW SEGS power plant in the Mojave Desert.

The world's largest geothermal power installation is The Geysers in California, with a rated

capacity of 750 MW. Brazil has one of the largest renewable energy programs in the world,

involving production of ethanol fuel from sugar cane, and ethanol now provides 18% of the

country's automotive fuel. Ethanol fuel is also widely available in the USA.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

Renewable energy resources and significant opportunities for energy efficiency exist over wide

geographical areas, in contrast to other energy sources, which are concentrated in a limited

number of countries. Rapid deployment of renewable energy and energy efficiency, and

technological diversification of energy sources, would result in significant energy security and

economic benefits.

Renewable energy replaces conventional fuels in four distinct areas: electricity generation, hot

water/space heating, motor fuels, and rural (off-grid) energy services:

Power generation. Renewable energy provides 21.7% of electricity generation worldwide

as of 2013. Renewable power generators are spread across many countries, and wind

power alone already provides a significant share of electricity in some areas: for example,

14% in the U.S. state of Iowa, 40% in the northern German state of Schleswig-Holstein,

and 49% in Denmark. Some countries get most of their power from renewables,

including Iceland (100%), Norway (98%), Brazil (86%), Austria (62%), New Zealand

(65%), and Sweden (54%).

Heating. Solar hot water makes an important contribution to renewable heat in many

countries, most notably in China, which now has 70% of the global total (180 GWth).

Most of these systems are installed on multi-family apartment buildings and meet a

portion of the hot water needs of an estimated 5060 million households in China.

Worldwide, total installed solar water heating systems meet a portion of the water heating

needs of over 70 million households. The use of biomass for heating continues to grow as

well. In Sweden, national use of biomass energy has surpassed that of oil. Direct

geothermal for heating is also growing rapidly.

Transport fuels. Renewable biofuels have contributed to a significant decline in oil

consumption in the United States since 2006. The 93 billion liters of biofuels produced

worldwide in 2009 displaced the equivalent of an estimated 68 billion liters of gasoline,

equal to about 5% of world gasoline production.

As of 2011, small solar PV systems provide electricity to a few million households, and microhydro configured into mini-grids serves many more. Over 44 million households

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

use biogas made in household-scale digesters for lighting and/or cooking, and more than 166

million households rely on a new generation of more-efficient biomass cookstoves. United

Nations' Secretary-General Ban Ki-moon has said that renewable energy has the ability to lift the

poorest nations to new levels of prosperity.

At the national level, at least 30 nations around the world already have renewable energy

contributing more than 20% of energy supply. National renewable energy markets are projected

to continue to grow strongly in the coming decade and beyond, and some 120 countries have

various policy targets for longer-term shares of renewable energy, including a 20% target of all

electricity generated for the European Union by 2020. Some countries have much higher longterm policy targets of up to 100% renewables. Outside Europe, a diverse group of 20 or more

other countries target renewable energy shares in the 20202030 time frame that range from 10%

to 50%.

Climate change and global warming concerns, coupled with high oil prices, peak oil, and

increasing government support, are driving increasing renewable energy legislation, incentives

and commercialization. New government spending, regulation and policies helped the industry

weather the global financial crisis better than many other sectors. According to a 2011 projection

by the International Energy Agency, solar power generators may produce most of the world's

electricity within 50 years, reducing the emissions of greenhouse gases that harm the

environment.

Renewable energy sources, that derive their energy from the sun, either directly or indirectly,

such as hydro and wind, are expected to be capable of supplying humanity energy for almost

another 1 billion years, at which point the predicted increase in heat from the sun is expected to

make the surface of the earth too hot for liquid water to exist.

1.3 Biomass

Biomass is a term used to describe all organic matter produced by photosynthesis, existing on the

earths surface. They include all water- and land-based vegetation and trees, and all waste

biomass such as municipal solid waste (MSW), municipal biosolids (sewage), and animal wastes

(manures), forestry and agricultural residues, and certain types of industrial wastes. The world's

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

energy markets have relied heavily on the fossil fuels. Biomass is the only other naturally

occurring energy-containing carbon resource that is large enough in quantity to be used as a

substitute for fossil fuels.

Through the process of photosynthesis, chlorophyll in plants captures the sun's energy by

converting carbon dioxide from the air and water from the ground into carbohydrates, i.e.,

complex compounds composed of carbon, hydrogen, and oxygen. When these carbohydrates are

burned, they turn back into carbon dioxide and water and release the sun's energy they contain. In

this way, biomass functions as a sort of natural battery for storing solar energy.

The exploitation of energy from biomass has played a key role in the evolution of mankind. Until

relatively recently it was the only form of energy which was usefully exploited by humans and is

still the main source of energy for more than half the worlds population for domestic energy

needs. One of the simplest forms of biomass is a basic open fire used to provide heat for cooking,

warming water or warming the air in our home. More sophisticated technologies exist for

extracting this energy and converting it into useful heat or power in an efficient way. In the mid1800s, biomass, principally wood biomass, supplied over 90% of U.S. energy and fuel needs,

after which biomass energy usage began to decrease as fossil fuels became the preferred energy

resources. This eventuality of fossil fuel and the adverse impact of fossil fuel usage on the

environment are expected to be the driving forces that stimulate the transformation of biomass

into one of the dominant energy resources.

Unlike fossil fuels, biomass is renewable in the sense that only a short period of time is needed to

replace what is used as an energy resource. Biomass also is the only renewable energy source that

releases carbon dioxide in use. However the release is compensated by the fact that the biomass

grown uses the carbon dioxide from the atmosphere to store energy during photosynthesis. If the

biomass resource is being used sustainably, there are no net carbon emissions over the time frame

of a cycle of biomass production. Figure 1 shows a biomass energy cycle and the way biomass is

utilized for energy generation in an environmentally friendly scheme.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

Fig. 1.2 Biomass Energy Cycle

1.4 Background

Biomass is a term for all organic material that stems from plants (including algae, trees and

crops). Biomass is produced by green plants converting sunlight into plant material through

photosynthesis and includes all land- and water-based vegetation, as well as all organic

wastes. The biomass resource can be considered as organic matter, in which the energy of

sunlight is stored in chemical bonds. When the bonds between adjacent carbon, hydrogen

and oxygen molecules are broken by digestion, combustion, or decomposition, these substances release their stored, chemical energy. Biomass has always been a major source of

energy for mankind and is presently estimated to contribute of the order 10 14% of the

worlds energy supply.

This paper is the first in a three-part series examining the use of biomass as a fuel source,

with emphasis on its potential use as a supplementary fuel for power generation, using

landfill gas fuelled, spark ignition gas engines.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

The conversion of biomass into energy can be achieved in a number of ways. To provide a

fuel suitable for direct use in spark ignition gas engines (s.i.g.e.), the fuel must be provided

in either a gaseous, or a liquid form. Production of a gaseous fuel from biomass can be

achieved by the application of a number of technologies, each with its specific requirements,

advantages and disadvantages.

