Seamless Tubes Brochure

Seamless Tubes Brochure

Uploaded by

Nisarg PandyaCopyright:

Available Formats

Seamless Tubes Brochure

Seamless Tubes Brochure

Uploaded by

Nisarg PandyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Seamless Tubes Brochure

Seamless Tubes Brochure

Uploaded by

Nisarg PandyaCopyright:

Available Formats

Seamless Tubes Division

Core Values

Integrity

Conduct all business dealings along

transparent lines.

Respect for Individual

Recognise each individual's contribution in

the growth and development of the Company.

Treat all Jindalites with respect and dignity.

Meritocracy

Foster an environment of excellence in

performance.

Dynamic Thinking

Demonstrate a winner's attitude with a crystal

clear focus to deliver sustained value for all

Stakeholders.

Creativity & Innovation

Encourage creative experimentation,

embrace new ideas and institutionalize

continuous improvement in all aspects of

business and performance.

Social Responsibility

Dedicate efforts to the social and

environmental issues to enrich the quality of

life of the communities we serve.

The Jindal Group

The first Jindal plant was set up in 1970 by the visionary, Mr. O.P. Jindal. Over the years, the organisation has

grown from a single-unit steel plant in Hissar, Haryana, India, to become what it is today - a multi-billion dollar,

multi-location and multi-product steel conglomerate.

With every new objective, the organization has been continuously expanding, integrating, amalgamating and

growing in new directions.

The Jindal name proudly commands a special status in the Iron & Steel sector. Ranked fourth amongst the top

Indian Business Houses in terms of assets, the Group today is a US $18.5 Billion conglomerate, spread over 13

plants at 10 strategic locations in India and various facilities across the globe. Major group companies include

Jindal Saw Limited, JSW Steel Ltd., Jindal Steel & Power Ltd. and Jindal Stainless Ltd.

Jindal Saw Limited

Jindal Saw Ltd., (JSL) provides Total Pipe Solutions and is the leading manufacturer of Seamless Tubes and

Pipes, Large Diameter submerged Arc Welded pipes, and Ductile Iron Pipes The company has 4

manufacturing plants located in India and one at Baytown, Houston, Texas (USA). It has a sales turnover in

excess of US $ 1 billion.

Jindal Saw Limited

(Seamless Tubes Division)

The Seamless Tubes Division produces Tubes &

Pipes at a state-of-the-art manufacturing facility at

Nashik, approximately 200 kms from Mumbai, in

Maharashtra, India. The expertise and equipment

have been acquired from SMS-MEER of Germany acknowledged world leaders in Seamless Tube &

Pipe technology.

Cutting-edge Technology

With an annual installed capacity of 220,000 M Tons

for Carbon & Alloy Steel Pipes, the plant is equipped

with modern manufacturing machinery and boasts a

state-of-the-art PQF Mill from SMS MEER, Germany.

Additionally, we have a modern Quench and

Temper Furnace, Upsetter, Hydro tester, MAC EMI &

UT and PMC Threading machines.

Our coating plant provides Fusion Bonded Epoxy (FBE), 3-layer Polyethylene (3LPE) External coating, and 3layer Polypropylene (3LPP) External coating Up-to-date testing facilities complete the gamut, ensuring that all of

our products that reach the market meet international standards.

At Jindal Saw, we firmly believe that Quality translates into Success

Quality of Thought

Innovation and flexibility in thinking allows us to look at ideas from

diverse perspectives, enabling us to venture into uncharted territories

and discover newer options

Quality of Action

Up-gradation of ideas and products enables us to position ourselves

at the right time and the right place in the market arena

Quality of People

Our team is made up of dedicated, performance-oriented,

well-informed individuals, with a proven track-record

Value-addition at every stage

Value-added Products

Constant Technology up-gradation and continuous research,

combined with proactive marketing are critical factors that have

contributed towards making us a supplier of quality products.

A Valuable Team

The invaluable support of a dedicated team of technocrats and

workforce, strengthens our resolve to achieve excellence in whatever

we do. It is this team that sets the momentum for our growth. Each and

every member of our team is considered a precious asset.

