Lecture4 - Power Density in Welding

Lecture4 - Power Density in Welding

Uploaded by

Zundali FirdausCopyright:

Available Formats

Lecture4 - Power Density in Welding

Lecture4 - Power Density in Welding

Uploaded by

Zundali FirdausOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Lecture4 - Power Density in Welding

Lecture4 - Power Density in Welding

Uploaded by

Zundali FirdausCopyright:

Available Formats

Lecture: 4

Power density and welding process

In this chapter, energy density and temperature associated with different welding

processes have been presented. Further, the influence of energy density on the

performance parameters of the weld joints has also been described.

Keywords: Power density, temperature of heat source, heat input, distortion,

mechanical properties

4.1

Introduction

Fusion welding processes can be looked into on the basis of range of energy density

which they can apply for melting the faying surfaces of base metal for joining. Heat

required for fusion of faying surfaces of components being welded comes from

different sources in different fusion welding processes (gas, arc and high energy

beam). Each type of heat source has capability to supply heat at different energy

densities (kW/mm2). Even for a given arc power (arc current I X arc voltage V),

different welding processes provide heat at different energy densities due to the fact

that it is applied over different areas on the surface of base metal in case of different

processes. Energy density (kW/mm2) is directly governed by the area over which

heat is applied by a particular process besides welding parameters. Power density in

ascending order from gas welding to arc welding to energy beam based welding

processes is shown in table 4.1. Typical values of energy densities and approximate

maximum temperature generated during welding by different processes are shown in

Table 4.1.

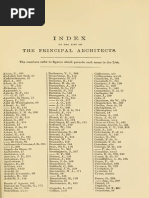

Table 4.1 Heat intensity and maximum temperature related with different

welding processes

Sr. No.

Welding process

Heat density (W/cm2) Temperature (0C)

Gas welding

102 -103

2500-3500

Shielded meta arc welding

104

>6000

Gas metal arc welding

105

8000-10000

Plasma arc welding

106

15000-30000

Electron beam welding

107 -108

Laser beam welding

>10

20,000-30000

>30,000

4.2 Effect of power density

Energy density associated with a particular welding process directly affects amount

of heat required to be supplied for fusion of the faying surfaces. An increase in power

density decreases the heat input required for melting and welding of work pieces

because it decreases time over which heat is to be applied during welding for

melting. The decrease in heat application time in turn lowers the amount of heat

dissipated away from the faying surfaces to the base metal so the most of the heat

applied on the faying surfaces is used for their fusion only. However, it is important to

note that heat required for melting the unit quantity of a given metal is constant and

is a property of material. Heat for melting comprises sensible heat and latent heat.

Latent heat for steel is 2 kJ/mm3.

Fusion welding processes are based on localized melting using high-density heat

energy. To ensure melting of base metal in short time it is necessary that energy

density of welding process is high enough (Fig. 4.1). Time to melt the base metal is

found inversely proportional to the power density of heat source i.e. power of (arc or

flame) / area of work piece over which it is applied (W/cm2). Lower the energy

density of heat source greater will be the heat input needed for fusion of faying

surface welding as a large amount of heat is dissipated to colder base material of

work piece away from the faying surface by thermal conduction (Fig. 4.2).

Fig. 4.1 Effect of energy density and time on energy input

Heat input to workpiece

increasing

Increasingthermal

damagedamage

to

workprices

to workpiece

Gas

welding

Arc

welding

High energy

beam welding

Increasing penetration,

welding speed, weld

quality and equipment

cost

Power density of heat source

Fig. 4.2 Effect of power density of heat source on heat input required for welding

[Kou S, 2003]

4.3

Need of optimum power density of welding process

As stated, low power density processes need higher heat input than high power

density processes. Neither too low nor too high heat input is considered good for

developing a sound weld joint. As low heat input can lead to lack of penetration and

poor fusion of faying surfaces during welding while excessive heat input may cause

damage to the base metal in terms of distortion, softening of HAZ and reduced

mechanical properties (Fig. 4.3). High heat input has been reported to lower the

tensile strength of many aluminium alloys of commercial importance due to thermal

softening of HAZ and development of undesirable metallurgical properties of the

weldment (Fig. 4.4). Moreover, use of high power density offers many advantages

such as deep penetration, high welding speed and improved quality of welding joints.

