100%(1)100% found this document useful (1 vote)

47 viewsNTPC Syllabus

NTPC Syllabus

Uploaded by

VimleshKumarSharmaThe document outlines the key topics covered in an engineering curriculum, including:

1) Engineering mechanics concepts such as equilibrium, trusses, kinematics, and dynamics.

2) Properties and applications of engineering materials like metals and their stress-strain behavior.

3) Analysis of stresses and deflections in structural members like beams, columns, and curved bars.

4) Dynamic analysis and kinematic synthesis of mechanisms like linkages, gears, and flywheels.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

NTPC Syllabus

NTPC Syllabus

Uploaded by

VimleshKumarSharma100%(1)100% found this document useful (1 vote)

47 views3 pagesThe document outlines the key topics covered in an engineering curriculum, including:

1) Engineering mechanics concepts such as equilibrium, trusses, kinematics, and dynamics.

2) Properties and applications of engineering materials like metals and their stress-strain behavior.

3) Analysis of stresses and deflections in structural members like beams, columns, and curved bars.

4) Dynamic analysis and kinematic synthesis of mechanisms like linkages, gears, and flywheels.

Original Title

ntpc syllabus

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document outlines the key topics covered in an engineering curriculum, including:

1) Engineering mechanics concepts such as equilibrium, trusses, kinematics, and dynamics.

2) Properties and applications of engineering materials like metals and their stress-strain behavior.

3) Analysis of stresses and deflections in structural members like beams, columns, and curved bars.

4) Dynamic analysis and kinematic synthesis of mechanisms like linkages, gears, and flywheels.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

100%(1)100% found this document useful (1 vote)

47 views3 pagesNTPC Syllabus

NTPC Syllabus

Uploaded by

VimleshKumarSharmaThe document outlines the key topics covered in an engineering curriculum, including:

1) Engineering mechanics concepts such as equilibrium, trusses, kinematics, and dynamics.

2) Properties and applications of engineering materials like metals and their stress-strain behavior.

3) Analysis of stresses and deflections in structural members like beams, columns, and curved bars.

4) Dynamic analysis and kinematic synthesis of mechanisms like linkages, gears, and flywheels.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

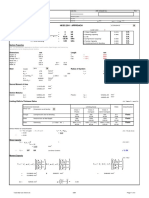

Engineering Mechanics: Free body diagrams and equilibrium; trusses and

frames; virtual work; kinematics and dynamics of particles and of rigid

bodies in plane motion, including impulse and momentum (linear and

angular) and energy formulations; impact.

Engineering Materials: Structure and properties of engineering materials and

their applications, heat treatment, stress-strain diagrams for engineering

materials.

Strength of Materials: Stress and strain, stress-strain relationship and elastic

constants, Mohrs circle for plane stress and plane strain, thin cylinders,

thick-walled vessels; shear force and bending moment diagrams; bending

and shear stresses; deflection of beams; torsion of circular members;

columns and struts; strain energy and impact loading; thermal stresses;

Rotating Rims & Discs; Bending of Curved Bars.

Theory of Machines: Displacement, velocity and acceleration analysis of

plane mechanisms, kinematic synthesis of mechanisms; dynamic analysis of

slider-crank mechanism; gear trains; flywheels; static and dynamic force

analysis; balancing of rotating components; governors.

Thermodynamics: Thermodynamic system and processes; Zeroth, First and

Second laws of thermodynamics;; Carnot cycle. irreversibility and

availability; behaviour of pure substances, ideal and real gases; calculation

of work and heat in ideal and real processes; Rankine and Brayton cycles

with modifications, analysis of thermodynamic cycles related to energy

conversion; vapour refrigeration cycle, heat pumps, gas refrigeration,

reverse Brayton cycle.

Moist Air: psychrometric chart, basic psychrometric processes.

Energy Conversion: Fuels and combustion; high pressure steam boilers; flow

through nozzles; Gas turbines with intercooling, reheat and regenerators,

Steam turbines, velocity diagram, power output and efficiency, maximum

blade efficiency of single stage impulse turbine, blade friction, compounding

of impulse turbine; reaction turbine, degree of reaction, velocity diagram,

power output, efficiency; losses in steam turbines, stage efficiency, overall

efficiency and reheat factor; governing of steam turbines; steam

condensers, condenser vacuum, sources of air leakage & its disadvantages.