1.5 Drivers for biomass

In the past 10 years, there has been renewed interest, world-wide, in biomass as an energy

source. There are several reasons for this situation:

Firstly, technological developments relating to the conversion, crop production, etc.

promise the application of biomass at lower cost and with higher con- version efficiency

than was possible previously. For example, when low cost biomass residues are used for

fuel, the cost of electricity is already now often competitive with fossil fuel-based power

generation. More advanced options to produce electricity are looking promising and allow a

cost-effective use of energy crops e.g. production of methanol and hydro- gen by means of

gasification processes.

The second main stimulus is the agricultural sector in Western Europe and in the US, which

is producing food surpluses. This situation has led to a policy in which land is set aside in

order to reduce surpluses. Related problems, such as the de-population of rural areas and

payment of significant subsidies to keep land fallow, makes the introduction of alternative,

non-food crops desirable. Demand for energy will provide an almost infinite market for

energy crops grown on such (potentially) surplus land.

Thirdly, the potential threat posed by climate change, due to high emission levels of

greenhouse gases (CO2 being the most important one), has become a major stimulus for

renewable energy sources in general. When produced by sustainable means, biomass emits

roughly the same amount of carbon during conversion as is taken up during plant growth.

The use of biomass therefore does not contribute to a build up of CO2 in the atmosphere.

But these three main issues are not the only stimuli: biomass is also an indigenous energy

source, available in most countries and its application may diversify the fuel-supply in many

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

situations, which in turn may lead to a more secure energy supply. Biomass production can

generate employment and if intensive agriculture is re- placed by less intensively managed

energy crops, there are likely to be environmental benefits, such as reduced leaching of

fertilisers and reduced use of pesticides. Moreover, if appropriate crops are selected,

restoration of degraded lands may be possible. Depending on the crops used and the way the

biomass is cultivated, in- creased biodiversity can be obtained, compared to cur- rent

agricultural practice.

Biomass is available on a renewable basis, either through natural processes, or it can be

made available as a by-product of human activities i.e. organic wastes. The potential of

biomass energy derived from forest and agricultural residues world-wide, is estimated at

about

30 EJ/yr, compared to an annual world-wide energy demand of over 400 EJ. If biomass is to

contribute to a larger extent to the worlds energy supply, then energy farming, the

cultivation of dedicated crops for energy purposes, will be required, using fallow land and

marginal lands, the latter being largely unsuited for food crops. When energy crops are

considered as a source of biomass, the total energy potential of biomass for energy

production may be considerably larger than the energy potential of biomass residues. In

1992 at the Rio United Nations Conference on environment and development, the

renewable intensive global energy scenario (RIGES) suggested that, by 2050, approximately

half the worlds current primary energy consumption of about 400 EJ/yr, could be met by

biomass and that 60% of the worlds electricity market could be supplied by renewables, of

which biomass is a significant component.

Biomass can be converted into three main types of product:

electrical/heat energy,

transport fuel,

chemical feedstock.

Of particular interest in this study is the generation of electricity but the two other endproducts will be examined briefly.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

Biomass Energy

1.6 Biomass types

Researchers characterise the various types of biomass in different ways but one simple

method is to define four main types, namely;

woody plants,

herbaceous plants/grasses,

aquatic plants,

manures.

Within this categorisation, herbaceous plants can be further subdivided into those with highand low-moisture contents. Apart from specific applications or needs, most commercial

activity has been directed towards the lower moisture-content types, woody plants and

herbaceous species and these will be the types of biomass investigated in this study. Aquatic

plants and manures are intrinsically high-moisture materials and as such, are more suited to

wet processing techniques.

Based primarily upon the biomass moisture content, the type of biomass selected

subsequently dictates the most likely form of energy conversion process. High- moisture

content biomass, such as the herbaceous plant sugarcane, lends itself to a wet/aqueous

conversion process, involving biologically mediated reactions, such as fermentation, while a

dry biomass such as wood chips, is more economically suited to gasification, pyrolysis or

combustion. Aqueous processing is used when the moisture content of the material is such

that the energy required for drying would be inordinately large compared to the energy

content of the product formed.

However, there are other factors which must be taken into consideration in determining the

selection of the conversion process, apart from simply moisture content, especially in

relation to those forms of biomass which lie midway between the two extremes of wet and

dry. Examples of such factors are the ash, alkali and trace component contents, which

impact adversely on thermal conversion processes and the cellulose content, which

influences biochemical fermentation processes.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

10

Biomass Energy

1.7 Biomass Energy Techniologies

Biogas

The production of biogas through anaerobic digestion offers signicant advantages over

other forms of bioenergy production. It has been evaluated as one of the most energy

efcient and environmentally benecial technology for bioenergy production. For the

production of biogas it is possible to use several different raw materials and digestion

technologies. This variety and the various elds of application for the biogas and

digested product result in great differences in the environmental performance among the

potential biogas systems. Among the raw materials are organic waste from households

and the food industry, dedicated energy crops, and agricultural waste products, such as

crop residues and manure.

The large amounts of animal manure and slurries produced today by the animal

breeding sector as well as the wet organic waste streams represent a constant pollution

risk with a potential negative impact on the environment, if not managed optimally. To

prevent emissions of greenhouse gases (GHG) and leaching of nutrients and organic

matter to the natural environment it is necessary to close the loops from production to

utilization by optimal recycling measures.

Biogas is a mixture of gases that is composed mainly of CH 4 4070%, CO2 3060%,

and other gases 15%. The caloric value of biogas is about 1620 MJ m3. Methane

fermentation is a complex process, which can be divided up into four phases: hydrolysis,

acidogenesis, acetogenesis/dehydrogenation and methanation.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

11

Biomass Energy

Fig. 1.3 Conversion from wind power to electrical power in a wind turbine

Fig. 1.4 Schematic representation of the sustainable cycle of anaerobic co-digestion

of animal manure and organic wastes

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

12

Biomass Energy

Borjesson and Berglund present an overview of biogas systems. It include emissions

from the energy input in the entire biogas production chain; that is, the handling of raw

materials, the digestion of the raw materials in farm-scale and large-scale biogas plants,

and the nal use of the digestates and bio- gas. Handling of energy crops includes the

entire energy input and emissions from the cultivation and harvesting of the crop, since

it is assumed to be cultivated primarily for biogas production. These crops are assumed

to be cultivated on set-aside arable land, and hence, the analysis does not treat the

production of food or fodder replacements. The other raw materials are assumed to be

waste products. Consequently, the analysis includes only the additional energy input and

emissions associated with the handling and trans- port of these waste products, and

none of the input used in the production of the main product.

Biogas has denite advantages, even if compared to other renewable energy

alternatives. It can be produced when needed and can easily be stored. It can be

distributed through the existing natural gas infrastructure and used in the same

applications like the natural gas. The biogas can directly be used for domestic cooking,

transportation fuel or distributed on the natural gas grid for end application.

