Appendix A - Quality Procedure

Appendix A - Quality Procedure

Uploaded by

Khalid SulehriCopyright:

Available Formats

Appendix A - Quality Procedure

Appendix A - Quality Procedure

Uploaded by

Khalid SulehriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Appendix A - Quality Procedure

Appendix A - Quality Procedure

Uploaded by

Khalid SulehriCopyright:

Available Formats

APPENDIX A

QUALITY PROCEDURE

No. PROCEDURE

INSPECTION OR TEST TO

BE CARRIED OUT

INSPECTION OR TEST

POINT / STAGE

ACEPTANCE QUALITY

CRITERIA

RESPNOSIBILTY FOR

THE TEST / INSPECTION

Check supplier dockets for

material specifications,

AS3700

Inspect on site and measure

for correct installation.,

AS3700

Inspect on site and measure

for correct installation.,

AS3700

Inspect on site and measure

for correct installation.,

AS3700

Check supplier dockets for

material specifications,

AS3700, AS3972

Check supplier dockets for

material specifications and

sand size

Inspect on site and measure

for correct installation.,

AS3700

Inspect on site and verify for

correct installation., AS3700

Bricklayer, Site Supervisor

TRADE - MASONRY

1

Check brick type, size and color are as

specified

Check for detail work such as sills, headers,

Banding, Corbelling, Stepouts, Soldier

courses, arches

Check reinforcing, anchors, vermin proofing

and ties

Visual Inspection, colour

matching with approved

sample

Visual Inspection, check

plans for opening size and

correct details

Visual Inspection, check

plans for correct details

Prior to laying bricks

Visual Inspection, check for

correct course type and

joint spacing

Visual Inspection, check

cement sacks for deatils

While brickwork in progress

and at completion

While brickwork in progress

and at completion

While brickwork in progress

and at completion

Bricklayer, Site Supervisor

Bricklayer, Site Supervisor

Bricklayer, Site Supervisor

Check mortar and joints per plans and specs

Check cement type for mortar

Check sand type and quality for mortar

Visual Inspection

While brickwork in progress

and at completion

Check that Joints are consistent in width

While brickwork in progress

and at completion

Check that built in flashings are installed

Visual Inspection, check for

correct course type and

joint spacing

Visual Inspection, check

plans for details

Check positioning and installation of expansion Visual Inspection, check

control joints

plans for details

While brickwork in progress Inspect on site and verify for Bricklayer, Site Supervisor

and at completion

correct installation., AS3700

10

Check for cleanly laid brickwork to ensure an

acceptable finish at the completion of the final

brick clean

While brickwork in progress Inspect on site and verify for Bricklayer, Site Supervisor

and at completion

correct installation., AS3700

Visual Inspection, staright

edge, plumb bob

While brickwork in progress

and at completion

While brickwork in progress

and at completion

Bricklayer, Site Supervisor

Bricklayer, Site Supervisor

Bricklayer, Site Supervisor

Bricklayer, Site Supervisor

TRADE - FRAMING

1

WALL FRAMES

Check that walls are located per Drawings

Measurements, drawing

compliance.

Check walls for straightness, plumb, and

Measurements, plumb,

square; correct size timber for studs and lintals level, visual.

Prior to framing work

commencing.

During installation is in

progress.

Check by measuring,verify Carpenter, Site Supervisor

layout from plans.

Check by measuring, using Carpenter, Site Supervisor

a straight edge and a level.

Visual ispection, compliance

with framing schedule.

Check lintal locations and sizes to ensure that Location, size.

they comply with framing codes

During installation is in

progress.

Check location and size

compliance with plans.

AS1684, BCA.

Check bracing sheet size, manufacturers

installation instructions, and nailing schedule

per code

During installation is in

progress.

Check window and door openings; dimensions, Size, location, line and

plumb, square. Ensure that openings have

level.

sufficient allowance to accommodate the

chosen windows and doors.

During installation is in

progress.

Check bracing comply with Carpenter, Site Supervisor

designrequirements, ensure

braces are correct and

within 30 to 60 degrees.

AS1684

Measure and check with

Carpenter, Site Supervisor

straight edge and level.