Heat-Transfer: Modes of heat transfer; one dimensional heat conduction,

resistance concept, electrical analogy, unsteady heat conduction, fins;

dimensionless parameters in free and forced convective heat transfer,

various correlations for heat transfer in flow over flat plates and through

pipes; thermal boundary layer; effect of turbulence; radiative heat transfer,

black and grey surfaces, shape factors, network analysis; heat exchanger

performance, LMTD and NTU methods.

Fluid Mechanics: Fluid properties; fluid statics, manometry, buoyancy;

control-volume analysis of mass, momentum and energy; fluid acceleration;

differential equations of continuity and momentum; Bernoullis equation;

viscous flow of incompressible fluids; boundary layer; elementary turbulent

flow; flow through pipes, head losses in pipes, bends etc.

Vibrations: Free and forced vibration of single degree of freedom systems;

effect of damping; harmonically excited and transient vibrations;

introduction to multi-degree of freedom systems; vibration isolation;

resonance, critical speeds of shafts.

Design: Design for static and dynamic loading; failure theories; fatigue

strength and the S-N diagram; principles of the design of machine elements

such as bolted, riveted and welded joints, shafts, spur gears, rolling and

sliding contact bearings, keys, couplings, brakes and clutches; Selection of

Materials.

Fluid Machines: Pelton, Francis, propeller and Kaplan turbines; performance

characteristics and governing of hydraulic turbines; introduction to Deriaz

and Bulb turbines; selection of turbines; Centrifugal & axial pumps and fans,

reciprocating pumps.

Joining: Chemistry of welding, design of welding joints, pre- and post-heat

treatment of welded joints; brazing and soldering; adhesive bonding.

Machining and Machine Tool Operations: Mechanics of metal cutting and chip

formation, single and multi-point cutting tools, tool geometry and materials,

tool life and wear; principles of non-conventional machining processes;

principles of work clamping, principles of design of jigs and fixtures.

Metrology and Inspection: Limits, fits and tolerances; linear and angular

measurements; comparators; gauge design; interferometry; form and finish

measurement; alignment and testing methods; tolerance analysis in

manufacturing and assembly.

Computer Integrated Manufacturing: Basic concepts of CAD/CAM and their

integration tools. 16. Production Planning and Control: Forecasting models,

aggregate production planning, scheduling, materials requirement planning.

Inventory Control: Deterministic and probabilistic models; safety stock

inventory control systems, economic order quantity.

Operations Research: Linear programming, simplex and duplex method,

transportation, assignment, network flow models, simple queuing models,

PERT and CPM.

Product Design and Development: Principles of good product design,

tolerance design; quality and cost considerations; product life cycle;

standardization, simplification, diversification, value engineering and

analysis, concurrent engineering.

Industrial Safety: Introduction, types of accidents, causes and common

sources of accidents, methods of safety, first aid.

Engineering Economy and Costing: Elementary cost accounting and methods

of depreciation; break-even analysis, techniques for evaluation of capital

investments, financial statements.

Management Information System: Value of information; information storage

and retrieval system database and data structures; knowledge based

systems.

You might also like

- Pipe Bridge DesignDocument2 pagesPipe Bridge DesignerickquintoNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Proceedings IPW11Document568 pagesProceedings IPW11Pablo BenitezNo ratings yet

- Principle Stress ExamplesDocument36 pagesPrinciple Stress ExamplesPaldexNo ratings yet

- Discipline: Mechanical EngineeringDocument3 pagesDiscipline: Mechanical EngineeringAshish TanwarNo ratings yet

- Mechanical Engineering Syllabus 2 Recruitment of Officers 24-25Document3 pagesMechanical Engineering Syllabus 2 Recruitment of Officers 24-25ttv 27 ttv 27No ratings yet

- Syllabus For Mechanical Engineer 30082022Document3 pagesSyllabus For Mechanical Engineer 30082022Swaraj SinghNo ratings yet

- Gate Mechanical Engineering SyllabusDocument3 pagesGate Mechanical Engineering SyllabusNikhil JoshiNo ratings yet

