ALARP

ALARP

Uploaded by

medobasCopyright:

Available Formats

ALARP

ALARP

Uploaded by

medobasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ALARP

ALARP

Uploaded by

medobasCopyright:

Available Formats

Guidance note

N-04300-GN0166 Revision 5 June 2014

ALARP

Core concepts

One of the main objectives of the Commonwealth Offshore Petroleum and Greenhouse Gas Storage

(Safety) Regulations 2009 [OPGGS(S)] is to ensure that the risks to health and safety of people at

offshore facilities are reduced to a level that is as low as reasonably practicable (ALARP).

A safety case has to show how an operator meets, or will meet, the requirements of the regulatory

provisions relevant to the control of major accident event risks and the risks to health and safety of

people at the operators facility. Many of the requirements are qualified by the phrase reduce the

risks to a level that is as low as reasonably practicable. This means that the operator has to show,

through reasoned and supported arguments, that there are no other practical measures that could

reasonably be taken to reduce risks further.

The adopted control measures for any particular identified major accident event must be shown to

collectively eliminate, or reduce to a level that is ALARP, the risk to health and safety.

The approach employed in providing the required evidence of ALARP within a safety case is at the

discretion of the operator. In practice a combination of approaches is likely to be necessary.

Only by inclusion of a sufficient level of detail of information will NOPSEMA be able to make a

judgement on the appropriateness of the safety case in accordance with OPGGS(S) Regulation 2.26 (for

new safety cases) or Regulation 2.34 (for revised safety cases).

This guidance note addresses how the ALARP concept can be addressed in the context of a safety case.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

1 of 22

Guidance note

ALARP

Table of Contents

1

2

3

4

5

6

7

8

9

10

Introduction

1.1 Intent and purpose of this guidance note

1.2 Summary of the legislative requirements

Application of the ALARP principle

Key Principles

What descriptions are required?

4

5

6

4.1 Control measures

4.2 SMS ALARP aspects

4.3 What are the fundamental approaches to consider?

Suitability of control measures for MAEs

11

5.1 Summary of factors in selecting or rejecting control measures

13

Risk assessment and providing evidence

14

6.1 Risk assessment tools

14

6.2 Risk criteria

14

6.3 Continuous improvement

16

Use of Industry Codes and Standards

Good practice and reasonable practicability

Critical factors for success

References, Acknowledgements & Notes

17

20

21

22

Abbreviations/Acronyms

ALARP

As Low As Reasonably Practicable

CBA

Cost Benefit Analysis

EERA

Evacuation, Escape and Rescue Analysis

FERA

Fire and Explosion Risk Analysis

FSA

Formal Safety Assessment

FPSO

Floating, Production, Storage and Offloading

HSC

Health and Safety Commission

HSE

United Kingdom Health and Safety Executive

ICAF

Implied Cost of Averting a statistical Fatality

IMO

International Maritime Organisation

IPRA

Individual Risk Per Annum

LSA

Life Saving Appliances

MAE

Major Accident Event

MODU

Mobile Offshore Drilling Unit

NOPSEMA

National Offshore Petroleum Safety and Environmental Management Authority

OPGGSA

Offshore Petroleum Greenhouse Gas Storage Act 2006

OPGGS(S)

Offshore Petroleum and Greenhouse Gas Storage (Safety) Regulations 2009

QRA

Quantitative Risk Assessment

SMS

Safety Management System

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

2 of 22

Guidance note

ALARP

Key Definitions for this Guidance Note

Reasonably Practicable:

The legal definition on this was set out in England by Lord Justice Asquith in Edwards vs. National Coal

Board [1949] who said:

Reasonably practicable is a narrower term than physically possible and seems to me to imply that a

computation must be made by the owner, in which the quantum of risk is placed on one scale and the

sacrifice involved in the measures necessary for averting the risk (whether in money, time or trouble) is

placed in the other; and that if it be shown that there is a gross disproportion between them the risk being

insignificant in relation to the sacrifice the defendants discharge the onus on them. Moreover, this

computation falls to be made by the owner at a point of time anterior to the accident.

This English decision has since been confirmed by the Australian High Court 1.

1

Slivak v Lurgi (Australia) Pty Ltd (2001) 205 CLR 304 cited in Bluff & Johnstone (2004) The relationship between Reasonably

Practicable and Risk Management (WP 27 ANU National Research Centre for OHS Regulation)

Introduction

1.1 Intent and purpose of this guidance note

This document is part of a suite of documents (see Figure 1) that provide guidance on the preparation of

safety cases for Australias offshore facilities, as required under the Commonwealth Offshore Petroleum

and Greenhouse Gas Storage (Safety) Regulations 2009 [the OPGGS(S) Regulations] and the corresponding

laws of each State and of the Northern Territory where powers have been conferred on NOPSEMA.

This guidance note in particular, ALARP, provides direction on the descriptions that could be included in a

safety case submission as a means of addressing the requirements of the OPGGS(S) Regulations in

providing evidence that risks are reduced to a level that is ALARP. The guidance will be of use to those with

responsibility for health and safety at offshore petroleum facilities, and particularly those developing the

facility safety case.

Figure 1 Safety Case Guidance Note Map

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

3 of 22

Guidance note

ALARP

The purpose of the guidance is to explain the objectives of the OPGGS(S) Regulations, to identify the

general issues that should be considered, and to provide practical examples to illustrate the concepts and

potential approaches that can be taken in the preparation of safety cases. It is not the intention of the

guidance to provide detailed approaches or detailed regulatory assessment criteria.

Guidance notes indicate what is explicitly required by the regulations, discuss good practice and suggest

possible approaches. An explicit regulatory requirement is indicated by the word must, while other cases

are indicated by the words should, may, etc. NOPSEMA acknowledges that what is good practice, and

what approaches are valid and viable, will vary according to the nature of different offshore petroleum

facilities and their hazards. This guidance note is not a substitute for detailed advice on the OPGGS(S)

Regulations or the Act under which the OPGGS(S) Regulations have been made.

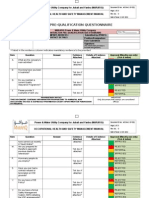

1.2 Summary of the legislative requirements

Summary tables of the legislative requirements with respect to providing evidence that the risks to health

and safety of persons at the facilities are reduced to a level that is ALARP are included as a quick reference

throughout this document. However, the reader is encouraged to work directly from the regulations.

Application of the ALARP principle

OPGGS(S) Regulations Objects

Reg 1.4

(3) An object of these regulations is to ensure that the risks to the health and safety of

persons at offshore petroleum facilities are reduced to a level that is as low as

reasonably practicable.

A safety case has to show how an operator meets, or will meet, the requirements of the regulatory

provisions relevant to the control of major accident event risks and the risks to health and safety of people

at the operators facility. Many of the requirements are qualified by the phrase reduce the risks to a level

that is as low as reasonably practicable. This means that the operator has to show, through reasoned and

supported arguments, that there are no other practical measures that could reasonably be taken to reduce

risks further.