Welding process (where melting is required) should have power density

approximately 10(W/mm2). Vaporization of metal takes place at about 10,000W/mm2

power-density. Processes (electron and laser beam) with such high energy density

are used in controlled removal of metal for shaping of difficult to machine metals.

Welding processes with power density in ascending order are shown in Fig. 4.5.

Distortion (degree)

GTAW

6

EBW

20

10

30

40

Thickness (mm)

Fig. 4.3 Effect of welding process on angular distortion of weld joint as a function of

plate thickness[Kou S, 2003]

Tensile strength

Al-Mg-Si

Al-Cu-Mg

Al-Mg-Si

Heat input

Fig. 4.4 Schematic diagram showing effect of heat input on tensile strength of

aluminium alloy weld joints (magnfication of micrograph in figure is 200 X) [Kou S,

2003]

EBW

LBW

PAW

GMAW

SMAW

GW

Fig. 4.5 Power densities of different welding processes

References and books for further reading

Welding handbook, American Welding Society, 1983, 7th edition, volume 1 &

2, USA.

Sindo Kou, Welding metallurgy, John Willey, 2003, 2nd edition, USA.

S V Nadkarni, Modern Arc Welding Technology, Ador Welding Limited, 2010,

New Delhi.

http://www6.conestogac.on.ca/~ffulkerson/MANU1060_files/solutions_ch31.pdf

http://eagar.mit.edu/EagarPapers/Eagar061.pdf

You might also like

- Astm B16-B16M-05Document5 pagesAstm B16-B16M-05reza acbariNo ratings yet

- S126 - PPT - Safe Welding, Grinding and Cutting Awareness - Rev 01 2Document42 pagesS126 - PPT - Safe Welding, Grinding and Cutting Awareness - Rev 01 2Aisha Khan100% (1)

- Sheetpile Handbook ch3 PDFDocument18 pagesSheetpile Handbook ch3 PDFTarek HareedyNo ratings yet

- Charles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelDocument66 pagesCharles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelAlarmakNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + S31803)Document7 pagesPurchase Spec. For Plates-Weld Overlay (CS + S31803)Daison PaulNo ratings yet

- PEH3-12 - Q3 - Mod2 - Energy-System - (Dance Activities) - Version3Document15 pagesPEH3-12 - Q3 - Mod2 - Energy-System - (Dance Activities) - Version3mark david sabella75% (8)

- LipidsDocument60 pagesLipidsEuneun Bustamante100% (1)

- JIS - G - 3507-1 - Carbon Steels For Cold Heading - Part 1 Wire RodsDocument18 pagesJIS - G - 3507-1 - Carbon Steels For Cold Heading - Part 1 Wire Rodsjijith njNo ratings yet

- E 643-84 - E517-00 - Standard Test Method For Ball Punch TestDocument4 pagesE 643-84 - E517-00 - Standard Test Method For Ball Punch TestAgustin AlonsoNo ratings yet

- BS en - 1011 1 2009Document12 pagesBS en - 1011 1 2009Paco0% (1)

- NF en 10056-2Document3 pagesNF en 10056-2VijitKumarPrasadNo ratings yet

- BS en 10149-2-1996Document12 pagesBS en 10149-2-1996Snezana Vulovic0% (1)

- Steel Industry Fact SheetDocument4 pagesSteel Industry Fact SheetYbonnie Mae T. LAPINIGNo ratings yet