Check for square corners in critical areas;

kitchens, baths, and utility areas where

cabinets and benchtops are tops designed for

90 degree angles

Check measurements required for spaces

which cannot be altered such as Cabinets and

Vanities, Showers and Tubs or Built-in

Furniture

Check that walls have adequate temporary

bracing to maintain straightness and plumb

prior to loading trusses

Size, location, line and

level.

During installation is in

progress.

Location, type, number.

Size, location, line and

level.

Sturdiness, location, line

and level.

Carpenter, Site Supervisor

Measure and check with

Carpenter, Site Supervisor

straight edge and level.

Verify compliance with

plans.

During installation is in

Measure and check with

Carpenter, Site Supervisor

progress.

straight edge and level.

Verify compliance with

plans.

During installation is in

Visual inspection, check

Carpenter, Site Supervisor

progress. Prior to installing with straight edge and level.

trusses.

TRADE - ROOFING

1

ROOFING

Check Drawings and Specifications for type,

Colour, size.

color, size and manufacturer of roof coverings.

Locate all penetrations to the roof prior to

Location, size.

installation of roofing. Vents and flashing will

be provided by Plumbing and Heating

contractors and installed as per their layout

and are not the responsibility of the Roofing

contractor. Vents and flashing are usually

required for plumbing, wood stove or fireplace,

attic ventilation, wet area room fans.

Appendix A - Quality Procedure

Prior to roofing works

commencing.

Prior to roofing works

commencing.

Roofer, Site Supervisor

Roofer, Site Supervisor

Visual inspection,

compliance with

specifications and drawings,

approved sample, supplier

dockets.

Roofer, Site Supervisor

Visual inspection,

compliance with

specifications and drawings.

Verify locations.

Page of 2

APPENDIX A

QUALITY PROCEDURE

No. PROCEDURE

INSPECTION OR TEST TO

BE CARRIED OUT

Check metal drip edges at rakes or eaves if

required

Location, level.

Check manufacturers warranty for weather

exposure and nailing pattern, sealers,

membranes, cements, fasteners

Check roofing material for square,

straightness, color uniformity, no buckling or

cracks

Check roofing material fits tightly around all

stack vents and installed with flashing to shed

water.

Check nails are galvanized and not exposed to

weather unless special protection provided by

manufacturer or Trade Contractor

Documentation.

Check all debris removed from roof and site

Appendix A - Quality Procedure

INSPECTION OR TEST

POINT / STAGE

ACEPTANCE QUALITY

CRITERIA

RESPNOSIBILTY FOR

THE TEST / INSPECTION

During works, as soon as

installed.

Visual inspection. Verify

Roofer, Site Supervisor

locations and starightness

and plumb.

During works, prior to

Check supplier dockets and Roofer, Site Supervisor

installation and at delivery. complance certificates.

Correctness

During works, prior to

Check supplier dockets and Roofer, Site Supervisor

installation and at delivery. complance documentation.

Correctness

During works.

Material verfication.

During works. Prior to use. Check dockets and packing Roofer, Site Supervisor

for material specification,

visual inspection.

Visual

During works. Prior to

completion.

Verify workmanship, visual. Roofer, Site Supervisor

Visual inspection.

Roofer, Site Supervisor

Page of 2

You might also like

- 21001-Dy Mausoleum DD SetDocument8 pages21001-Dy Mausoleum DD SetJizzus100% (1)

- Method Statement For Door FrameDocument12 pagesMethod Statement For Door FrameMin Luo100% (5)

- Itp For Overhead Line Contruction WorksDocument8 pagesItp For Overhead Line Contruction Worksmatreng0% (2)

- Checklist For Curtain Wall & Glazing InstallationDocument1 pageChecklist For Curtain Wall & Glazing InstallationChristos Loutrakis100% (2)

- Method Statement For Welding PDFDocument8 pagesMethod Statement For Welding PDFpadmasree200286% (7)

- Aluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and MarkingDocument4 pagesAluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and Markinganbunilavan67% (3)

- CHECKLIST For Installation & Testing of Fire Fighting Pipe WorkDocument1 pageCHECKLIST For Installation & Testing of Fire Fighting Pipe WorkTHEOPHILUS ATO FLETCHER75% (4)