Value Creation for Customers

Superior business ethics high quality products proactive

marketing competitive pricing timely deliveries these are just a

few of the factors that create value for our customers and contribute

towards our success in the marketplace. And our customers are happy

to come back to us time and time again.

Industries that Value our Products

Oil and Gas

Refineries

Petroleum and Petrochemicals

Power / Boilers, Heat Exchangers & Condenser Applications

Fertilizers

Dairy and Sugar

Mechanical Tubing & Structural Applications

Automobile Applications

General Engineering

Fluid Conveyance Applications

Bearing Steel Tube Industry

The JSL Corporate

Strategy:

To aim for holistic integration of its

product line and emerge as a

global performer, providing a

comprehensive range of products

in the category

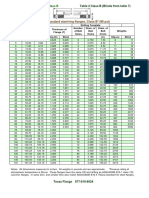

Product Range

Product

Hot Finished Carbon /

Alloy Steel Seamless Tubes

and Pipes

Seamless Casing and

Tubing conforming to API

5CT

Outside Diameter Wall Thickness Outside Diameter Wall Thickness

(t) (mm)

(D) (mm)

(OD) (inch)

(t) (inch)

1.00 to 8.00

0.13 to 1.25

33.40 to 219.10

3.38 to 32.00

2-3/8 to 7.00

0.15 to 0.75

60.30 to 177.80

4.00 to 19.05

Annual Capacity

80,000 MT

100,000 MT

Seamless Drill Pipes

conforming to API 5DP

2-3/8 to 6-5/8

0.25 to 0.50

60.30 to 168.30

6.45 to 12.70

Cold Finished Carbon/

Alloy Steel Seamless Tubes

and Pipes

0.5 to 6.61

0.07 to 0.75

19.05 to 168.12

1.65 to 19.05

Couplings for OCTG

Products

2-3/8 to 7.00

Anti Corrosion 3 LPE,3LPP/

FBE External coating.

40,000 MT

60.30 to 177.80

2 to 14 as per DIN 30670, DIN 30678 & Customers specs

1 million SQM

Note: Make and Break, Hard Banding and Internal Plastic Coating are also available for Drill Pipes confirming to API 5DP

Specification on customer request.

SPECIFICATIONS CATERED

ASTM (A53, A519, A106, A335), SA (106,179,192,210,213), DIN (2391, 17175), IS (3601, 3074), BS (3059), NACE, SOUR

SERVICE etc.

API 5L (B, X42, X52, X56, X60, X65, PSL 1 & PSL 2),

API 5CT (J55, K55, N80, L80, L80 (13Cr), C90, C95, C110,T91,T95, P110, P110 HC, Q125),

API 5DP (E75, X95, G105, S135, SS105) Ss105

MAJOR STEEL GRADES

SAE 1019, 1518, 1035, 1040, 1541, 4130, 4140, 8620, EN19, ST 52,SUJ2/SAE52100/100Cr6,16MnCr5 & other Steel Grades

as per Customer requirement.

The Winning Combination

With the unbeatable combination of Rotary

Hearth Furnace, Conical Type Piercer, PQF Mill,

Stretch Reducing Mill, Q&T Furnace, Upsetter,

Cold Draw Facility, Coating Facility, In house

Coupling Manufacturing and Balancing

Equipment, Jindal Saw Limited is perfectly

positioned to cater to the varied demands of

domestic as well as international markets.

Hot Finishing Process

The round billet is heated in a rotary hearth furnace and

pierced by means of an internal piercing plug and a

two-roll conical type piercer. The shell is then rolled in a

PQF Mill for wall thickness reduction and shell

elongation. The Shell is reheated in an induction

furnace and rolled in a stretch-reducing mill to

decrease the outside diameter to the desired

specifications. Finally, Pipe finishing is carried out via

several processes - air-cooling on a cooling bed,

straightening, cutting and beveling. Finished seamless

pipes undergo Hydrostatic testing, Non-Destructive

Testing, as well as inspection for dimensional

irregularities.