- Bolts BS4190 PDFDocument30 pagesBolts BS4190 PDFmecjaviNo ratings yet

- Iso 6507 4 2018 en PDFDocument11 pagesIso 6507 4 2018 en PDFkhkim118No ratings yet

- En 20898-1 (Iso 898-1) (Ex Uni 3740-3) Caratteristiche Meccaniche Degli Elementi Di Collegamento Viti e Viti PrigioniereDocument7 pagesEn 20898-1 (Iso 898-1) (Ex Uni 3740-3) Caratteristiche Meccaniche Degli Elementi Di Collegamento Viti e Viti Prigionierearmando2380% (1)

- Iso 16834Document19 pagesIso 16834getatodicaNo ratings yet

- En (1179)Document1 pageEn (1179)reacharunkNo ratings yet

- Cen TR 14633 (E)Document9 pagesCen TR 14633 (E)consssNo ratings yet

- Iso 9956 1Document19 pagesIso 9956 1vignesh balamuthuNo ratings yet

- Din en 10219-2Document38 pagesDin en 10219-2Leonardo FerreiraNo ratings yet

- Iso 4063 2023Document11 pagesIso 4063 2023erhan ertürkNo ratings yet

- DIN EN 10025-2: Hot Rolled Products of Structural SteelsDocument34 pagesDIN EN 10025-2: Hot Rolled Products of Structural SteelsaldairlopesNo ratings yet

- BS EN 4050-4 2012Document10 pagesBS EN 4050-4 2012HMM-techNo ratings yet

- 2713 1T3 PDFDocument34 pages2713 1T3 PDFJitendra Mahida100% (2)

- Iso 18275-2005Document34 pagesIso 18275-2005RaajNo ratings yet

- BS Iso 23208-2017Document16 pagesBS Iso 23208-2017Orcun Yildiz100% (1)

- Is 2062 - 2006 - Hot Rolled Low, Medium and High Tensile Structural Steel PDFDocument13 pagesIs 2062 - 2006 - Hot Rolled Low, Medium and High Tensile Structural Steel PDFThenna Arasu100% (1)

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDocument8 pagesWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesNo ratings yet

- Automatic Measurement of Centreline Segregation in Continuously Cast Line Pipe Steel SlabsDocument8 pagesAutomatic Measurement of Centreline Segregation in Continuously Cast Line Pipe Steel SlabsHenrique severiano de jesusNo ratings yet

- BS709 1983Document17 pagesBS709 1983Sang SekNo ratings yet

- WPQR SBM 029Document3 pagesWPQR SBM 029HoJienHauNo ratings yet

- E-570 Flujo DispersoDocument7 pagesE-570 Flujo DispersoAriel TerrensNo ratings yet

- En 875-Impact TestDocument14 pagesEn 875-Impact TestMadley RockNo ratings yet

- BS Au 050-1.6.1C-2002 (Iso 5751-1-2001) PDFDocument22 pagesBS Au 050-1.6.1C-2002 (Iso 5751-1-2001) PDFamerNo ratings yet

- BS en 1011-5-2003Document14 pagesBS en 1011-5-2003pham khietNo ratings yet

- Is 14394 1996 PDFDocument10 pagesIs 14394 1996 PDFSantosh KumarNo ratings yet

- 109.8181.MPI - Pre.Unit.730395.Cover RadiatorDocument2 pages109.8181.MPI - Pre.Unit.730395.Cover RadiatorHerr Ddiman100% (1)

- Australian Standard: Welding, Brazing and Cutting of Metals - Glossary of TermsDocument6 pagesAustralian Standard: Welding, Brazing and Cutting of Metals - Glossary of TermsBá Lĩnh0% (1)

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulNo ratings yet

- Steel Ss41p Jis g3101Document7 pagesSteel Ss41p Jis g3101mahmoud_allam3No ratings yet

- BSI 709 DT Fusion WeldedDocument24 pagesBSI 709 DT Fusion WeldedbonnicoNo ratings yet