The concept of reasonably practicable is central to the safety case regime. It allows operators to set goals

for their own safety performance rather than following prescriptive requirements. It also allows NOPSEMA

to accept or reject the operators arrangements under the safety case. This flexibility is a great advantage

but it can be challenging because it requires people to exercise judgement with respect to how they are

going to manage their risks. In the great majority of cases, a decision can be made by referring to existing

good practice that has been established. However, for complex situations it may be difficult to reach a

decision on the basis of good practice alone. There may be some situations, for example in the case of

new technology, where there is no relevant good practice that can be followed. In these situations other

decision-making techniques need to be applied to inform our judgment.

Other regulators such as the United Kingdoms Health and Safety Executive (HSE) and the Norwegian

Petroleum Directorate have been successfully administering safety case regimes for many years. The HSE,

in particular, has developed constructive guidance on the topic of the application of ALARP (available on

the HSE website www.hse.gov.uk) and readers are encouraged to make reference to it. However, it is

essential to bear in mind that while there are parallels in the regulatory approach, there are also important

variations in the safety case legislation between the UK and Australia, and as such the HSE guidance should

only be referenced to for concepts and principles.

Key aspects of the HSE guidance are distilled in this guidance note with respect to how to go about

constructing an ALARP argument.

Further information is available in the NOPSEMA Policy:

Safety Case Assessment

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

4 of 22

Guidance note

ALARP

Key Principles

It is important to understand the key principles underpinning the ALARP principle. The following

descriptions have been adapted from HSE information sheet no. 2/2006.

Reasonable practicability Determining whether risks have been reduced as low as is reasonably

practicable involves an assessment of the risk to be avoided, and an assessment of the sacrifice (in money,

time and effort) involved in taking measures to avoid that risk, and a comparison of the two. A risk may sit

on a spectrum from very low (where it is very unlikely that it would be possible to reduce the risk further)

through to levels of risk that are very high. The greater the initial level of risk under consideration, the

greater the effort likely to be required to demonstrate that risks have been reduced to a level that is as low

as reasonably practicable, however, just because the initial level of risk may be low doesnt mean it may

not be reasonably practicable to reduce it further. The basis on which the comparison is made involves the

test of gross disproportion.

Gross disproportion if a measure is practicable and it cannot be shown that the cost of the measure is

grossly disproportionate to the benefit gained; then the measure is considered reasonably practicable and

should be implemented. The criterion is reasonably practicable not reasonably affordable: justifiable cost

and effort is not determined by the budget constraints/viability of a project.

Inherently safer design It is good practice to apply the principles of prevention as a hierarchy.

Elimination of risk by removing the hazard;

Substitution of a hazard with a less hazardous one;

Prevention of potential events;

Separation of people from the consequences of potential events;

Control of the magnitude and frequency of an event;

Mitigation of the impact of an event on people; and

Emergency response and contingency planning.

Operators are entitled to apply these general principles as they see fit. However, NOPSEMA promotes the

incorporation of inherently safer design features, where appropriate.

Choosing between options for new facilities or brown-field redevelopment projects, a selection among

options may be needed at any stage in any project, not least at the design stage, which will involve making

a choice between differing design concepts for the project as a whole. In making choices it is good practice

for operators to consider the risks involved over the whole life cycle of a project. However, it is expected

that a new installation would not give rise to a residual level of risk greater than that achieved by the best

examples of existing good practice for comparable functions. The reasonable practicability of any further

risk reduction should be measured against this baseline. Safety cases should show that the lowest risk

option has been selected in all cases, or why the selected higher risk option is ALARP.

Good practice within the HSE and their ALARP guidance documentation, good practice is the term used

for those standards for controlling risk which have been judged and recognised by the HSC (Health and

Safety Commission) as satisfying the law when applied to a particular relevant case in an appropriate

manner. This is not the case in Australia. NOPSEMA has not endorsed any approved codes of practice or

standards to allow them a special legal status. The term good practice in NOPSEMA guidance

documentation therefore is taken to refer to any well-defined and established standard practice adopted

by an industrial/occupational sector, including learnings from incidents that may yet to be incorporated

into standards. Good practice generally represents a preferred approach; however it is not the only

approach that may be taken. While good practice informs, it neither constrains, nor substitutes for, the

need for professional judgement. Good practice may change over time because of technical innovation, or

because of increased knowledge and understanding.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

5 of 22

Guidance note

ALARP

Reverse ALARP operators have from time to time tried to show through quantitative risk assessment

(QRA) and cost benefit analysis (CBA) that moving to a less protected situation will meet the legal

requirement to reduce risks to a level that is ALARP, sometimes arguing that the increase in risk is more

than balanced by gains in reduced operational costs or increased operating profit a reverse ALARP

argument. The legal requirement to reduce risks as low as reasonably practicable would rule out

NOPSEMA accepting a less protected but significantly cheaper approach to the control of risks.

Changed circumstances operators may wish to introduce new processes, new technology or alter the

conditions in which equipment is operated in response to changed circumstances. Such changes may

result in a change to the risk profile - some risks may increase. This may be permissible provided control

measures are taken to ensure that the risks are reduced as low as reasonably practicable for the new

situation.

What descriptions are required?

4.1 Control measures

OPGGS(S) Regulations FSA Description

Reg 2.5(2)

The safety case for the facility must also contain a detailed description of the

formal safety assessment for the facility, being an assessment, or series of

assessments, conducted by the operator that:

(a) identifies all hazards having the potential to cause a major accident event;

and

(b) is a detailed and systematic assessment of the risk associated with each of

those hazards, including the likelihood and consequences of each potential

major accident event; and

(c) identifies the technical and other control measures that are necessary to

reduce that risk to a level that is as low as reasonably practicable.

The formalised descriptions within the safety case must provide evidence a formal safety assessment (FSA)

has been carried out for the facility, and that the FSA has identified the technical (i.e. hardware and

software) and other (i.e. procedural) control measures that are necessary to reduce risk to a level that is

ALARP. In respect of this requirement, the OPGGS(S) Regulations also explicitly require two studies in

particular to be carried out as part of the FSA:

an evacuation, escape and rescue analysis (EERA) that identifies control measures necessary to

reduce the risks associated with emergencies to a level that is ALARP [OPGGS(S) subregulation

2.16(2)(h)];and

a fire and explosion risk analysis (FERA) that identifies control measures necessary to reduce the risks

associated with fires and explosions to a level that is ALARP [OPGGS(S) subregulation 2.17(2)(g)].

Operators should note that the regulations require the consideration of a range of control measures in each

instance, including different procedures, a range of amenities and/or equipment, alternative measures, etc.

[OPGGS(S) subregulation 2.16(2) and subregulation 2.17(2)]. Consequently, information presented in the

safety case should not simply focus on promoting or selling the chosen design option but rather a

discussion on the merits of different options and a justification that the chosen option is indeed the one

that reduces risk to a level that is ALARP.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

6 of 22

Guidance note

ALARP

Suitability of control measures for MAEs

For existing facilities, operators should not merely concentrate on providing information on design

features of control measures, but should also put effort into providing knowledge acquired from

operating the facility, such as adequacy assurance gained from control measure performance data over

time. Design ALARP should be taken as a starting point only.

5.1 SMS ALARP aspects

OPGGS(S) Regulations SMS Description

Reg 2.5(3)

The safety case for the facility must contain a detailed description of the safety

management system that:

(e) provides for the reduction to a level that is as low as reasonably practicable of risks

to health and safety of persons at or near the facility including, but not limited to:

(i) risks arising during evacuation, escape and rescue in case of emergency; and

(ii) risks arising from equipment and hardware.