Premium Quality Finishing Mill

ROUNDS

ROTARY

HEARTH FURNACE

CONE TYPE

PIERCER

STRETCH

REDUCING MILL

INDUCTION

HEATER

PQF

MILL

STRAIGHTENING

&

CUTTING

COOLING BED

HOT FINISHED

TUBES

Rotary Hearth Furnace

HYDRO TESTING

NON DESTRUCTIVE

TESTING

24 Stand Stretch Reducing Mill

Cold Drawing Process

The hollow tube, after surface treatment, is drawn over a stationary plug and a die. The relative movement

between the stationary plug and the flowing tube material results in friction on the inner surface. As a

consequence, the tube is reduced with a high degree of accuracy, to the desired outer diameter and thickness.

The tube is now passed through an annealing furnace, straightened and cut to the required length. Quality

checks like Hydrostatic testing, Non-Destructive testing and Visual Inspection ensure that the product meets

with the required specifications, within strict tolerances.

HOT MILL TUBE

COATING / SOAPING

COLD DRAW BENCH

HEAT TREATMENT

STRAIGHTENING

NDT / HYDRO

Cold Draw Bench

BUNDLING & DESPATCH

CUTTING

Drill Pipe Process

Rolled Pipe ends are either External Upset or

Internal upset or Internal External upset and heattreated full length by the Quench and Temper

process to achieve uniform mechanical properties.

The heat-treated pipes are 100% nondestructively

inspected for possible longitudinal and transverse

defects and wall thickness.

Q & T of Weld Zone

Friction Welder

Magnetic particle inspection of the upset ends is

done to ensure that the upsets are free from defects.

The OD & ID and face of the upsets are CNC

machined for a clean surface as part of pipe

preparation prior to welding.

Tools joints are attached to the drill pipe by friction

welding to produce a high integrity solid state weld

connection between the tool joint and the upset drill

pipe tube.

Hard Banding and ID coating facilities are also

available on customer request.

Upsetter

GREEN PIPE

HEAT TREATMENT

UPSETTING

POST WELD

HEAT TREATMENT

OD & ID GRINDING

HARDNESS, UT & MPI

Rolled pipes are heat treated in a Q&T furnace to

achieve properties that conform to API grades. In

the case of tubing, the ends are upsetted. The pipes

are straightened and subjected to EMI & UT and

Hydrostatic testing. Subsequently, threads are cut

and couplers are power-tightened.

Q&T Furnace

TOOL JOINT

FRICTION WELDING

PROTECTIVE

COATING

FINAL INSPECTION

ID COATING /

HARD BANDING

(OPTIONAL)

Tuboscope EMI & UT

HOT MILL TUBE

OCTG Manufacturing Process

STRAIGHTENING

NDT INSPECTION

PIPE PREPARATION

BUNDLING

& DESPATCH

MPI Machine

HEAT TREATMENT

STRAIGHTENING

UPSETTING IN

CASE OF TUBING

NON DESTRUCTIVE

TESTING

HYDROTESTING

COUPLING

APPLICATOR

THREAD INSPECTION IN

API STD. GAUGE

THREADING

(BOTH SIDES)

VISUAL INSPECTION & DRIFT TEST

AUTOMATIC BUNDLING

STENCILING &

& DESPATCH

PROTECTIVE COATING

MAC EMI & UT

PMC Threading Machine

Anti-Corrosion Coating Process

The external coating 3LPE, 3LPP, & FBE is a multilayer anticorrosion coating comprising of a high performance fusion

bonded epoxy (FBE) layer, followed by a copolymer adhesive

and an outer layer of polyethylene. This coating ensures that

our tubes are tough and durable, especially in sour conditions.

Coating Facility

BARE PIPE

WATER

QUENCHING

END FINISHING

SHOT BLASTING

VISUAL INSPECTION

INDUCTION

HEATING

EPOXY

COATING

ADHESIVE

& HDPE COATING

HOLIDAY TESTING

FINAL INSPECTION

DESPATCH

STENCILLING / BUNDLING

Coupling Manufacturing Process

Tubes referred to as coupling stock are cut into blanks by

Automated Band Saws. The blanks are transported to the CNC

machines, where OD & ID machining and threads are cut to

API thread specification with stringent tolerances and

meticulous precision. The couplings are subjected to visual

inspections under UV light for longitudinal and transverse

flaws.