- Tehnička Keramika PDFDocument215 pagesTehnička Keramika PDFRafija SoftićNo ratings yet

- Tolerante en 10029Document1 pageTolerante en 10029r3loop100% (1)

- 021 - Final Inspection ReleaseDocument1 page021 - Final Inspection ReleaseDelil Ozan100% (1)

- DIN 18800-7 Antrag EnglDocument9 pagesDIN 18800-7 Antrag Englgorgika papandNo ratings yet

- Preparation of Steel Substrates Before Application of Paints and Related Products Specifications For Non-Metallic Blast-Cleaning AbrasivesDocument12 pagesPreparation of Steel Substrates Before Application of Paints and Related Products Specifications For Non-Metallic Blast-Cleaning AbrasivesHossam EssawyNo ratings yet

- BS en 10052 94 PDFDocument35 pagesBS en 10052 94 PDFAshraf TomizehNo ratings yet

- BS en 758-97 PDFDocument16 pagesBS en 758-97 PDFAhmet Memiş100% (1)

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- ManufProc 6 JoiningAssemblyDocument118 pagesManufProc 6 JoiningAssemblyHannan yusuf KhanNo ratings yet

- Induction Surface HardeningDocument10 pagesInduction Surface HardeningSebastián Andrés Rojas MontielNo ratings yet

- Heat FlowDocument21 pagesHeat FlowSiddharth ShahNo ratings yet

- Titipan ZahraDocument7 pagesTitipan ZahraDikaAfriandiNo ratings yet

- Induction Heating: From Wikipedia, The Free EncyclopediaDocument4 pagesInduction Heating: From Wikipedia, The Free EncyclopediajerryakilaNo ratings yet

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDocument8 pagesStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelIJMERNo ratings yet

- Heat Balance in Fusion WeldingDocument12 pagesHeat Balance in Fusion Weldingpuwarin najaNo ratings yet

- Effects of Arc Voltage and Welding Current On The Arc Length of Tungsten Inert Gas Welding (TIG)Document9 pagesEffects of Arc Voltage and Welding Current On The Arc Length of Tungsten Inert Gas Welding (TIG)emtedadNo ratings yet

- Induction Heating Tecnology - VerDocument8 pagesInduction Heating Tecnology - Verdenivaldo2009No ratings yet

- 2022 S5 ME MFG S - Welding IntroDocument109 pages2022 S5 ME MFG S - Welding IntroTom TambeNo ratings yet

- Fundamentals of Friction Stir Welding, Its Application, and AdvancementsDocument50 pagesFundamentals of Friction Stir Welding, Its Application, and Advancementsjose ramirez cruzNo ratings yet

- List of MaterialDocument4 pagesList of MaterialZundali FirdausNo ratings yet

- Welcome To The Discrete-Event Simulation Training Module: Self-Learning Anyone Developing A Training ProgramDocument34 pagesWelcome To The Discrete-Event Simulation Training Module: Self-Learning Anyone Developing A Training ProgramZundali FirdausNo ratings yet

- Pen Rchive Oulouse Rchive Uverte : O A T A O OataoDocument14 pagesPen Rchive Oulouse Rchive Uverte : O A T A O OataoZundali FirdausNo ratings yet

- Curriculum For The Master of Science in Mechanical EngineeringDocument1 pageCurriculum For The Master of Science in Mechanical EngineeringZundali FirdausNo ratings yet

- Ankit SaxenaDocument3 pagesAnkit Saxenaankitsaxena123No ratings yet

- BTD 18ME33 - Dec 2018-Jan 2019Document3 pagesBTD 18ME33 - Dec 2018-Jan 2019RaviparasheraNo ratings yet

- Directive 94/9/EC: Guidance On CE Marking For ProfessionalsDocument16 pagesDirective 94/9/EC: Guidance On CE Marking For ProfessionalsDan SbarceaNo ratings yet