While the FSA must identify the technical and other control measures that are necessary to reduce risk to

ALARP, the SMS must be comprehensive and integrated to cover all control measures. The so called

other control measures are found within the safety management system (SMS), and include elements

such as policies and procedures. The regulatory requirement is that SMS itself must provide for reduction of

risks to ALARP; and that the detailed description within the safety case provides information to support that

the SMS achieves this requirement. This aspect is particularly relevant for safety cases which cover ongoing

activities and operations over time. The safety case should show how effectiveness is maintained and how

deviations are managed to ensure they achieve a risk profile that is ALARP.

OPGGS(S) Regulations SMS Description

Reg 2.5(3)

The safety case for the facility must contain a detailed description of the safety

management system that:

(i) specifies the performance standards that apply.

In order to maintain risks at a level that is ALARP it is essential that control measures remain effective. The

information provided in the safety case in support of the ALARP argument should cover the following

aspects as a minimum:

Performance standards have been established.

Performance is measured against set performance standards within inspection, maintenance and

safety management systems.

There is periodic review of the process by which performance standards are established and

maintained, including checks that the right things are being measured.

Further guidance is available in the NOPSEMA guidance note:

Control Measures and Performance Standards

5.2 What are the fundamental approaches to consider?

There is no prescribed methodology for demonstrating that the necessary control measures have been

identified to reduce risks to ALARP, or the comprehensiveness of an SMS. However, there are several basic

approaches which may be used to support an operator's provision of evidence and justification within the

safety case. Operators could consider using one or more of these approaches, but should also be prepared

to consider developing specific approaches appropriate to their facilities. In practice, it is likely that most

facilities will require a combination of approaches.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

7 of 22

Guidance note

ALARP

In setting out to provide evidence that the risks are reduced to a level that is ALARP, it is a fundamental

requirement to demonstrate, in the first instance, that the hazard identification and risk assessment carried

out have been systematic and detailed, as they provide the foundation on which to base the control

measure selection. The following approaches may be considered:

Hazard / Risk Criteria Approach

Define criteria that is considered to correspond to reducing risk to a level that is as low as is

reasonably practicable, assess performance quantitatively or qualitatively (using matrices for

example) and compare against the criteria.

Comparative Assessment of Risks, Costs and Benefits

Evaluate risk and associated costs for a range of control measure options for the facility and

compare the relative merits of the different options, selecting the options which are practicable.

Cost Benefit Analysis [CBA]

The numerical assessment of the costs of implementing a design change or modification and the

likely reduction in fatalities that this would be expected to achieve. The quality of the modelling

and the data will affect the robustness of the numerical estimate and the uncertainties in it must

always be borne in mind when using the estimate in risk management decisions. In making this

assessment there is a need to set criteria on the value of a life or implied cost of averting a

statistical fatality (ICAF). In reality of course there is no simple cut-off and a whole range of factors,

including uncertainty need to be taken into account in the decision-making process.

Comparison with Codes and Standards

Compare design, the management system framework and operational procedures against

recognised national, international or industry standards, codes of practice, guides etc.

Audit against good practice

Audit the basis and implementation of the management system, including operations and

maintenance systems, against good practice for offshore facilities, vessels, or relevant similar

industries onshore.

Technical Analysis

Evaluate control measures in technical terms; assess strengths and weaknesses, e.g. effectiveness,

functionality, availability, reliability, technical feasibility, compatibility, survivability, correspondence

of control measures to hazards and risks, appropriateness of performance standards, etc.

Performance Data

Evaluate MAE safety-related performance data as evidence of adequacy or satisfactory levels of

performance, e.g. data on the operational effectiveness or reliability of a control measure may

support the demonstration of its appropriateness for that service.

Improvement Approach

Demonstrate the extent of relative improvements in performance for the facility based on past,

present and planned modifications and enhancements.

Judgement Approach

Present considered judgements as to the suitability of control measures and the management

systems, or the perceptions of a cross-section of various stakeholders, e.g. key members of the

workforce, senior management, plus independent observers.

Practical Tests

Demonstrate that the management system and/or control measures function effectively, using

major accident event simulations, management system tests, equipment breakdown and recovery

tests, etc. For example, it may be possible to conduct fire impingement tests to show that fire

rating of the material being used is appropriate.

For safety case acceptance purposes, NOPSEMA will evaluate the operators approach in terms of its

robustness, transparency and appropriateness to the facility. The operator should therefore define the

underlying rationale, criteria and decision-making basis for the case.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

8 of 22

Guidance note

ALARP

The description must be convincing; this means that the rationale for deciding the completeness of the

hazard identification and the adequacy of the measures employed should be supported and accompanied

by all assumptions made and conclusions drawn. Where appropriate, it should present/summarise the

results of supporting studies that have been performed.

The description should demonstrate that the process was systematic which means that it followed a fixed

and pre-established scope. Finally, the degree of analysis in support of the demonstration should be

proportionate to the risk and to the complexity of the facility, hazards and the control measures.

Example application of a model using a combination of approaches

Note: The following model is an example of using a combination of approaches. It is included as an illustration only

and is not required to be prescriptively followed. It should be noted that following such a model does not necessarily

lead to reducing the risks to a level that is ALARP.

The UK offshore oil and gas industry has developed a framework to assist risk-related decision making (Oil

& Gas UK, formerly UKOOA, 1999), which helps decision-makers choose an appropriate basis for their

decisions. A summary of the framework is shown in Figure 2.

The framework takes the form of a spectrum of decision bases, ranging from those decisions dominated

purely by engineering concerns to those where company and societal values are the most relevant factors.

Down the right-hand edge of the framework are typical characteristics which indicate the decision context;

these can be used to help the user determine the context of the specific decision. Once this level has been

identified, reading horizontally across the framework shows the suggested balance of decision bases to be

taken into account in the decision. Some means of calibrating or checking the decision basis are shown on

the left-hand side of the framework.

Figure 2 Risk Related Decision Support Framework (UKOOA 1999)

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

9 of 22

Guidance note

ALARP

This approach shows that risk assessment may have a major input to Type B decisions involving some

uncertainty, deviation from standard practice, risk trade-offs etc., whilst codes and standards are likely to

have a major input to Type A decisions, with less influence on Type B and C. What is evident from the

model is that a combination of decision bases is most likely to be applicable in any case.

The model is intended to be dynamic with the diagonal lines shifting either towards the X-axis or the Y-axis

depending on circumstances of the application being considered. It is advisable to make reference to the

Oil & Gas UK guidelines themselves for detail on the use of the framework as the diagram is complex and its

interpretation can be very subjective.

As an additional caution, operators who are making Type A decisions that rely predominantly on codes and

standards as a decision basis should ensure they truly understand how the codes and standards act to

minimise risks. Without this knowledge it is difficult to identify when change (planned or otherwise) will

undermine the effectiveness of that standard or code as a control measure.

The following example gives an application of the framework for illustration purposes: three facilities, three

different outcomes.

Table 1 - Example of applying the risk related decision support framework

Facility 1

Facility 2

Facility 3

Scenario

Standard temperature /

pressure pipeline in a

mature oil and gas

development area with no

known unique

environmental concerns

and much existing similar

infrastructure.