Fig. 1.5 The stages of the methane fermentation process

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

13

Biomass Energy

Fig. 1.6 Overview of the biogas systems analysed. The arrows represent material

ows, energy ows, and emissions from the system.

Biogas systems are considered to be strong alternatives to the traditional space heating

systems (stoves) in rural Turkey. Biogas systems for heating was found economical

viable when compared with traditional heating systems fuelled by wood, coal and wood

mixture, and dried animal waste. Power generation from bio- gas is quite possible in

both duel fuel mode and 100 percent biogas run engine. The overall engine performance

was improved when scrubbed biogas was used in duel fuel engine as compared to raw

gas duel fuel engine.

Biogas technology provides an excellent opportunity for mitigation of greenhouse gas

emission and reducing global warming through substituting rewood for cooking,

kerosene for lighting and cooking and chemical fertilizers. The global warming

mitigation potential of a family size biogas plant was 9.7 tons CO 2 equiv. year1 and

with the current price of US $10 tons 1 CO2 equiv., car- bon credit of US $97 year1

could be earned from such reduction in greenhouse gas emission under the clean

development mechanism.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

14

Biomass Energy

Biodiesel

With reference to world energy scenario, some 8590% of world primary energy

consumption will continue (until 2030) to be based on fossil fuels. At the same time

rising petroleum prices, increasing threat to the environment from exhaust emissions

and global warming have generated intense international interest in developing

alternative non-petroleum fuels for engines. The use of vegetable oil in internal

combustion engines is not a recent innovation. Rudolf Diesel (18581913), creator of

the diesel cycle engines, used peanut vegetable oil to demonstrate his invention in Paris

in 1900. In 1912, Diesel said, The use of vegetable oils as engine fuel may seem

negligible today. Nevertheless, such oils may become, in the passing years, as important

as oil and coal tar presently. Nowadays, it is known that oil is a nite resource and that

its price tends to increase exponentially, as its reserves are fast depleting. Biodiesel is a

clean burning fuel that is renewable and biodegradable. Biodiesel is being extracted

from Mahua oil, rubber seed oil, Pongamia pinnata oil, palm oil, Jatropha curcas, duck

tallow, and castor seed oil, and its blends showed performance characteristics close to

diesel,

Straight vegetable oil has higher viscosity and one of the most common methods used

to reduce oil viscosity in the biodiesel industry is called transesterication,

Transesterication is the process of exchanging the alkoxy group of an ester compound

by another alcohol. These reactions are often catalyzed by the addition of a base and

acid. Bases can catalyze the reaction by removing a proton from the alcohol, thus

making it more reactive, while acids can catalyze the reaction by donating a proton to

the carbonyl group, thus making it more reactive. Biodiesel has the potential to reduce

emissions from the trans- port industry, which is the largest producer of greenhouse

gases. The use of biodiesel also reduces the particulate matter released into the

atmosphere as a result of burning fuels, providing potential benets to human health. A

study was reported in Indian context that if 10% of total production of castor seed oil is

transestered into biodiesel, then about 79,782 tons of CO 2 emission can be saved on

annual basis. The CO2 released during combustion of biodiesel can be recycled through

next crop production, therefore, no additional burden on environment.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

15

Biomass Energy

Biomass gasier

Gasier is a device which converts solid fuel into gaseous fuel through thermo chemical

conversion route. In the gasier low grade fuel, i.e. biomass gets converted in high grade

fuel known as charcoal and further into low caloric gas called producer gas. The gas thus

produced by gasier can be utilized to produce process heat for thermal application. To

disseminate the gasica- tion technology in actual uses, Ministry of New and Renewable

Energy (MNRE) has taken initiative to develop research group within India for technology

and man power development, as a consequence Indian premier institute like Indian Institute

of Science, Bangalore (IISc). The Energy and Resource Institute (TERI), Sardar Patel

Renewable Energy Research Institute (SPRERI), etc. have been involved in the eld of

biomass combustion and gasication technology. More than 350 TERI gasier systems have

been successfully installed in the eld throughout India with a cumulative installed capacity

of over 13 MWth. The gasier technologies available in India are based on downdraft

gasication and designed primarily for woody biomass.

Package of practice was developed by IISc, Bangalore to dry marigold ower with open top

downdraft gasier. The developed gasier is in position to replace 2000 l of diesel or LDO

per day completely. The system operates over 140 h per week on a nearly nonstop mode and

over 4000 h of operation replacing fossil fuel completely. Work on development of modular

throat type down draft gasier having 1.39 MW thermal capacities was carried out by

Pathak et al.. There is huge scope to utilize the gasication technology in small scale

industries for low temperature applications. Study was conducted on open core downdraft

gasier in small scale industries to produce process heat in the temperature range of 200

350 C for backing bakery items. During the study it was found that 6.5 kg of LPG was

replaced by 38 kg of woody biomass. Over 3000 h of operation gasier has resulted in a

saving of about 19.5 tons of LPG, implying a saving of about

Gasier based power generation system

Biomass use for power generation has become an attractive option for the increase of

energy production with the increase of efciency, decrease of environment degradation

and waste utilization. Gas turbines cannot be red directly with biomass, because the

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

16

Biomass Energy

biomass combustion products would damage the turbine blades. However, by rst

gasifying the biomass and cleaning the gas before combustion, it is feasible to operate

gas turbines with biomass

Fig. 1.7 A biomass-gasier/gas turbine combined cycle

1.8 Climate change scenario

Climate change is one of the primary concerns for humanity in the 21st century It may

affect health through a range of path- ways, for example as a result of increased

frequency and intensity of heat waves, reduction in cold related deaths, increased oods

and droughts, changes in the distribution of vector-borne diseases and effects on the risk

of disasters and malnutrition. The overall balance of effects on health is likely to be

negative and populations in low income countries are likely to be particularly

vulnerable to the adverse effects. The experience of the 2003 heat wave in Europe

showed that high-income countries may also be adversely affected The potentially most

important environmental problem relating to energy is global climate change (global

warming or the greenhouse effect). The increasing concentration of greenhouse gases

such as CO2, CH4, CFCs, halons, N2O, ozone, and peroxyacetylnitrate in the

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

17

Biomass Energy

atmosphere is acting to trap heat radiated from Earths surface and is raising the surface

temperature of Earth A schematic representation of this global climate change problem

is illustrated.

Many scientic studies reveal that overall CO2 levels have increased 31% in the past

200 years, 20 Gt of Carbon added to environment since 1800 only due to deforestation

and the concentration of methane gas which is responsible for ozone layer depletion has

more than doubled since then. The global mean surface temperature has increased by

0.40.8 C in the last century above the baseline of 14 C. Increasing global temperature

ultimately increases global mean sea levels at an average annual rate of 12 mm over

the last century. Arctic sea ice thinned by 40% and decreased in extent by 1015% in

summer since the 1950s

Fig. 1.8 A schematic illustration of greenhouse effect

Industry contributes directly and indirectly (through electricity consumption) about 37%

of the global greenhouse gas emissions, of which over 80% is from energy use. Total

energy-related emissions, which were 9.9 Gt CO2 in 2004, have grown by 65% since

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

18

Biomass Energy

1971 There is ample scope to minimize emission of greenhouse gases if efcient

utilization of renewable energy sources in actual energy meeting route is promoted.