Subsequently, the couplings are phosphated with

Manganese Phosphate Layer which provides protection

against corrosion and improves galling resistance. Finally the

couplings are colour coded as per the specification and oiled

on the inside surface.

CNC Machines

COUPLING STOCK

CUTTING

INTO BLANKS

OD & ID

MACHINING

MPI

INLINE

INSPECTION

THREAD CUTTING

AUTOMATIC

STAMPING

PHOSPHATING

PAINTING

FINISHED

COUPLING

OILING

MPI Machine

Couplings

ISO 9001

ISO 14001

API5L

BSOHSASS 18001

API5CT

PED

API5DP

IBR

Quality Assurance & Approvals

An Eye for Perfection

Commitment to Customers, Flexibility in Manufacturing and Total Quality Management

are principles which have enabled JINDAL SAW LIMITED to deliver value to our

customers. Stringent system-based quality control is implemented at each stage of

production. Our service standards focus on customer requirements and we strive for the

highest user satisfaction.

1) ISO 9001-2008, ISO-14001 : 2004, BS OHSASS 18001 : 2007 certification by TUV

NORD CERT GmbH

2) API 5L, API 5CT & API 5DP

3) PED Certification by DNV

4) Well Known Tube/Pipe maker under Indian Boiler Regulation.

Leading Third Party Inspecting authorities like EIL, LRIS, Bureau Veritas, DNV, TUV etc.

regularly visit our manufacturing facilities for inspection while fulfilling various customer

orders.

Quality is our Mantra

All our products are submitted to strict quality checks at every stage of production.

Raw Material:

All incoming material is inspected in detail for mechanical and metallurgical defects.

Macro Etch test:

This is used to study the macro structure of raw material.

Metallography:

The micro structure of the material is examined in careful detail.

Chemical Testing:

The chemical properties of the steel are analysed using a 'Spectrolab'.

Mechanical Testing:

The material is also tested for its mechanical properties to check for tensile strength,

hardness, resilience to impact, bending, flaring, flattening and Flange testing.

Hydrostatic Testing:

Hydrostatic testing is conducted as per API, ASTM, DIN, IS or equivalent standards.

Eddy Current Testing:

Eddy Current testing is carried out to detect surface irregularities on the entire length of

the tube. This is done using the Circograph and Technofour machines.

EMI & Ultrasonic Testing:

The Tuboscope, MAC Electromagnetic Induction and Ultrasonic flaw detection

equipment are used to verify the external and internal surface quality of the tubes and

wall measurements along their length. This ascertains the soundness of the material in

accordance with API 5CT, 5DP, 5L norms while meeting national and international

specifications.

Magnetic Particle Inspection:

MPI is conducted to detect for outer and inner surface imperfections in couplings, as per

ASTM & API standards.

SSC / HIC Test as per API 5L / 5CT / NACE requirements.

Our Commitment to the Environment

and the Community

At Jindal Saw, we hold ourselves responsible for protecting

the environment and the communities that live and work

within our surroundings.

We believe in finding a harmonious balance between the

demands made by industrialization and ethics concerning

the environment.

Strict environment management systems for air, water and

waste treatment in and around our workplace ensure that

we live and work in harmony with the eco-system.

We are committed to improving the lives of the people who

work with us and the communities who live around us.

While we stress on continuous technical training for our

workforce, we strive to ensure that the social needs of the

community are always given due importance - an everevolving process, which we are happy to consider our

corporate responsibility.

The Jindal Advantage

One of the largest pipe manufacturing companies

with a strong international presence

Established track record

Prestigious accreditations

State-of-the-art manufacturing facilities and testing

equipment, technologically at par with the best

seamless mills, globally

Raw material, in the form of Vacuum Degassed

Clean Steel Billets, is sourced primarily from Group

Companies ensuring consistent quality and timely

deliveries

Skilled and experienced manpower

Long-term relationships forged with leading

companies across the world

This is Jindal Saw Limited.