Normally attended facility

which has some

hydrocarbon processing

equipment on board. There

is nothing new or unusual

about the equipment or

process but this is the first

time a facility of this type

has been installed and

operated by this operator.

Normally attended facility

with novel technologies and

complex hydrocarbon

processing equipment that

requires frequent

monitoring during the initial

start-up phase of

operations. The facility has

a large number of

personnel on board and is

located a long way from the

mainland.

Decision

Type

Nothing new or unusual,

company and external

codes cover this application

extensively, the best design,

installation and

maintenance approaches

are known and well

established over many

years. The decision type is

A.

Hydrocarbon processing

facilities are not novel but

they are new to the

operator and thus deviate

from established company

practice. Qualified

engineering judgement and

some risk based assessment

will be required to

determine that the design is

ALARP. The decision type is

B.

Some new and novel

technologies are utilised

and the number of

potentially exposed

personnel is high. The

impacts from any loss of

containment are potentially

very high. The decision is

type C.

Risk

reduction

measures

Standard measures

specified in design codes

and adopted on the existing

infrastructure are put in

place.

Standard measures put in

place for processing

facilities and decisions

made regarding increased

monitoring and inspection.

The decision type means

that much more effort is

expended on examining risk

reduction options and

proving the design is ALARP.

Although costly, a standby

vessel is incorporated into

the design and operation

philosophy for the facility.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

10 of 22

Guidance note

ALARP

Suitability of control measures for MAEs

The basic requirement for control measures for MAEs is that they must collectively reduce the risk to the

health and safety of people to a level as low as is reasonably practicable (ALARP). Risk assessment provides

information necessary to test this requirement, and it is this information that must be included in the safety

case. Reduction of risk to ALARP is dependent on identification of hazards having the potential to cause

MAEs and proper selection of the necessary control measures for each of them. This has several aspects, all

of which will in general apply to each facility:

The knock-on effects of hazards must be considered, i.e. any chain of events, causes and contributing

factors leading to MAEs.

For any MAE there may be several independent hazards or combinations of hazards, each of which

could lead to that event, and several control measures which may be particularly important because

they may impact on one or more of those hazards.

The potential for escalation of major accident events needs to be considered, i.e. the cumulative

consequences of apparently separate events that may be triggered by each other.

In cases where a large number of different hazards and potential incidents exist, the cumulative risk

may be significant even if the risk arising from each is low. For example, the cumulative effects of

many sources of risk in an offshore accommodation area may identify an unacceptable risk even if

each source is low risk.

Consequently the demonstration that risks from MAEs are eliminated or reduced to ALARP may need to be

made for hazards individually, in groups, and as a whole.

As stated earlier, there is no single correct way to demonstrate ALARP. However, it is expected that for

each MAE identified for the facility, the demonstration would contain elements of the following process:

Identification and consideration of a range of potential measures for risk reduction (both those

adopted and those rejected);

Systematic analysis of each of the identified measures and a view formed on the safety benefit

associated with each of them;

Evaluation of the reasonable practicability of the identified measures and the adoption or rejection of

each; and

Recording of the process and results, to be summarised in the safety case.

Clearly, the balance between benefits in terms of reduced risk and the costs of control measures will play a

part in achieving and justifying ALARP. For example, if a control measure has a benefit that greatly

outweighs the cost, this control measure would almost always have to be implemented, or very good

reasons provided for not doing so. In contrast, if the cost greatly outweighs the benefit, demonstrating that

the control measure is not appropriate is straightforward, as other options will almost certainly exist that

are able to achieve a similar level of risk reduction at lower cost. If benefits and costs are both high, or are

both low, more careful consideration may be required before selecting or rejecting control measures.

The operator may be able to rank available control measure options according to their benefits and costs in

qualitative or quantitative terms. This will enable the operator to show that the appropriate balance has

been achieved, where further steps to reduce risk would incur unreasonably high cost with little gain.

For existing facilities, in undertaking risk assessment and providing justification, operators shouldalso

consider if newly adopted control measures could pose additional hazards or contribute to incident

scenarios, e.g. during installation or commissioning of new control equipment, or arising from spurious

operation of control measures.

Implementation arrangements should be included for any risk control measures that are planned but not

yet in place, i.e. scheduled implementation. Specific and explicit commitments should be included that

demonstrate the operators intention not to operate their facilities at an increased level of risk, in that

activities will not be carried out until such time as the corresponding control measures have been fully

implemented.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

11 of 22

Guidance note

ALARP

While there is no explicit requirement within the OPGGS(S) Regulations to record in the safety case the

range of control measures that has been considered, the content and level of detail needs to be sufficient

to gain an appreciation of the scope and process for undertaking the consideration including sources of

data and rationale for excluding or discounting items from consideration. It is difficult to see how an

operator could show that risks are as low as reasonably practicable without making reference to other,

discarded risk control measures.

Given all of the issues that may need consideration in demonstrating that the necessary control measures

have been identified, it is appropriate to develop an approach that is logical, structured and efficient. For

example, it would be inefficient to assess the effect of a control measure in detail if itwas not practicable

from a cost perspective. Equally, if there are control measures that can eliminate hazards, there may be

little purpose in devoting significant effort to the assessment of measures for reduction or mitigation of the

identified associated MAE.

Performance standards should be set for MAE control measures, and the safety case will need to include a

convincing argument that these standards are appropriate. This is required to provide evidence to enable

NOPSEMA to make a decision on whether the safety case is appropriate to the facility in accordance with

OPGGS(S) subregulation 2.5(2)(c). These factors are discussed in greater detail in NOPSEMA Guidance Note

Control Measures and Performance Standards.

Further guidance is available in the NOPSEMA guidance note:

Control Measures and Performance Standards

Example for a New-Build FPSO

An example of adopting a risk management strategy incorporating a hierarchy of controls and

inherently safe design principles is encompassed in the case of reducing risks associated with

conventional FPSO cargo pumps(located in a pump room) by using motor driven submersible pumps

located on deck.

The safety issues associated with a conventional pump room versus deep well pumps located in

each crude oil tank were evaluated. The review concluded there are advantages and disadvantages

to both options, however the pump room option does not satisfy established isolation protocol as

the pump seals are prone to leak thus posing significant fire and gas risk in the enclosed pump room

space. Based on this evaluation, the deep well pump option was selected.

A further review was then carried out to examine the safety issues associated with hydraulic versus

electric driven deep well pumps. Overall, it was concluded that the electric pump option is safer,

primarily because the lower personnel exposure more than offsets the higher ignition potential. For

this reason, the electric pump option was chosen for the design. Once the decision was made, the

design and provision was finalised incorporating inputs from ergonomic, material handling and

human factor interface reviews.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

12 of 22

Guidance note

ALARP

6.1 Summary of factors in selecting or rejecting control measures

Methodology for

understanding controls

Points to Consider

Control Measure Hierarchy

Elimination

Prevention

Reduction

Mitigation

Is there a control higher up the hierarchy that would more

effectively manage the hazard?

Where appropriate, is there a spread of controls across the

hierarchy?

Types of Control Measure

Technical (Hardware/software)

Other (SMS/Procedural)

Common Mode Failures

Is there an appropriate spread of technical and other controls?

Have failure modes been identified for each control measure

and then compared to identify common mode failures?

Layers of Protection

Design Standards

Control Systems

Operating Procedures

Safety Devices

Emergency Systems

Are the layers of protection provided adequate for the level of

risk posed by the hazard?