1.9 Renewable energy challenges

To reduce per unit cost of renewable energy. Increase efficiency. Harness

lower wind speeds. Challenge the energy of tides and waves to produce

energy. Use of larger grids with lower losses of electricity. Use of hydrogen as

an energy storage or carrier.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

19

Biomass Energy

Chapter-2

LITERATURE REVIEW

Introduction

The interest in using renewable energy resources increases more and more in the past decades.

Because the known fossil resources (oil, natural gasses and others) are considered almost

exhausted, the only chance of human kind for the near future remains the renewable resources.

Even if governments adopt dynamic policies to conserve energy, the demand continues to

increase.

Energy problems are today so acute at the international level that it is no longer possible to satisfy

the worlds constantly growing needs by continuing to exploit, as before, too limited a range of

resources. This growth of energy demand must be increasingly satisfied by diversified energy

resources, including sustainable and renewable sources (Tripsa, 2006; Buzdugan and Tripsa,

2006; Gavrilescu and Chisti, 2005).

Another phenomenon, which threats the whole humankind is the climate change and global

warming of Earth due to greenhouse effect, determined by increasing the content of the so named

greenhouse gases (CO2, CH4, NOx) in the upper layers of atmosphere. Earth global warming

determines the Sppearance of some dangerous meteorological phenomenons: hurricanes,

tornados, higher and unexpected floods, El Nio phenomenon of which dimension is higher

every passing year, giving rise of huge damages, agricultural fields emptiness on higher altitudes.

Biomass resources include wood and wood wastes, agricultural crops and their waste byproducts,

municipal solid waste, animal wastes, waste from food processing, aquatic plants and algae

(Gavrilescu and Chisti, 2005;Demirbas, 2001).

Biomass is the plant material derived from the reaction between CO 2 in the air, water and

sunlight, via photosynthesis, to produce carbohydrates that form the building blocks of biomass.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

20

Biomass Energy

Typically photosynthesis converts less than 1% of the available sunlight to stored, chemical

energy. The solar energy driving photosynthesis is stored in the chemical bonds of the structural

components of biomass. If biomass is efficiently processed, either chemically or biologically, by

extracting the energy stored in the chemical bonds and the subsequent energy product combined

with oxygen, the carbon is oxidized to produce CO2 and water. The process is cyclic, as the CO2

is then available to produce new biomass (McKendry, 2001).

Biomass is being used as a source of primary energy all over the world since ancient times. The

use of biomass to produce energy is only one form of renewable energy that can be utilized to

reduce the impact of energy production and use on the global environment, in contrast to fossil

fuels.

As with any energy rears limitation on the use and applicability source there are limitation on the

use and applicability of biomass and it must compete not only with fossil fuels but with other

renewable energy sources such as wind, solar and wave power (McKendry, 2002a, b).

Energy sources will play an important role in the worlds future. They have been grouped into

three categories: fossil fuels (coal, petroleum and natural gas), renewable sources and nuclear

sources (Demirbas, 2000a, b; Parikka, 2004).

Biomass is used to meet a variety of energy needs, including generating electricity, heating

homes, fueling vehicles and providing process heat for industrial facilities. It can be converted

into useful forms of energy using a number of different processes (McKendry, 2001, 2002a).

Resources of biomass

Biomass differs from other alternative energy sources in that the resource is variable, and it can

be converted to energy through many conversion processes. Biomass resources can be divided

into four general categories:

Wastes: agricultural production wastes, agricultural processing wastes, crop residues, mill wood

wastes, urban wood wastes, and urban organic wastes;

Forest products: wood, logging residues, trees, shrubs and wood residues, sawdust, bark etc. from

forest clearings;

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

21

Biomass Energy

Energy crops: short rotation woody crops, herbaceous woody crops, grasses, starch crops (corn,

wheat and barley), sugar crops (cane and beet), forage crops (grasses, alfalfa and clover), oilseed

crops (soybean, sunflower, safflower);

Aquatic plants: algae, water weeds, water hyacinth, reed and rushes.

Biomass contributes about 12% of todays world primary energy supply, while in many developing countries, its contribution ranges from 40% to 50% (Buzdugan and Tripsa, 2006).

World production of biomass is estimated at 146 billion metric tons a year, mostly wild plant

growth. Some farm crops and trees can produce up to 20 metric tons per acre of biomass a year.

Types of algae and grasses may produce 50 metric tons per year (Demirbas, 2001). Conversion

of biomass to energy is undertaken using two main process technologies: thermo- chemical and

bio-chemical/biological.

Fig. 2.1 Main steps of biomass technology

Energetic potential of biomass

Romania has a considerable energetic potential of biomass, evaluated at 7594 tap/year (318x10 9

MJ/an) representing almost 19% from the total primary energy resources in the year 2004. This

potential leads to the following biomass fuel category:

wood wastes from woods and wood for fire, 1175 x 103 tap/an (49.2 PJ/an);

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

22

Biomass Energy

sawdust and others wood wastes, 487 x 103 tap (20.4 PJ/an);

agricultural wastes, resulting from cereals, corn, vine residues, 4799 x 10 3 tap (200.9

PJ/an);

biogas, 588 x 103 tap/an;

urban and household wastes 545 x 103 tap/an.

Wood for fire and agricultural wastes represent almost 80% from the total biomass quantity,

while wood wastes coming from industrial processes, almost 6.5%.

The heat resulted from biomass burning holds various\ percentages in primary resources balance,

in respect with the type of wastes or final destination (Buzdugan and Tripsa, 2006).

Biogas was used in past in large quantities. Nowadays, biomass is used only for heating,

spontaneous burning for cooking and hot water preparing. House heating is on the second place

of using biomass. Almost 95% of used biomass nowadays is fire wood and agricultural wastes,

the rest being represented by wastes coming from wood processing. Production capacity of wood

saws is 3.3 Math, while in other industry fields is 4.7MW.

Market potential for biomass conversion is very large, but funding and subventions are necessary

for developing this field. Direct burning in stoves and roasters for burning, cooking and preparing

hot water represents almost 95% from the total used biomass, with a total capacity of 4.8 kW.

The feed is manually and has efficiency between 15% and 50%. Burning in steam generators and

industrial applications represents almost 5% from the total amount of used biomass (Jefferson,

2006).