A company that is steadfastly committed to its

customers, its people, its community and to its

environment.

Jindal Saw Ltd. (Seamless Tubes Division)

Works & Marketing Office

A-59/60, MIDC, Malegaon, Sinnar, Dist: Nashik - 422 113 Maharashtra, INDIA

Phone: +91-2551-227200 Fax: +91-2551-230967

Email: seamless.export@jindalsaw.com / marketing.nashik@jindalsaw.com

Website: www.jindalsaw.com

Jindal Saw USA LLC

Works Office

1411 South FM 565, Baytown, TX 77523-USA

Phone: +1 281-573-2300 Fax: +1 281-575-3838

Marketing Office

1401 McKinney Street, Suite 300, 5 Houston Center, Houston, TX 77010-USA

Phone: 713-650-9000 Fax: 713-650-9001

You might also like

- MIDREX StatsBook 2009rev4Document12 pagesMIDREX StatsBook 2009rev4Rupesh TiwariNo ratings yet

- JSS & JSG Guide PDFDocument186 pagesJSS & JSG Guide PDFfunson12350% (2)

- Bhushan Steels Or.Document189 pagesBhushan Steels Or.Naveen SinghNo ratings yet

- Coal in Direct Ironmaking ProcessesDocument101 pagesCoal in Direct Ironmaking ProcessesJanaína MachadoNo ratings yet

- Multi Grooving ToolsDocument12 pagesMulti Grooving ToolsSyawatulshuhada SyawalNo ratings yet

- Pulverized Coal and Igcc Plant Cost and Performance EstimatesDocument22 pagesPulverized Coal and Igcc Plant Cost and Performance EstimatesVinod DahiyaNo ratings yet

- Paper Presentation On Developing Supply Chain Management Stratergy For Indian Foundry SectorDocument14 pagesPaper Presentation On Developing Supply Chain Management Stratergy For Indian Foundry SectorGaurao WarungaseNo ratings yet

- Preparation of A Coal Conversion Systems Technical Data BookDocument229 pagesPreparation of A Coal Conversion Systems Technical Data BookjuliomilitaoNo ratings yet

- M N DasturDocument34 pagesM N DasturmalevolentNo ratings yet

- IcboilerDocument589 pagesIcboilerlanikhilNo ratings yet

- Coal To Biomass Conversion: Adam Nicholson Ceng Fimeche 19 February 2019Document47 pagesCoal To Biomass Conversion: Adam Nicholson Ceng Fimeche 19 February 2019Diego Martínez FernándezNo ratings yet

- JSW Steel - WikipediaDocument28 pagesJSW Steel - WikipediaPawan SrivastavaNo ratings yet

- Internship Report: Railway Wheels and Axel ManufacturingDocument55 pagesInternship Report: Railway Wheels and Axel ManufacturingadityaNo ratings yet

- BOF Post Combustion PaperDocument7 pagesBOF Post Combustion PaperAvs RamachandraNo ratings yet

- Manu BIPLDocument52 pagesManu BIPLManoharNo ratings yet

- Reference Manual (Tech) (Diploma-Be) PDFDocument254 pagesReference Manual (Tech) (Diploma-Be) PDFAnaruzzaman SheikhNo ratings yet

- Effects of Calcination Conditions On The Properties of LimeDocument15 pagesEffects of Calcination Conditions On The Properties of Limealexander_suarez_19No ratings yet

- Yield ImprmntDocument61 pagesYield ImprmntAmeyaditya SinghNo ratings yet

- Cyclones: Cyclone Efficiency Generally Increases WithDocument12 pagesCyclones: Cyclone Efficiency Generally Increases Withnkhanzada100% (1)

- PRESENTATION On ShreeCementDocument20 pagesPRESENTATION On ShreeCementDinesh SutharNo ratings yet

- Hos Pet Steels LimitedDocument116 pagesHos Pet Steels LimitedArvind GargNo ratings yet

- Monojit Paul - Industrial Visit Report On Ramco CementDocument12 pagesMonojit Paul - Industrial Visit Report On Ramco CementSiladitya MitraNo ratings yet