Operating Circumstances

Environment

Operating conditions

Activities being carried out

Focus of Control Measure

Have the controls been assessed for effectiveness over the range

of different operating circumstances they may have to operate

in?

Does the relative importance or vulnerability of the control

measure justify a higher depth of scrutiny than others

Effective

Functionality

Availability

Reliability

Survivability

ALARP

Has the functionality, availability, reliability and survivability,

been established for each control measure?

Have means of improving these aspects been considered?

Has each control measure been assessed for practicability, and

those found practicable been implemented while those found to

be not practicable noted as such with sufficient justification?

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

13 of 22

Guidance note

ALARP

Risk assessment and providing evidence

Operators of offshore facilities must adopt a comprehensive and systematic method for assessing the risks

of major accident events at their facilities. Some operators may choose to adopt quantitative methods,

particularly if this is common practice in their company, whereas others may choose to adopt qualitative

methods. The results of such assessments should be used to support the evidence that necessary control

measures have been identified, and to show that risks are eliminated or reduced to a level that is ALARP.

NOPSEMA expects the operator to justify the adopted risk assessment methodology and associated risk

acceptance criteria as being suitable and appropriate to the specific facility.

7.1 Risk assessment tools

Approaches to formal safety assessment are discussed in numerous publications, and in NOPSEMA

Guidance Note: Risk Assessment, so only limited details of risk assessment methods are provided in this

guidance note. ISO 17776, in relation to offshore production facilities, may provide further guidance on

tools and techniques for hazard identification and risk assessment. The requirement is for the operator to

select an approach which supports decision-making on control measures. Risk assessment will be an

important part of this process, by showing that risks are reduced to a level that is as low as reasonably

practicable, and by showing that decision-making relates to the level of risk.

Further guidance is available in the NOPSEMA guidance note:

Risk Assessment

7.2 Risk criteria

Many operators of offshore facilities may elect to assess and evaluate risks in a quantitative or semiquantitative manner, and to develop criteria against which to compare the estimated risk levels. It must be

noted, however, that all risk assessment is subject to uncertainty. For this reason, most approaches

evaluate risk based on broad ranges of risk, rather than on specific criteria.

Increasing individual risks and societal concerns

Figure 3 - Example of an ALARP triangle

Unacceptable /

Intolerable Region

IRPA 1x10 -3

ALARP

Region

IRPA 1x10 -6

Broadly

Acceptable

Region

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

14 of 22

Guidance note

ALARP

Risk is most commonly represented on an inverted triangle (such as Figure 3 above) as increasing from a

broadly acceptable risk region, through a tolerable region only if shown to be ALARP, to an intolerable

region, in which the risk cannot be justified on any grounds. Such diagrams also typically introduce

numerical thresholds between the risk bands, often in terms of the Individual Risk Per Annum (IRPA) of a

fatality. Operators may find it helpful to think of risk in terms of the inverted ALARP risk triangle; however it

is important to be aware that the overall provisions the operator has to make through the safety case need

to consider hazards and risks in all regions of the triangle.

As shown in Figure 4, a more accurate representation of an ALARP triangle in the context of the OPGGS(S)

Regulations is simpler, but more challenging, with the sole requirement being the reduction in risk to

ALARP. It is notable that in order to keep risk at a level that is ALARP requires ongoing action to ensure the

integrity of the control measures is maintained.

Figure 4 OPGGS(S) ALARP triangle diagram

Increasing individual risks and societal concerns

For each OHS Hazard

Untreated

Risk

Application of

cost effective

control measures

to reduce risk

Ongoing action to

maintain integrity of

control measures

Risk reduced to a

level that is

ALARP

Cost of further risk

treatment grossly

disproportionate to

the reduction in risk

Although the Australian safety case regime may appear broadly compatible with that applied

internationally, it is important to stress that the requirements contained within the OPGGS(S) Regulations

incorporate continuous improvement aspects. This means that at the lowest risk band, it may be

reasonably practicable to further reduce the risk, and the regulations also require that this is considered.

The safety case will have to show that:

all hazards with the potential to lead to a major accident event have had all reasonably practicable

risk reduction measures applied;

any hazards or risks that may arise in the future will be effectively dealt with; and

there are suitable and reliable processes for continuing to manage hazards and risks at all levels,

and for achieving continuous improvement

It is appropriate to apply concepts of proportionality to treating risks, and to concentrate effort on high

risk areas. Numerical categorisation of risk may provide a yardstick to assist understanding and

prioritizing risk reduction measures, however it should not be used as a single acceptance criterion.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

15 of 22

Guidance note

ALARP

7.3 Continuous improvement

While the safety case may place emphasis on reducing the risk to a level that is ALARP, it should not detract

from the need for continuous improvement. Reducing risks to a level that is ALARP and continual

improvement are both key objectives of the regulations, and relate both to what is done currently and to

what is planned for the future.

If carried out properly, the process of developing the safety case will improve safety of offshore activities by

ensuring a systematic review of the hazards, their associated risks and the control measures that are

applied at the facility to either eliminate the hazards or otherwise reduce the risks. Progress, in terms of

risk reduction, is achieved by applying the process both during initial development of the safety case and

subsequently in the course of continuous improvement (Figure 5).

Level of RIsk

Figure 5 - Continuous Improvement in Safety through Implementation of the Safety Case

Safety Case Development

Continuous Improvement

Identify

Hazards

Assess

Risks

Implement

Controls

Identify

Controls

Identify

Hazards

Manage

Safety

Implement

Controls

Identify

Controls

Assess

Risks

Safety Case

Submission

ALARP

It is expected that over the life of a facility an operators risk managementprocesses will identify

opportunities to enhance the effectiveness of existing control measures or implement additional control

measures and that a proportion of these will be reasonably practical to implement. This expectation is

based on both ongoing developments in the state of knowledge concerning hazards and risks and the

associated control measures and the over-arching duty of an operator to take all reasonably practicable

steps to ensure that the facility and activities carried out at the facility are safe and without risk to the

health and safety of any person at or near the facility.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

16 of 22

Guidance note

ALARP

Use of Industry Codes and Standards

For most facilities, compliance with industry standards, codes or practices may play an important role in

providing evidence that necessary and appropriate control measures have been identified and adopted. In

principle, such standards may be Australian Standards, equivalents from overseas organisations such as ISO

standards, international industry practices such as those from the American Petroleum Institute, or

company-specific standards. However, the existence of a published standard does not imply that it is

always useful or correct. Whichever standards are being used, these standards, and the control measures

that they apply, should all be shown to be suitable and appropriate to the specific facility, taking account of

its type, scale, activities, location, etc. Operators have the responsibility to consider the available

standards, specify the correct one, enforce compliance, and use the system or equipment correctly.

Validation of suitability of standards for safety-critical equipment is also necessary.

Further guidance is available in the NOPSEMA guidance note:

Control Measures and Performance Standards

Technical standards issued by classification societies, IMO, national authorities and industry bodies

underpin the design of many aspects of most offshore installations. For example, ISO 13702 (Control and

mitigation of fires and explosions on offshore production installations), ISO 15544 (Requirements and

guidelines for emergency response) and ISO 10418 (Basic surface process safety systems) provide guidance

in relation to offshore production facilities. These standards have been developed using the expertise of

the industry, responding to previous accident and incident experience and, in general, prescribe specific

design solutions. The aim of technical standards is to ensure that, provided the installation is used for a

standard application under good safety management, the risks will be reduced. However, it is an

established part of good safety management to make use of risk assessment to identify hazards and

minimise risks. Compliance with technical standards provides a sound design basis for standard offshore

installations, but does not replace risk assessment altogether.