- Raw Mix Design CementDocument4 pagesRaw Mix Design Cementtariqshah100% (1)

- VIE WorkingDocument3 pagesVIE WorkinghmnnhgczdmNo ratings yet

- Accc/Tw Lisbon (310) : Data SheetDocument1 pageAccc/Tw Lisbon (310) : Data SheetkmiqdNo ratings yet

- A Simplified Model For Real Gas Expansion Between Two Reservoirs Connected by A Thin TubeDocument14 pagesA Simplified Model For Real Gas Expansion Between Two Reservoirs Connected by A Thin TubeSatyanarayan SahooNo ratings yet

- Mathematical Modelling of Forest Fires Propagation Taking Account of The FirebreaksDocument7 pagesMathematical Modelling of Forest Fires Propagation Taking Account of The FirebreaksSEP-PublisherNo ratings yet

- SCR Brochure - 2012 11 28Document2 pagesSCR Brochure - 2012 11 28Jorge Luis Tanaka ConchaNo ratings yet

- Zone RefiningDocument21 pagesZone RefiningHảo Vũ ĐứcNo ratings yet

- Literature Review On Reverse OsmosisDocument8 pagesLiterature Review On Reverse Osmosisc5rjgvg7100% (1)

- D3 2019 396652 BibliographyDocument2 pagesD3 2019 396652 Bibliographydwi kuntoroNo ratings yet

- 1st PU Chemistry May 2015 PDFDocument2 pages1st PU Chemistry May 2015 PDFPrasad C M69% (16)

- C#&,3#/#0 (W%A# (E&A (4 %'S, (W%A# (E&A (: Fqzpi (DJG FQZPP (DJG (Document19 pagesC#&,3#/#0 (W%A# (E&A (4 %'S, (W%A# (E&A (: Fqzpi (DJG FQZPP (DJG (MohammadNo ratings yet

- SoapDocument24 pagesSoapDebraj DattaNo ratings yet

- Lab 1 Measurment in ChemistryDocument7 pagesLab 1 Measurment in ChemistryAmanda WilliamsNo ratings yet

- Improved Recovery: Membrane PurificationDocument2 pagesImproved Recovery: Membrane PurificationAjgaj1No ratings yet

- ASRB-NETMockTest1byDr EetelaSathyanarayanaDocument4 pagesASRB-NETMockTest1byDr EetelaSathyanarayanaRohit Kumar ChoudhuryNo ratings yet

- Victaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsDocument2 pagesVictaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsRobson Custódio de SouzaNo ratings yet

- Sikaflex-403-Tanksilo - Joint Sealing CompoundDocument5 pagesSikaflex-403-Tanksilo - Joint Sealing CompoundtinashemambarizaNo ratings yet

- E ST SG AC.10 11 Rev6 WEB - With Corrections From Corr.1 PDFDocument512 pagesE ST SG AC.10 11 Rev6 WEB - With Corrections From Corr.1 PDFLola BenitesNo ratings yet

- OLYMPIA - WatersoftenerDocument4 pagesOLYMPIA - WatersoftenerBudiNo ratings yet

- 4 Carbon and Its Compounds NCERT Hack (Prashant Kirad)Document21 pages4 Carbon and Its Compounds NCERT Hack (Prashant Kirad)kigid55721No ratings yet

- Lab #2 - AlcoholsDocument2 pagesLab #2 - Alcoholstassiahenry11No ratings yet

- The Ability of Yeast To Ferment Different Sugars: Fermentation Lab ReportDocument5 pagesThe Ability of Yeast To Ferment Different Sugars: Fermentation Lab ReportIan MullenNo ratings yet

- MSEE02: RamaiahDocument2 pagesMSEE02: Ramaiahhari krishnaNo ratings yet

- (PC - 373) Cera Seal Primer Edition 2022Document2 pages(PC - 373) Cera Seal Primer Edition 2022Sivamurugan SivanayagamNo ratings yet