- GATE 2019 Syllabus For ME (Gatepsu - In)Document5 pagesGATE 2019 Syllabus For ME (Gatepsu - In)Rupesh kashyapNo ratings yet

- MMRCDocument2 pagesMMRCLaxman KadamNo ratings yet

- Mechanical Engineering Syllabus 141023Document3 pagesMechanical Engineering Syllabus 141023rishi.manglik.me.2018No ratings yet

- Syllabus For Mechanical Engg 090623Document3 pagesSyllabus For Mechanical Engg 090623mnnitplacement2023No ratings yet

- Gate Syllabus For Mechanical EngineeringDocument3 pagesGate Syllabus For Mechanical EngineeringPhani ShankarNo ratings yet

- ME Mechanical EngineeringDocument3 pagesME Mechanical EngineeringLocky ChristinNo ratings yet

- General Aptitude (Ga) :: Engineering MathematicsDocument3 pagesGeneral Aptitude (Ga) :: Engineering MathematicsreddygjNo ratings yet

- Drdo Syllabus MechanicalDocument2 pagesDrdo Syllabus MechanicalArvind SinghNo ratings yet

- GATE 2014: Graduate Aptitude Test in Engineering 2014Document2 pagesGATE 2014: Graduate Aptitude Test in Engineering 2014Akash Kumar DevNo ratings yet

- Mech Gate SyllabusDocument2 pagesMech Gate SyllabuscpprodNo ratings yet

- Syllabus of HPCLDocument12 pagesSyllabus of HPCLAniketNo ratings yet

- Part - 1: ThermodynamicsDocument8 pagesPart - 1: ThermodynamicsparveenmeNo ratings yet

- Mechanical Gate SyllabusDocument2 pagesMechanical Gate SyllabusmicmechNo ratings yet

- Gate Syllbus MeDocument3 pagesGate Syllbus Mesameersaurabh5No ratings yet

- Mechanical Engineering (GATE 2020)Document2 pagesMechanical Engineering (GATE 2020)Murali DharanNo ratings yet

- Fluid Mechanics: Mechanical EngineeringDocument5 pagesFluid Mechanics: Mechanical EngineeringErin BarryNo ratings yet

- Gate SyllabusDocument3 pagesGate SyllabusPARTH PATELNo ratings yet

- GATE Mechanical Engineering (ME) SyllabusDocument4 pagesGATE Mechanical Engineering (ME) SyllabusCyril JasonNo ratings yet

- Syllabus For Mechanical Engineering (Me) : Linear AlgebraDocument4 pagesSyllabus For Mechanical Engineering (Me) : Linear Algebrachauhan.nutanNo ratings yet

- GATE Syllabus For Mechnical Engineering - ME Engineering MathematicsDocument2 pagesGATE Syllabus For Mechnical Engineering - ME Engineering MathematicsHusain K.N.No ratings yet

- GATE Mechanical EngineeringDocument3 pagesGATE Mechanical EngineeringstudyurselfNo ratings yet

- Mechanical-Engineering Gate2016.InfoDocument3 pagesMechanical-Engineering Gate2016.InfoHenryNo ratings yet

- Syllabus For Mechanical Engineering (ME)Document3 pagesSyllabus For Mechanical Engineering (ME)UpendraChaudhariNo ratings yet

- Syllabus Inspector Factories Boilers (Factories & Boilers Deptt)Document2 pagesSyllabus Inspector Factories Boilers (Factories & Boilers Deptt)mittalnipun2009No ratings yet

- Engineering Mathematics: Linear AlgebraDocument3 pagesEngineering Mathematics: Linear AlgebraSai KrishnaNo ratings yet

- Mechanical Engineering (ME) : PGECET-2014Document3 pagesMechanical Engineering (ME) : PGECET-2014swaroop24x7No ratings yet

- GATE 2014: Syllabus For Mechanical Engineering (ME)Document3 pagesGATE 2014: Syllabus For Mechanical Engineering (ME)javed alamNo ratings yet

- Syllabus M. TECH. ENTRANCE TEST-2018-19 Mechanical Engineering Department Jamia Milla Islamia, New DelhiDocument2 pagesSyllabus M. TECH. ENTRANCE TEST-2018-19 Mechanical Engineering Department Jamia Milla Islamia, New DelhiAbid YusufNo ratings yet