Biomass usages can be classified in the following market segments:

replacing a part of fossile fuels from urban heating installations ( wood splints)

using biomass as substituent of fossile fuel (wood splints and logs as industrial fuel from

steam generators and hot water boilers) instead of oil;

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

23

Biomass Energy

improving the usage of biomass for urban heating in small towns and villages, located

near resources, where the population doesnt have access to gas network distribution;

usage of straws and other agricultural wastes in generators for biomass burning to heat

the isolated farms or small villages ;

maximum priority is using biomass for thermal purposes and to replace the oil.

Biomass conversion could be the best and cheapest method for urban heating in

Romania.

Conversion of biomass

Biomass can be converted into useful forms of energy using a number of different processes.

Factors that influence the choice of conversion process are: the type and quantity of biomass

feedstock, the desired form of the energy, i.e. end-use requirements, environmental standards,

economic conditions, and project specific factors. In many situations the form in which the

energy is required determines the process route followed by the available types and quantities of

biomass (Demirbas, 2001; Gavrilescu and Christi, 2005). The conversion technologies to utilize

biomass can be classified into four basic categories (, 2001):

direct combustion;

thermochemical processes;

biochemical processes;

agrochemical processes.

Biomass can be converted into three main products: two related to energy power/heat

generation and transportation fuels and one as a chemical feedstock (McKendry, 2001).

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

24

Biomass Energy

Fig. 2.2 Main biomass conversion processes

Benefits of biomass utilization

Biomass is a renewable, potentially sustainable and relatively environmentally benign source of

energy. If it is grown and utilized on a sustainable basis, biomass is carbon dioxide neutral.

Thus, the substitution of fossil fuels for energy production using biomass will result in a

net reduction in greenhouse gas emissions and the replacement of a non-renewable energy

source. Many large power producers in industrialized countries are looking for biomass as a

means of meeting greenhouse gas reduction targets (Demirbas, 2001). The natural decomposition

of biomass produces methane, which is about twenty times more active as a greenhouse gas than

carbon dioxide (Demirbas, 2000a, b).

There is, therefore, an additional greenhouse gas emission in burning biogas, landfill gas and

biomass residues to produce carbon dioxide.

Biomass fuels have negligible sulfur content and, therefore, do not contribute to sulfur dioxide

emissions, which cause acid rain. The combustion of biomass produces less ash than coal

combustion, and the ash produced can be used as a soil additive on farm targets.

Biomass is a domestic resource, which is not subject to world price fluctuations or the supply

uncertainties of imported fuels. In developing countries in particular, the use of liquid biofuels,

such as biodiesel and ethanol, reduces the economic pressures of importing petroleum products.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

25

Biomass Energy

Perennial energy crops (grasses and trees) have lower environmental impacts than conventional

agricultural crops.

Environmental impacts of biomass energy

As with all forms of energy production, biomass energy systems raise some environmental issues

that must be addressed. In biomass energy projects, issues such as air pollution, impacts on

forests and impacts due to crop cultivation must be addressed on a case by case basis. Unlike

other non- renewable forms of energy, biomass energy can be produced and consumed in a

sustainable fashion, and there is no net contribution of carbon dioxide to global warming. One

example is a closed loop system in which carbon dioxide will be taken up by new plant growth

at the same rate that it is released by using the harvested biomass for fuel. (Jefferson, 2006; Robu

et al., 2005) Such bioenergy crops would have little or no net contribution to atmospheric carbon

dioxide as a greenhouse gas. On the other hand, when fossil fuels are burned, carbon is released

that has been stored underground for millions of years, making a net contribution to atmospheric

greenhouse gases. Therefore, if managed carefully, biomass energy can have

significant

environmental advantages over the use of fossil fuels. An appropriate level of biomass energy use

can have less environmental impacts than our current means of energy production.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

26

Biomass Energy

Chapter-3

METHODS OF EXTRACTING BIOMASS ENERGY

Biomass can be converted to thermal energy, liquid, solid or gaseous fuels and other chemical

products through a variety of conversion processes. Biopower technologies are proven

electricity-generation options in the United States, with 10GW of installed capacity . All of

today's capacity is based on mature, direct-combustion technology. Future efficiency

improvements will include co-firing of biomass in existing coal-fired boilers and the introduction

of high-efficiency gasification, combined-cycle systems, fuel cell systems, and modular systems .

Generally, the prominent biopower technologies are comprised of direct combustion, co-firing,

gasification, pyrolysis, anaerobic digestion, and fermentation.

3.1 Direct Combustion

This is perhaps the simplest method of extracting energy from biomass. Industrial biomass

combustion facilities can burn many types of biomass fuel, including wood, agricultural residues,

wood pulping liquor, municipal solid waste (MSW) and refuse-derived fuel. Biomass is burned

to produce steam, the steam turns a turbine and the turbine drives a generator, producing

electricity. Because of potential ash build-up (which fouls boilers, reduces efficiency and

increases costs), only certain types of biomass materials are used for direct combustion.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

27

Biomass Energy

3.2 Gasification

Gasification is a process that exposes a solid fuel to high temperatures and limited oxygen, to

produce a gaseous fuel. The gas produced by the process as shown in Figure 2 is a mix of gases

such as carbon monoxide, carbon dioxide, nitrogen, hydrogen, and methane. The gas is then used

to drive a high- efficiency, combined-cycle gas turbine. Gasification has several advantages over

burning solid fuel. One is convenience one of the resultant gases, methane, can be treated in a

similar way as natural gas, and used for the same purposes.

Fig. 3.1 Gasification Process

Another advantage of gasification is that it produces a fuel that has had many impurities removed

and could therefore cause fewer pollution problems when burnt. Under suitable circumstances, it

can also produce synthesis gas, a mixture of carbon monoxide and hydrogen which can be used

to make hydrocarbon (e.g., methane and methanol) for replacing fossil fuels. Hydrogen itself is a

potential fuel without much pollution which can conceivably substitute oil and petroleum in a

foreseeable future.

3.3 Pyrolysis

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

28

Biomass Energy

In its simplest form, pyrolysis represents heating the biomass to drive off the volatile matter and

leaving behind the charcoal. This process has doubled the energy density of the original material

because charcoal, which is half the weight of the original biomass, contains the same amount of

energy, making the fuel more transportable. The charcoal also burns at a much higher

temperature than the original biomass, making it more useful for manufacturing processes. More

sophisticated pyrolysis techniques are developed recently to collect volatiles that are otherwise

lost to the system. The collected volatiles produce a gas which is rich in hydrogen (a potential

fuel) and carbon monoxide. These compounds are synthesized into methane, methanol, and other

hydrocarbons.

The steps involved in this process are illustrated in Figure.