Example: Option Selection

Standards, for the most part, allow for multiple solutions to a design. For example, in a project

design process a decision would be made on, for instance, a type of compression to be adopted on

the facility and then the appropriate standards are applied to the type of compression selected.

Standards compliance on its own does little to demonstrate an ALARP decision process, since one

type of compression may be of inherently lower risk than the other. The real ALARP decision process

centres on the option choice whereas the standards argument is merely demonstrating that the

chosen option meets appropriate standards for the option selected.

In some cases there may be a single over-arching standard that appears to apply. An example is the

International Maritime Organisation Code for the Construction and Equipment of Mobile Offshore Drilling

Units, (MODU Code) for most of the marine standards for an offshore drilling unit. For simple facilities, it

may be possible to present evidence that risk related to design aspects are ALARP based largely on such

standards, however the overall requirement for evidence of ALARP applies equally to construction,

operation, ongoing maintenance and decommissioning phases (depending on the stage(s) in the life of the

facility addressed in the safety case) as well as the facility design. In addition, a significant component of

the ALARP requirements of the OPGGS(S) Regulations relates to the safety management system [OPGGS(S)

subregulation 2.5(3)(e)] and therefore it is not normally possible to base an ALARP demonstration on

standards alone.

For particularly large or complex facilities, it may be necessary to go beyond the established standards in

order to demonstrate that risks related to facility design are ALARP. For example:

The standards may not address the types of incident that are of prime concern to the facility;

There may be gaps in the standards, such that the particular standard does not govern all aspects of

hazards and risks at a facility; and

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

17 of 22

Guidance note

ALARP

The standard has fallen behind current good practice, or the facility has fallen behind the standard

as that has been further developed.

Example: Lifeboat Capacity

An operator may decide to comply with the Life-Saving Appliances (LSA) IMO code for all lifeboats on

a specific facility, since LSA is an internationally recognised standard for lifeboats on vessels. The

operator should recognise according to the LSA code, lifeboat capacity is based on a person having

an average mass of 82.5kg. If the average weight for the personnel on the operators facility is

typically 90kg then the operator should identify the limitation of the LSA code and ensure their

lifeboat capacities are reclassified accordingly.

Example: Hazardous Area Zoning

An operator suspected that hazardous area classification zones described in a standard used by their

organisation might not accurately reflect what was occurring in practice. As a result, a gas

monitoring system was set up that identified the hazardous area zones needed to be increased due to

the specific site circumstances. Under a goal-setting regime, it is also possible for operators to make

such zones smaller if they can demonstrate it is reasonable to do so.

In the petroleum and chemical processing industries, there are no single over-arching standards for all

aspects of facility design and operation. Rather, there are detailed standards in specific areas of design

such as pressure vessels, hazardous area classification, fire-protection, and so on, plus general standards

related to safety management. Standards are good at a system or equipment level but not necessarily

suitable at a holistic level; they cannot be relied upon to give an indication of the adequacy of risk

management of a combination of unique hazards on a specific facility. In this situation, it is common for an

operator to adopt a suite of standards, perhaps taken from a number of different organisations. In such

cases, significant effort may be necessary to show that this overall suite of standards is suitable and

appropriate, as well as the individual parts.

Particular issues that will need additional consideration, which may not be covered by the individual

standards, include plant layout, routing of escape-routes and protection of manned areas. In such cases

there will be particular benefit in the operator developing a basis for safety for the specific facility.

Whatever standard or set of standards is used, the operator should take care to justify applicability and

recognise limitations of those standards.

There may be cases where the current most relevant standard is not complied with in certain respects. An

example may be a complex or novel facility where there are no applicable standards; another may be an

ageing facility designed and constructed to standards now superseded. In such cases, the operator should

show that additional measures have been introduced to compensate (i.e. to show that equivalent safety

has been achieved), or that additional measures are not reasonably practicable. Examplesof measures that

may achieve equivalent safety are re-rating of equipment and introduction of more frequent testing or

inspection. Where weaknesses are known or suspected to exist, for example if there is a gap in overall

control measures, or a measure has been compromised by age, this must be explicitly identified. Solutions

for addressing these weaknesses must be explored, and the chosen solution incorporated.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

18 of 22

Guidance note

ALARP

OPGGS(S) Regulations Objects

Reg 1.4(2)

An object of these regulations is to ensure that safety cases for offshore petroleum

facilities make provision for the following matters in relation to the health and safety of

persons at or near the facilities:

(a) the identification of hazards

(b) the implementation of measures to eliminate the hazards or otherwise control the

risks;

(c)

a comprehensive and integrated system for management of the hazards and risks;

(d) monitoring, audit, review and continuous improvement.

With respect to OPGGS(S) subregulation 1.4(2)(d) the review of facility hazards and risks should be a

periodic process whereby the applied standards on a facility are reviewed against new and updated

standards. If new standards or requirements are introduced they cannot be dismissed because the plant or

facility was built prior to them; neither should they be automatically adopted: the risk assessment process

must be undertaken. The task would be to understand the intent of the new standard and the change that

it evokes from the current/existing operating situation. Once the assessment has taken place then

decisions can be made about implications for a new understanding of risk on the facility and the steps that

need to be taken.

Example: MODU Code

A number of MODUs operating in Australian waters are only classed to the 1979 MODU Code (rather

than the 1989 Code or 2001 amendment). One area of significant difference with later versions of

this code is considerations for ballast control following the Ocean Ranger incident in which a MODU

and all on board were lost. Any ALARP argument for the management of ballasting related MAEs

should explicitly consider the limitations of the older code and implementation of the current code or

equivalent control measures unless it can be demonstrated not to be reasonably practicable to do so.

It is also an option for an operator to use earlier versions of a code or standard if it can be shown that by

doing so the risks are reduced to a level that is ALARP. In taking such an approach an operator wouldalso

need to be mindful of the basis for the change to the code or standard noting that such changes are

generally improvements in response to an identified failure or weakness of the code or standard.

Example: Electrical colour coding

An operator may in the past have complied with Electrical Installation Standard AS 3000 which was

revised in 2007 with respect to selection of cables for size and colour. The operator may assess that

there is a risk arising from the use of two different cable colour schemes in the same system.

NOPSEMA would expect under such circumstances that older conductors would be thoroughly tested

to ensure that their physical condition is acceptable and that existing cables do actually meet the

standard the operator has quoted in terms of adequate cross-sectional area, voltage drop levels,

cable grouping etc.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

19 of 22

Guidance note

ALARP

Good practice and reasonable practicability

In determining what is reasonably practicable (or not), the courts usually do so in the context of an incident

and therefore take an event focus - they consider in hindsight an alleged breach associated with a

particular incident, and each incident is judged on a case by case basis. Due to the event focus of

prosecutions, courts traditionally have not been concerned with what proactive steps might need to be

taken by an operator to address risk across a facility. In contrast, risk management provisions in the

OPGGS(S) Regulations are framed as a proactive and holistic process, to prevent or control risks before

incidents occur rather than simply reacting to them when they do.