- Acbi IndiaDocument43 pagesAcbi IndiaPriyankaNo ratings yet

- Analysis of Impurities in Feedwater and SteamDocument30 pagesAnalysis of Impurities in Feedwater and SteamMohan Babu100% (1)

- Seamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Document8 pagesSeamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00refeiNo ratings yet

- Coal Washeries May-10Document112 pagesCoal Washeries May-10Micheal AhmadNo ratings yet

- Essar Group PresentationDocument59 pagesEssar Group PresentationchetanpatelhNo ratings yet

- Pulverized CoalDocument11 pagesPulverized CoalAdrian ManzanoNo ratings yet

- Organic - New - 2019 Product ProfileDocument15 pagesOrganic - New - 2019 Product Profilevaibhav khodakeNo ratings yet

- DLT 5210.5-2009 - Part 5 Piping & SystemDocument147 pagesDLT 5210.5-2009 - Part 5 Piping & SystemecsuperalNo ratings yet

- Group 2 - Zinc Electrothermic FurnaceDocument12 pagesGroup 2 - Zinc Electrothermic FurnacekudaNo ratings yet

- L11-Coal Crushing - StorageDocument34 pagesL11-Coal Crushing - StorageRahmat YusufNo ratings yet

- Coker ProcessesDocument2 pagesCoker ProcessesKY TianaNo ratings yet

- Project On Bullhead HammersDocument55 pagesProject On Bullhead HammersManoj BallaNo ratings yet

- GSHPA Vertical Borehole Standard PDFDocument45 pagesGSHPA Vertical Borehole Standard PDFSibolga SatuNo ratings yet

- Manpower Study - Dairy Industry (2075-076)Document83 pagesManpower Study - Dairy Industry (2075-076)Gaurav PradhanNo ratings yet

- FBC Boilers in Power PlantDocument20 pagesFBC Boilers in Power PlantVenkatesan SundaramNo ratings yet

- NTPC BADARPUR Summer Tranning ReportDocument52 pagesNTPC BADARPUR Summer Tranning ReportRavi Jain100% (3)

- Report For 92MW Power Plant of UltratechDocument52 pagesReport For 92MW Power Plant of UltratechNirav Parmar100% (1)

- CementDocument11 pagesCementAbubakar Musa100% (1)

- Design and Development of A Centrifugal Casting Machine For Pistons ProductionDocument21 pagesDesign and Development of A Centrifugal Casting Machine For Pistons ProductionThankgodIsraelNo ratings yet

- Bonatrans IndiaDocument20 pagesBonatrans IndiasutanuprojectsNo ratings yet

- Research Project Report On Ferrous Steel Scrap Demand in FoundariesDocument10 pagesResearch Project Report On Ferrous Steel Scrap Demand in FoundariesAarushi NarangNo ratings yet

- Boiler and Its Efficiency-1Document38 pagesBoiler and Its Efficiency-1Madhu KamshettyNo ratings yet

- Chlorine and Its SafetypDocument54 pagesChlorine and Its SafetypHiranmoy MisraNo ratings yet

- UCC Wet-To-Dry Brochure PDFDocument12 pagesUCC Wet-To-Dry Brochure PDFNadia Hana SorayaNo ratings yet

- Research and Innovations For Continuous Miner's Cutting Head, For Efficient Cutting Process of Rock/CoalDocument12 pagesResearch and Innovations For Continuous Miner's Cutting Head, For Efficient Cutting Process of Rock/CoalKarthii Aju100% (1)

- Blast Furnace HydraulicsDocument36 pagesBlast Furnace Hydraulicssghane5674No ratings yet

- Recycling of Steel Plant Wastes Through CorexDocument1 pageRecycling of Steel Plant Wastes Through CorexSubhransu Sekhar SahooNo ratings yet

- The Alter NRG Plasma Gasification Process - Turner Valley PresentationDocument19 pagesThe Alter NRG Plasma Gasification Process - Turner Valley PresentationPerro Col100% (1)