Fig. 3.2 Pyrolysis Process

Flash pyrolysis is used to produce bio-crude, a combustible fuel. Heat is used to chemically

convert biomass into pyrolysis oil. The oil, which is easier to store and transport than solid

biomass material, is then burned like petroleum to generate electricity. Pyrolysis can also convert

biomass into phenol oil, a chemical used to make wood adhesives, molded plastics, and foam

insulation.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

29

Biomass Energy

3.4 Digestion

Biomass digestion works by utilizing anaerobic bacteria. These microorganisms usually live at

the bottom of swamps or in other places where there is no air, consuming dead organic matter to

produce methane and hydrogen. We put these bacteria to work for us. By feeding organic matter

such as animal dung or human sewage into tanks, called digesters, and adding bacteria, we

collect the emitted gas to use as an energy source. This process is a very efficient means of

extracting usable energy from such biomass. Usually, up to two thirds of the fuel energy of the

animal dung could be recovered. Another related technique is to collect methane gas from landfill

sites. A large proportion of household biomass waste, such as kitchen scraps, lawn clipping and

pruning, ends up at the local tip. Over a period of several decades, anaerobic bacteria at the

bottom of such tips could steadily decompose the organic matter and emit methane. The gas can

be extracted and used by capping a landfill site with an impervious layer of clay and then

inserting perforated pipes that would collect the gas and bring it to the surface.

3.5 Fermentation

For centuries, people have used yeasts and other microorganisms to ferment the sugar of various

plants into ethanol. Producing fuel from biomass by fermentation is just an extension of this

process, although a wider range of plant material from sugar cane to wood fiber can be used. For

instance, the waste from a wheat mill in New South Wales is used to produce ethanol through

fermentation. Ethanol is then mixed with diesel to produce diesehol, a product used by trucks

and buses in Australia.

Technological advances will inevitably improve the method. For example, scientists in Australia

and the U.S. have substituted a genetically engineered bacterium for yeast in the fermentation

process. The process has vastly increased the efficiency by which waste paper and other forms of

wood fiber is fermented into ethanol.

Biofuels: Biomass is converted into transportation fuels such as ethanol, methanol, biodiesel and

additives for reformulated gasoline. Biofuels are used in pure form or blended with gasoline.

Ethanol: Ethanol, the most widely used biofuel, is made by fermenting biomass in a process

similar to brewing beer. Currently, most of the 1.5 billion gallons of ethanol used in the

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

30

Biomass Energy

U.S. each year is made from corn and blended with gasoline to improve vehicle performance and

reduce air pollution.

Methanol: Biomass-derived methanol is produced through gasification. The biomass is converted

into a synthesis gas (syngas) that is processed into methanol. Most of the 1.2 billion gallons of

methanol annually produced in the U.S. are made from natural gas and used as solvent,

antifreeze, or to synthesize other chemicals. About 38 percent is used for transportation as a blend

or in reformulated gasoline.

Biodiesel: Biodiesel fuel, made from oils and fats found in micro-algae and other plants, is

substituted for or blended with diesel fuel.

Chapter-4

BIOMASS ENERGY GENERATION

4.1 Constraints to Biomass Energy Use:

Biomass is still an expensive source of energy, both in terms of producing biomass and

converting it into alcohols, as a very large quantity of biomass is needed.

On a small scale there is most likely a net loss of energy as a lot of energy must be used

for growing the plant mass; biomass is difficult to store in the raw form.

One of the disadvantages of biomass is that direct combustion of biomass can be harmful

to the environment as burning biomass releases carbon dioxide, which contributes to the

warming of the atmosphere and possible climatic change. Burning also creates soot and

other air pollutants.

Over-collecting wood can destroy forests. Soils bared of trees erode easily and do not

hold rainfall. Increased run- off can cause flooding downstream.

When plant and animal wastes are used as fuel, they cannot be added to the soil as

fertilizer. Soil without fertilizer is depleted of nutrients and produce fewer crops.

Biomass has less energy than a similar volume of fossil fuels.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

31

Biomass Energy

4.2 Energy production

It is acknowledged that each species of biomass has a specific yield/output, dependent on

climate, soil, etc. However, to provide data for outline process designs, it is useful to assume

some general biomass properties.

In the case of wood derived from SRC, it is assumed that the average LHV is 18 MJ/kg. At

full generation rate, 1 kg of woodchips converts to 1 kWh(e) via use in a gasifier/gas engine

generator, giving an overall efficiency of conversion to electricity of about 20%: this takes

no account of the potentially useful heat available from the gasifier/gas engine (Warren et

al., 1995).

At yields of 15 dmt/ha/a and with 1dmt equal to 1 MWh(e), 1ha (based on a 3 yr. harvesting

cycle) of SRC biomass would provide 15 MWh(e)/a. Assuming an annual operating time of

95%, a 100 kW(e) gas engine generator set would require about 55 ha to provide the

necessary biomass feedstock: for a 1 MW(e) gas engine generator set, the land take would

be about 550 ha.

The above calculation suggests that a significant land- take is required to produce a

relatively modest energy output as electricity, due to the low overall efficiency of conversion

i.e. 20%, of biomass to electricity. Combus- tion processes using high-efficiency, multi-pass,

steam turbines to produce electricity, can achieve an overall efficiency of 3540%, reducing

the necessary land-take for a 1 MW(e) output to between 270310 ha. Integrated

gasification combined cycle (IGCC) gas turbines can achieve about 60% efficiency.

However, the object of the study was to provide gas to supplement existing LFG supplies.

Assuming a 20% supplement for a 1 MW(e) LFG power generation scheme, the land-take

required for SRC is about 110 ha, large for most (closed) landfill sites but more realistic in

terms of being able to use the existing site in combination with additional, adjacent land.

It can be seen that if biomass with an equivalent CV to SRC willow but with a greater

crop yield were available, the necessary land-take would reduce in pro- portion to the

increased yield. The reported range of yields for Miscanthus is quoted as being equivalent to

SRC willow at the lower end, while the upper end is about twice that for SRC willow. If this

were the case, the land-take for a 20% energy supplement for a 1 MW(e) LFG power

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

32

Biomass Energy

scheme would reduce from 110 ha for SRC willow, to 55 ha for Miscanthus. The effect of

energy yield on land-take requirements can be seen clearly to be a significant factor in any

biomass power generation scheme.

In practice the actual amount of energy obtained and the form of that energy, will vary from

one conversion process technology to another.

Two examples may help to illustrate the above point:

Gasifying wood gives the same potential release of

energy as burning the wood in a combustor but the form of the energy released by

gasification may be of more use than that derived from combustion e.g. a useable, low CV

gas, that could be used to fuel a gas engine, rather than hot air, which can only pro- vide

process heat/steam, or power a steam turbine to generate electricity.

Fermenting wheat to produce ethanol provides a fuel suitable for vehicles, which is not

possible via combustion or gasification processes.