- CHECKLIST For Installation & Insulation of HVAC Duct WorkDocument1 pageCHECKLIST For Installation & Insulation of HVAC Duct WorkTHEOPHILUS ATO FLETCHER0% (1)

- CRSI - Field Inspection of Reinforcing BarsDocument8 pagesCRSI - Field Inspection of Reinforcing Barsgonzalo100% (1)

- PIPING FOREMAN Roles and ResponsibilitiesDocument1 pagePIPING FOREMAN Roles and ResponsibilitiesEM30 113 AslamAhammed100% (2)

- Method Statement DoorDocument2 pagesMethod Statement DoorAriel Orogo Papica50% (8)

- Firefighting Procedures Volume 1, Book 2 October 6, 2000: Ection Itle AGEDocument63 pagesFirefighting Procedures Volume 1, Book 2 October 6, 2000: Ection Itle AGEAdam ThimmigNo ratings yet

- Thumb Rules For Civil Engineers PDFDocument4 pagesThumb Rules For Civil Engineers PDFA KNo ratings yet

- Condition 43 - Roofing Compliance Installation Certification - Section J AMG PDFDocument1 pageCondition 43 - Roofing Compliance Installation Certification - Section J AMG PDFMoustafa IbrahimNo ratings yet

- Kitchen Snag ListDocument2 pagesKitchen Snag Listayan mitra100% (4)

- Lightning Protection Calculation SheetDocument133 pagesLightning Protection Calculation SheetEkoFujisyahMaulwanto50% (2)

- E-Design (R3 R4 R5) PDFDocument263 pagesE-Design (R3 R4 R5) PDFJaime PamintuanNo ratings yet

- Quality Method Statement For Quality Method Statement For Plasterboard PanelsDocument6 pagesQuality Method Statement For Quality Method Statement For Plasterboard PanelszmzhaviazNo ratings yet

- MOS Grills and DiffusersDocument5 pagesMOS Grills and Diffuserssuban hari kumar100% (1)

- Method Statement For Installation of Cable TrayRDocument2 pagesMethod Statement For Installation of Cable TrayRMariam Awad0% (1)

- 0.quality Check Point BriefDocument9 pages0.quality Check Point BriefTPAVANKUMARNo ratings yet

- Checklist For Door ShuttersDocument1 pageChecklist For Door Shutterssanket.sakpalNo ratings yet

- Method Statement For Installatioin of Grills, Diffusers, Registers & LouversDocument2 pagesMethod Statement For Installatioin of Grills, Diffusers, Registers & LouversDong Vanra0% (1)

- Rebar InspectionDocument3 pagesRebar InspectionSturuj100% (2)

- QCP Block Works Maged FawzyDocument5 pagesQCP Block Works Maged FawzyMaged FawzyNo ratings yet

- Methodology For Rebars InstallationDocument4 pagesMethodology For Rebars InstallationVector DesignsNo ratings yet

- Method Statement - MS PipingDocument13 pagesMethod Statement - MS PipingAnish KumarNo ratings yet

- Shell Plate Dimension CheckDocument7 pagesShell Plate Dimension Checksetak0% (1)

- Quality Systems Manual Method StatementDocument9 pagesQuality Systems Manual Method StatementLloyd MariNo ratings yet

- Falcon ChecklistDocument30 pagesFalcon Checklisttheclasse sriramNo ratings yet

- PLS150129-SBY-A-MST-AW-0001 V0.2 Door Window Louvres Installation Works PDFDocument16 pagesPLS150129-SBY-A-MST-AW-0001 V0.2 Door Window Louvres Installation Works PDFMohammad Hadoumi SaldanNo ratings yet

- QA Main ChecklistDocument5 pagesQA Main ChecklistbkgboqdraftsmanNo ratings yet

- KagogipizuzDocument3 pagesKagogipizuznemakondevhNo ratings yet

- Checklist For Door FrameDocument1 pageChecklist For Door Framesanket.sakpalNo ratings yet