- Blast FurnaceDocument28 pagesBlast Furnaceavanisharma_1991No ratings yet

- EIA-Coal Washery Raigarh1Document198 pagesEIA-Coal Washery Raigarh1Pritam Patnaik100% (1)

- Utilization of Fly Ash and Rice Husk Ash As A Supplement To Concrete Materials - A Critical ReviewDocument9 pagesUtilization of Fly Ash and Rice Husk Ash As A Supplement To Concrete Materials - A Critical Reviewijetrm journalNo ratings yet

- Circular Pelletizing Technology General Presentation: We Just Made It BetterDocument46 pagesCircular Pelletizing Technology General Presentation: We Just Made It Betterkalai100% (1)

- Technologies For The Design and Operation of Phosphate Fertilizer & Sulfuric Acid PlantsDocument12 pagesTechnologies For The Design and Operation of Phosphate Fertilizer & Sulfuric Acid PlantsJavier Alejandro RodriguezNo ratings yet

- Supply Chain Management PDFDocument134 pagesSupply Chain Management PDFBhasker Taneja100% (1)

- The Complete EngineeringDocument8 pagesThe Complete EngineeringRafeek AliNo ratings yet

- Business Research On Tubular PolesDocument65 pagesBusiness Research On Tubular Polesgoyalneeraj0% (1)

- Deepak Brass CatalogDocument34 pagesDeepak Brass Catalogkishan.thiyagarajanNo ratings yet

- Star Wires India LimitedDocument10 pagesStar Wires India LimitedDesh Deepak0% (1)

- Buoyancy Per Unit LengthDocument4 pagesBuoyancy Per Unit LengthNisarg PandyaNo ratings yet

- Hydro Test Pressure CalculationDocument1 pageHydro Test Pressure CalculationNisarg PandyaNo ratings yet

- Asme ptc2 7Document1 pageAsme ptc2 7Nisarg PandyaNo ratings yet

- WIC Role of InspectorDocument19 pagesWIC Role of InspectorNisarg PandyaNo ratings yet

- FlangesDocument5 pagesFlangesNisarg PandyaNo ratings yet

- Weldolet 4X2Document1 pageWeldolet 4X2Nisarg PandyaNo ratings yet

- BS137991974 PDFDocument1 pageBS137991974 PDFNisarg PandyaNo ratings yet

- BS137991974 PDFDocument1 pageBS137991974 PDFNisarg PandyaNo ratings yet

- Asme ptc2 4Document1 pageAsme ptc2 4Nisarg PandyaNo ratings yet

- 6 Designation: Parallel Pipe Thread ISO 7/1-Rp 1 Taper Pipe Thread ISO 711-Rc 1 Always Taper Pipe Thread ISO 7/ L-R 1Document1 page6 Designation: Parallel Pipe Thread ISO 7/1-Rp 1 Taper Pipe Thread ISO 711-Rc 1 Always Taper Pipe Thread ISO 7/ L-R 1Nisarg PandyaNo ratings yet

- Asme Fap-1 PDFDocument34 pagesAsme Fap-1 PDFNisarg PandyaNo ratings yet

- QW 482 Suggested Format For Welding ProcedureDocument1 pageQW 482 Suggested Format For Welding ProcedureNisarg PandyaNo ratings yet

- Asme ptc2 5Document1 pageAsme ptc2 5Nisarg PandyaNo ratings yet

- AWWA Standard Steel-Ring Flanges, Class B (86 Psi)Document1 pageAWWA Standard Steel-Ring Flanges, Class B (86 Psi)Nisarg PandyaNo ratings yet

- QW 482 Suggested Format For Welding ProcedureDocument1 pageQW 482 Suggested Format For Welding ProcedureNisarg PandyaNo ratings yet

- AWWA Standard Steel-Hub Flanges, Class D (175-150 Psi) : Texas Flange 877-610-8924Document1 pageAWWA Standard Steel-Hub Flanges, Class D (175-150 Psi) : Texas Flange 877-610-8924Nisarg PandyaNo ratings yet

- Evaluating UT E 317 94Document1 pageEvaluating UT E 317 94Nisarg PandyaNo ratings yet