Apart from energy being available in a more suitable or convenient form, the overall

conversion efficiency from biomass source to alternative energy product, for each type of

conversion process, is of interest. For ex- ample, while combustion releases all of the

available chemical energy stored in the biomass source, converting the hot gases (via a

boiler) to produce steam (at an efficiency of 88%) and subsequent conversion to electricity

(via a turbo-generator), gives an overall thermal efficiency of about 40% for large plant and

as low as 10 15% for simple, steam plant. The importance of these thermodynamic

considerations will depend on the particular economic factors associated with specific

projects.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

33

Biomass Energy

Chapter-5

BIOMASS POWER PRODUCTION WORLD WIDE

Biomass already contributes 5% of the European Union's (EU) energy supply, and 65% of the

total renewable energy production; predominately for heat and power applications. In the long

term, the contribution of biomass in the EU energy supply may increase to 20%, depending on

the policies adopted by the EU in relation to agriculture, sustainability, a secure energy supply

and Kyoto obligations Renewable Energy Systems (RES) mainly produce electricity. However,

only 20% of current EU energy supply is in the form of electricity - the remaining 80% is in the

form of fuels for heating and transport. Biomass is the only RES which produces solid or liquid

fuels, which could be used as, or transformed into, fuels for heating (in buildings and industry)

and transport. In addition, biofuels are one of the few options for a net CO2-free system for

transport applications. Some of the biomass facilities in the world are described below.

5.1 Lahti Gasification Cofiring Project, Lahti, Finland

The goal of the Lahden Lampovoima Oys Kymijarvi power plant gasification project is to

demonstrate the direct gasification of wet biofuel and the use of hot, raw and very low-Btu gas

directly its coal boiler. Lahden Lampovoima Oy (LLO) operates the Kymijarvi power plant near

the city of Lahti in southern Finland.

In Europe, typically about 30-150 MW of biofuel energy is available within 50 km from the

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

34

Biomass Energy

power plant. This amount can be gasified and used directly in mid- or large- sized coal fired

boilers. Thus, a power plant concept consisting of a gasifier connected to a large conventional

boiler with a high efficiency steam cycle offers an attractive and efficient way to use local

biomass sources in energy production.

In Europe, typically about 30-150 MW of biofuel energy is available within 50 km from the

power plant. This amount can be gasified and used directly in mid- or large- sized coal fired

boilers. Thus, a power plant concept consisting of a gasifier connected to a large conventional

boiler with a high efficiency steam cycle offers an attractive and efficient way to use local

biomass sources in energy production.

The amount of biofuels and refuse fuels available each year is enough to substitute for about 15%

of the fuels burned in the Lahti plants boiler, or to substitute for 30% of the coal burned.

Assuming 7000 h/yr of plant operation, 300 GWh/yr is equivalent to about 43 MW of thermal

energy available from local bio fuels. In addition to the REF fuel components, peat, demolition

wood waste, and shredded tires are used as fuels in the gasification plant.

5.2 Biomass in Asia

In Southeast Asia, biomass is an important source of energy since fuel wood is still the dominant

source of energy in almost 50 percent of the region. By country, the share of biomass in the

primary energy supply in 1999 was: Myanmar - 86%; Lao PDR - 86%; Cambodia - 83%;

Vietnam - 48%; Indonesia - 29%; Philippines - 21%; Thailand - 17%; and Malaysia - 8%.

Biomass energy is largely used in the household sector and in small-scale industries. Recently, its

use in combined heat and power generation is increasing. The role of biomass is presently limited

in power development, but opportunities exist for increasing its share.

In Asia, the potential of biomass for power generation is promising: about 50,000 MW for all

biomass resources in Indonesia approximately 3,000 MW in Thailand about 1,117 MW in palm

oil industry of Malaysia about 60-90 MW from bagasse and 352 MW from ricehulls in the

Philippines and

250 MW from bagasse in Vietnam. About 920 MW in installed capacity could be expected from

over 19 million tons of residues in ASEAN wood industry.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

35

Biomass Energy

Many of this potential could be developed through cogeneration. However, in order to tap the

estimated potential, the following key challenges have to be addressed:

1) Establishment of a level playing field for biomass power in competition with the often

subsidised centralized power generation;

2) establishment of mechanisms to compensate for the avoided external costs of biomass power

generation, for example through a so-called environmental adder on top of the normal buyback rate;

3) access to power grid under clear and fair terms and conditions; and

4) development of a market for biomass waste resources. Thailand is facing these challenges by

initially launching a competitive bidding for 300 MW of renewable energy generation, mainly

biomass. The Thai government has also established a fund to provide developers assistance to

cover the differential between production and market price of biomass power. In Malaysia, grid

access regulations and buy-back power rates are being developed, and the first grid-based

biomass power plant is being constructed.

In India, more than 2000 gasifiers have been established with a capacity in excess of 22 MW and

a number of villages have been electrified with biomass gasifier based generators. Being an

agrarian country there is easy availability of agricultural based mass, which can be used to

generate energy, burning this biomass is the easiest and oldest method of generating energy and

also the least efficient. Over 70% of the population of India is in villages but it is these villages,

which receive neither electricity nor a steady supply of water-crucial to survival and economic

and social development and growth. Biomass exists in these villages and needs to be tapped

intelligently to provide not only electricity but also water to irrigate and cultivate fields to further

increase production of biomass (either as a main product or as a by-product), ensuring steady

generation of electricity. Biomass gasification in India offers immense scope and potential for:

Water pumping, Electricity generation: 3 to 1 MW power plants, Heat generation: for cooking

gas smokeless environment, Rural electrification means better healthcare, better education and

improved quality of life.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

36

Biomass Energy

Chapter-6

ENVIRONMENTAL & BIOMASS ENERGY

The purpose of using Renewable Energy is to provide energy with reduced emissions of

greenhouse gases. The concentration of CO2 in the atmosphere remained below 280 parts per

million (ppm) for 800 thousand years until the start of the Industrial Revolution in the eighteenth

century.

The concentration has risen from 280 ppm in 1780 up to 400 ppm in 2013. The effects of this

accelerating trend on our future environment are unknown, but scientists are debating the effects

of these trends and the risks of reaching tipping points that may not be reversible.

So we need to come back down to the present and consider the Environmental Impact of any new

project.

Adopting Renewable Energy technologies is one recommended way of reducing the

environmental impact of what we do.

However, we have to consider the environmental impact of any renewable energy technologies

we adopt. There are some environmental costs to most of the renewable energy technologies so it

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

37

Biomass Energy

is worth examining these.

How Does Renewable Energy Contribute to Cleaner Air?

Not only does renewable energy have little or no greenhouse gas emissions, but also other air

pollutant emissions which cause smog, acid-rain or hazardous air pollution are zero for most

forms of renewable energy. When low-emitting forms of renewable energy are used to replace

fossil-fuel energy, reductions in air pollution occur and cleaner air is the result.

Those forms of renewable energy based on combustion of biomass do cause some air pollution

that contributes to smog, but not to acid-rain. However, geothermal energy from geological

sources can release sulphur dioxide which will contribute to acid rain. As for fossil fuels,

pollution control technologies can be used to reduce these emissions.