- Method StatementDocument12 pagesMethod StatementCindy AmyzaNo ratings yet

- Methodology For Formworks InstallationDocument3 pagesMethodology For Formworks InstallationVector DesignsNo ratings yet

- Gypsum Board Installation To Wall (Drywall & Partitions)Document5 pagesGypsum Board Installation To Wall (Drywall & Partitions)xomilaaNo ratings yet

- FM QA 06 13 Curtain WallDocument1 pageFM QA 06 13 Curtain Wallengmohammedosama2014No ratings yet

- Inspection Test PlanDocument11 pagesInspection Test PlanJonathan PedreraNo ratings yet

- Field Inspection of RFTDocument8 pagesField Inspection of RFTHany Seif-Aldien NasserNo ratings yet

- Method StatementDocument13 pagesMethod StatementGrace tpplNo ratings yet

- Method Statement - Air Inlets & OutletsDocument11 pagesMethod Statement - Air Inlets & OutletsdedeerlandNo ratings yet

- 0012-wms For Wall & Floor TilesDocument7 pages0012-wms For Wall & Floor TilesRaman Bhadouria100% (1)

- Method Statement For ScaffoldingDocument3 pagesMethod Statement For Scaffoldingamg007100% (7)

- False Celling Check ListDocument2 pagesFalse Celling Check Listjohn paul100% (1)

- Achu Ajil A QAQC 24Document13 pagesAchu Ajil A QAQC 24qaqcNo ratings yet

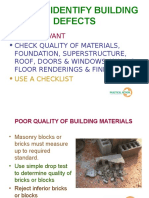

- How To Identify Building Defects: - Be ObservantDocument20 pagesHow To Identify Building Defects: - Be ObservantArslan RaoNo ratings yet

- MOS For Floor & Planter Wall Tiles Installatoin - SCBDDocument9 pagesMOS For Floor & Planter Wall Tiles Installatoin - SCBDIqbal HossainNo ratings yet

- Method Statement of Drywall Installation For Gypsum BoardsDocument7 pagesMethod Statement of Drywall Installation For Gypsum BoardsBassey Abasiene100% (1)

- Method Statement Gypsum BoardDocument6 pagesMethod Statement Gypsum Boardsajin100% (1)

- 7 Method Statement For Gypsum PartitionDocument9 pages7 Method Statement For Gypsum PartitionRachit AgarwalNo ratings yet

- Quality Method Statement For Galvanized Raised Floor System With Chipboard PanelsDocument5 pagesQuality Method Statement For Galvanized Raised Floor System With Chipboard PanelszmzhaviazNo ratings yet

- Method Statement - Drain PipingDocument17 pagesMethod Statement - Drain PipingAnish KumarNo ratings yet

- Method Statement For Ceramic Floor TileDocument10 pagesMethod Statement For Ceramic Floor Tileadeniyi abiolaNo ratings yet

- Inspection Methodology For Bulk - ItemsDocument8 pagesInspection Methodology For Bulk - Itemsprasad raikarNo ratings yet

- Inspection Methodology For Bulk - ItemsDocument8 pagesInspection Methodology For Bulk - Itemsprasad raikarNo ratings yet

- Method Statement On Grouted RiprapDocument3 pagesMethod Statement On Grouted RiprapHayle Dela CruzNo ratings yet

- Method Statement On As Thermoplastic Road MarkingsDocument7 pagesMethod Statement On As Thermoplastic Road MarkingsHayle Dela CruzNo ratings yet

- Mos - Ceiling Works With Metal FurringDocument6 pagesMos - Ceiling Works With Metal FurringMiguel BernabeNo ratings yet

- Installation, Testing - Flushing of Firefighting SystemDocument7 pagesInstallation, Testing - Flushing of Firefighting SystemWahid Husain100% (1)

- Fire Piping Installation and FlushingDocument7 pagesFire Piping Installation and Flushingsunny_84tNo ratings yet

- Installation, Testing & Flushing of Firefighting Piping SystemDocument5 pagesInstallation, Testing & Flushing of Firefighting Piping SystemJoy MalakNo ratings yet

- Construction Methodologies & Procedures for Civil Engineers - Part -1From EverandConstruction Methodologies & Procedures for Civil Engineers - Part -1No ratings yet