- TS PGECET Mechanical Engineering (ME) Exam Syllabus & PatternDocument3 pagesTS PGECET Mechanical Engineering (ME) Exam Syllabus & PatternpavaniNo ratings yet

- Gate+ Ese Combined Syllabus: Section 2: Applied Mechanics and DesignDocument4 pagesGate+ Ese Combined Syllabus: Section 2: Applied Mechanics and Designgopal dasNo ratings yet

- Gate SyllDocument3 pagesGate Syllalways23100% (2)

- Gate Syl 2010Document3 pagesGate Syl 2010api-3846488No ratings yet

- MECHANICAL Engineering (ME)Document2 pagesMECHANICAL Engineering (ME)sanyasirao1No ratings yet

- Gate Me Syllabus 2014Document4 pagesGate Me Syllabus 2014Hittendra SinghNo ratings yet

- GateDocument3 pagesGatesaurabhsubhuNo ratings yet

- Gate Engineering SyllabusDocument2 pagesGate Engineering SyllabusKarthick VenkateshNo ratings yet

- North Maharashtra University, Jalgaon Syllabus For Paper Ii of Course Work Examination For PHD in Mechanical EngineeringDocument3 pagesNorth Maharashtra University, Jalgaon Syllabus For Paper Ii of Course Work Examination For PHD in Mechanical EngineeringAkshayNo ratings yet

- Indicative Syllabus of Mechanical EngineeringDocument4 pagesIndicative Syllabus of Mechanical EngineeringSuryesh PathakNo ratings yet

- GATE Mechanical EngineeringDocument3 pagesGATE Mechanical EngineeringShiron K JohnsonNo ratings yet

- Gate-Me-2023, V-IDocument418 pagesGate-Me-2023, V-Iyash guptaNo ratings yet

- Syllabus For Mechanical Engineering (ME) - GATE 2013Document3 pagesSyllabus For Mechanical Engineering (ME) - GATE 2013Arun Anand A PNo ratings yet

- Mechanics of Materials: Stress and Strain, Elastic Constants, Poisson's Ratio Mohr's Circle For PlaneDocument3 pagesMechanics of Materials: Stress and Strain, Elastic Constants, Poisson's Ratio Mohr's Circle For PlanescNo ratings yet

- Join Us On Telegram @truelyengineers Click Here: Section 1: Engineering MathematicsDocument2 pagesJoin Us On Telegram @truelyengineers Click Here: Section 1: Engineering Mathematicsmanoj thiwariNo ratings yet

- Mechanical Engineering PaperDocument3 pagesMechanical Engineering PaperAkshay JoshiNo ratings yet

- Gate 2012 Me SyllabusDocument2 pagesGate 2012 Me SyllabusDeepak KushwahaNo ratings yet

- Mechanical Gate 2013 Mechanical SyllabusDocument4 pagesMechanical Gate 2013 Mechanical SyllabusVp SinghNo ratings yet

- Mechanical Engineering Paper-I: (For Both Objective and Conventional Type PapersDocument5 pagesMechanical Engineering Paper-I: (For Both Objective and Conventional Type PapersSachin KalsiNo ratings yet

- Me - Mechanical EngineeringDocument3 pagesMe - Mechanical EngineeringnabemduNo ratings yet

- Mechanical Engineering Paper: 1. ThermodynamicsDocument3 pagesMechanical Engineering Paper: 1. Thermodynamicsjithinaravind007No ratings yet

- Gate 2012 Mechanical Engineering (ME) Syllabus Engineering Mathematics Maths Linear AlgebraDocument4 pagesGate 2012 Mechanical Engineering (ME) Syllabus Engineering Mathematics Maths Linear AlgebraPrem KumarNo ratings yet

- GATE 2014: Syllabus For Mechanical Engineering (ME)Document5 pagesGATE 2014: Syllabus For Mechanical Engineering (ME)Swapnil Singh SolankiNo ratings yet

- Forest Product EngineeringDocument93 pagesForest Product EngineeringHonie Liane Tagose VillamorNo ratings yet