Renewable energy still has other effects on the environment, such as the disturbance of land and

eco-systems in hydro reservoirs or because of variable streamflow downstream of dams; the

water effluent from processing of biomass or renewable fuels; ambient air pollution coming from

wood smoke when heating with wood; waste ash from biomass combustion; and the impacts on

land from intensive agricultural operations for bioenergy. Furthermore, in the full life cycle of

renewable energy, the construction of renewable energy production facilities often involves the

use of fossil-fuels, which themselves have significant impacts. Given that all forms of energy

production have some level of environmental impact, ultimately a compromise must be reached

between energy development needs and environmental stewardship. The concept of sustainable

development can be a valuable tool in guiding new project development and mitigating any

potential impacts on the environment.

6.1 The most important effects on the environment

Visual Effects

Wind turbines must be in exposed areas and are therefore highly visible. They are considered

unsightly by some people, and concerns have increased with the larger size of new generation

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

38

Biomass Energy

turbines.

Noise

Wind turbines produce aerodynamic noise, from air passing over the blades and mechanical

noise from the moving parts of the turbine, especially the gearbox. Better designs have reduced

noise, and research continues. Wind farms developed far from highly populated areas are, by

definition, less offensive.

Electromagnetic Interference

Wind turbines may scatter electromagnetic signals causing interference to communication

systems. Appropriate siting (avoiding military zones or airports) can minimise this impact.

Bird Safety

Birds get killed when they collide with the rotating blades of a turbine. Migratory species are at

higher risk than resident species. Siting the turbines away from migratory routes reduces the

impact.

Renewable energy entails a number of other potential environmental impacts. On the negative

side, renewable energy can make large tracts of land unusable for competing uses, disrupt marine

life, bird life and flora/fauna, and produce visual and noise pollution. Generally though, these

potential environmental impacts are site-specific and there are a number of ways to minimise the

effects, which are usually small and reversible. There are environmental benefits from

renewables other than reduction of greenhouse gas and other air emissions. For example,

hydroelectric schemes can improve water supplies and facilitate reclamation of degraded land

and habitat.

The use of bioenergy can have many environmental benefits if the resource is produced and used

in a sustainable way. If the land from which bioenergy is produced is replanted, bioenergy is used

sustainably and the carbon released will be recycled into the next generation of growing plants.

The extent to which bioenergy can displace net emissions of CO2, will depend on the efficiency

with which it can be produced and used. Bioenergy plants have lower emissions of SO2 than do

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

39

Biomass Energy

coal and oil plants, but they may produce more particulate matter.

Acoustics (Noise)

Operations of heat recovery systems of a biomass power plant, milling rooms and boilers of a

biofuel facility, wood chippers, and steam turbine generators would result in occupational

noise that would exceed the Occupational Safety and Health Administration (OSHA) 8-hour

noise threshold limit. Personnel working in these areas would be required to wear hearing

protection. Insulation of these areas would reduce noise levels so that hearing protection

would not be required outside these areas. Noise levels in other parts of the facility would

most likely be below the 8-hour threshold limit established by OSHA.

Other noise sources would include exhaust stacks, mechanical-draft cooling systems,

switchgear atsubstations, corona noise from transmission lines, vehicular traffic, and

maintenance facilities.

No adverse community reaction would be expected as a result of noise levels below 50 A

weighted decibels (dBA) at the nearest sensitive receptor (e.g., closest residence). Noise

control equipment could be incorporated to achieve these levels.

Air Quality (including Global Climate Change and Carbon Footprint)

Operation of biomass facilities results in emissions of criteria air pollutants and hazardous air

pollutants (HAPs). Criteria air pollutants include particulate matter, carbon monoxide, sulfur

oxides, nitrogen oxides, lead, and volatile organic compounds (VOCs). HAPs are 189 toxic

chemicals, known or suspected to be carcinogens, which are regulated by the U.S.

Environmental Protection Agency as directed by the 1990 Clean Air Act. If the facility is in

an area designated as "attainment" for all state and national ambient air quality standards

(NAAQS), then emissions from operation, when added to the natural background levels,

must not cause or contribute to ambient pollution levels that exceed the ambient air quality

standards.

In particular, combustion of municipal solid wastes could result in trace quantities of

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

40

Biomass Energy

mercury, other heavy metals, and dioxins in the air emissions. The use of Best Available

Control Technology (BACT) would minimize the potential for adverse air quality impacts

from biomass facilities. A gas-fired regenerative thermal oxidizer would reduce VOCs by

95%. Baghouses, which are a type of dust collector using fabric filters, control particulate

matter. Enclosing the processing equipment in a slight negative pressure envelope in addition

to the use of baghouses could minimize fugitive dustemissions from milling operations.

The use of cultivated biomass fuels (i.e., fuel specifically grown for energy production) in

place offossil fuels like coal, oil, and natural gas can result in a reduction in the amount

of carbon dioxidethat accumulates in the atmosphere only if the carbon released by

combustion of biomass fuels is effectively recaptured by the next generation of feedstock

plants. If the biomass source is not replaced by growing more plants, the carbon released in

biomass combustion is not recaptured; therefore, these forms of biomass energy can only be

considered to be carbon-free if the energy production cycle includes replanting of

the feedstock. Using perennial or fast-growing biomass plants, such as switchgrass or poplar

hybrids, can increase the rate of carbon recapture. While the combustion of biomass fuels

under these conditions can be considered to be carbon-free, in practice, any gains in terms of

reduced carbon dioxide emissions are offset by carbon dioxide emissions associated with the

use of fossil fuels in the cultivation, harvesting, and transportation of the biomass feedstock.

Certain agricultural practices (e.g., no-till agriculture and use of perennial feedstock crops)

produce fewer carbon dioxide emissions than conventional practices. Biomass energy derived

from waste product fuels (e.g., residues from forestry operations, construction wastes,

municipal wastes) is not considered to be carbon-free as the energy production cycle does not

involve any cultivation of new biomass.

Cultural Resources

Impacts during the operations phase would be limited to unauthorized collection of artifacts

andvisual impacts. The threat of unauthorized collection would be present once the access

roads are constructed in the construction phase, making remote lands accessible to the public.

Visual impacts resulting from the presence of a biomass facility and transmission lines could

affect some cultural resources, such as sacred landscapes or historic trails.

Laxmi Devi Institute of Engineering & Technology, Chikani, Alwar (Raj.)

41

Biomass Energy

Ecological Resources

During operation, adverse ecological effects could occur from:

(1) disturbance of wildlife by equipment noise and human activity,

(2) exposure of biota to chemical spills and other contaminants, and

(3) mortality of wildlife from increased vehicular traffic and collisions with and/or

electrocution by transmission lines. Disturbed wildlife would be expected to acclimatize to

facility operations.

Deposition of water and salts from the operation of mechanical-draft cooling towers has the

potential to impact vegetation.

Intake structures for withdrawal of water from lakes or rivers would result in impingement

and entrainment of aquatic species. Proper design of these structures can minimize these