- The Complete Guide to Contracting Your Home: A Step-by-Step Method for Managing Home ConstructionFrom EverandThe Complete Guide to Contracting Your Home: A Step-by-Step Method for Managing Home ConstructionRating: 3.5 out of 5 stars3.5/5 (4)

- QUIZ 5-One Way SlabDocument1 pageQUIZ 5-One Way SlabMac KYNo ratings yet

- Structural Engineering Design Criteria: Appendix 10BDocument33 pagesStructural Engineering Design Criteria: Appendix 10BErnesto MarinNo ratings yet

- Module Title Construction Technology I Module Code Credits Prerequisites Module Aim(s)Document2 pagesModule Title Construction Technology I Module Code Credits Prerequisites Module Aim(s)LokuliyanaNNo ratings yet

- BOMA - Gross Areas of A Building Standard Methods of Measurement Appendix PDFDocument18 pagesBOMA - Gross Areas of A Building Standard Methods of Measurement Appendix PDFxavestNo ratings yet

- Seattle: Design GuidelinesDocument31 pagesSeattle: Design GuidelinesChs BlogNo ratings yet

- Segmental Box CulvertDocument5 pagesSegmental Box Culvertramudu oneNo ratings yet

- 1 - 1 Typcal Plinth Beam Section: Proposed Construction of Kyela District Hospital To Be Built at Kyela District MbeyaDocument1 page1 - 1 Typcal Plinth Beam Section: Proposed Construction of Kyela District Hospital To Be Built at Kyela District MbeyaamonbrightsonNo ratings yet

- QCS 2014 Section 1-1Document3 pagesQCS 2014 Section 1-1sahilNo ratings yet

- The Auditorium Space Types Are Areas For Large MeetingsDocument6 pagesThe Auditorium Space Types Are Areas For Large MeetingsChaitali Thakur100% (1)

- Analysis of Flat Slab Building With and Without Shear Wall PDFDocument9 pagesAnalysis of Flat Slab Building With and Without Shear Wall PDFvishalgoreNo ratings yet

- Plastic Piling From APE Plastic PilingDocument2 pagesPlastic Piling From APE Plastic PilingNguyen Thanh LuanNo ratings yet

- Construction of Barracks (2X20X12) For Security Guard at Kalabagh-1ADocument23 pagesConstruction of Barracks (2X20X12) For Security Guard at Kalabagh-1AAun Abbas SyedNo ratings yet

- Lattice Girders Designs@30Document4 pagesLattice Girders Designs@30Olawuni semiuNo ratings yet

- 001 - Vendor & MnufctrDocument22 pages001 - Vendor & Mnufctrmogbel1100% (1)

- Project (2645)Document29 pagesProject (2645)Namuna ChapagainNo ratings yet

- Framing Guidelines PDFDocument9 pagesFraming Guidelines PDFJase72HR100% (3)

- Duct Accessories - RevDocument5 pagesDuct Accessories - RevLuis Gabriel BautistaNo ratings yet

- Strengthening For RB3 Beam PDFDocument3 pagesStrengthening For RB3 Beam PDFbarbiesmilezNo ratings yet

- Three Case Studies: Moisture Control in A Hot, Humid ClimateDocument14 pagesThree Case Studies: Moisture Control in A Hot, Humid ClimateDineshroyal DineshNo ratings yet

- RA 9266 and PD 1096 ResearchDocument18 pagesRA 9266 and PD 1096 ResearchJin DanNo ratings yet

- Ashrae - 2009 I-P - F09 - AddDocument2 pagesAshrae - 2009 I-P - F09 - AddSergio SemmNo ratings yet

- Structural Glazing: Submitted To:-Submitted By: Ar. Gourav Agrawal Chhaya, Tanvi, Suraj, Prakash, SumanDocument19 pagesStructural Glazing: Submitted To:-Submitted By: Ar. Gourav Agrawal Chhaya, Tanvi, Suraj, Prakash, Sumanshreenu211204No ratings yet

- Repair and Retrofitting Manual Session 1Document47 pagesRepair and Retrofitting Manual Session 1Kirti Chandra JoshiNo ratings yet