- Features and SpecificationsDocument8 pagesFeatures and SpecificationsluisNo ratings yet

- Corrosion Inhibition by An Aqueous Extract of Henna Leaves (Lawsonia Inermis L)Document8 pagesCorrosion Inhibition by An Aqueous Extract of Henna Leaves (Lawsonia Inermis L)nanoNo ratings yet

- Soil Pollution and Noise Pollution 2Document31 pagesSoil Pollution and Noise Pollution 2RajeshNo ratings yet

- MSE-21-Optical Properties (61) - 2007-05-31Document61 pagesMSE-21-Optical Properties (61) - 2007-05-31Surendra PandaNo ratings yet

- Penampakan Paramoeba Dan NeoparamoebaDocument3 pagesPenampakan Paramoeba Dan NeoparamoebaSyarif Hidayat AmrullahNo ratings yet

- Ana ChemDocument1 pageAna ChemElizer Robles Jr.No ratings yet

- El ProgDocument2 pagesEl ProgMaherNo ratings yet

- Draft A e A Tank Farm Design GuidelinesDocument2 pagesDraft A e A Tank Farm Design GuidelinesSigit BintanNo ratings yet

- Chemistry HL - FAST FACTS - Second Edition - Pearson 2014Document65 pagesChemistry HL - FAST FACTS - Second Edition - Pearson 2014sahilNo ratings yet

- Chromatographic Analysis of Phytopharmaceuticals - A ReviewDocument5 pagesChromatographic Analysis of Phytopharmaceuticals - A ReviewHarshaNo ratings yet

- Brain Lipid WrittenDocument19 pagesBrain Lipid WrittenAldwin Ray Pamplona100% (2)

- Bainite in SteelsDocument479 pagesBainite in SteelsSteel Being100% (1)

- TolyltriazoleDocument4 pagesTolyltriazolemnasiroleslamiNo ratings yet

- Electrochemistry PDFDocument7 pagesElectrochemistry PDFYogesh chandraNo ratings yet

- 4 - A High Entropy Perovskite Titanate Lithium Ion Battery AnodeDocument10 pages4 - A High Entropy Perovskite Titanate Lithium Ion Battery Anodekenny5350No ratings yet

- Mining CompaniesDocument140 pagesMining CompaniesrobertmrgnNo ratings yet

- Forming HandsheetsDocument6 pagesForming HandsheetsgcardinalNo ratings yet

- Defects in Injection MouldingDocument44 pagesDefects in Injection Mouldingsatish100% (1)

- AmlodipinebesylatepaperDocument6 pagesAmlodipinebesylatepaperRakesh RauniyarNo ratings yet

- Problemas OrdinarioDocument10 pagesProblemas OrdinarioAngelo EdoraNo ratings yet

- Asme Section II A Sa-352 Sa-352mDocument8 pagesAsme Section II A Sa-352 Sa-352mAnonymous GhPzn1xNo ratings yet

- Lecture HAZOP ExampleDocument29 pagesLecture HAZOP ExampleIbtida SultanaNo ratings yet

- Autumn Olive BCPDocument7 pagesAutumn Olive BCPKicki AnderssonNo ratings yet

- Daily Brightening Serum: Good MoleculesDocument5 pagesDaily Brightening Serum: Good MoleculesTran Thi Kim AnhNo ratings yet

- Qualitative Analysis of Air Freshener SprayDocument15 pagesQualitative Analysis of Air Freshener SprayderhicoNo ratings yet

- Organometallic Reactions and Catalysis - 2Document34 pagesOrganometallic Reactions and Catalysis - 2Irma AlfaBetNo ratings yet

- Potassium HumateDocument7 pagesPotassium HumateAnonymous Wc69e8wpnNo ratings yet

- Bendable Concrete ReviewDocument7 pagesBendable Concrete ReviewDUAA SALAHNo ratings yet

- Name of The Experiment: Determination of Chloride in The SuppliedDocument3 pagesName of The Experiment: Determination of Chloride in The SuppliedShohag HosenNo ratings yet