- Cie 136Document151 pagesCie 136Sancho BilogNo ratings yet

- CH 9.3Document39 pagesCH 9.3Rammiris ManNo ratings yet

- Chemical Anchor Technical Handbook 072008Document89 pagesChemical Anchor Technical Handbook 072008amadhubalanNo ratings yet

- Steel ReviewerDocument242 pagesSteel ReviewerKrishia Mae SarabiaNo ratings yet

- TS 500 English VersionDocument82 pagesTS 500 English VersionArman Malekloo50% (6)

- Response of Tall Building G 21 Under SeiDocument6 pagesResponse of Tall Building G 21 Under Seiamlan jyoti ChakravortyNo ratings yet

- Asme Code BPVC 2017 Pdfs S3-D1-AppDocument647 pagesAsme Code BPVC 2017 Pdfs S3-D1-App노진환No ratings yet

- Analysis of Bending Stress at Root of The Spur Gear by Finite Element MethodDocument5 pagesAnalysis of Bending Stress at Root of The Spur Gear by Finite Element MethodAnil PatilNo ratings yet

- Experimental Validation of Replaceable Shear Links For Eccentrically Braced Steel FramesDocument12 pagesExperimental Validation of Replaceable Shear Links For Eccentrically Braced Steel FramesAhmad FauzanNo ratings yet

- Conveyor Belt IdlersDocument12 pagesConveyor Belt IdlersStefan IstratescuNo ratings yet

- Mechanics of Deformable Bodies I Lecture Notes Lecture 1Document54 pagesMechanics of Deformable Bodies I Lecture Notes Lecture 1Data StatsNo ratings yet

- Lab 1 Strength MEC424Document27 pagesLab 1 Strength MEC424doremon100% (1)

- Singly Reinforced BeamDocument3 pagesSingly Reinforced BeamriverieNo ratings yet

- Hose Handling Doc TKO AS3 2Document10 pagesHose Handling Doc TKO AS3 2Rhdh kldmkNo ratings yet

- Crane Runway Beam Design - Beam Section Check Using CSA S16-14 Code-3Document4 pagesCrane Runway Beam Design - Beam Section Check Using CSA S16-14 Code-3sergiooiNo ratings yet

- M.tech - Se - FT - 2015-16-1Document37 pagesM.tech - Se - FT - 2015-16-1swastikNo ratings yet

- Analytical Study of End-Plate Connection On CrucifDocument6 pagesAnalytical Study of End-Plate Connection On CrucifMohamed GamalNo ratings yet

- 4.2b SB2 UC CheckDocument3 pages4.2b SB2 UC CheckBQ HeNo ratings yet

- Shaftings: Cebu Institute of Technology - UniversityDocument29 pagesShaftings: Cebu Institute of Technology - UniversityRenniel DingcongNo ratings yet

- Me Automation & Robotics SyllabusDocument27 pagesMe Automation & Robotics SyllabusweenniiNo ratings yet

- 1219 - Offshore Foundation Design - 2 Pile - A1Document138 pages1219 - Offshore Foundation Design - 2 Pile - A1naseebNo ratings yet

- APC of RC Building by Non-Linear Static AnalysisDocument46 pagesAPC of RC Building by Non-Linear Static AnalysisMuhannad AbdulRaoufNo ratings yet

- J. N. Reddy - 1980 - A Penalty Plate Bending Element For The Analysis of Laminated Anisotropic Composite PlatesDocument20 pagesJ. N. Reddy - 1980 - A Penalty Plate Bending Element For The Analysis of Laminated Anisotropic Composite PlatesSevim GüçlüNo ratings yet

- Mechanical and Human Reliability: 7243 - C006.fm Page 65 Friday, February 3, 2006 2:21 PMDocument21 pagesMechanical and Human Reliability: 7243 - C006.fm Page 65 Friday, February 3, 2006 2:21 PMDanangSetiawanNo ratings yet

- Scale RC-3.5 M Concrete BeamDocument5 pagesScale RC-3.5 M Concrete BeamfNo ratings yet

- Development Length & Splices of ReinforcementDocument19 pagesDevelopment Length & Splices of ReinforcementAshraf ZayedNo ratings yet