In the decision by Lord Asquith, the computation associated with reasonably practicable falls to be made

by the owner at a point of time anterior to the accident. Furthermore, in regard to what is practicable,

the test of gross disproportion applies: if a measure is practicable and it cannot be shown that the cost of

the measure is grossly disproportionate to the benefit gained, then the measure is considered reasonably

practicable and must be implemented. This reinforces a precautionary approach by requiring the requisite

control measures to be implemented unless there is an obvious imbalance between the sacrifice (cost) and

the risk and further that as risk levels rise so too does the sacrifice (cost) that could reasonably be

considered as being grossly disproportionate. .

When reviewing health or safety control measures for an existing facility, plant, installation or for a

particular situation (such as when considering retrofitting, safety reviews or upgrades), operators should

compare existing measures against current good practice. The good practice measuresshould be adopted

so far as is reasonably practicable. It might not be reasonably practicable to apply retrospectively to

existing plant, for example, all the good practice expected for new plant. However, there may still be ways

to reduce the risk e.g. by partial solutions, alternative measures, etc.

In determining what is reasonably practicable, the starting point for the risk/sacrifice computation should

be the current situation. Operators should also consider the adequacy of the relevant good practice. An

operators SMS should incorporate processes to monitor changes to applicable codes and standards. When

a code or standard is updated to a higher standard, the facility, plant, installation or situation should be

examined to see if it can be brought up to the new standard. Any such upgrades must be undertaken if it is

reasonably practicable to do so.

New plant, installations or situations should conform to current good practice, as a starting point. Other

potential options should be considered to determine whether further risk reduction measures are

reasonably practicable. As a guide, designers can aim and compare against levels of safety that are known

to have been achieved in other good practice designs.

The use of good practice at the design stage is essential to demonstrating achievement of ALARP.

Therefore, it is important that the operator capture all of the relevant information about risk-reduction

decisions made during the early design stages. This should include use of sound design principles (e.g.

inherent safety) as well as codes, standards and guidance. The earlier an operator undertakes an ALARP

evaluation, the greater the ability to reduce risks to a level that is ALARP. Practicability is reduced as the

project progresses and inherent safety opportunities are often lost beyond the concept selection stage. As

previously mentioned, the criterion is reasonably practicable, not reasonably affordable: justifiable cost and

effort is not determined by the budget constraints/viability of the project.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

20 of 22

Guidance note

ALARP

10 Critical factors for success

NOPSEMA expects the operator to address at least the following specific factors in their consideration of

ALARP in the safety case submission:

Timeliness. The earlier an operator undertakes an ALARP evaluation, the greater the ability to reduce

risks to a level that is ALARP.

Safety case content that is consistent with the requirements specified in the OPGGS(S) Regulations;

Involvement of people who know the facility or a very similar operation;

Access to a wide range of reference material such as standards, safety alerts, etc.;

Description with an sufficient level of detail that explains the means by which the operator ensures

suitability of the design, construction, installation, operation, maintenance or modification that is

appropriate to the facility;

A transparent and robust presentation of evidence showing that the adopted control measures

reduce risk to ALARP; and

A transparent and robust presentation of evidence that the SMS provides for and will continue to

provide for reduction of risk to ALARP, and that the SMS is comprehensive and integrated.

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

21 of 22

Guidance note

ALARP

11 References, Acknowledgements & Notes

Offshore Petroleum and Greenhouse Gas Storage Act 2006

Offshore Petroleum and Greenhouse Gas Storage (Safety) Regulations 2009

HSE Offshore Information Sheet 2/2006 The Role of Offshore Installations (Safety Case) Regulations 2005

regulation 12 http://www.hse.gov.uk/offshore/sheet22006.pdf

ISO 10418 Petroleum and natural gas industries -- Offshore production platforms - Basic surface process

safety systems

ISO 13702 Petroleum and natural gas industries -- Control and mitigation of fires and explosions on

offshore production installations -- Requirements and guidelines

ISO 15544 Petroleum and natural gas industries -- Offshore production installations -- Requirements and

guidelines for emergency response

ISO 17776 Petroleum and natural gas industries -- Offshore production installations -- Guidelines on tools

and techniques for hazard identification and risk assessment

National Research Centre for Occupational Health and Safety Regulation, The Relationship Between

Reasonably Practicable and Risk Management Regulation, Bluff and Johnstone, 2004

UK HSE Assessment Principles for Offshore Safety Cases 2005

UK HSE Assessing compliance with the law in individual cases and the use of good practice

UK HSE Principles and Guidelines to assist HSE in its judgements that duty holders have reduced risk as low

as reasonably practicable

UK HSE Policy and guidance on reducing risks as low as reasonably practicable in Design

The UK offshore oil and gas industry A framework to assist risk-related decision making (Oil & Gas UK,

formerly UKOOA, 1999)

Note: All regulatory references contained within this Guidance Note are from the Commonwealth Offshore

Petroleum and Greenhouse Gas Storage Act 2006 and the associated Commonwealth Offshore Petroleum

and Greenhouse Gas Storage (Safety) Regulations 2009. For facilities located in Victorian designated coastal

waters, please refer to the Victorian Offshore Petroleum and Greenhouse Gas Storage Act 2010 and the

associated Offshore Petroleum and Greenhouse Gas Storage Regulations 2011. For facilities located in

other designated coastal waters, please refer to the relevant State or Northern Territory legislation.

NOPSEMA would like to acknowledge the UK Health and Safety Executive (HSE) and WorkSafe Victoria for

their assistance in the preparation of this guidance documentation. For more information regarding this

guidance note, contact the National Offshore Petroleum Safety and Environmental Management Authority

(NOPSEMA):

Telephone:

e-mail:

+61 (0)8 6188-8700, or

safetycaseguidance@nopsema.gov.au

National Offshore Petroleum Safety and Environmental Management Authority

A138249

June 2014

22 of 22

You might also like

- Iveco F4ge PDFDocument142 pagesIveco F4ge PDFHandy Lee75% (4)

- Presentation and Preparation of FS FINALDocument86 pagesPresentation and Preparation of FS FINALJoen Sinamag100% (1)

- Handbook of Failure FrequenciesDocument33 pagesHandbook of Failure Frequenciesa.f.nakshaNo ratings yet

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Event Tree AnalyisisDocument27 pagesEvent Tree AnalyisisELVIS KIPKORIRNo ratings yet

- Guideline For Implementing PSMDocument5 pagesGuideline For Implementing PSMShiva Prakash Ponniah0% (2)

- Sample ALARP WorksheetDocument7 pagesSample ALARP WorksheetP100% (1)

- PSM Workbook CanadaDocument56 pagesPSM Workbook CanadaSPIDERMAB33100% (1)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Chapter 31 - Assessment and Management of Patients With Vascular DisordersDocument7 pagesChapter 31 - Assessment and Management of Patients With Vascular DisordersMichael Boado100% (1)

- Alarp-Comah 2003Document18 pagesAlarp-Comah 2003kenoly123No ratings yet

- ALARP JustificationDocument8 pagesALARP JustificationAli RizviNo ratings yet

- COMAH and Safety Case RegulationsDocument16 pagesCOMAH and Safety Case RegulationsAdeel RazaNo ratings yet

- Inherently Safer Design Review and Their Timing During Chemical Process Development and DesignDocument12 pagesInherently Safer Design Review and Their Timing During Chemical Process Development and Designhaslinda Abdul SahakNo ratings yet

- Six Steps To Effectively Update and Revalidate PHAsDocument8 pagesSix Steps To Effectively Update and Revalidate PHAspolaris44No ratings yet

- Consequence Modeling and PSMDocument35 pagesConsequence Modeling and PSMTom Tao100% (1)

- Chapter 1 - Chemical Process QRADocument56 pagesChapter 1 - Chemical Process QRANitesh KirnakeNo ratings yet

- Jepg ... SJEC - Jan 2023 Module On PROCESS SAFETYDocument20 pagesJepg ... SJEC - Jan 2023 Module On PROCESS SAFETYL JayanthiNo ratings yet

- The Evaluation of Safety Barriers Using The Method LopaDocument7 pagesThe Evaluation of Safety Barriers Using The Method LopaDiegoNo ratings yet

- Use Maximum-Credible Accident Scenarios For Realistic and Reliable Risk AssessmentDocument9 pagesUse Maximum-Credible Accident Scenarios For Realistic and Reliable Risk AssessmentArman MohammadiNo ratings yet

- 2 SafetyRiskAnalysis-GasPlantItalyDocument2 pages2 SafetyRiskAnalysis-GasPlantItalySDP02100% (1)

- Relief Design For Laboratories and Pilot PlantsDocument3 pagesRelief Design For Laboratories and Pilot PlantsNattapong Pongboot100% (1)

- Fertil Hazop StudyDocument9 pagesFertil Hazop Studypkannan0% (1)

- Fire and Explosion Hazard Management Rev 1Document36 pagesFire and Explosion Hazard Management Rev 1fxgb0% (1)

- Efficient PHA of Non-Continuous Operating ModesDocument25 pagesEfficient PHA of Non-Continuous Operating ModesShakirNo ratings yet

- Consequence Modeling Using AlohaDocument40 pagesConsequence Modeling Using AlohaNageswar MakalaNo ratings yet

- Chemical Reactivity HazardsDocument101 pagesChemical Reactivity HazardsSandeep VermaNo ratings yet

- PHAST 6.4 Operating ManualDocument37 pagesPHAST 6.4 Operating Manualhanchuin100% (1)

- Quantitative Risk Analyses in The - Process IndustriesDocument97 pagesQuantitative Risk Analyses in The - Process IndustriesHadjerNo ratings yet

- Paper 2Document8 pagesPaper 2Nitesh Kirnake100% (1)

- LOPA - Quantifying Human Performance in IE and IPLDocument25 pagesLOPA - Quantifying Human Performance in IE and IPLfelisianus100% (1)

- Chemical Exposure IndexDocument23 pagesChemical Exposure IndexwankartikaNo ratings yet

- Societal Risk MappingDocument31 pagesSocietal Risk MappingCalNo ratings yet

- Dust Explosion ProtectionDocument6 pagesDust Explosion Protectionjkj_13874No ratings yet

- ARAMIS Project - Event Prediction (General)Document19 pagesARAMIS Project - Event Prediction (General)Titania AlrayshaNo ratings yet

- One Day Seminar: A Report ForDocument5 pagesOne Day Seminar: A Report ForBrijesh100% (2)

- Canadian Bleve TextDocument31 pagesCanadian Bleve Textarachman297988No ratings yet

- Application of The Mond Fire Explosion IndexDocument17 pagesApplication of The Mond Fire Explosion IndexenviroNo ratings yet

- CN3135 Process Safety and Environment Consequence Modeling PDFDocument10 pagesCN3135 Process Safety and Environment Consequence Modeling PDFVincent ChongNo ratings yet

- Accuracy in QRADocument8 pagesAccuracy in QRAJohm Robert taylor100% (1)

- Fixed Gaseous SuppressionDocument3 pagesFixed Gaseous SuppressionVijay Sharma100% (2)

- Toxic Release and Dispersion ModelsDocument57 pagesToxic Release and Dispersion ModelsRaushan KumarNo ratings yet

- OGP Ignition Probabilities 434-6Document30 pagesOGP Ignition Probabilities 434-6jms1952100% (2)

- 998 2095 01 26 15ar0 - enDocument10 pages998 2095 01 26 15ar0 - enRichard AmorinNo ratings yet

- Designing Risk Matrices To Avoid Risk Ranking Reversal ErrorsDocument6 pagesDesigning Risk Matrices To Avoid Risk Ranking Reversal Errorsravxall88No ratings yet

- Inherently Safer DesignDocument64 pagesInherently Safer Designchetan_7927No ratings yet

- 07process Safety Performance Indicators Health and Safety ExecutiveDocument23 pages07process Safety Performance Indicators Health and Safety ExecutiveSergio A. Rdz. F.No ratings yet

- Consequenc Assessment Model For Incidents Involving Release From LNG CarrierDocument128 pagesConsequenc Assessment Model For Incidents Involving Release From LNG CarrierRichard HollidayNo ratings yet

- Journal of Loss Prevention in The Process Industries: Souvik Biswas, Benjamin J. FischerDocument11 pagesJournal of Loss Prevention in The Process Industries: Souvik Biswas, Benjamin J. FischerkrazylionNo ratings yet

- Introduction To Inherently Safer DesignDocument15 pagesIntroduction To Inherently Safer DesignJP_Bourke100% (1)

- ALARP PrincipleDocument1 pageALARP Principlekenoly123No ratings yet

- CCPS Monograph Reflections From Global Process Safety LeadersDocument29 pagesCCPS Monograph Reflections From Global Process Safety LeadersKiranNo ratings yet

- Introduction To Source Models: Prof. Shishir SinhaDocument47 pagesIntroduction To Source Models: Prof. Shishir SinhaRekha100% (1)

- UC 2018 Phast - Safeti 8.1 WorkshopDocument14 pagesUC 2018 Phast - Safeti 8.1 Workshopanub0025100% (1)

- Toxic Release and Dispersion ModelsDocument42 pagesToxic Release and Dispersion ModelsvictorvikramNo ratings yet

- CCPS Guidelines For LOPC CasesDocument24 pagesCCPS Guidelines For LOPC CasesMuhammad Wahaj Butt100% (1)

- 2 Consequence Modelling - Overview of HazardsDocument75 pages2 Consequence Modelling - Overview of HazardsJeampierr Jiménez Chero100% (1)

- Methods of Approximation and Determination of Human Vulnerability For Offshore Major Accident Hazard AssessmentDocument55 pagesMethods of Approximation and Determination of Human Vulnerability For Offshore Major Accident Hazard AssessmenthazopmanNo ratings yet

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Essential Practices for Creating, Strengthening, and Sustaining Process Safety CultureFrom EverandEssential Practices for Creating, Strengthening, and Sustaining Process Safety CultureNo ratings yet

- Guidelines for Integrating Process Safety into Engineering ProjectsFrom EverandGuidelines for Integrating Process Safety into Engineering ProjectsNo ratings yet

- Guidelines for Determining the Probability of Ignition of a Released Flammable MassFrom EverandGuidelines for Determining the Probability of Ignition of a Released Flammable MassNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)